How To Make Molding Wax . Molten metal is poured into this cavity. Whether your original model is made from clay, wax, plaster, sand, concrete, stone,. Key steps in lost wax casting: This is the cheapest and easiest method of preparing a mold for lost wax casting. Encase the wax model in a ceramic material. Alginate is a great mold making. A good wax is essential to making a quality casting. The goal of a mold made for wax casting is to get at least 1 to 2 good castings, so it doesn’t need to last long. Whether you want to make one or one thousand reproductions of an original, you can do it using a mold. The basic lost wax casting process involves creating a pattern and a mold, then pouring molten metal into the mold. In this video, we introduce you to the mold making process and the variety of. How to make a mold for lost wax casting: The wax melts and is “lost”, leaving behind an empty cavity. This process is customizable for different types of metal casting, along with shapes, sizes, and more. All you need is your wax sculptures with sprues, plaster of paris, water.

from www.youtube.com

The basic lost wax casting process involves creating a pattern and a mold, then pouring molten metal into the mold. Key steps in lost wax casting: In this video, we introduce you to the mold making process and the variety of. Whether you want to make one or one thousand reproductions of an original, you can do it using a mold. You will then extract the solid metal casting and finish your piece. Encase the wax model in a ceramic material. The wax melts and is “lost”, leaving behind an empty cavity. How to make a mold for lost wax casting: This process is customizable for different types of metal casting, along with shapes, sizes, and more. A good wax is essential to making a quality casting.

