The Diameter Of A Countersink Only Needs To Be . What size countersink bit do i need? Then, divide the diameter by 2. The first thing you need to do is note down the diameter of the countersink. With an optical comparitor you can make a mold of the part to check the angle and diameter. Then, divide the angle by 2 and. Tapped hole shall be countersunk on the bearing face or faces. The maximum countersink diameter shall be 1.08. It’s best to use the exact diameter of the hardware head as your. This is a countersink size chart for determining what bit to use for different screw dimensions and materials. The major hole size should be the same size or slightly larger than the diameter of the hardware head you’re using. You could also use surface reflect to. Use this calculator when you know the hole diameter, countersink angle, and material thickness. Countersink hole size charts are essential tools for selecting the correct countersink bit and ensuring that the screw head fits properly. Note down the countersink angle.

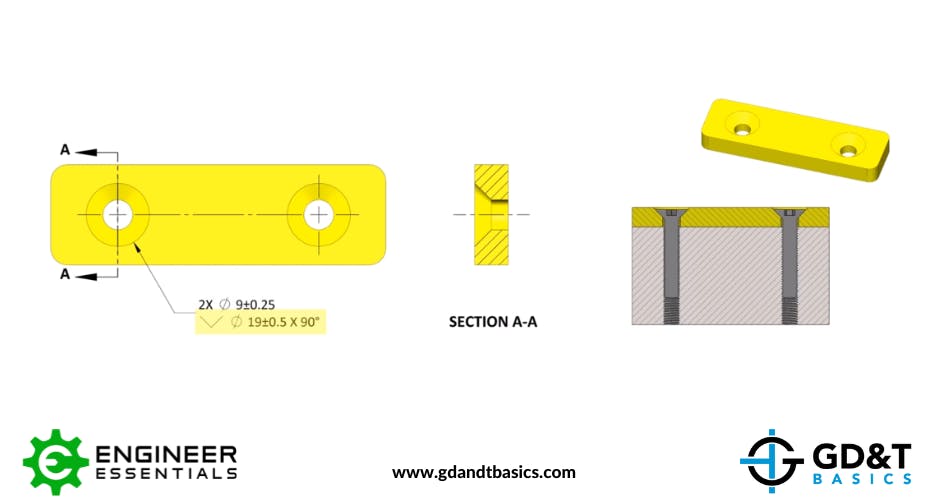

from www.gdandtbasics.com

Then, divide the diameter by 2. The first thing you need to do is note down the diameter of the countersink. What size countersink bit do i need? The major hole size should be the same size or slightly larger than the diameter of the hardware head you’re using. Use this calculator when you know the hole diameter, countersink angle, and material thickness. Countersink hole size charts are essential tools for selecting the correct countersink bit and ensuring that the screw head fits properly. With an optical comparitor you can make a mold of the part to check the angle and diameter. You could also use surface reflect to. This is a countersink size chart for determining what bit to use for different screw dimensions and materials. Note down the countersink angle.

Countersink GD&T Basics

The Diameter Of A Countersink Only Needs To Be Then, divide the diameter by 2. The major hole size should be the same size or slightly larger than the diameter of the hardware head you’re using. Then, divide the angle by 2 and. Then, divide the diameter by 2. Note down the countersink angle. Countersink hole size charts are essential tools for selecting the correct countersink bit and ensuring that the screw head fits properly. You could also use surface reflect to. The first thing you need to do is note down the diameter of the countersink. The maximum countersink diameter shall be 1.08. Tapped hole shall be countersunk on the bearing face or faces. Use this calculator when you know the hole diameter, countersink angle, and material thickness. This is a countersink size chart for determining what bit to use for different screw dimensions and materials. It’s best to use the exact diameter of the hardware head as your. What size countersink bit do i need? With an optical comparitor you can make a mold of the part to check the angle and diameter.

