Rack And Pinion Standard Sizes . Circular pitch products solve these problems. The “module” of a rack & pinion denotes the size and pitch of the gear teeth. The index on the next page provides an overview of our standard range of straight (spur) and helical tooth pinions. A smaller module means a smaller tooth and a larger module means a larger tooth. This problem is solved by cp racks and pinions where one rotation of a pinion moves it precisely 50,. Sizes can be as low as. Learn how to select a rack and pinion drive for linear motion applications based on force, torque, and speed calculations. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and.

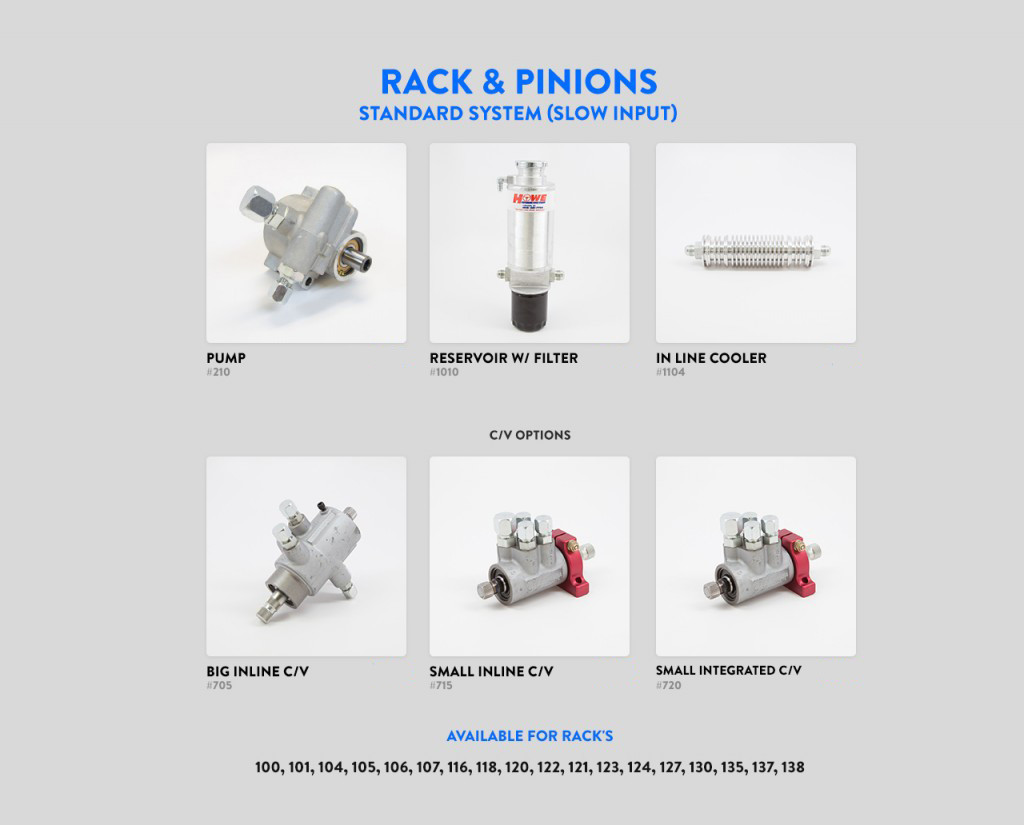

from www.howeperformance.com

This problem is solved by cp racks and pinions where one rotation of a pinion moves it precisely 50,. The “module” of a rack & pinion denotes the size and pitch of the gear teeth. The index on the next page provides an overview of our standard range of straight (spur) and helical tooth pinions. Learn how to select a rack and pinion drive for linear motion applications based on force, torque, and speed calculations. Circular pitch products solve these problems. Sizes can be as low as. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. A smaller module means a smaller tooth and a larger module means a larger tooth.

Rack & Pinions Parts Categories Howe

Rack And Pinion Standard Sizes The “module” of a rack & pinion denotes the size and pitch of the gear teeth. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Circular pitch products solve these problems. The “module” of a rack & pinion denotes the size and pitch of the gear teeth. The index on the next page provides an overview of our standard range of straight (spur) and helical tooth pinions. Sizes can be as low as. Learn how to select a rack and pinion drive for linear motion applications based on force, torque, and speed calculations. This problem is solved by cp racks and pinions where one rotation of a pinion moves it precisely 50,. A smaller module means a smaller tooth and a larger module means a larger tooth.