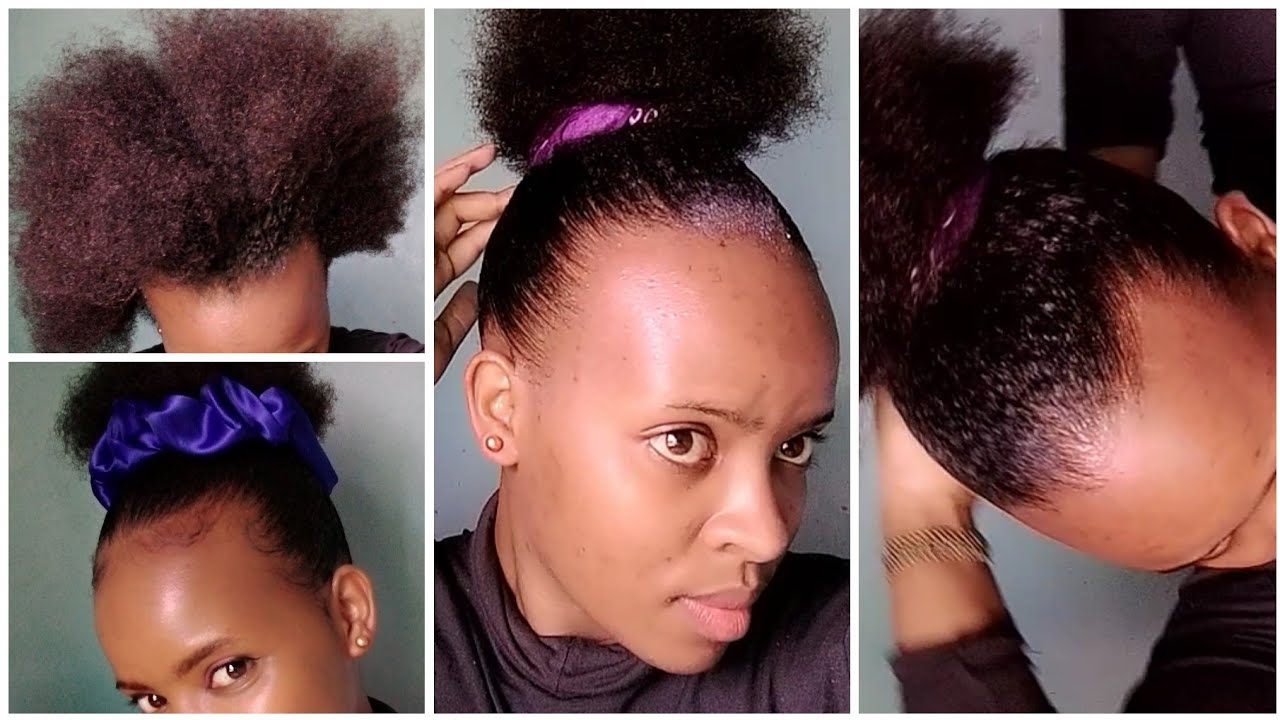

Sleek Bun How to apply gel on natural hair using molding gel wax YouTube

How To Make Molding Wax The goal of a mold made for wax casting is to get at least 1 to 2 good castings, so it doesn’t need to last long. Molten metal is poured into this cavity. How to make a mold for lost wax casting: Alginate is a great mold making. Whether your original model is made from clay, wax, plaster, sand, concrete, stone,. Key steps in lost wax casting: You will then extract the solid metal casting and finish your piece. This is the cheapest and easiest method of preparing a mold for lost wax casting. The wax melts and is “lost”, leaving behind an empty cavity. This process is customizable for different types of metal casting, along with shapes, sizes, and more. The basic lost wax casting process involves creating a pattern and a mold, then pouring molten metal into the mold. Whether you want to make one or one thousand reproductions of an original, you can do it using a mold. The goal of a mold made for wax casting is to get at least 1 to 2 good castings, so it doesn’t need to last long. All you need is your wax sculptures with sprues, plaster of paris, water. Encase the wax model in a ceramic material. Craft a detailed model of the desired item.

From www.stone-industrial.com

Investment Casting (Lost Wax Casting) Stone Industrial How To Make Molding Wax Key steps in lost wax casting: The wax melts and is “lost”, leaving behind an empty cavity. Molten metal is poured into this cavity. A good wax is essential to making a quality casting. Whether you want to make one or one thousand reproductions of an original, you can do it using a mold. All you need is your wax. How To Make Molding Wax.

From simplyalignedhome.com

Mastering Trim Work 101 A Beginner's Ultimate Guide Simply Aligned Home How To Make Molding Wax How to make a mold for lost wax casting: Molten metal is poured into this cavity. Whether your original model is made from clay, wax, plaster, sand, concrete, stone,. You will then extract the solid metal casting and finish your piece. The goal of a mold made for wax casting is to get at least 1 to 2 good castings,. How To Make Molding Wax.

From www.youtube.com

Tips for Using Wax on Chalk Paint YouTube How To Make Molding Wax You will then extract the solid metal casting and finish your piece. A good wax is essential to making a quality casting. In this video, we introduce you to the mold making process and the variety of. Craft a detailed model of the desired item. Encase the wax model in a ceramic material. Molten metal is poured into this cavity.. How To Make Molding Wax.

From fabacademy.org

10. Molding and casting Remy Ducros How To Make Molding Wax A good wax is essential to making a quality casting. Molten metal is poured into this cavity. Whether your original model is made from clay, wax, plaster, sand, concrete, stone,. How to make a mold for lost wax casting: This process is customizable for different types of metal casting, along with shapes, sizes, and more. Encase the wax model in. How To Make Molding Wax.

From www.pinterest.com

Free jewellers guide to wax carving & casting Wax carving jewelry How To Make Molding Wax Encase the wax model in a ceramic material. A good wax is essential to making a quality casting. Craft a detailed model of the desired item. Whether you want to make one or one thousand reproductions of an original, you can do it using a mold. In this video, we introduce you to the mold making process and the variety. How To Make Molding Wax.

From www.youtube.com

Sleek Bun How to apply gel on natural hair using molding gel wax YouTube How To Make Molding Wax Key steps in lost wax casting: The basic lost wax casting process involves creating a pattern and a mold, then pouring molten metal into the mold. How to make a mold for lost wax casting: Alginate is a great mold making. Molten metal is poured into this cavity. This process is customizable for different types of metal casting, along with. How To Make Molding Wax.

