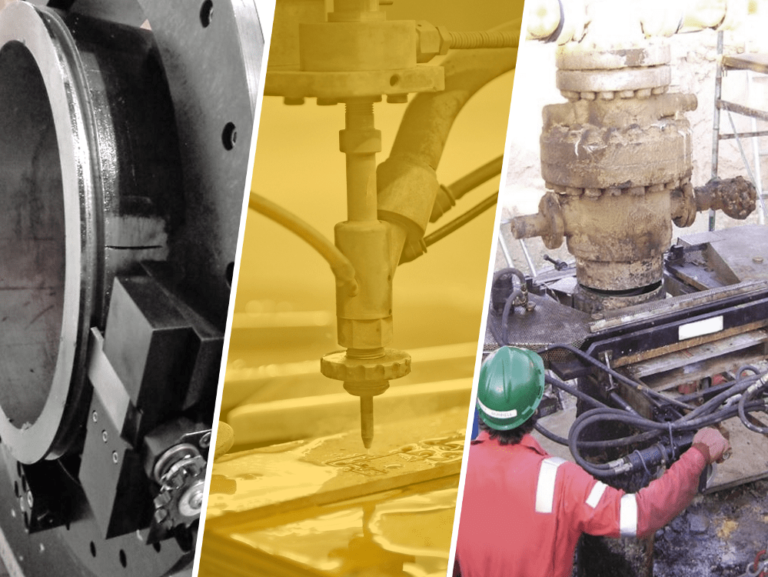

Cold Cutting Steel Plate Methods . cold cutting is a versatile, precise, and safe method of cutting pipe that allows the operator to operate the cutting. with the right supporting structure built around the application, they can be used for cutting shapes into vessels or for severing iron girders and concrete structures. the cold cutting method, exemplified by technologies such as water jet cutting and diamond wire saws, operates under a principle that eschews heat to minimize the impact on material properties. Three commonly used types of cold cutting machines are clamshell cutters, cold cutting saws, and abrasive water jet cutters. While thermal cutting includes flame cutting, plasma cutting and laser. cold cutting can be further classified into water jet cutting and abrasive cutting; learn about the innovative technique of cold cutting, its various methods, benefits, and applications across industries. Waterjet cutting can handle a wide range of materials, including metals, ceramics, glass, and composites. Waterjet cutting is a cold process, meaning it doesn't produce heat, preserving material integrity. Discover how cold cutting enhances safety and precision in cutting operations. This technique ensures that the heat affected zone (haz) is eliminated, preserving the original characteristics of the metal or pipe being. waterjet cutting is known for its versatility and precision, especially when cutting thicker steel plates.

from blog.enerpac.com

Waterjet cutting can handle a wide range of materials, including metals, ceramics, glass, and composites. cold cutting is a versatile, precise, and safe method of cutting pipe that allows the operator to operate the cutting. with the right supporting structure built around the application, they can be used for cutting shapes into vessels or for severing iron girders and concrete structures. cold cutting can be further classified into water jet cutting and abrasive cutting; This technique ensures that the heat affected zone (haz) is eliminated, preserving the original characteristics of the metal or pipe being. the cold cutting method, exemplified by technologies such as water jet cutting and diamond wire saws, operates under a principle that eschews heat to minimize the impact on material properties. Waterjet cutting is a cold process, meaning it doesn't produce heat, preserving material integrity. Three commonly used types of cold cutting machines are clamshell cutters, cold cutting saws, and abrasive water jet cutters. learn about the innovative technique of cold cutting, its various methods, benefits, and applications across industries. Discover how cold cutting enhances safety and precision in cutting operations.

