Zinc Plated Temperature . The benefits of zinc plating. The melting point of elemental zinc is approximately 780° f (415° c). Temperature — the temperature of the plating bath will also have a direct impact on the zinc plating outcome. Regular maintenance and protective coatings are essential. The correct temperature is crucial for the efficiency of the plating process and the quality of the final coating. Several factors affect the results of zinc plating, such as current density, zinc concentration on the plating bath, temperature, electrode positions, and more. Zinc plating acts as a barrier, but prolonged exposure to moisture can compromise its effectiveness.

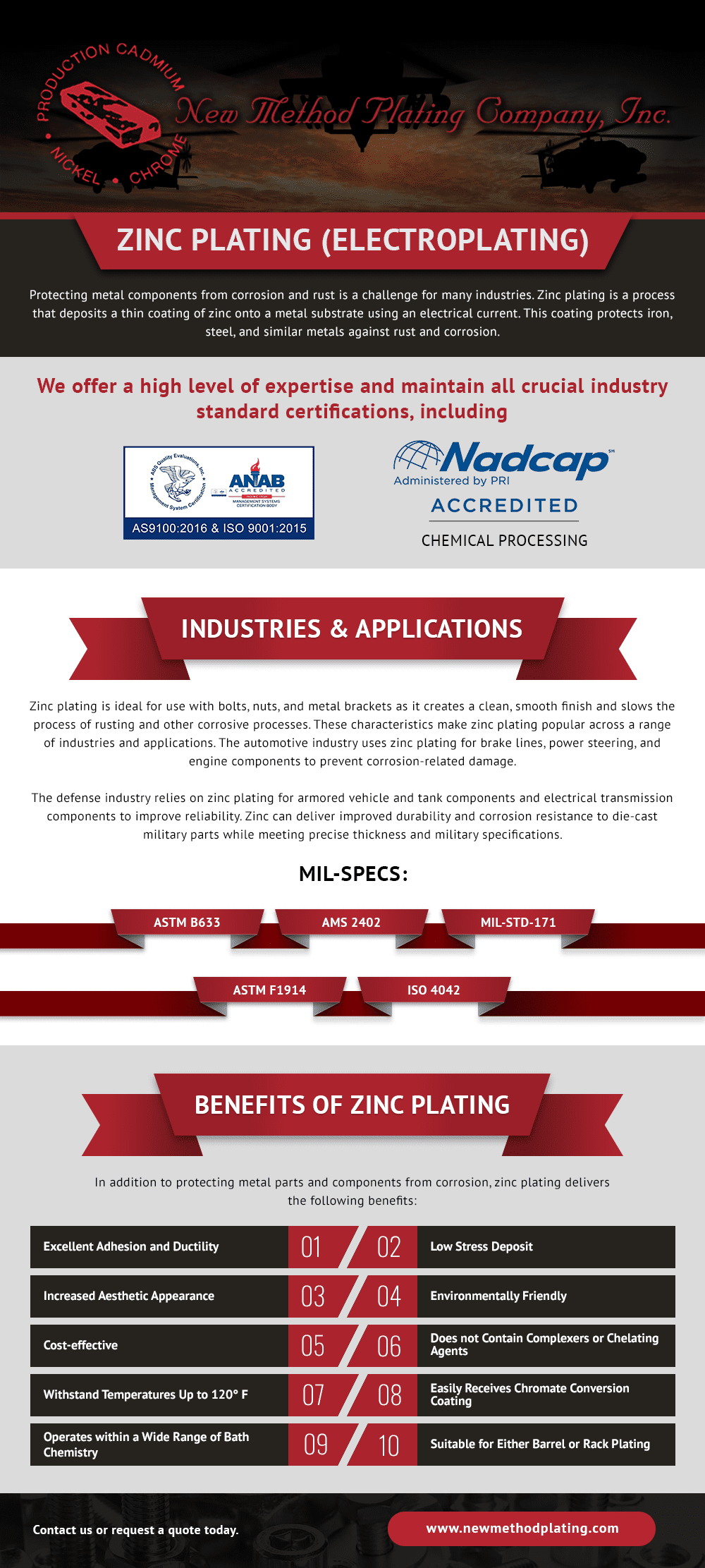

from www.newmethodplating.com

Regular maintenance and protective coatings are essential. The melting point of elemental zinc is approximately 780° f (415° c). Temperature — the temperature of the plating bath will also have a direct impact on the zinc plating outcome. Zinc plating acts as a barrier, but prolonged exposure to moisture can compromise its effectiveness. Several factors affect the results of zinc plating, such as current density, zinc concentration on the plating bath, temperature, electrode positions, and more. The benefits of zinc plating. The correct temperature is crucial for the efficiency of the plating process and the quality of the final coating.

