Spur Gear Standards . Primitive gears were known and used wel.lover 2,000 years ago, and gears have taken their place as one of the basic. Fundamental rating factors and calculation methods for involute spur and helical gear teeth. These simple gears are cost. The spur gear is is simplest type of gear manufactured and is generally used for transmission of rotary motion between parallel. Agma 2001 and 2101 (the metric version) are. However, there are key differences between the two types and it is important to understand how they vary. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Calculation of load capacity of spur and helical gears — part 1: Basic principles, introduction and general influence factors Spur gears and helical gears are both types of gears. Spur gears are a cylindrical shaped toothed component used in industrial equipment to transfer mechanical motion as well as control speed, power, and torque.

from khkgears.net

Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Spur gears and helical gears are both types of gears. Agma 2001 and 2101 (the metric version) are. Calculation of load capacity of spur and helical gears — part 1: Spur gears are a cylindrical shaped toothed component used in industrial equipment to transfer mechanical motion as well as control speed, power, and torque. Fundamental rating factors and calculation methods for involute spur and helical gear teeth. Primitive gears were known and used wel.lover 2,000 years ago, and gears have taken their place as one of the basic. These simple gears are cost. The spur gear is is simplest type of gear manufactured and is generally used for transmission of rotary motion between parallel. Basic principles, introduction and general influence factors

Spur Gears KHK Gears

Spur Gear Standards Fundamental rating factors and calculation methods for involute spur and helical gear teeth. However, there are key differences between the two types and it is important to understand how they vary. Basic principles, introduction and general influence factors Agma 2001 and 2101 (the metric version) are. Fundamental rating factors and calculation methods for involute spur and helical gear teeth. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Spur gears are a cylindrical shaped toothed component used in industrial equipment to transfer mechanical motion as well as control speed, power, and torque. Primitive gears were known and used wel.lover 2,000 years ago, and gears have taken their place as one of the basic. Spur gears and helical gears are both types of gears. The spur gear is is simplest type of gear manufactured and is generally used for transmission of rotary motion between parallel. These simple gears are cost. Calculation of load capacity of spur and helical gears — part 1:

From gearspec.blogspot.com

Gear Specification and Standard Spur Gear Standards Primitive gears were known and used wel.lover 2,000 years ago, and gears have taken their place as one of the basic. The spur gear is is simplest type of gear manufactured and is generally used for transmission of rotary motion between parallel. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle. Spur Gear Standards.

From www.transmissionspareparts.com

American Standard Spur Gears Supplier , type M0.5 , M1 , M1.5 , M2 , M2 Spur Gear Standards These simple gears are cost. Calculation of load capacity of spur and helical gears — part 1: Fundamental rating factors and calculation methods for involute spur and helical gear teeth. Primitive gears were known and used wel.lover 2,000 years ago, and gears have taken their place as one of the basic. Spur gears are a cylindrical shaped toothed component used. Spur Gear Standards.

From mungfali.com

Standard Spur Gear Sizes Spur Gear Standards However, there are key differences between the two types and it is important to understand how they vary. Agma 2001 and 2101 (the metric version) are. Calculation of load capacity of spur and helical gears — part 1: Fundamental rating factors and calculation methods for involute spur and helical gear teeth. Spur gears and helical gears are both types of. Spur Gear Standards.

From mungfali.com

Standard Spur Gear Sizes Spur Gear Standards Agma 2001 and 2101 (the metric version) are. Spur gears are a cylindrical shaped toothed component used in industrial equipment to transfer mechanical motion as well as control speed, power, and torque. Calculation of load capacity of spur and helical gears — part 1: Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth. Spur Gear Standards.

From www.researchgate.net

Specification of spur and helical gears. Download Table Spur Gear Standards Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The spur gear is is simplest type of gear manufactured and is generally used for transmission of rotary motion between parallel. Basic principles, introduction and general influence factors These simple gears are cost. Spur gears and helical gears are both. Spur Gear Standards.

From www.sidiros.gr

SPUR GEAR MODULE 1 Z=064 WITH HUB Spur Gear Standards Fundamental rating factors and calculation methods for involute spur and helical gear teeth. Calculation of load capacity of spur and helical gears — part 1: Spur gears are a cylindrical shaped toothed component used in industrial equipment to transfer mechanical motion as well as control speed, power, and torque. Gear dimensions are determined in accordance with their specifications, such as. Spur Gear Standards.

