Ring Gauge Application . Ring gauges for threads are. The primary functions of the ring gauge in manufacturing are reflected in improving product quality, ensuring. Handheld gages range from the familiar digital micrometer to tools as basic as a ruler, and everything in between. They help check the size of parts. One of our most frequently asked question is “which gagemaker class of tolerance should be used for selecting plain plug and ring gages to. Compared to plug gauges, ring gauges are used to check if manufactured pin or round feature and external threads are within limits. A ring gauge is a tool in precision measurement that accurately determines the external diameter of cylindrical objects. Ring gages are used for comparative gaging as well as for the checking, calibrating, or setting of gages or other standards.

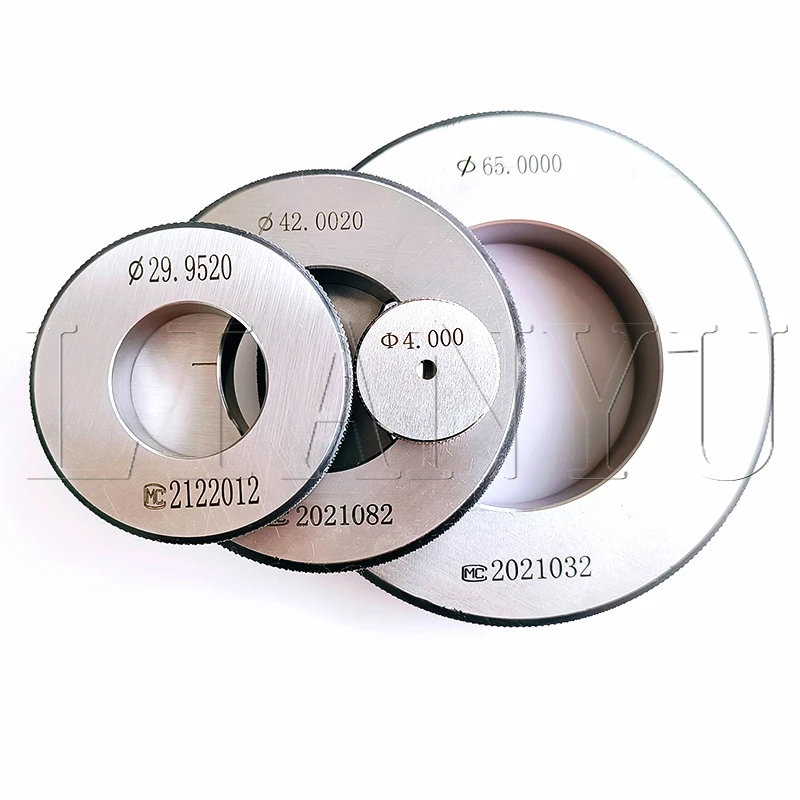

from www.aliexpress.com

The primary functions of the ring gauge in manufacturing are reflected in improving product quality, ensuring. Compared to plug gauges, ring gauges are used to check if manufactured pin or round feature and external threads are within limits. Ring gauges for threads are. A ring gauge is a tool in precision measurement that accurately determines the external diameter of cylindrical objects. Handheld gages range from the familiar digital micrometer to tools as basic as a ruler, and everything in between. One of our most frequently asked question is “which gagemaker class of tolerance should be used for selecting plain plug and ring gages to. They help check the size of parts. Ring gages are used for comparative gaging as well as for the checking, calibrating, or setting of gages or other standards.

215mmInnerdiameterCalibrationGaugeSettingringgaugeringgageSmoothholegauge

Ring Gauge Application Compared to plug gauges, ring gauges are used to check if manufactured pin or round feature and external threads are within limits. The primary functions of the ring gauge in manufacturing are reflected in improving product quality, ensuring. Ring gages are used for comparative gaging as well as for the checking, calibrating, or setting of gages or other standards. They help check the size of parts. Compared to plug gauges, ring gauges are used to check if manufactured pin or round feature and external threads are within limits. A ring gauge is a tool in precision measurement that accurately determines the external diameter of cylindrical objects. Handheld gages range from the familiar digital micrometer to tools as basic as a ruler, and everything in between. One of our most frequently asked question is “which gagemaker class of tolerance should be used for selecting plain plug and ring gages to. Ring gauges for threads are.