Zinc Plating Services New Method Plating Company, Inc.

Zinc Plated Temperature Zinc plating acts as a barrier, but prolonged exposure to moisture can compromise its effectiveness. Several factors affect the results of zinc plating, such as current density, zinc concentration on the plating bath, temperature, electrode positions, and more. The correct temperature is crucial for the efficiency of the plating process and the quality of the final coating. Regular maintenance and protective coatings are essential. Zinc plating acts as a barrier, but prolonged exposure to moisture can compromise its effectiveness. The benefits of zinc plating. Temperature — the temperature of the plating bath will also have a direct impact on the zinc plating outcome. The melting point of elemental zinc is approximately 780° f (415° c).

From twbfinishing.co.uk

Zinc Plating TWB Finishing Zinc Plated Temperature Temperature — the temperature of the plating bath will also have a direct impact on the zinc plating outcome. The benefits of zinc plating. Regular maintenance and protective coatings are essential. Zinc plating acts as a barrier, but prolonged exposure to moisture can compromise its effectiveness. The correct temperature is crucial for the efficiency of the plating process and the. Zinc Plated Temperature.

From sjzafricachina.en.made-in-china.com

High Standard Zinc Plated Steel Silo with PreCleaner /Temperature Measurement China Silo and Zinc Plated Temperature Several factors affect the results of zinc plating, such as current density, zinc concentration on the plating bath, temperature, electrode positions, and more. Zinc plating acts as a barrier, but prolonged exposure to moisture can compromise its effectiveness. The benefits of zinc plating. The correct temperature is crucial for the efficiency of the plating process and the quality of the. Zinc Plated Temperature.

From www.slideserve.com

PPT Decoding the Diversity of Zinc Plating Types of Zinc Plating Zinc Plated Temperature The melting point of elemental zinc is approximately 780° f (415° c). Temperature — the temperature of the plating bath will also have a direct impact on the zinc plating outcome. Zinc plating acts as a barrier, but prolonged exposure to moisture can compromise its effectiveness. Regular maintenance and protective coatings are essential. The benefits of zinc plating. Several factors. Zinc Plated Temperature.

From www.researchgate.net

Temperature variation of the zinc liquid. Download Scientific Diagram Zinc Plated Temperature Several factors affect the results of zinc plating, such as current density, zinc concentration on the plating bath, temperature, electrode positions, and more. The melting point of elemental zinc is approximately 780° f (415° c). The benefits of zinc plating. Temperature — the temperature of the plating bath will also have a direct impact on the zinc plating outcome. Zinc. Zinc Plated Temperature.

From osencmagnet.com

Zinc Plating for Neodymium A Quick Introduction Zinc Plated Temperature Regular maintenance and protective coatings are essential. The melting point of elemental zinc is approximately 780° f (415° c). The benefits of zinc plating. Temperature — the temperature of the plating bath will also have a direct impact on the zinc plating outcome. The correct temperature is crucial for the efficiency of the plating process and the quality of the. Zinc Plated Temperature.

From www.guysmagnets.com

15 mm x 5 mm N35H, high temperature, Zinc plated neodymium disk Zinc Plated Temperature The benefits of zinc plating. The melting point of elemental zinc is approximately 780° f (415° c). Zinc plating acts as a barrier, but prolonged exposure to moisture can compromise its effectiveness. Several factors affect the results of zinc plating, such as current density, zinc concentration on the plating bath, temperature, electrode positions, and more. Regular maintenance and protective coatings. Zinc Plated Temperature.

From mechanicalfinishersinc.blogspot.com

The Different Steps Involved In The Zinc Plating Process Zinc Plated Temperature Regular maintenance and protective coatings are essential. The benefits of zinc plating. Temperature — the temperature of the plating bath will also have a direct impact on the zinc plating outcome. The melting point of elemental zinc is approximately 780° f (415° c). Several factors affect the results of zinc plating, such as current density, zinc concentration on the plating. Zinc Plated Temperature.