From www.ultraflex.it

Rack and pinion steering systems Ultraflex Rack And Pinion Standard Sizes This problem is solved by cp racks and pinions where one rotation of a pinion moves it precisely 50,. Sizes can be as low as. The index on the next page provides an overview of our standard range of straight (spur) and helical tooth pinions. The “module” of a rack & pinion denotes the size and pitch of the gear. Rack And Pinion Standard Sizes.

From www.iqsdirectory.com

Lift Table What Is It? How Does It Work? Types, Uses Rack And Pinion Standard Sizes Circular pitch products solve these problems. A smaller module means a smaller tooth and a larger module means a larger tooth. The “module” of a rack & pinion denotes the size and pitch of the gear teeth. Learn how to select a rack and pinion drive for linear motion applications based on force, torque, and speed calculations. Sizes can be. Rack And Pinion Standard Sizes.

From www.engineeringchoice.com

What is Rack and Pinion? Definition and Application Engineering Choice Rack And Pinion Standard Sizes Sizes can be as low as. This problem is solved by cp racks and pinions where one rotation of a pinion moves it precisely 50,. The “module” of a rack & pinion denotes the size and pitch of the gear teeth. Circular pitch products solve these problems. The index on the next page provides an overview of our standard range. Rack And Pinion Standard Sizes.

From www.youtube.com

Rack & Pinion Mechanism in SolidWorks Motion Study in SolidWorks Rack And Pinion Standard Sizes Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. A smaller module means a smaller tooth and a larger module means a larger tooth. Learn how to select a rack and pinion drive for linear motion applications based on force, torque, and speed calculations. This problem is solved by. Rack And Pinion Standard Sizes.

From www.designworldonline.com

What are rackandpinion sets? Technical summary Rack And Pinion Standard Sizes This problem is solved by cp racks and pinions where one rotation of a pinion moves it precisely 50,. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Learn how to select a rack and pinion drive for linear motion applications based on force, torque, and speed calculations. Circular. Rack And Pinion Standard Sizes.

From www.youtube.com

Rack and Pinion Steering Gearbox Mechanism Working Explained with Rack And Pinion Standard Sizes A smaller module means a smaller tooth and a larger module means a larger tooth. Sizes can be as low as. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The “module” of a rack & pinion denotes the size and pitch of the gear teeth. This problem is. Rack And Pinion Standard Sizes.

From btprecision.com.au

Rack and Pinion (Helical and Straight Cut) BT Precision Rack And Pinion Standard Sizes Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The “module” of a rack & pinion denotes the size and pitch of the gear teeth. Circular pitch products solve these problems. This problem is solved by cp racks and pinions where one rotation of a pinion moves it precisely. Rack And Pinion Standard Sizes.

From www.youtube.com

Steering Rack and pinion Mechanism in Solidworks YouTube Rack And Pinion Standard Sizes Learn how to select a rack and pinion drive for linear motion applications based on force, torque, and speed calculations. This problem is solved by cp racks and pinions where one rotation of a pinion moves it precisely 50,. Sizes can be as low as. Circular pitch products solve these problems. The index on the next page provides an overview. Rack And Pinion Standard Sizes.

From www.gudel.com

Rack & pinion Rack And Pinion Standard Sizes This problem is solved by cp racks and pinions where one rotation of a pinion moves it precisely 50,. Circular pitch products solve these problems. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Sizes can be as low as. The index on the next page provides an overview. Rack And Pinion Standard Sizes.

From www.slideshare.net

2012 rack and pinion (1) Rack And Pinion Standard Sizes Sizes can be as low as. The “module” of a rack & pinion denotes the size and pitch of the gear teeth. A smaller module means a smaller tooth and a larger module means a larger tooth. Circular pitch products solve these problems. This problem is solved by cp racks and pinions where one rotation of a pinion moves it. Rack And Pinion Standard Sizes.

From www.linearmotiontips.com

Rack and pinion systems designs and applications Rack And Pinion Standard Sizes Learn how to select a rack and pinion drive for linear motion applications based on force, torque, and speed calculations. Sizes can be as low as. This problem is solved by cp racks and pinions where one rotation of a pinion moves it precisely 50,. A smaller module means a smaller tooth and a larger module means a larger tooth.. Rack And Pinion Standard Sizes.

From www.alibaba.com

Gear Rack Pinion For Linear Motion Cnc Machine Helical Tooth Rack And Rack And Pinion Standard Sizes Circular pitch products solve these problems. A smaller module means a smaller tooth and a larger module means a larger tooth. The index on the next page provides an overview of our standard range of straight (spur) and helical tooth pinions. Learn how to select a rack and pinion drive for linear motion applications based on force, torque, and speed. Rack And Pinion Standard Sizes.