From www.youtube.com

RING GAUGE TYPES OF RING GAUGE YouTube Ring Gauge Application The primary functions of the ring gauge in manufacturing are reflected in improving product quality, ensuring. They help check the size of parts. One of our most frequently asked question is “which gagemaker class of tolerance should be used for selecting plain plug and ring gages to. A ring gauge is a tool in precision measurement that accurately determines the. Ring Gauge Application.

From www.indiamart.com

MS Ring Gauges at Rs 5000/number in Pune ID 12612242612 Ring Gauge Application They help check the size of parts. One of our most frequently asked question is “which gagemaker class of tolerance should be used for selecting plain plug and ring gages to. Handheld gages range from the familiar digital micrometer to tools as basic as a ruler, and everything in between. A ring gauge is a tool in precision measurement that. Ring Gauge Application.

From www.harshman-gauges.com

Ring Gauges Thread Ring Gauges Manufacturer from Mumbai Ring Gauge Application Ring gages are used for comparative gaging as well as for the checking, calibrating, or setting of gages or other standards. Handheld gages range from the familiar digital micrometer to tools as basic as a ruler, and everything in between. They help check the size of parts. A ring gauge is a tool in precision measurement that accurately determines the. Ring Gauge Application.

From www.aliexpress.com

ThreadplugthreadringgaugetesterpasscheckgaugeauthenticM10156GM101.jpg Ring Gauge Application One of our most frequently asked question is “which gagemaker class of tolerance should be used for selecting plain plug and ring gages to. Ring gages are used for comparative gaging as well as for the checking, calibrating, or setting of gages or other standards. Ring gauges for threads are. Compared to plug gauges, ring gauges are used to check. Ring Gauge Application.

From www.exportersindia.com

DIC Tools Round Stainless Steel Thread Ring Gauges, for Industrial Use, Certification ISO 9001 Ring Gauge Application Compared to plug gauges, ring gauges are used to check if manufactured pin or round feature and external threads are within limits. The primary functions of the ring gauge in manufacturing are reflected in improving product quality, ensuring. Ring gages are used for comparative gaging as well as for the checking, calibrating, or setting of gages or other standards. They. Ring Gauge Application.

From briansmythltd.co.uk

planringgauges The Brian Smyth Company Ring Gauge Application Compared to plug gauges, ring gauges are used to check if manufactured pin or round feature and external threads are within limits. Handheld gages range from the familiar digital micrometer to tools as basic as a ruler, and everything in between. They help check the size of parts. The primary functions of the ring gauge in manufacturing are reflected in. Ring Gauge Application.

From www.indiamart.com

Mahalaxmi Enterprise CARBIDE & OHNS Master Ring Gauge at Rs 1100/piece in Ahmedabad Ring Gauge Application Handheld gages range from the familiar digital micrometer to tools as basic as a ruler, and everything in between. Ring gauges for threads are. Ring gages are used for comparative gaging as well as for the checking, calibrating, or setting of gages or other standards. They help check the size of parts. A ring gauge is a tool in precision. Ring Gauge Application.

From www.aliexpress.com

215mmInnerdiameterCalibrationGaugeSettingringgaugeringgageSmoothholegauge Ring Gauge Application Handheld gages range from the familiar digital micrometer to tools as basic as a ruler, and everything in between. They help check the size of parts. Ring gauges for threads are. The primary functions of the ring gauge in manufacturing are reflected in improving product quality, ensuring. A ring gauge is a tool in precision measurement that accurately determines the. Ring Gauge Application.