From blog.thepipingmart.com

Zinc Nickel Plating vs Cadmium Plating What's the Difference Zinc Plated Temperature Several factors affect the results of zinc plating, such as current density, zinc concentration on the plating bath, temperature, electrode positions, and more. Zinc plating acts as a barrier, but prolonged exposure to moisture can compromise its effectiveness. Temperature — the temperature of the plating bath will also have a direct impact on the zinc plating outcome. The correct temperature. Zinc Plated Temperature.

From www.newmethodplating.com

Zinc Plating Services New Method Plating Company, Inc. Zinc Plated Temperature The correct temperature is crucial for the efficiency of the plating process and the quality of the final coating. Several factors affect the results of zinc plating, such as current density, zinc concentration on the plating bath, temperature, electrode positions, and more. Zinc plating acts as a barrier, but prolonged exposure to moisture can compromise its effectiveness. The melting point. Zinc Plated Temperature.

From www.youtube.com

Tank zincplating tutorial how to zincplate mechanical components Tifoo zincplating Zinc Plated Temperature The correct temperature is crucial for the efficiency of the plating process and the quality of the final coating. Temperature — the temperature of the plating bath will also have a direct impact on the zinc plating outcome. Zinc plating acts as a barrier, but prolonged exposure to moisture can compromise its effectiveness. Regular maintenance and protective coatings are essential.. Zinc Plated Temperature.

From www.mdpi.com

Batteries Free FullText RoomTemperature LiquidMetal Coated Zn Electrode for Long Life Zinc Plated Temperature The melting point of elemental zinc is approximately 780° f (415° c). The correct temperature is crucial for the efficiency of the plating process and the quality of the final coating. The benefits of zinc plating. Regular maintenance and protective coatings are essential. Temperature — the temperature of the plating bath will also have a direct impact on the zinc. Zinc Plated Temperature.

From www.slideserve.com

PPT Decoding the Diversity of Zinc Plating Types of Zinc Plating Zinc Plated Temperature Several factors affect the results of zinc plating, such as current density, zinc concentration on the plating bath, temperature, electrode positions, and more. The melting point of elemental zinc is approximately 780° f (415° c). The benefits of zinc plating. Regular maintenance and protective coatings are essential. Zinc plating acts as a barrier, but prolonged exposure to moisture can compromise. Zinc Plated Temperature.

From www.sarcoatings.com

Understand the Electroplating with Zinc Plating Barrels Zinc Plated Temperature The benefits of zinc plating. The melting point of elemental zinc is approximately 780° f (415° c). Temperature — the temperature of the plating bath will also have a direct impact on the zinc plating outcome. Regular maintenance and protective coatings are essential. The correct temperature is crucial for the efficiency of the plating process and the quality of the. Zinc Plated Temperature.

From atelier-yuwa.ciao.jp

Zinc Plating Corrosion Test Did It Survive Months Of Wet Weather? atelieryuwa.ciao.jp Zinc Plated Temperature The melting point of elemental zinc is approximately 780° f (415° c). Zinc plating acts as a barrier, but prolonged exposure to moisture can compromise its effectiveness. The correct temperature is crucial for the efficiency of the plating process and the quality of the final coating. Regular maintenance and protective coatings are essential. Temperature — the temperature of the plating. Zinc Plated Temperature.

From www.azz.com

HotDip Galvanizing and Zinc Plating What’s the Difference? AZZ Zinc Plated Temperature Temperature — the temperature of the plating bath will also have a direct impact on the zinc plating outcome. Several factors affect the results of zinc plating, such as current density, zinc concentration on the plating bath, temperature, electrode positions, and more. Zinc plating acts as a barrier, but prolonged exposure to moisture can compromise its effectiveness. The melting point. Zinc Plated Temperature.

From www.researchgate.net

Effect of temperature on the recovery of zinc from zinc concentrate.... Download Scientific Zinc Plated Temperature The correct temperature is crucial for the efficiency of the plating process and the quality of the final coating. The melting point of elemental zinc is approximately 780° f (415° c). Zinc plating acts as a barrier, but prolonged exposure to moisture can compromise its effectiveness. Several factors affect the results of zinc plating, such as current density, zinc concentration. Zinc Plated Temperature.