From amalremixbah.blogspot.com

Rack And Pinion Inner Tie Rod Rack And Pinion Standard Sizes A smaller module means a smaller tooth and a larger module means a larger tooth. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The “module” of a rack & pinion denotes the size and pitch of the gear teeth. Circular pitch products solve these problems. The index on. Rack And Pinion Standard Sizes.

From www.autozone.com

Repair Guides Steering Manual Rack And Pinion Rack And Pinion Standard Sizes A smaller module means a smaller tooth and a larger module means a larger tooth. The index on the next page provides an overview of our standard range of straight (spur) and helical tooth pinions. Sizes can be as low as. This problem is solved by cp racks and pinions where one rotation of a pinion moves it precisely 50,.. Rack And Pinion Standard Sizes.

From www.damencnc.com

Rack and Pinion Systems Gear module 2 Z=20 teeth DamenCNC B.V. Rack And Pinion Standard Sizes This problem is solved by cp racks and pinions where one rotation of a pinion moves it precisely 50,. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Circular pitch products solve these problems. The “module” of a rack & pinion denotes the size and pitch of the gear. Rack And Pinion Standard Sizes.

From www.youtube.com

Rack pinion and crank design in Solidworks YouTube Rack And Pinion Standard Sizes The “module” of a rack & pinion denotes the size and pitch of the gear teeth. A smaller module means a smaller tooth and a larger module means a larger tooth. The index on the next page provides an overview of our standard range of straight (spur) and helical tooth pinions. Circular pitch products solve these problems. Gear dimensions are. Rack And Pinion Standard Sizes.

From www.alibaba.com

Gear Rack And Pinion Buy Gear Rack,Rack And Pinion,Rack Gear Product Rack And Pinion Standard Sizes The “module” of a rack & pinion denotes the size and pitch of the gear teeth. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. A smaller module means a smaller tooth and a larger module means a larger tooth. Circular pitch products solve these problems. This problem is. Rack And Pinion Standard Sizes.

From www.apexdyna.nl

Calculate a rack and pinion drive, how do you do that? Rack And Pinion Standard Sizes Learn how to select a rack and pinion drive for linear motion applications based on force, torque, and speed calculations. A smaller module means a smaller tooth and a larger module means a larger tooth. Sizes can be as low as. Circular pitch products solve these problems. The “module” of a rack & pinion denotes the size and pitch of. Rack And Pinion Standard Sizes.

From www.2carpros.com

Streering Rack and Pinion What Is the Torque Spec for Rack and Rack And Pinion Standard Sizes The “module” of a rack & pinion denotes the size and pitch of the gear teeth. A smaller module means a smaller tooth and a larger module means a larger tooth. This problem is solved by cp racks and pinions where one rotation of a pinion moves it precisely 50,. Sizes can be as low as. The index on the. Rack And Pinion Standard Sizes.

From schematicdigest.z13.web.core.windows.net

Rack And Pinion Specification Rack And Pinion Standard Sizes The “module” of a rack & pinion denotes the size and pitch of the gear teeth. The index on the next page provides an overview of our standard range of straight (spur) and helical tooth pinions. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Sizes can be as. Rack And Pinion Standard Sizes.

From www.researchgate.net

Sideways motion of the rack and pinion gear Download Scientific Diagram Rack And Pinion Standard Sizes This problem is solved by cp racks and pinions where one rotation of a pinion moves it precisely 50,. The index on the next page provides an overview of our standard range of straight (spur) and helical tooth pinions. Circular pitch products solve these problems. Learn how to select a rack and pinion drive for linear motion applications based on. Rack And Pinion Standard Sizes.

From www.alamy.com

Diagram of a rack and pinion Stock Photo Alamy Rack And Pinion Standard Sizes Learn how to select a rack and pinion drive for linear motion applications based on force, torque, and speed calculations. Sizes can be as low as. This problem is solved by cp racks and pinions where one rotation of a pinion moves it precisely 50,. A smaller module means a smaller tooth and a larger module means a larger tooth.. Rack And Pinion Standard Sizes.

From www.youtube.com

ME05 rack & pinion gears YouTube Rack And Pinion Standard Sizes The index on the next page provides an overview of our standard range of straight (spur) and helical tooth pinions. This problem is solved by cp racks and pinions where one rotation of a pinion moves it precisely 50,. The “module” of a rack & pinion denotes the size and pitch of the gear teeth. Gear dimensions are determined in. Rack And Pinion Standard Sizes.