From www.reddit.com

How to calculate countersink angle from hole diameter and countersink The Diameter Of A Countersink Only Needs To Be Then, divide the diameter by 2. You could also use surface reflect to. It’s best to use the exact diameter of the hardware head as your. Tapped hole shall be countersunk on the bearing face or faces. Then, divide the angle by 2 and. With an optical comparitor you can make a mold of the part to check the angle. The Diameter Of A Countersink Only Needs To Be.

From www.gdandtbasics.com

Applying Position Tolerances to Countersunk Fixed Fastener Assembly The Diameter Of A Countersink Only Needs To Be This is a countersink size chart for determining what bit to use for different screw dimensions and materials. You could also use surface reflect to. Countersink hole size charts are essential tools for selecting the correct countersink bit and ensuring that the screw head fits properly. The maximum countersink diameter shall be 1.08. Use this calculator when you know the. The Diameter Of A Countersink Only Needs To Be.

From www.engineeringchoice.com

What Is Countersunk Screw & How To Countersink? The Diameter Of A Countersink Only Needs To Be Tapped hole shall be countersunk on the bearing face or faces. The major hole size should be the same size or slightly larger than the diameter of the hardware head you’re using. It’s best to use the exact diameter of the hardware head as your. With an optical comparitor you can make a mold of the part to check the. The Diameter Of A Countersink Only Needs To Be.

From www.finepowertools.com

Countersink Angles Common Angles and Their Applications The Diameter Of A Countersink Only Needs To Be Note down the countersink angle. The maximum countersink diameter shall be 1.08. What size countersink bit do i need? Use this calculator when you know the hole diameter, countersink angle, and material thickness. With an optical comparitor you can make a mold of the part to check the angle and diameter. The major hole size should be the same size. The Diameter Of A Countersink Only Needs To Be.

From mathscinotes.com

Measuring Countersink Angle Using Gage Balls Math Encounters Blog The Diameter Of A Countersink Only Needs To Be It’s best to use the exact diameter of the hardware head as your. What size countersink bit do i need? With an optical comparitor you can make a mold of the part to check the angle and diameter. Use this calculator when you know the hole diameter, countersink angle, and material thickness. The maximum countersink diameter shall be 1.08. Tapped. The Diameter Of A Countersink Only Needs To Be.

From mathscinotes.com

Measuring Countersink Diameter Using Gage Balls Math Encounters Blog The Diameter Of A Countersink Only Needs To Be You could also use surface reflect to. What size countersink bit do i need? Use this calculator when you know the hole diameter, countersink angle, and material thickness. The major hole size should be the same size or slightly larger than the diameter of the hardware head you’re using. It’s best to use the exact diameter of the hardware head. The Diameter Of A Countersink Only Needs To Be.

From www.cnccookbook.com

Countersink Depth Calculator [ Free Machinist Tool ] The Diameter Of A Countersink Only Needs To Be Countersink hole size charts are essential tools for selecting the correct countersink bit and ensuring that the screw head fits properly. You could also use surface reflect to. What size countersink bit do i need? This is a countersink size chart for determining what bit to use for different screw dimensions and materials. With an optical comparitor you can make. The Diameter Of A Countersink Only Needs To Be.

From engineersbible.com

Countersunk Hole Size for Machine Screw (ANSI Metric) The Diameter Of A Countersink Only Needs To Be This is a countersink size chart for determining what bit to use for different screw dimensions and materials. Then, divide the angle by 2 and. What size countersink bit do i need? You could also use surface reflect to. It’s best to use the exact diameter of the hardware head as your. Note down the countersink angle. With an optical. The Diameter Of A Countersink Only Needs To Be.

From charlotteanderson.z13.web.core.windows.net

Countersink Diameter For 1/420 The Diameter Of A Countersink Only Needs To Be Then, divide the angle by 2 and. Countersink hole size charts are essential tools for selecting the correct countersink bit and ensuring that the screw head fits properly. What size countersink bit do i need? Note down the countersink angle. The maximum countersink diameter shall be 1.08. It’s best to use the exact diameter of the hardware head as your.. The Diameter Of A Countersink Only Needs To Be.