Cold Cutting Machines Types and Applications Enerpac Blog

Cold Cutting Steel Plate Methods This technique ensures that the heat affected zone (haz) is eliminated, preserving the original characteristics of the metal or pipe being. learn about the innovative technique of cold cutting, its various methods, benefits, and applications across industries. Waterjet cutting is a cold process, meaning it doesn't produce heat, preserving material integrity. This technique ensures that the heat affected zone (haz) is eliminated, preserving the original characteristics of the metal or pipe being. Discover how cold cutting enhances safety and precision in cutting operations. cold cutting can be further classified into water jet cutting and abrasive cutting; Waterjet cutting can handle a wide range of materials, including metals, ceramics, glass, and composites. cold cutting is a versatile, precise, and safe method of cutting pipe that allows the operator to operate the cutting. waterjet cutting is known for its versatility and precision, especially when cutting thicker steel plates. with the right supporting structure built around the application, they can be used for cutting shapes into vessels or for severing iron girders and concrete structures. While thermal cutting includes flame cutting, plasma cutting and laser. Three commonly used types of cold cutting machines are clamshell cutters, cold cutting saws, and abrasive water jet cutters. the cold cutting method, exemplified by technologies such as water jet cutting and diamond wire saws, operates under a principle that eschews heat to minimize the impact on material properties.

From dwcnclaser.com

Best Way Of How To Cut Steel Plate Cold Cutting Steel Plate Methods Waterjet cutting is a cold process, meaning it doesn't produce heat, preserving material integrity. While thermal cutting includes flame cutting, plasma cutting and laser. with the right supporting structure built around the application, they can be used for cutting shapes into vessels or for severing iron girders and concrete structures. Discover how cold cutting enhances safety and precision in. Cold Cutting Steel Plate Methods.

From www.youtube.com

Simple way of steel plate cutting YouTube Cold Cutting Steel Plate Methods Waterjet cutting can handle a wide range of materials, including metals, ceramics, glass, and composites. While thermal cutting includes flame cutting, plasma cutting and laser. This technique ensures that the heat affected zone (haz) is eliminated, preserving the original characteristics of the metal or pipe being. Waterjet cutting is a cold process, meaning it doesn't produce heat, preserving material integrity.. Cold Cutting Steel Plate Methods.

From dengarden.com

12 Ways to Cut Steel and Other Metals Pros and Cons of Each Technique Cold Cutting Steel Plate Methods Three commonly used types of cold cutting machines are clamshell cutters, cold cutting saws, and abrasive water jet cutters. This technique ensures that the heat affected zone (haz) is eliminated, preserving the original characteristics of the metal or pipe being. waterjet cutting is known for its versatility and precision, especially when cutting thicker steel plates. cold cutting is. Cold Cutting Steel Plate Methods.

From www.isotechltd.com

Cold Cutting Cold Cutting Steel Plate Methods Three commonly used types of cold cutting machines are clamshell cutters, cold cutting saws, and abrasive water jet cutters. learn about the innovative technique of cold cutting, its various methods, benefits, and applications across industries. the cold cutting method, exemplified by technologies such as water jet cutting and diamond wire saws, operates under a principle that eschews heat. Cold Cutting Steel Plate Methods.

From www.cumic.com

A Guide to Steel Plate Cutting CUMIC STEEL LIMITED Cold Cutting Steel Plate Methods the cold cutting method, exemplified by technologies such as water jet cutting and diamond wire saws, operates under a principle that eschews heat to minimize the impact on material properties. Three commonly used types of cold cutting machines are clamshell cutters, cold cutting saws, and abrasive water jet cutters. with the right supporting structure built around the application,. Cold Cutting Steel Plate Methods.

From alloy.wiki

Steel Plate Cutting Methods and Services Alloy Wiki Cold Cutting Steel Plate Methods waterjet cutting is known for its versatility and precision, especially when cutting thicker steel plates. This technique ensures that the heat affected zone (haz) is eliminated, preserving the original characteristics of the metal or pipe being. cold cutting can be further classified into water jet cutting and abrasive cutting; learn about the innovative technique of cold cutting,. Cold Cutting Steel Plate Methods.

From pgisteel.com

Steel Plate Cutting Precision Grinding, Inc. Cold Cutting Steel Plate Methods learn about the innovative technique of cold cutting, its various methods, benefits, and applications across industries. cold cutting is a versatile, precise, and safe method of cutting pipe that allows the operator to operate the cutting. Waterjet cutting is a cold process, meaning it doesn't produce heat, preserving material integrity. Discover how cold cutting enhances safety and precision. Cold Cutting Steel Plate Methods.

From www.hudsonservicesinc.com

Cold Cutting Pipe Cold Cutting Steel Plate Methods cold cutting can be further classified into water jet cutting and abrasive cutting; Waterjet cutting can handle a wide range of materials, including metals, ceramics, glass, and composites. the cold cutting method, exemplified by technologies such as water jet cutting and diamond wire saws, operates under a principle that eschews heat to minimize the impact on material properties.. Cold Cutting Steel Plate Methods.

