Saw Welding Positions . Saw process’s defining element is how it protects the weld metal from atmospheric contamination. Saw offers one of the highest deposition rates among arc welding processes. Submerged arc welding (saw) is a joining process that involves the formation of an electric arc between a continuously fed electrode and the workpiece to be welded. Submerged arc welding (saw) is a welding method where similarly to other arc welding processes, the base metals are joined by forming an electric arc between the workpiece and an electrode. Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals by generating.

from welderslab.com

Saw process’s defining element is how it protects the weld metal from atmospheric contamination. Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals by generating. Submerged arc welding (saw) is a welding method where similarly to other arc welding processes, the base metals are joined by forming an electric arc between the workpiece and an electrode. Saw offers one of the highest deposition rates among arc welding processes. Submerged arc welding (saw) is a joining process that involves the formation of an electric arc between a continuously fed electrode and the workpiece to be welded.

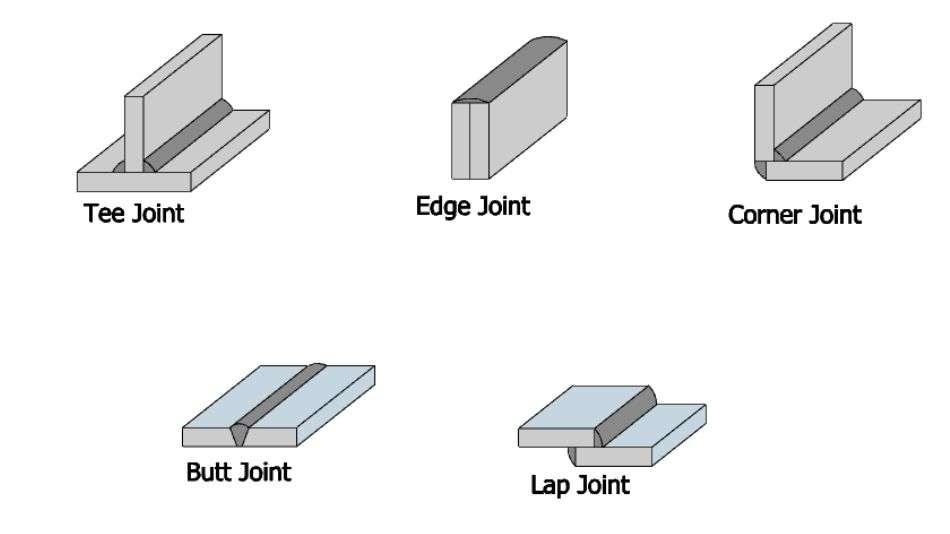

What Are the 5 Basic Types of Welding Joints A Beginner's Guide

Saw Welding Positions Saw offers one of the highest deposition rates among arc welding processes. Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals by generating. Saw process’s defining element is how it protects the weld metal from atmospheric contamination. Submerged arc welding (saw) is a welding method where similarly to other arc welding processes, the base metals are joined by forming an electric arc between the workpiece and an electrode. Submerged arc welding (saw) is a joining process that involves the formation of an electric arc between a continuously fed electrode and the workpiece to be welded. Saw offers one of the highest deposition rates among arc welding processes.

From www.fleetmaintenance.com

Welding Types and Positions poster Fleet Maintenance Saw Welding Positions Submerged arc welding (saw) is a welding method where similarly to other arc welding processes, the base metals are joined by forming an electric arc between the workpiece and an electrode. Saw offers one of the highest deposition rates among arc welding processes. Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join. Saw Welding Positions.

From www.studocu.com

Basic welding Position Flat Welding Position Basic Welding Position Saw Welding Positions Submerged arc welding (saw) is a joining process that involves the formation of an electric arc between a continuously fed electrode and the workpiece to be welded. Submerged arc welding (saw) is a welding method where similarly to other arc welding processes, the base metals are joined by forming an electric arc between the workpiece and an electrode. Saw process’s. Saw Welding Positions.