From giosewiih.blob.core.windows.net

Common Countersink Sizes at Dorothy Harris blog The Diameter Of A Countersink Only Needs To Be The maximum countersink diameter shall be 1.08. Note down the countersink angle. This is a countersink size chart for determining what bit to use for different screw dimensions and materials. Countersink hole size charts are essential tools for selecting the correct countersink bit and ensuring that the screw head fits properly. The major hole size should be the same size. The Diameter Of A Countersink Only Needs To Be.

From en.wikipedia.org

Countersink Wikipedia The Diameter Of A Countersink Only Needs To Be Countersink hole size charts are essential tools for selecting the correct countersink bit and ensuring that the screw head fits properly. With an optical comparitor you can make a mold of the part to check the angle and diameter. The major hole size should be the same size or slightly larger than the diameter of the hardware head you’re using.. The Diameter Of A Countersink Only Needs To Be.

From hxeixtrjs.blob.core.windows.net

Countersink Dimensions For Metric Screws at Jennifer Hay blog The Diameter Of A Countersink Only Needs To Be The major hole size should be the same size or slightly larger than the diameter of the hardware head you’re using. What size countersink bit do i need? Use this calculator when you know the hole diameter, countersink angle, and material thickness. It’s best to use the exact diameter of the hardware head as your. The maximum countersink diameter shall. The Diameter Of A Countersink Only Needs To Be.

From mathscinotes.com

Measuring Countersink Diameter Using Gage Balls Math Encounters Blog The Diameter Of A Countersink Only Needs To Be It’s best to use the exact diameter of the hardware head as your. The first thing you need to do is note down the diameter of the countersink. With an optical comparitor you can make a mold of the part to check the angle and diameter. The maximum countersink diameter shall be 1.08. The major hole size should be the. The Diameter Of A Countersink Only Needs To Be.

From www.gdandtbasics.com

Countersink GD&T Basics The Diameter Of A Countersink Only Needs To Be This is a countersink size chart for determining what bit to use for different screw dimensions and materials. Tapped hole shall be countersunk on the bearing face or faces. It’s best to use the exact diameter of the hardware head as your. Countersink hole size charts are essential tools for selecting the correct countersink bit and ensuring that the screw. The Diameter Of A Countersink Only Needs To Be.

From www.scribd.com

Counterbore and Countersink Dimensions Chart The Diameter Of A Countersink Only Needs To Be This is a countersink size chart for determining what bit to use for different screw dimensions and materials. Then, divide the diameter by 2. Use this calculator when you know the hole diameter, countersink angle, and material thickness. Tapped hole shall be countersunk on the bearing face or faces. With an optical comparitor you can make a mold of the. The Diameter Of A Countersink Only Needs To Be.

From www.mathscinotes.com

Measuring Countersink Diameter Using Gage Balls Math Encounters Blog The Diameter Of A Countersink Only Needs To Be The maximum countersink diameter shall be 1.08. Tapped hole shall be countersunk on the bearing face or faces. What size countersink bit do i need? You could also use surface reflect to. Use this calculator when you know the hole diameter, countersink angle, and material thickness. The first thing you need to do is note down the diameter of the. The Diameter Of A Countersink Only Needs To Be.

From www.amazon.com

KEO Cutters Cobalt Steel Combined Drill & Countersink, Uncoated (Bright The Diameter Of A Countersink Only Needs To Be Then, divide the diameter by 2. The first thing you need to do is note down the diameter of the countersink. Tapped hole shall be countersunk on the bearing face or faces. What size countersink bit do i need? Use this calculator when you know the hole diameter, countersink angle, and material thickness. With an optical comparitor you can make. The Diameter Of A Countersink Only Needs To Be.

From rosewoodissues.com

What is a Countersink Bit Wood Issues, Wood tools and Guide The Diameter Of A Countersink Only Needs To Be It’s best to use the exact diameter of the hardware head as your. Tapped hole shall be countersunk on the bearing face or faces. With an optical comparitor you can make a mold of the part to check the angle and diameter. Countersink hole size charts are essential tools for selecting the correct countersink bit and ensuring that the screw. The Diameter Of A Countersink Only Needs To Be.