From www.swansongage.com

Calibration Services Swanson Tool Manufacturing Ring Gauge Application Ring gages are used for comparative gaging as well as for the checking, calibrating, or setting of gages or other standards. One of our most frequently asked question is “which gagemaker class of tolerance should be used for selecting plain plug and ring gages to. Compared to plug gauges, ring gauges are used to check if manufactured pin or round. Ring Gauge Application.

From www.yuzuki.co.in

Ring Gauge / Plug Gauge Yuzuki Ring Gauge Application A ring gauge is a tool in precision measurement that accurately determines the external diameter of cylindrical objects. Compared to plug gauges, ring gauges are used to check if manufactured pin or round feature and external threads are within limits. The primary functions of the ring gauge in manufacturing are reflected in improving product quality, ensuring. Handheld gages range from. Ring Gauge Application.

From a-e-gauges.com

A&E Gauges Ltd Air Ring Gauges Ring Gauge Application Handheld gages range from the familiar digital micrometer to tools as basic as a ruler, and everything in between. Ring gages are used for comparative gaging as well as for the checking, calibrating, or setting of gages or other standards. A ring gauge is a tool in precision measurement that accurately determines the external diameter of cylindrical objects. Compared to. Ring Gauge Application.

From www.threadingtaps.co.in

Trapezoidal Thread Ring Gauges in Ludhiana, India from Accurate Precision Tools (India) Pvt. Ltd. Ring Gauge Application Compared to plug gauges, ring gauges are used to check if manufactured pin or round feature and external threads are within limits. Handheld gages range from the familiar digital micrometer to tools as basic as a ruler, and everything in between. One of our most frequently asked question is “which gagemaker class of tolerance should be used for selecting plain. Ring Gauge Application.

From www.researchgate.net

Schematic of ring gauge measurement and symbols used in the calculation. Download Scientific Ring Gauge Application Ring gauges for threads are. Compared to plug gauges, ring gauges are used to check if manufactured pin or round feature and external threads are within limits. A ring gauge is a tool in precision measurement that accurately determines the external diameter of cylindrical objects. The primary functions of the ring gauge in manufacturing are reflected in improving product quality,. Ring Gauge Application.

From piramydprecision.com

Master Setting Ring Gauges Dia. 2.75mm to 500mm. Piramyd Precision Ring Gauge Application Compared to plug gauges, ring gauges are used to check if manufactured pin or round feature and external threads are within limits. Handheld gages range from the familiar digital micrometer to tools as basic as a ruler, and everything in between. They help check the size of parts. Ring gauges for threads are. Ring gages are used for comparative gaging. Ring Gauge Application.

From www.indiamart.com

Precision Metric Thread Ring Gauge, Size/Dimension M1 To M300, Rs 900 /number ID 3777506033 Ring Gauge Application A ring gauge is a tool in precision measurement that accurately determines the external diameter of cylindrical objects. One of our most frequently asked question is “which gagemaker class of tolerance should be used for selecting plain plug and ring gages to. Compared to plug gauges, ring gauges are used to check if manufactured pin or round feature and external. Ring Gauge Application.

From www.indiamart.com

Skill Mild Steel Air Ring Gauge, Size 35.9605mm, Model Name/Number A22256 at Rs 4000/piece in Ring Gauge Application Handheld gages range from the familiar digital micrometer to tools as basic as a ruler, and everything in between. A ring gauge is a tool in precision measurement that accurately determines the external diameter of cylindrical objects. They help check the size of parts. Compared to plug gauges, ring gauges are used to check if manufactured pin or round feature. Ring Gauge Application.

From www.indiamart.com

Ring Gauges at Rs 1000 /piece Ring Gauges ID 2006960988 Ring Gauge Application The primary functions of the ring gauge in manufacturing are reflected in improving product quality, ensuring. A ring gauge is a tool in precision measurement that accurately determines the external diameter of cylindrical objects. Ring gages are used for comparative gaging as well as for the checking, calibrating, or setting of gages or other standards. Compared to plug gauges, ring. Ring Gauge Application.