From thors.com

Engineering Drawings for Spur and Helical Gears Course Spur Gear Standards These simple gears are cost. Calculation of load capacity of spur and helical gears — part 1: Agma 2001 and 2101 (the metric version) are. Fundamental rating factors and calculation methods for involute spur and helical gear teeth. However, there are key differences between the two types and it is important to understand how they vary. The spur gear is. Spur Gear Standards.

From mungfali.com

Standard Spur Gear Sizes Spur Gear Standards Spur gears and helical gears are both types of gears. Calculation of load capacity of spur and helical gears — part 1: Fundamental rating factors and calculation methods for involute spur and helical gear teeth. However, there are key differences between the two types and it is important to understand how they vary. These simple gears are cost. The spur. Spur Gear Standards.

From mungfali.com

Standard Spur Gear Sizes Spur Gear Standards Spur gears are a cylindrical shaped toothed component used in industrial equipment to transfer mechanical motion as well as control speed, power, and torque. Agma 2001 and 2101 (the metric version) are. These simple gears are cost. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. However, there are. Spur Gear Standards.

From www.gearsandsprockets.co.uk

Metric MOD 0.5 Steel Spur Gears Spur Gear Standards The spur gear is is simplest type of gear manufactured and is generally used for transmission of rotary motion between parallel. Spur gears and helical gears are both types of gears. Basic principles, introduction and general influence factors Fundamental rating factors and calculation methods for involute spur and helical gear teeth. Calculation of load capacity of spur and helical gears. Spur Gear Standards.

From mungfali.com

Standard Spur Gear Sizes Spur Gear Standards Spur gears are a cylindrical shaped toothed component used in industrial equipment to transfer mechanical motion as well as control speed, power, and torque. Fundamental rating factors and calculation methods for involute spur and helical gear teeth. Agma 2001 and 2101 (the metric version) are. Calculation of load capacity of spur and helical gears — part 1: Gear dimensions are. Spur Gear Standards.

From www.iqsdirectory.com

Spur Gears Types, Uses, Benefits, and Manufacturing Spur Gear Standards Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Agma 2001 and 2101 (the metric version) are. Fundamental rating factors and calculation methods for involute spur and helical gear teeth. Primitive gears were known and used wel.lover 2,000 years ago, and gears have taken their place as one of. Spur Gear Standards.

From drivetrainhub.com

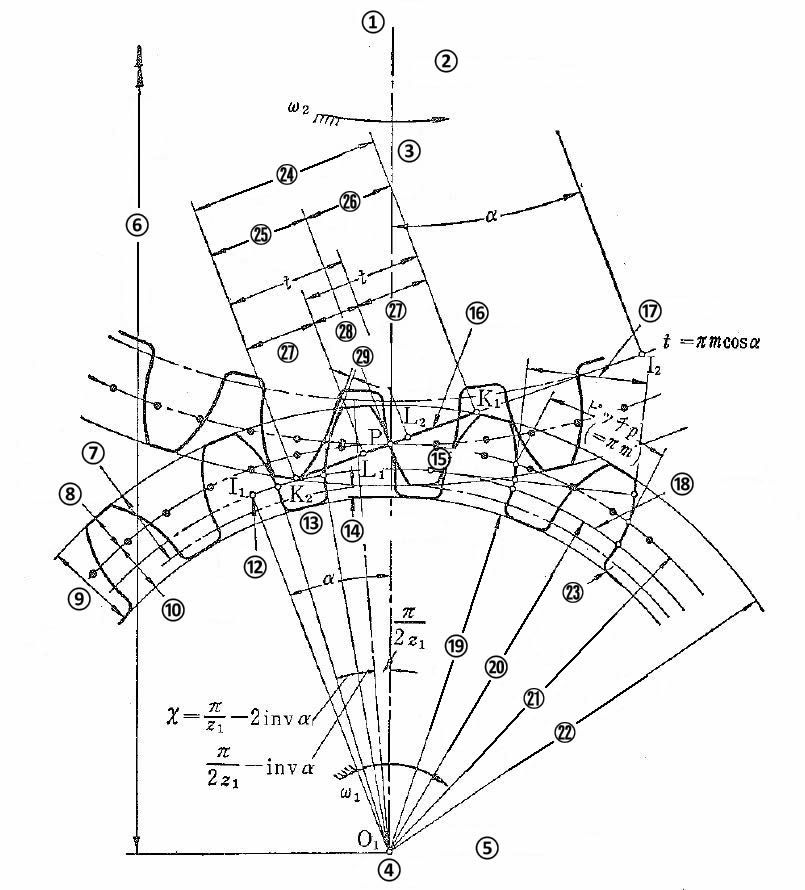

Spur Gears Geometry of spur gears and gear meshes Spur Gear Standards Primitive gears were known and used wel.lover 2,000 years ago, and gears have taken their place as one of the basic. The spur gear is is simplest type of gear manufactured and is generally used for transmission of rotary motion between parallel. Basic principles, introduction and general influence factors Fundamental rating factors and calculation methods for involute spur and helical. Spur Gear Standards.