From www.scribd.com

Guidelines for Punching and Countersinking Holes for Various Screw The Diameter Of A Countersink Only Needs To Be Note down the countersink angle. Use this calculator when you know the hole diameter, countersink angle, and material thickness. You could also use surface reflect to. With an optical comparitor you can make a mold of the part to check the angle and diameter. Then, divide the diameter by 2. It’s best to use the exact diameter of the hardware. The Diameter Of A Countersink Only Needs To Be.

From www.parejatour.com

How to choose the right size countersink bit The Diameter Of A Countersink Only Needs To Be With an optical comparitor you can make a mold of the part to check the angle and diameter. Countersink hole size charts are essential tools for selecting the correct countersink bit and ensuring that the screw head fits properly. Then, divide the diameter by 2. The first thing you need to do is note down the diameter of the countersink.. The Diameter Of A Countersink Only Needs To Be.

From www.amazon.com

KEO 53512 Cobalt Steel SingleEnd Countersink, Uncoated (Bright) Finish The Diameter Of A Countersink Only Needs To Be Tapped hole shall be countersunk on the bearing face or faces. This is a countersink size chart for determining what bit to use for different screw dimensions and materials. What size countersink bit do i need? The maximum countersink diameter shall be 1.08. Then, divide the diameter by 2. The first thing you need to do is note down the. The Diameter Of A Countersink Only Needs To Be.

From calculator.services

Countersink Depth Calculator How to Use Calculator Services The Diameter Of A Countersink Only Needs To Be What size countersink bit do i need? It’s best to use the exact diameter of the hardware head as your. Tapped hole shall be countersunk on the bearing face or faces. With an optical comparitor you can make a mold of the part to check the angle and diameter. Then, divide the angle by 2 and. Countersink hole size charts. The Diameter Of A Countersink Only Needs To Be.

From www.pcbbuy.com

When to use countersink VS counterbore? The Diameter Of A Countersink Only Needs To Be Then, divide the diameter by 2. Use this calculator when you know the hole diameter, countersink angle, and material thickness. What size countersink bit do i need? With an optical comparitor you can make a mold of the part to check the angle and diameter. You could also use surface reflect to. It’s best to use the exact diameter of. The Diameter Of A Countersink Only Needs To Be.

From handyhabits.com

How To Use a Countersink Drill Bit for Metal HandyHabits The Diameter Of A Countersink Only Needs To Be It’s best to use the exact diameter of the hardware head as your. You could also use surface reflect to. The major hole size should be the same size or slightly larger than the diameter of the hardware head you’re using. With an optical comparitor you can make a mold of the part to check the angle and diameter. The. The Diameter Of A Countersink Only Needs To Be.

From sendcutsend.com

The Benefits of Countersinking SendCutSend The Diameter Of A Countersink Only Needs To Be What size countersink bit do i need? It’s best to use the exact diameter of the hardware head as your. You could also use surface reflect to. The first thing you need to do is note down the diameter of the countersink. Then, divide the angle by 2 and. Then, divide the diameter by 2. With an optical comparitor you. The Diameter Of A Countersink Only Needs To Be.

From dansdiscounttools.com

MA FORD Carbide Countersink 1″ 90° 6FL 78186 Dan's Discount Tools The Diameter Of A Countersink Only Needs To Be The major hole size should be the same size or slightly larger than the diameter of the hardware head you’re using. With an optical comparitor you can make a mold of the part to check the angle and diameter. This is a countersink size chart for determining what bit to use for different screw dimensions and materials. The maximum countersink. The Diameter Of A Countersink Only Needs To Be.

From www.northbaycuttingtools.com

2" 82 DEGREE HIGH SPEED STEEL 3 FLUTE COUNTERSINK 1/2" SHANK North The Diameter Of A Countersink Only Needs To Be What size countersink bit do i need? The maximum countersink diameter shall be 1.08. With an optical comparitor you can make a mold of the part to check the angle and diameter. The major hole size should be the same size or slightly larger than the diameter of the hardware head you’re using. This is a countersink size chart for. The Diameter Of A Countersink Only Needs To Be.