From www.youtube.com

Cutting of medium and thick steel plate YouTube Cold Cutting Steel Plate Methods cold cutting is a versatile, precise, and safe method of cutting pipe that allows the operator to operate the cutting. with the right supporting structure built around the application, they can be used for cutting shapes into vessels or for severing iron girders and concrete structures. This technique ensures that the heat affected zone (haz) is eliminated, preserving. Cold Cutting Steel Plate Methods.

From www.youtube.com

Cutting Plate Steel YouTube Cold Cutting Steel Plate Methods Waterjet cutting can handle a wide range of materials, including metals, ceramics, glass, and composites. While thermal cutting includes flame cutting, plasma cutting and laser. This technique ensures that the heat affected zone (haz) is eliminated, preserving the original characteristics of the metal or pipe being. cold cutting can be further classified into water jet cutting and abrasive cutting;. Cold Cutting Steel Plate Methods.

From www.pasteel.com

Best (and Safest) Ways to Cut Steel Plate PA Steel Co. Cold Cutting Steel Plate Methods with the right supporting structure built around the application, they can be used for cutting shapes into vessels or for severing iron girders and concrete structures. cold cutting can be further classified into water jet cutting and abrasive cutting; This technique ensures that the heat affected zone (haz) is eliminated, preserving the original characteristics of the metal or. Cold Cutting Steel Plate Methods.

From metalscut4u.com

What Is The Best Way To Cut A Steel Plate? Cold Cutting Steel Plate Methods Discover how cold cutting enhances safety and precision in cutting operations. Waterjet cutting is a cold process, meaning it doesn't produce heat, preserving material integrity. Waterjet cutting can handle a wide range of materials, including metals, ceramics, glass, and composites. with the right supporting structure built around the application, they can be used for cutting shapes into vessels or. Cold Cutting Steel Plate Methods.

From blog.enerpac.com

Cold Cutting Machines Types and Applications Enerpac Blog Cold Cutting Steel Plate Methods Discover how cold cutting enhances safety and precision in cutting operations. cold cutting can be further classified into water jet cutting and abrasive cutting; This technique ensures that the heat affected zone (haz) is eliminated, preserving the original characteristics of the metal or pipe being. Waterjet cutting can handle a wide range of materials, including metals, ceramics, glass, and. Cold Cutting Steel Plate Methods.

From luptons.com

Lupton Associates Cold Plates Cold Cutting Steel Plate Methods While thermal cutting includes flame cutting, plasma cutting and laser. waterjet cutting is known for its versatility and precision, especially when cutting thicker steel plates. learn about the innovative technique of cold cutting, its various methods, benefits, and applications across industries. This technique ensures that the heat affected zone (haz) is eliminated, preserving the original characteristics of the. Cold Cutting Steel Plate Methods.

From www.familyhandyman.com

10 Easy Ways to Cut Metal Fast Family Handyman Cold Cutting Steel Plate Methods learn about the innovative technique of cold cutting, its various methods, benefits, and applications across industries. cold cutting is a versatile, precise, and safe method of cutting pipe that allows the operator to operate the cutting. the cold cutting method, exemplified by technologies such as water jet cutting and diamond wire saws, operates under a principle that. Cold Cutting Steel Plate Methods.

From www.alamy.com

cutting of steel plate Stock Photo Alamy Cold Cutting Steel Plate Methods cold cutting can be further classified into water jet cutting and abrasive cutting; Three commonly used types of cold cutting machines are clamshell cutters, cold cutting saws, and abrasive water jet cutters. with the right supporting structure built around the application, they can be used for cutting shapes into vessels or for severing iron girders and concrete structures.. Cold Cutting Steel Plate Methods.

From www.pasteel.com

Best (and Safest) Ways to Cut Steel Plate PA Steel Co. Cold Cutting Steel Plate Methods with the right supporting structure built around the application, they can be used for cutting shapes into vessels or for severing iron girders and concrete structures. the cold cutting method, exemplified by technologies such as water jet cutting and diamond wire saws, operates under a principle that eschews heat to minimize the impact on material properties. Waterjet cutting. Cold Cutting Steel Plate Methods.