From welderslab.com

What Are the 5 Basic Types of Welding Joints A Beginner's Guide Saw Welding Positions Saw process’s defining element is how it protects the weld metal from atmospheric contamination. Saw offers one of the highest deposition rates among arc welding processes. Submerged arc welding (saw) is a welding method where similarly to other arc welding processes, the base metals are joined by forming an electric arc between the workpiece and an electrode. Submerged arc welding. Saw Welding Positions.

From proper-cooking.info

Welding Joints And Positions Saw Welding Positions Submerged arc welding (saw) is a joining process that involves the formation of an electric arc between a continuously fed electrode and the workpiece to be welded. Saw process’s defining element is how it protects the weld metal from atmospheric contamination. Submerged arc welding (saw) is a welding method where similarly to other arc welding processes, the base metals are. Saw Welding Positions.

From weldingclarity.com

4 Essential Welding Position Types for Perfect Joints Saw Welding Positions Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals by generating. Submerged arc welding (saw) is a joining process that involves the formation of an electric arc between a continuously fed electrode and the workpiece to be welded. Saw process’s defining element is how it protects the weld metal from. Saw Welding Positions.

From www.scribd.com

Welding Positions Saw Welding Positions Saw offers one of the highest deposition rates among arc welding processes. Submerged arc welding (saw) is a welding method where similarly to other arc welding processes, the base metals are joined by forming an electric arc between the workpiece and an electrode. Submerged arc welding (saw) is a joining process that involves the formation of an electric arc between. Saw Welding Positions.

From www.electronicshub.org

Master Every Weld Welding Positions & Labels Explained! Saw Welding Positions Saw process’s defining element is how it protects the weld metal from atmospheric contamination. Submerged arc welding (saw) is a joining process that involves the formation of an electric arc between a continuously fed electrode and the workpiece to be welded. Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals. Saw Welding Positions.

From weldingclarity.com

4 Essential Welding Position Types for Perfect Joints Saw Welding Positions Saw offers one of the highest deposition rates among arc welding processes. Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals by generating. Submerged arc welding (saw) is a welding method where similarly to other arc welding processes, the base metals are joined by forming an electric arc between the. Saw Welding Positions.

From engineeringlearn.com

Welding Position Types of Welding Positions, 1G, 2G, 3G, 4G, 5G and 6G Saw Welding Positions Saw process’s defining element is how it protects the weld metal from atmospheric contamination. Submerged arc welding (saw) is a joining process that involves the formation of an electric arc between a continuously fed electrode and the workpiece to be welded. Submerged arc welding (saw) is a welding method where similarly to other arc welding processes, the base metals are. Saw Welding Positions.

From www.studypool.com

SOLUTION welding welding welding welding welding welding welding Types Saw Welding Positions Saw process’s defining element is how it protects the weld metal from atmospheric contamination. Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals by generating. Submerged arc welding (saw) is a joining process that involves the formation of an electric arc between a continuously fed electrode and the workpiece to. Saw Welding Positions.

From weldingclarity.com

4 Essential Welding Position Types for Perfect Joints Saw Welding Positions Submerged arc welding (saw) is a welding method where similarly to other arc welding processes, the base metals are joined by forming an electric arc between the workpiece and an electrode. Saw process’s defining element is how it protects the weld metal from atmospheric contamination. Submerged arc welding (saw) is a joining process that involves the formation of an electric. Saw Welding Positions.

From www.hollyfab.com

Common Welding Methods Saw Welding Positions Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals by generating. Submerged arc welding (saw) is a joining process that involves the formation of an electric arc between a continuously fed electrode and the workpiece to be welded. Submerged arc welding (saw) is a welding method where similarly to other. Saw Welding Positions.

From weldingtroop.com

The 4 Main Welding Positions You Should Know Complete Guide Saw Welding Positions Saw offers one of the highest deposition rates among arc welding processes. Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals by generating. Submerged arc welding (saw) is a joining process that involves the formation of an electric arc between a continuously fed electrode and the workpiece to be welded.. Saw Welding Positions.

From www.wcwelding.com

Basic Welding Positions Saw Welding Positions Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals by generating. Saw process’s defining element is how it protects the weld metal from atmospheric contamination. Saw offers one of the highest deposition rates among arc welding processes. Submerged arc welding (saw) is a welding method where similarly to other arc. Saw Welding Positions.