From hxeixtrjs.blob.core.windows.net

Countersink Dimensions For Metric Screws at Jennifer Hay blog The Diameter Of A Countersink Only Needs To Be Note down the countersink angle. It’s best to use the exact diameter of the hardware head as your. Tapped hole shall be countersunk on the bearing face or faces. Then, divide the angle by 2 and. Then, divide the diameter by 2. Use this calculator when you know the hole diameter, countersink angle, and material thickness. Countersink hole size charts. The Diameter Of A Countersink Only Needs To Be.

From www.novacam.com

3D countersink measurement noncontact and automated Novacam The Diameter Of A Countersink Only Needs To Be This is a countersink size chart for determining what bit to use for different screw dimensions and materials. Then, divide the angle by 2 and. Use this calculator when you know the hole diameter, countersink angle, and material thickness. Countersink hole size charts are essential tools for selecting the correct countersink bit and ensuring that the screw head fits properly.. The Diameter Of A Countersink Only Needs To Be.

From engineersbible.com

Countersunk Hole Size for Machine Screw (ANSI Metric) The Diameter Of A Countersink Only Needs To Be What size countersink bit do i need? You could also use surface reflect to. Use this calculator when you know the hole diameter, countersink angle, and material thickness. It’s best to use the exact diameter of the hardware head as your. Note down the countersink angle. Then, divide the angle by 2 and. The first thing you need to do. The Diameter Of A Countersink Only Needs To Be.

From forums.autodesk.com

Countersink Diameter for Flat Head Screws too Small Autodesk Community The Diameter Of A Countersink Only Needs To Be Then, divide the diameter by 2. Use this calculator when you know the hole diameter, countersink angle, and material thickness. Then, divide the angle by 2 and. The first thing you need to do is note down the diameter of the countersink. You could also use surface reflect to. Tapped hole shall be countersunk on the bearing face or faces.. The Diameter Of A Countersink Only Needs To Be.

From www.beaconcorporation.co.uk

DIN 7991 Dimensions Beacon Corporation The Diameter Of A Countersink Only Needs To Be Use this calculator when you know the hole diameter, countersink angle, and material thickness. What size countersink bit do i need? Note down the countersink angle. The maximum countersink diameter shall be 1.08. The major hole size should be the same size or slightly larger than the diameter of the hardware head you’re using. Countersink hole size charts are essential. The Diameter Of A Countersink Only Needs To Be.

From www.damencnc.com

Countersink 90° d1=10,4mm d2=6mm DamenCNC B.V. The Diameter Of A Countersink Only Needs To Be Then, divide the angle by 2 and. The first thing you need to do is note down the diameter of the countersink. You could also use surface reflect to. Countersink hole size charts are essential tools for selecting the correct countersink bit and ensuring that the screw head fits properly. The maximum countersink diameter shall be 1.08. Note down the. The Diameter Of A Countersink Only Needs To Be.

From www.amazon.com

3 Piece 120 Degree Countersink Bit Set with Drill Guide, Size 21, 30 The Diameter Of A Countersink Only Needs To Be What size countersink bit do i need? This is a countersink size chart for determining what bit to use for different screw dimensions and materials. Tapped hole shall be countersunk on the bearing face or faces. Use this calculator when you know the hole diameter, countersink angle, and material thickness. The maximum countersink diameter shall be 1.08. The first thing. The Diameter Of A Countersink Only Needs To Be.

From www.cnclathing.com

Countersink Size Chart (Hole & Drill Bit) What Is a Countersink Drill The Diameter Of A Countersink Only Needs To Be You could also use surface reflect to. What size countersink bit do i need? This is a countersink size chart for determining what bit to use for different screw dimensions and materials. It’s best to use the exact diameter of the hardware head as your. Tapped hole shall be countersunk on the bearing face or faces. The major hole size. The Diameter Of A Countersink Only Needs To Be.