From atelier-yuwa.ciao.jp

Zinc Plating Corrosion Test Did It Survive Months Of Wet Weather? atelieryuwa.ciao.jp Zinc Plated Temperature Several factors affect the results of zinc plating, such as current density, zinc concentration on the plating bath, temperature, electrode positions, and more. The correct temperature is crucial for the efficiency of the plating process and the quality of the final coating. The melting point of elemental zinc is approximately 780° f (415° c). The benefits of zinc plating. Temperature. Zinc Plated Temperature.

From audreygong1718.en.made-in-china.com

Zinc Plated Steel Temperature of The Surface Via Bimetallic Base Easy Move Thermometer China Zinc Plated Temperature Regular maintenance and protective coatings are essential. The melting point of elemental zinc is approximately 780° f (415° c). Temperature — the temperature of the plating bath will also have a direct impact on the zinc plating outcome. Zinc plating acts as a barrier, but prolonged exposure to moisture can compromise its effectiveness. The correct temperature is crucial for the. Zinc Plated Temperature.

From blog.thepipingmart.com

Zinc Plating vs Anodizing What’s the Difference Zinc Plated Temperature Regular maintenance and protective coatings are essential. Several factors affect the results of zinc plating, such as current density, zinc concentration on the plating bath, temperature, electrode positions, and more. Temperature — the temperature of the plating bath will also have a direct impact on the zinc plating outcome. The melting point of elemental zinc is approximately 780° f (415°. Zinc Plated Temperature.

From www.researchgate.net

Electrical resistivity of Nickel Zinc Ferrite and Copper Nickel Zinc... Download Scientific Zinc Plated Temperature Zinc plating acts as a barrier, but prolonged exposure to moisture can compromise its effectiveness. Several factors affect the results of zinc plating, such as current density, zinc concentration on the plating bath, temperature, electrode positions, and more. Regular maintenance and protective coatings are essential. The benefits of zinc plating. The melting point of elemental zinc is approximately 780° f. Zinc Plated Temperature.

From www.superior-tech.net

How zinc coating and the galvanizing process protects iron from rust Zinc Plated Temperature Regular maintenance and protective coatings are essential. The melting point of elemental zinc is approximately 780° f (415° c). The benefits of zinc plating. Zinc plating acts as a barrier, but prolonged exposure to moisture can compromise its effectiveness. The correct temperature is crucial for the efficiency of the plating process and the quality of the final coating. Several factors. Zinc Plated Temperature.

From blog.thepipingmart.com

Zinc Plating vs Hot Dip Galvanizing What's the Difference Zinc Plated Temperature Temperature — the temperature of the plating bath will also have a direct impact on the zinc plating outcome. The benefits of zinc plating. Regular maintenance and protective coatings are essential. The correct temperature is crucial for the efficiency of the plating process and the quality of the final coating. Several factors affect the results of zinc plating, such as. Zinc Plated Temperature.

From sharp-industries.in

Zinc Electroplating Sharp Industries Zinc Plated Temperature Temperature — the temperature of the plating bath will also have a direct impact on the zinc plating outcome. The correct temperature is crucial for the efficiency of the plating process and the quality of the final coating. Zinc plating acts as a barrier, but prolonged exposure to moisture can compromise its effectiveness. Regular maintenance and protective coatings are essential.. Zinc Plated Temperature.

From gtbolt.en.made-in-china.com

Carbon Steel M10 M8 High Temperature Zinc Plated Flange Nut China Flange Hex Nut M20 and Zinc Plated Temperature Regular maintenance and protective coatings are essential. Temperature — the temperature of the plating bath will also have a direct impact on the zinc plating outcome. The correct temperature is crucial for the efficiency of the plating process and the quality of the final coating. Several factors affect the results of zinc plating, such as current density, zinc concentration on. Zinc Plated Temperature.

From elmplating.com

ZINC BARREL PLATING Elm Plating Company Zinc Plated Temperature Several factors affect the results of zinc plating, such as current density, zinc concentration on the plating bath, temperature, electrode positions, and more. The correct temperature is crucial for the efficiency of the plating process and the quality of the final coating. The benefits of zinc plating. The melting point of elemental zinc is approximately 780° f (415° c). Temperature. Zinc Plated Temperature.

From www.youtube.com

Zinc Plating on Copper Metal YouTube Zinc Plated Temperature The benefits of zinc plating. The melting point of elemental zinc is approximately 780° f (415° c). Several factors affect the results of zinc plating, such as current density, zinc concentration on the plating bath, temperature, electrode positions, and more. The correct temperature is crucial for the efficiency of the plating process and the quality of the final coating. Temperature. Zinc Plated Temperature.