From www.kingsofwelding.com

The Complete Guide of How to Stick Weld (SMAW) Kings of Welding Saw Welding Positions Saw process’s defining element is how it protects the weld metal from atmospheric contamination. Saw offers one of the highest deposition rates among arc welding processes. Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals by generating. Submerged arc welding (saw) is a joining process that involves the formation of. Saw Welding Positions.

From weldspeconline.com

Information Download Welding Procedures Saw Welding Positions Submerged arc welding (saw) is a welding method where similarly to other arc welding processes, the base metals are joined by forming an electric arc between the workpiece and an electrode. Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals by generating. Submerged arc welding (saw) is a joining process. Saw Welding Positions.

From www.weldingandndt.com

Welding Positions Welding and NDT Saw Welding Positions Submerged arc welding (saw) is a joining process that involves the formation of an electric arc between a continuously fed electrode and the workpiece to be welded. Saw offers one of the highest deposition rates among arc welding processes. Submerged arc welding (saw) is a welding method where similarly to other arc welding processes, the base metals are joined by. Saw Welding Positions.

From upweld.org

What are the 4 Basic Welding Positions for Fillet Welds Plate? UpWeld Saw Welding Positions Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals by generating. Submerged arc welding (saw) is a welding method where similarly to other arc welding processes, the base metals are joined by forming an electric arc between the workpiece and an electrode. Saw offers one of the highest deposition rates. Saw Welding Positions.

From www.capilla-gmbh.com

Welding position in accordance with EN ISO 6947 — Capilla Saw Welding Positions Saw offers one of the highest deposition rates among arc welding processes. Submerged arc welding (saw) is a joining process that involves the formation of an electric arc between a continuously fed electrode and the workpiece to be welded. Submerged arc welding (saw) is a welding method where similarly to other arc welding processes, the base metals are joined by. Saw Welding Positions.

From weldingclarity.com

4 Essential Welding Position Types for Perfect Joints Saw Welding Positions Submerged arc welding (saw) is a joining process that involves the formation of an electric arc between a continuously fed electrode and the workpiece to be welded. Submerged arc welding (saw) is a welding method where similarly to other arc welding processes, the base metals are joined by forming an electric arc between the workpiece and an electrode. Saw process’s. Saw Welding Positions.

From weldingtroop.com

The 4 Main Welding Positions You Should Know Complete Guide Saw Welding Positions Submerged arc welding (saw) is a welding method where similarly to other arc welding processes, the base metals are joined by forming an electric arc between the workpiece and an electrode. Saw process’s defining element is how it protects the weld metal from atmospheric contamination. Submerged arc welding (saw) is a joining process that involves the formation of an electric. Saw Welding Positions.

From www.onestopndt.com

An ultimate Guide to Weld Joints OnestopNDT Saw Welding Positions Saw process’s defining element is how it protects the weld metal from atmospheric contamination. Saw offers one of the highest deposition rates among arc welding processes. Submerged arc welding (saw) is a joining process that involves the formation of an electric arc between a continuously fed electrode and the workpiece to be welded. Submerged arc welding (saw) is a welding. Saw Welding Positions.

From fr.promotech.eu

Welding automation by means of welding carriages PROMOTECH Saw Welding Positions Saw offers one of the highest deposition rates among arc welding processes. Submerged arc welding (saw) is a joining process that involves the formation of an electric arc between a continuously fed electrode and the workpiece to be welded. Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals by generating.. Saw Welding Positions.

From workshopinsider.com

Insider's Guide to Submerged Arc Welding (SAW) Insider Saw Welding Positions Saw offers one of the highest deposition rates among arc welding processes. Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals by generating. Submerged arc welding (saw) is a welding method where similarly to other arc welding processes, the base metals are joined by forming an electric arc between the. Saw Welding Positions.

From www.weldingandndt.com

(SAW) Submerged Arc Welding Welding & NDT Saw Welding Positions Submerged arc welding (saw) is a joining process that involves the formation of an electric arc between a continuously fed electrode and the workpiece to be welded. Saw process’s defining element is how it protects the weld metal from atmospheric contamination. Submerged arc welding (saw) is a welding method where similarly to other arc welding processes, the base metals are. Saw Welding Positions.