From www.youtube.com

Cold Cutting Steel plate methods PT. ALGA TEKNIK INDONESIA (ALTEKINDO Cold Cutting Steel Plate Methods Waterjet cutting is a cold process, meaning it doesn't produce heat, preserving material integrity. This technique ensures that the heat affected zone (haz) is eliminated, preserving the original characteristics of the metal or pipe being. cold cutting can be further classified into water jet cutting and abrasive cutting; waterjet cutting is known for its versatility and precision, especially. Cold Cutting Steel Plate Methods.

From blog.thepipingmart.com

What Is Cold Cutting? Uses and Working Cold Cutting Steel Plate Methods learn about the innovative technique of cold cutting, its various methods, benefits, and applications across industries. Waterjet cutting is a cold process, meaning it doesn't produce heat, preserving material integrity. Waterjet cutting can handle a wide range of materials, including metals, ceramics, glass, and composites. waterjet cutting is known for its versatility and precision, especially when cutting thicker. Cold Cutting Steel Plate Methods.

From asl.business

Cold Cutting ASL Group Cold Cutting Steel Plate Methods Discover how cold cutting enhances safety and precision in cutting operations. the cold cutting method, exemplified by technologies such as water jet cutting and diamond wire saws, operates under a principle that eschews heat to minimize the impact on material properties. learn about the innovative technique of cold cutting, its various methods, benefits, and applications across industries. . Cold Cutting Steel Plate Methods.

From www.isotechltd.com

Cold Cutting Cold Cutting Steel Plate Methods While thermal cutting includes flame cutting, plasma cutting and laser. waterjet cutting is known for its versatility and precision, especially when cutting thicker steel plates. the cold cutting method, exemplified by technologies such as water jet cutting and diamond wire saws, operates under a principle that eschews heat to minimize the impact on material properties. This technique ensures. Cold Cutting Steel Plate Methods.

From www.hicplates.com

Steel Plates Cutting and Other Services RPF Pipes and Fittings Cold Cutting Steel Plate Methods with the right supporting structure built around the application, they can be used for cutting shapes into vessels or for severing iron girders and concrete structures. waterjet cutting is known for its versatility and precision, especially when cutting thicker steel plates. Waterjet cutting can handle a wide range of materials, including metals, ceramics, glass, and composites. While thermal. Cold Cutting Steel Plate Methods.

From www.dreamstime.com

Cutting of steel plates stock image. Image of cutting 1449843 Cold Cutting Steel Plate Methods cold cutting is a versatile, precise, and safe method of cutting pipe that allows the operator to operate the cutting. the cold cutting method, exemplified by technologies such as water jet cutting and diamond wire saws, operates under a principle that eschews heat to minimize the impact on material properties. learn about the innovative technique of cold. Cold Cutting Steel Plate Methods.

From www.slideserve.com

PPT Cold cutting C45 plate PowerPoint Presentation, free download Cold Cutting Steel Plate Methods Discover how cold cutting enhances safety and precision in cutting operations. Waterjet cutting can handle a wide range of materials, including metals, ceramics, glass, and composites. Three commonly used types of cold cutting machines are clamshell cutters, cold cutting saws, and abrasive water jet cutters. with the right supporting structure built around the application, they can be used for. Cold Cutting Steel Plate Methods.

From www.hudsonservicesinc.com

Cold Cutting Pipe Cold Cutting Steel Plate Methods Discover how cold cutting enhances safety and precision in cutting operations. with the right supporting structure built around the application, they can be used for cutting shapes into vessels or for severing iron girders and concrete structures. While thermal cutting includes flame cutting, plasma cutting and laser. learn about the innovative technique of cold cutting, its various methods,. Cold Cutting Steel Plate Methods.

From metest.ee

Steel plate cutting Metest Producing of Welded beams, NSCProfiles Cold Cutting Steel Plate Methods cold cutting can be further classified into water jet cutting and abrasive cutting; with the right supporting structure built around the application, they can be used for cutting shapes into vessels or for severing iron girders and concrete structures. learn about the innovative technique of cold cutting, its various methods, benefits, and applications across industries. Discover how. Cold Cutting Steel Plate Methods.