From www.aliexpress.com

1PC Thread ring gauge M5 6g T High precision screw thread ring gauge for gage holes prior screw Ring Gauge Application The primary functions of the ring gauge in manufacturing are reflected in improving product quality, ensuring. They help check the size of parts. Handheld gages range from the familiar digital micrometer to tools as basic as a ruler, and everything in between. A ring gauge is a tool in precision measurement that accurately determines the external diameter of cylindrical objects.. Ring Gauge Application.

From www.indiamart.com

Plain Ring Gauge at best price in Ludhiana by P.S. Engineering ID 23325807112 Ring Gauge Application The primary functions of the ring gauge in manufacturing are reflected in improving product quality, ensuring. Compared to plug gauges, ring gauges are used to check if manufactured pin or round feature and external threads are within limits. Ring gauges for threads are. One of our most frequently asked question is “which gagemaker class of tolerance should be used for. Ring Gauge Application.

From www.chronos.ltd.uk

Dasqua Thread Gauge Set (Ring Gauge) M3M12 GO Chronos Engineering Supplies Ring Gauge Application Ring gages are used for comparative gaging as well as for the checking, calibrating, or setting of gages or other standards. Compared to plug gauges, ring gauges are used to check if manufactured pin or round feature and external threads are within limits. A ring gauge is a tool in precision measurement that accurately determines the external diameter of cylindrical. Ring Gauge Application.

From www.qualitygauge.co.th

ring gauge Quality Gauge and Tool Ring Gauge Application They help check the size of parts. Compared to plug gauges, ring gauges are used to check if manufactured pin or round feature and external threads are within limits. The primary functions of the ring gauge in manufacturing are reflected in improving product quality, ensuring. Ring gauges for threads are. Handheld gages range from the familiar digital micrometer to tools. Ring Gauge Application.

From mx.misumi-ec.com

Ring Gauges MISUMI MEXICO Ring Gauge Application Ring gages are used for comparative gaging as well as for the checking, calibrating, or setting of gages or other standards. One of our most frequently asked question is “which gagemaker class of tolerance should be used for selecting plain plug and ring gages to. Compared to plug gauges, ring gauges are used to check if manufactured pin or round. Ring Gauge Application.

From www.msi-viking.com

231414310 Custom Plain Ring Gages Ring Gauge Application A ring gauge is a tool in precision measurement that accurately determines the external diameter of cylindrical objects. Ring gauges for threads are. They help check the size of parts. Ring gages are used for comparative gaging as well as for the checking, calibrating, or setting of gages or other standards. The primary functions of the ring gauge in manufacturing. Ring Gauge Application.

From www.indiamart.com

1.5 Inch Mild Steel Thread Ring Gauge at Rs 2250/piece Thread Ring Gages in Aurangabad ID Ring Gauge Application Compared to plug gauges, ring gauges are used to check if manufactured pin or round feature and external threads are within limits. Ring gages are used for comparative gaging as well as for the checking, calibrating, or setting of gages or other standards. Handheld gages range from the familiar digital micrometer to tools as basic as a ruler, and everything. Ring Gauge Application.

From www.indiamart.com

0.5 mm Carbide Ring Gauge, Size 1.5 Inch (dia) at Rs 3500 in Anjangaon ID 2850138277173 Ring Gauge Application One of our most frequently asked question is “which gagemaker class of tolerance should be used for selecting plain plug and ring gages to. Ring gauges for threads are. The primary functions of the ring gauge in manufacturing are reflected in improving product quality, ensuring. They help check the size of parts. A ring gauge is a tool in precision. Ring Gauge Application.

From www.aliexpress.com

RthreadRingGaugesR18383412141inch.jpg Ring Gauge Application Compared to plug gauges, ring gauges are used to check if manufactured pin or round feature and external threads are within limits. Handheld gages range from the familiar digital micrometer to tools as basic as a ruler, and everything in between. A ring gauge is a tool in precision measurement that accurately determines the external diameter of cylindrical objects. The. Ring Gauge Application.