From gtbolt.en.made-in-china.com

Carbon Steel M10 M8 High Temperature Zinc Plated Flange Nut China Flange Hex Nut M20 and Zinc Plated Temperature The benefits of zinc plating. Regular maintenance and protective coatings are essential. The correct temperature is crucial for the efficiency of the plating process and the quality of the final coating. Temperature — the temperature of the plating bath will also have a direct impact on the zinc plating outcome. Zinc plating acts as a barrier, but prolonged exposure to. Zinc Plated Temperature.

From gtbolt.en.made-in-china.com

Carbon Steel M10 M8 High Temperature Zinc Plated Flange Nut DIN 6923 China Reid Flange Nut and Zinc Plated Temperature Temperature — the temperature of the plating bath will also have a direct impact on the zinc plating outcome. The correct temperature is crucial for the efficiency of the plating process and the quality of the final coating. Regular maintenance and protective coatings are essential. The melting point of elemental zinc is approximately 780° f (415° c). Several factors affect. Zinc Plated Temperature.

From www.deepakfasteners.com

Deepak Fasteners Limited Zinc Electroplating Zinc Plated Temperature Zinc plating acts as a barrier, but prolonged exposure to moisture can compromise its effectiveness. The correct temperature is crucial for the efficiency of the plating process and the quality of the final coating. The benefits of zinc plating. Regular maintenance and protective coatings are essential. Several factors affect the results of zinc plating, such as current density, zinc concentration. Zinc Plated Temperature.

From www.youtube.com

Black passivation process for zinc plating YouTube Zinc Plated Temperature The correct temperature is crucial for the efficiency of the plating process and the quality of the final coating. Regular maintenance and protective coatings are essential. Zinc plating acts as a barrier, but prolonged exposure to moisture can compromise its effectiveness. The melting point of elemental zinc is approximately 780° f (415° c). The benefits of zinc plating. Temperature —. Zinc Plated Temperature.

From tymetal.en.made-in-china.com

Custom Zinc Plated Stainless Steel Special Shaped Wire Forming High Temperature Spring China Zinc Plated Temperature Zinc plating acts as a barrier, but prolonged exposure to moisture can compromise its effectiveness. Temperature — the temperature of the plating bath will also have a direct impact on the zinc plating outcome. The benefits of zinc plating. Several factors affect the results of zinc plating, such as current density, zinc concentration on the plating bath, temperature, electrode positions,. Zinc Plated Temperature.

From mavink.com

Zinc Plating Process Flow Chart Zinc Plated Temperature Regular maintenance and protective coatings are essential. Zinc plating acts as a barrier, but prolonged exposure to moisture can compromise its effectiveness. The benefits of zinc plating. Several factors affect the results of zinc plating, such as current density, zinc concentration on the plating bath, temperature, electrode positions, and more. The melting point of elemental zinc is approximately 780° f. Zinc Plated Temperature.

From hydraquip.co.uk

Mild Steel Zinc Plated, High Temperature Liner, M10 PClips, 20mm Band Hydraquip Zinc Plated Temperature The correct temperature is crucial for the efficiency of the plating process and the quality of the final coating. The benefits of zinc plating. The melting point of elemental zinc is approximately 780° f (415° c). Regular maintenance and protective coatings are essential. Several factors affect the results of zinc plating, such as current density, zinc concentration on the plating. Zinc Plated Temperature.

From blog.thepipingmart.com

Zinc Iron Plating Applications and Process Zinc Plated Temperature Several factors affect the results of zinc plating, such as current density, zinc concentration on the plating bath, temperature, electrode positions, and more. Zinc plating acts as a barrier, but prolonged exposure to moisture can compromise its effectiveness. The benefits of zinc plating. Regular maintenance and protective coatings are essential. The correct temperature is crucial for the efficiency of the. Zinc Plated Temperature.

From blog.thepipingmart.com

Advantages and Disadvantages of Zinc Plating Zinc Plated Temperature The correct temperature is crucial for the efficiency of the plating process and the quality of the final coating. The benefits of zinc plating. Several factors affect the results of zinc plating, such as current density, zinc concentration on the plating bath, temperature, electrode positions, and more. The melting point of elemental zinc is approximately 780° f (415° c). Zinc. Zinc Plated Temperature.