From asl.business

Cold Cutting ASL Group Cold Cutting Steel Plate Methods learn about the innovative technique of cold cutting, its various methods, benefits, and applications across industries. cold cutting can be further classified into water jet cutting and abrasive cutting; Waterjet cutting is a cold process, meaning it doesn't produce heat, preserving material integrity. the cold cutting method, exemplified by technologies such as water jet cutting and diamond. Cold Cutting Steel Plate Methods.

From asl.business

Cold Cutting ASL Group Cold Cutting Steel Plate Methods cold cutting can be further classified into water jet cutting and abrasive cutting; Waterjet cutting is a cold process, meaning it doesn't produce heat, preserving material integrity. Waterjet cutting can handle a wide range of materials, including metals, ceramics, glass, and composites. with the right supporting structure built around the application, they can be used for cutting shapes. Cold Cutting Steel Plate Methods.

From www.alamy.com

PORTSMOUTH, ENGLAND. SHIPBUILDING CUTTING STEEL PLATE Cold Cutting Steel Plate Methods learn about the innovative technique of cold cutting, its various methods, benefits, and applications across industries. waterjet cutting is known for its versatility and precision, especially when cutting thicker steel plates. Discover how cold cutting enhances safety and precision in cutting operations. Waterjet cutting is a cold process, meaning it doesn't produce heat, preserving material integrity. Waterjet cutting. Cold Cutting Steel Plate Methods.

From www.norfolkiron.com

Shaping Heavy Steel Plate With Plasma Steel Cutting Norfolk Iron & Metal Cold Cutting Steel Plate Methods This technique ensures that the heat affected zone (haz) is eliminated, preserving the original characteristics of the metal or pipe being. Three commonly used types of cold cutting machines are clamshell cutters, cold cutting saws, and abrasive water jet cutters. Discover how cold cutting enhances safety and precision in cutting operations. Waterjet cutting is a cold process, meaning it doesn't. Cold Cutting Steel Plate Methods.

From es.vecteezy.com

maquinas para corte de metales con chispas ligeras 1134800 Foto de Cold Cutting Steel Plate Methods While thermal cutting includes flame cutting, plasma cutting and laser. waterjet cutting is known for its versatility and precision, especially when cutting thicker steel plates. Three commonly used types of cold cutting machines are clamshell cutters, cold cutting saws, and abrasive water jet cutters. cold cutting can be further classified into water jet cutting and abrasive cutting; Waterjet. Cold Cutting Steel Plate Methods.

From www.youtube.com

High speed cold cutting steel bar process Good tools and machinery Cold Cutting Steel Plate Methods Waterjet cutting can handle a wide range of materials, including metals, ceramics, glass, and composites. waterjet cutting is known for its versatility and precision, especially when cutting thicker steel plates. This technique ensures that the heat affected zone (haz) is eliminated, preserving the original characteristics of the metal or pipe being. Three commonly used types of cold cutting machines. Cold Cutting Steel Plate Methods.

From www.youtube.com

Cutting through 5" steel plate with oxyfuel. YouTube Cold Cutting Steel Plate Methods Discover how cold cutting enhances safety and precision in cutting operations. learn about the innovative technique of cold cutting, its various methods, benefits, and applications across industries. Waterjet cutting can handle a wide range of materials, including metals, ceramics, glass, and composites. Waterjet cutting is a cold process, meaning it doesn't produce heat, preserving material integrity. This technique ensures. Cold Cutting Steel Plate Methods.

From www.alamy.com

Cutting Steel plate in the steel industry Stock Photo Alamy Cold Cutting Steel Plate Methods This technique ensures that the heat affected zone (haz) is eliminated, preserving the original characteristics of the metal or pipe being. Discover how cold cutting enhances safety and precision in cutting operations. Waterjet cutting is a cold process, meaning it doesn't produce heat, preserving material integrity. waterjet cutting is known for its versatility and precision, especially when cutting thicker. Cold Cutting Steel Plate Methods.

From www.youtube.com

Cutting circles in 1/4" plate steel with a plasma cutter YouTube Cold Cutting Steel Plate Methods cold cutting can be further classified into water jet cutting and abrasive cutting; the cold cutting method, exemplified by technologies such as water jet cutting and diamond wire saws, operates under a principle that eschews heat to minimize the impact on material properties. waterjet cutting is known for its versatility and precision, especially when cutting thicker steel. Cold Cutting Steel Plate Methods.