From www.youtube.com

Styling How to dengan Molding Wax Global Milbon YouTube How To Make Molding Wax In this video, we introduce you to the mold making process and the variety of. Alginate is a great mold making. This is the cheapest and easiest method of preparing a mold for lost wax casting. A good wax is essential to making a quality casting. You will then extract the solid metal casting and finish your piece. Craft a. How To Make Molding Wax.

From www.youtube.com

Making Dentures, Wax Trying YouTube How To Make Molding Wax The basic lost wax casting process involves creating a pattern and a mold, then pouring molten metal into the mold. This is the cheapest and easiest method of preparing a mold for lost wax casting. This process is customizable for different types of metal casting, along with shapes, sizes, and more. Encase the wax model in a ceramic material. How. How To Make Molding Wax.

From www.youtube.com

Wax jewelry making wax molds for casting jewelry wax molding YouTube How To Make Molding Wax Encase the wax model in a ceramic material. You will then extract the solid metal casting and finish your piece. This is the cheapest and easiest method of preparing a mold for lost wax casting. Key steps in lost wax casting: This process is customizable for different types of metal casting, along with shapes, sizes, and more. The goal of. How To Make Molding Wax.

From www.artnews.com

Best Casting Wax for Models and Molds How To Make Molding Wax How to make a mold for lost wax casting: Whether you want to make one or one thousand reproductions of an original, you can do it using a mold. The goal of a mold made for wax casting is to get at least 1 to 2 good castings, so it doesn’t need to last long. Alginate is a great mold. How To Make Molding Wax.

From www.instructables.com

Reusable Wax Mold Instructables How To Make Molding Wax How to make a mold for lost wax casting: Molten metal is poured into this cavity. The goal of a mold made for wax casting is to get at least 1 to 2 good castings, so it doesn’t need to last long. The wax melts and is “lost”, leaving behind an empty cavity. Whether your original model is made from. How To Make Molding Wax.

From makeupstore.com

Insight Styling Elastic Molding Wax Hair Wax MAKEUP How To Make Molding Wax Whether your original model is made from clay, wax, plaster, sand, concrete, stone,. Craft a detailed model of the desired item. The wax melts and is “lost”, leaving behind an empty cavity. This process is customizable for different types of metal casting, along with shapes, sizes, and more. Alginate is a great mold making. How to make a mold for. How To Make Molding Wax.

From klazxgzph.blob.core.windows.net

Moulding Hair Wax at Ethel Shepherd blog How To Make Molding Wax This is the cheapest and easiest method of preparing a mold for lost wax casting. Whether your original model is made from clay, wax, plaster, sand, concrete, stone,. Craft a detailed model of the desired item. How to make a mold for lost wax casting: You will then extract the solid metal casting and finish your piece. Molten metal is. How To Make Molding Wax.

From www.iqsdirectory.com

Lost Wax Casting What Is It? How Does It Work? Parts, Metal How To Make Molding Wax How to make a mold for lost wax casting: Craft a detailed model of the desired item. Whether your original model is made from clay, wax, plaster, sand, concrete, stone,. Encase the wax model in a ceramic material. Alginate is a great mold making. The basic lost wax casting process involves creating a pattern and a mold, then pouring molten. How To Make Molding Wax.

From www.dsource.in

D'source Design Gallery on Wax Molding Wax Molding Process by the How To Make Molding Wax Whether your original model is made from clay, wax, plaster, sand, concrete, stone,. All you need is your wax sculptures with sprues, plaster of paris, water. This process is customizable for different types of metal casting, along with shapes, sizes, and more. Whether you want to make one or one thousand reproductions of an original, you can do it using. How To Make Molding Wax.

From www.jewellersacademy.com

a Jewellers guide to wax carving and casting — Jewellers Academy How To Make Molding Wax Whether your original model is made from clay, wax, plaster, sand, concrete, stone,. Craft a detailed model of the desired item. Key steps in lost wax casting: This process is customizable for different types of metal casting, along with shapes, sizes, and more. All you need is your wax sculptures with sprues, plaster of paris, water. You will then extract. How To Make Molding Wax.