From sharetricksblog.wordpress.com

Welding Positions Diagram ShareTricks Saw Welding Positions Submerged arc welding (saw) is a joining process that involves the formation of an electric arc between a continuously fed electrode and the workpiece to be welded. Saw process’s defining element is how it protects the weld metal from atmospheric contamination. Submerged arc welding (saw) is a welding method where similarly to other arc welding processes, the base metals are. Saw Welding Positions.

From eziil.com

5 Types of Welding Positions 1g, 2f, 3g, 4g... Saw Welding Positions Submerged arc welding (saw) is a joining process that involves the formation of an electric arc between a continuously fed electrode and the workpiece to be welded. Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals by generating. Submerged arc welding (saw) is a welding method where similarly to other. Saw Welding Positions.

From waterwelders.com

Welding Symbols Chart An Explanation of the Basics (with Pictures Saw Welding Positions Submerged arc welding (saw) is a welding method where similarly to other arc welding processes, the base metals are joined by forming an electric arc between the workpiece and an electrode. Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals by generating. Saw process’s defining element is how it protects. Saw Welding Positions.

From www.muggyweld.com

Flat, Horizontal, Vertical And Overhead Welding Positions Explained Saw Welding Positions Submerged arc welding (saw) is a joining process that involves the formation of an electric arc between a continuously fed electrode and the workpiece to be welded. Saw offers one of the highest deposition rates among arc welding processes. Submerged arc welding (saw) is a welding method where similarly to other arc welding processes, the base metals are joined by. Saw Welding Positions.

From www.revacranes.com

Why SAW Welding is Beneficial ? Reva EOT Cranes and Electric Wire Saw Welding Positions Submerged arc welding (saw) is a welding method where similarly to other arc welding processes, the base metals are joined by forming an electric arc between the workpiece and an electrode. Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals by generating. Saw offers one of the highest deposition rates. Saw Welding Positions.

From eziil.com

5 Types of Welding Positions 1g, 2f, 3g, 4g... Saw Welding Positions Saw offers one of the highest deposition rates among arc welding processes. Saw process’s defining element is how it protects the weld metal from atmospheric contamination. Submerged arc welding (saw) is a joining process that involves the formation of an electric arc between a continuously fed electrode and the workpiece to be welded. Submerged arc welding (saw) is a welding. Saw Welding Positions.

From www.cruxweld.com

Submerged Arc Welding (SAW) Working Process, Equipment, Parts, and Its Saw Welding Positions Submerged arc welding (saw) is a welding method where similarly to other arc welding processes, the base metals are joined by forming an electric arc between the workpiece and an electrode. Submerged arc welding (saw) is a joining process that involves the formation of an electric arc between a continuously fed electrode and the workpiece to be welded. Submerged arc. Saw Welding Positions.

From www.theengineerspost.com

5 Different Types of Welding Positions [Pictures & PDF] Saw Welding Positions Submerged arc welding (saw) is a welding method where similarly to other arc welding processes, the base metals are joined by forming an electric arc between the workpiece and an electrode. Submerged arc welding (saw) is a joining process that involves the formation of an electric arc between a continuously fed electrode and the workpiece to be welded. Saw process’s. Saw Welding Positions.

From www.vehicleservicepros.com

Welding Types and Positions poster From Hobart Welders Vehicle Saw Welding Positions Saw process’s defining element is how it protects the weld metal from atmospheric contamination. Submerged arc welding (saw) is a joining process that involves the formation of an electric arc between a continuously fed electrode and the workpiece to be welded. Saw offers one of the highest deposition rates among arc welding processes. Submerged arc welding (saw) is a welding. Saw Welding Positions.

From de.slideshare.net

Weldmaster Welding Positions Saw Welding Positions Saw process’s defining element is how it protects the weld metal from atmospheric contamination. Submerged arc welding (saw) is a joining process that involves the formation of an electric arc between a continuously fed electrode and the workpiece to be welded. Saw offers one of the highest deposition rates among arc welding processes. Submerged arc welding (saw) is a welding. Saw Welding Positions.