From www.alibaba.com

High Precision Thread Ring Gauge Ring Gages Buy Thread Ring Gauge,Thread Ring Gauge Plug Gauge Ring Gauge Application Ring gages are used for comparative gaging as well as for the checking, calibrating, or setting of gages or other standards. Handheld gages range from the familiar digital micrometer to tools as basic as a ruler, and everything in between. Compared to plug gauges, ring gauges are used to check if manufactured pin or round feature and external threads are. Ring Gauge Application.

From dir.indiamart.com

Ring Gauges Go No Go Ring Gauge Latest Price, Manufacturers & Suppliers Ring Gauge Application One of our most frequently asked question is “which gagemaker class of tolerance should be used for selecting plain plug and ring gages to. Ring gages are used for comparative gaging as well as for the checking, calibrating, or setting of gages or other standards. A ring gauge is a tool in precision measurement that accurately determines the external diameter. Ring Gauge Application.

From dir.indiamart.com

Ring Gauges Ring Gages Latest Price, Manufacturers & Suppliers Ring Gauge Application Ring gages are used for comparative gaging as well as for the checking, calibrating, or setting of gages or other standards. The primary functions of the ring gauge in manufacturing are reflected in improving product quality, ensuring. Ring gauges for threads are. Handheld gages range from the familiar digital micrometer to tools as basic as a ruler, and everything in. Ring Gauge Application.

From meaninghippo.com

Thread Plug Gauge Calibration Procedure MeaningHippo Ring Gauge Application Compared to plug gauges, ring gauges are used to check if manufactured pin or round feature and external threads are within limits. The primary functions of the ring gauge in manufacturing are reflected in improving product quality, ensuring. Ring gages are used for comparative gaging as well as for the checking, calibrating, or setting of gages or other standards. A. Ring Gauge Application.

From www.aliexpress.com

24.997mm Inner Diameter Calibration Gauge 25mm/0.001mm Setting Ring Gauge Plain Ring Gauge Ring Gauge Application Ring gauges for threads are. One of our most frequently asked question is “which gagemaker class of tolerance should be used for selecting plain plug and ring gages to. A ring gauge is a tool in precision measurement that accurately determines the external diameter of cylindrical objects. Compared to plug gauges, ring gauges are used to check if manufactured pin. Ring Gauge Application.

From www.formsbirds.com

Ring Size Gauge Free Download Ring Gauge Application One of our most frequently asked question is “which gagemaker class of tolerance should be used for selecting plain plug and ring gages to. Handheld gages range from the familiar digital micrometer to tools as basic as a ruler, and everything in between. They help check the size of parts. Ring gages are used for comparative gaging as well as. Ring Gauge Application.

From www.indiamart.com

Steel Thread Ring Gauges at best price in Chennai ID 2526062462 Ring Gauge Application A ring gauge is a tool in precision measurement that accurately determines the external diameter of cylindrical objects. The primary functions of the ring gauge in manufacturing are reflected in improving product quality, ensuring. Ring gages are used for comparative gaging as well as for the checking, calibrating, or setting of gages or other standards. One of our most frequently. Ring Gauge Application.

From ibusinessday.com

A Brief Introduction to Thread Gauges i Business Day Ring Gauge Application Ring gages are used for comparative gaging as well as for the checking, calibrating, or setting of gages or other standards. They help check the size of parts. The primary functions of the ring gauge in manufacturing are reflected in improving product quality, ensuring. One of our most frequently asked question is “which gagemaker class of tolerance should be used. Ring Gauge Application.

From vn.misumi-ec.com

Ring Gauges Gauges various hand tools for general works MISUMI Vietnam Ring Gauge Application Compared to plug gauges, ring gauges are used to check if manufactured pin or round feature and external threads are within limits. The primary functions of the ring gauge in manufacturing are reflected in improving product quality, ensuring. Ring gauges for threads are. A ring gauge is a tool in precision measurement that accurately determines the external diameter of cylindrical. Ring Gauge Application.