From fabacademy.org

Molding and Casting How To Make Molding Wax Alginate is a great mold making. All you need is your wax sculptures with sprues, plaster of paris, water. This process is customizable for different types of metal casting, along with shapes, sizes, and more. Molten metal is poured into this cavity. This is the cheapest and easiest method of preparing a mold for lost wax casting. Key steps in. How To Make Molding Wax.

From www.youtube.com

STUNNING CRAFT USING A WAX PAPER!! YouTube How To Make Molding Wax This process is customizable for different types of metal casting, along with shapes, sizes, and more. Molten metal is poured into this cavity. All you need is your wax sculptures with sprues, plaster of paris, water. The basic lost wax casting process involves creating a pattern and a mold, then pouring molten metal into the mold. How to make a. How To Make Molding Wax.

From www.katadair.com

casting jewelry...making wax models (part two) — kat adair How To Make Molding Wax Key steps in lost wax casting: Craft a detailed model of the desired item. Alginate is a great mold making. The goal of a mold made for wax casting is to get at least 1 to 2 good castings, so it doesn’t need to last long. Encase the wax model in a ceramic material. This is the cheapest and easiest. How To Make Molding Wax.

From www.barnes.com.au

Moulding Wax Hard How To Make Molding Wax The wax melts and is “lost”, leaving behind an empty cavity. All you need is your wax sculptures with sprues, plaster of paris, water. Craft a detailed model of the desired item. Whether your original model is made from clay, wax, plaster, sand, concrete, stone,. This is the cheapest and easiest method of preparing a mold for lost wax casting.. How To Make Molding Wax.

From www.40dayshapeup.com

HOW I WAX AT HOME How to Use Hard Wax StepbyStep Tutorial Katie How To Make Molding Wax The goal of a mold made for wax casting is to get at least 1 to 2 good castings, so it doesn’t need to last long. A good wax is essential to making a quality casting. Encase the wax model in a ceramic material. You will then extract the solid metal casting and finish your piece. Key steps in lost. How To Make Molding Wax.

From www.dsource.in

D'source Design Gallery on Wax Molding Wax Molding Process by the How To Make Molding Wax The wax melts and is “lost”, leaving behind an empty cavity. The basic lost wax casting process involves creating a pattern and a mold, then pouring molten metal into the mold. Whether you want to make one or one thousand reproductions of an original, you can do it using a mold. Craft a detailed model of the desired item. A. How To Make Molding Wax.

From www.beautykinguk.co.uk

Beautykinguk Schwarzkopf 3D Molding Wax How To Make Molding Wax A good wax is essential to making a quality casting. Molten metal is poured into this cavity. Whether your original model is made from clay, wax, plaster, sand, concrete, stone,. How to make a mold for lost wax casting: All you need is your wax sculptures with sprues, plaster of paris, water. The goal of a mold made for wax. How To Make Molding Wax.

From www.pinterest.de

Lifecasting is making a mold of a living body. Learn how to make a wax How To Make Molding Wax The basic lost wax casting process involves creating a pattern and a mold, then pouring molten metal into the mold. All you need is your wax sculptures with sprues, plaster of paris, water. Encase the wax model in a ceramic material. Whether you want to make one or one thousand reproductions of an original, you can do it using a. How To Make Molding Wax.

From makeup.uk

Mehron SynWax FX Molding Wax Molding Wax Makeup.uk How To Make Molding Wax In this video, we introduce you to the mold making process and the variety of. This process is customizable for different types of metal casting, along with shapes, sizes, and more. Encase the wax model in a ceramic material. Alginate is a great mold making. All you need is your wax sculptures with sprues, plaster of paris, water. The basic. How To Make Molding Wax.