From www.howeperformance.com

Rack & Pinions Parts Categories Howe Rack And Pinion Standard Sizes Learn how to select a rack and pinion drive for linear motion applications based on force, torque, and speed calculations. A smaller module means a smaller tooth and a larger module means a larger tooth. This problem is solved by cp racks and pinions where one rotation of a pinion moves it precisely 50,. Gear dimensions are determined in accordance. Rack And Pinion Standard Sizes.

From www.thomasnet.com

All About Rack and Pinion Gears What They Are and How They Work Rack And Pinion Standard Sizes Learn how to select a rack and pinion drive for linear motion applications based on force, torque, and speed calculations. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The index on the next page provides an overview of our standard range of straight (spur) and helical tooth pinions.. Rack And Pinion Standard Sizes.

From www.onallcylinders.com

Rack and Pinion Revisited A Basic Guide to Rack and Pinion Steering Rack And Pinion Standard Sizes The index on the next page provides an overview of our standard range of straight (spur) and helical tooth pinions. A smaller module means a smaller tooth and a larger module means a larger tooth. The “module” of a rack & pinion denotes the size and pitch of the gear teeth. Learn how to select a rack and pinion drive. Rack And Pinion Standard Sizes.

From www.youtube.com

Mechanism 17 Rack and Pinion SolidWorks Tutorial YouTube Rack And Pinion Standard Sizes Learn how to select a rack and pinion drive for linear motion applications based on force, torque, and speed calculations. Circular pitch products solve these problems. Sizes can be as low as. The “module” of a rack & pinion denotes the size and pitch of the gear teeth. A smaller module means a smaller tooth and a larger module means. Rack And Pinion Standard Sizes.

From www.linearmotiontips.com

How to size a rackandpinion system for a precision motion axis Rack And Pinion Standard Sizes Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The “module” of a rack & pinion denotes the size and pitch of the gear teeth. Circular pitch products solve these problems. The index on the next page provides an overview of our standard range of straight (spur) and helical. Rack And Pinion Standard Sizes.

From www.autozone.com

Repair Guides Steering Rack And Pinion Assembly Rack And Pinion Standard Sizes The index on the next page provides an overview of our standard range of straight (spur) and helical tooth pinions. A smaller module means a smaller tooth and a larger module means a larger tooth. The “module” of a rack & pinion denotes the size and pitch of the gear teeth. Circular pitch products solve these problems. Gear dimensions are. Rack And Pinion Standard Sizes.

From www.youtube.com

Rack and pinion gear in Creo Parametric YouTube Rack And Pinion Standard Sizes The “module” of a rack & pinion denotes the size and pitch of the gear teeth. This problem is solved by cp racks and pinions where one rotation of a pinion moves it precisely 50,. A smaller module means a smaller tooth and a larger module means a larger tooth. Learn how to select a rack and pinion drive for. Rack And Pinion Standard Sizes.

From userdbcarmen.z13.web.core.windows.net

Rack And Pinion Schematic Diagram Rack And Pinion Standard Sizes Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Circular pitch products solve these problems. Learn how to select a rack and pinion drive for linear motion applications based on force, torque, and speed calculations. The index on the next page provides an overview of our standard range of. Rack And Pinion Standard Sizes.

From www.linearmotiontips.com

How to size a rackandpinion system for a precision motion axis Rack And Pinion Standard Sizes Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The index on the next page provides an overview of our standard range of straight (spur) and helical tooth pinions. A smaller module means a smaller tooth and a larger module means a larger tooth. Learn how to select a. Rack And Pinion Standard Sizes.

From grabcad.com

How to create Rack & Pinion using Inventor 2016 GrabCAD Tutorials Rack And Pinion Standard Sizes Circular pitch products solve these problems. Learn how to select a rack and pinion drive for linear motion applications based on force, torque, and speed calculations. This problem is solved by cp racks and pinions where one rotation of a pinion moves it precisely 50,. The “module” of a rack & pinion denotes the size and pitch of the gear. Rack And Pinion Standard Sizes.

From crm.vallder.com

Rack and Pinion Rack and Pinion Gearbox Rack And Pinion Standard Sizes The “module” of a rack & pinion denotes the size and pitch of the gear teeth. Learn how to select a rack and pinion drive for linear motion applications based on force, torque, and speed calculations. Circular pitch products solve these problems. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle. Rack And Pinion Standard Sizes.

From www.autozone.com

Repair Guides Steering Manual Rack And Pinion Steering Gear Rack And Pinion Standard Sizes Circular pitch products solve these problems. The “module” of a rack & pinion denotes the size and pitch of the gear teeth. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. This problem is solved by cp racks and pinions where one rotation of a pinion moves it precisely. Rack And Pinion Standard Sizes.