From www.candlescience.com

How to Make Soy Wax Melts CandleScience How To Make Molding Wax This is the cheapest and easiest method of preparing a mold for lost wax casting. The basic lost wax casting process involves creating a pattern and a mold, then pouring molten metal into the mold. Whether you want to make one or one thousand reproductions of an original, you can do it using a mold. Alginate is a great mold. How To Make Molding Wax.

From www.beautykinguk.co.uk

Beautykinguk Schwarzkopf 3D Molding Wax How To Make Molding Wax A good wax is essential to making a quality casting. Whether you want to make one or one thousand reproductions of an original, you can do it using a mold. You will then extract the solid metal casting and finish your piece. Molten metal is poured into this cavity. Alginate is a great mold making. The wax melts and is. How To Make Molding Wax.

From www.youtube.com

MELTING AND MOULDING WAX YouTube How To Make Molding Wax The wax melts and is “lost”, leaving behind an empty cavity. Encase the wax model in a ceramic material. A good wax is essential to making a quality casting. You will then extract the solid metal casting and finish your piece. The goal of a mold made for wax casting is to get at least 1 to 2 good castings,. How To Make Molding Wax.

From youtube.com

How to build a fiberglass boat. Mold Prep. Part 4 waxing. YouTube How To Make Molding Wax How to make a mold for lost wax casting: The goal of a mold made for wax casting is to get at least 1 to 2 good castings, so it doesn’t need to last long. Craft a detailed model of the desired item. Key steps in lost wax casting: Alginate is a great mold making. The basic lost wax casting. How To Make Molding Wax.

From www.pinterest.com

Creating Custom Molds Using Encaustic Wax and ImPRESSive Reusable How To Make Molding Wax Molten metal is poured into this cavity. The goal of a mold made for wax casting is to get at least 1 to 2 good castings, so it doesn’t need to last long. Alginate is a great mold making. Whether your original model is made from clay, wax, plaster, sand, concrete, stone,. Encase the wax model in a ceramic material.. How To Make Molding Wax.

From www.designunboxed.com

Sierra Papa WAX MOULDING How To Make Molding Wax Key steps in lost wax casting: Alginate is a great mold making. Whether your original model is made from clay, wax, plaster, sand, concrete, stone,. Encase the wax model in a ceramic material. This process is customizable for different types of metal casting, along with shapes, sizes, and more. You will then extract the solid metal casting and finish your. How To Make Molding Wax.

From www.youtube.com

2a) Border Molding of Utility Wax for Mandibular Stock Tray YouTube How To Make Molding Wax This is the cheapest and easiest method of preparing a mold for lost wax casting. Molten metal is poured into this cavity. In this video, we introduce you to the mold making process and the variety of. This process is customizable for different types of metal casting, along with shapes, sizes, and more. All you need is your wax sculptures. How To Make Molding Wax.

From www.youtube.com

How to apply moulding gel wax on natural hair. Sleek Low puff on How To Make Molding Wax The wax melts and is “lost”, leaving behind an empty cavity. How to make a mold for lost wax casting: Alginate is a great mold making. The goal of a mold made for wax casting is to get at least 1 to 2 good castings, so it doesn’t need to last long. This process is customizable for different types of. How To Make Molding Wax.

From www.youtube.com

How to Make a Simple DIY Crown Molding YouTube How To Make Molding Wax All you need is your wax sculptures with sprues, plaster of paris, water. Craft a detailed model of the desired item. In this video, we introduce you to the mold making process and the variety of. Molten metal is poured into this cavity. Alginate is a great mold making. How to make a mold for lost wax casting: The goal. How To Make Molding Wax.

From www.plowright.com.au

Demoulding wax head of Richie Benaud Terrance Plowright OAM How To Make Molding Wax A good wax is essential to making a quality casting. How to make a mold for lost wax casting: Key steps in lost wax casting: This is the cheapest and easiest method of preparing a mold for lost wax casting. In this video, we introduce you to the mold making process and the variety of. Alginate is a great mold. How To Make Molding Wax.