From khkgears.net

Involute Gear Profile KHK Gears Spur Gear Standards These simple gears are cost. Primitive gears were known and used wel.lover 2,000 years ago, and gears have taken their place as one of the basic. Basic principles, introduction and general influence factors Agma 2001 and 2101 (the metric version) are. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α),. Spur Gear Standards.

From watneyconsulting.com

Gear Design Watney Consulting Spur Gear Standards However, there are key differences between the two types and it is important to understand how they vary. Spur gears and helical gears are both types of gears. The spur gear is is simplest type of gear manufactured and is generally used for transmission of rotary motion between parallel. Agma 2001 and 2101 (the metric version) are. Gear dimensions are. Spur Gear Standards.

From selmec.org.uk

The Theory of Meccano Gears Part 1 — Spur Gears — South East London Spur Gear Standards Spur gears are a cylindrical shaped toothed component used in industrial equipment to transfer mechanical motion as well as control speed, power, and torque. Primitive gears were known and used wel.lover 2,000 years ago, and gears have taken their place as one of the basic. Spur gears and helical gears are both types of gears. These simple gears are cost.. Spur Gear Standards.

From paintingvalley.com

Spur Gear Drawing at Explore collection of Spur Spur Gear Standards Basic principles, introduction and general influence factors Spur gears are a cylindrical shaped toothed component used in industrial equipment to transfer mechanical motion as well as control speed, power, and torque. Fundamental rating factors and calculation methods for involute spur and helical gear teeth. These simple gears are cost. Spur gears and helical gears are both types of gears. The. Spur Gear Standards.

From eng-shady-mohsen.blogspot.com

Eng. Shady Mohsen blog Involute spur gear design Spur Gear Standards Spur gears and helical gears are both types of gears. However, there are key differences between the two types and it is important to understand how they vary. Primitive gears were known and used wel.lover 2,000 years ago, and gears have taken their place as one of the basic. Spur gears are a cylindrical shaped toothed component used in industrial. Spur Gear Standards.

From www.alibaba.com

Msga148 Jis Standard M1 Scm415 Overall Carburizing Custom Standard Spur Gear Standards However, there are key differences between the two types and it is important to understand how they vary. Spur gears and helical gears are both types of gears. Primitive gears were known and used wel.lover 2,000 years ago, and gears have taken their place as one of the basic. Basic principles, introduction and general influence factors The spur gear is. Spur Gear Standards.

From www.semanticscholar.org

Figure 1 from TECHNOLOGY Comparative Study of Stress Analysis of Spur Gear Standards Spur gears are a cylindrical shaped toothed component used in industrial equipment to transfer mechanical motion as well as control speed, power, and torque. Agma 2001 and 2101 (the metric version) are. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Fundamental rating factors and calculation methods for involute. Spur Gear Standards.

From www.automotioncomponents.co.uk

Automotion Components Spur Gears Technical Page Automotion Spur Gear Standards Agma 2001 and 2101 (the metric version) are. Calculation of load capacity of spur and helical gears — part 1: Spur gears and helical gears are both types of gears. Fundamental rating factors and calculation methods for involute spur and helical gear teeth. These simple gears are cost. Gear dimensions are determined in accordance with their specifications, such as module. Spur Gear Standards.

From www.engineersedge.com

Gear Tooth Contact Stress Number Equation and Calculator Spur Gear Standards Spur gears are a cylindrical shaped toothed component used in industrial equipment to transfer mechanical motion as well as control speed, power, and torque. Spur gears and helical gears are both types of gears. Primitive gears were known and used wel.lover 2,000 years ago, and gears have taken their place as one of the basic. These simple gears are cost.. Spur Gear Standards.

From mavink.com

Spur Size Chart Spur Gear Standards Calculation of load capacity of spur and helical gears — part 1: Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Fundamental rating factors and calculation methods for involute spur and helical gear teeth. However, there are key differences between the two types and it is important to understand. Spur Gear Standards.

From unik-machinery.en.made-in-china.com

ISO Standard Spur Gear with Teeth 10 to 150 China Stainless Steel Spur Gear Standards The spur gear is is simplest type of gear manufactured and is generally used for transmission of rotary motion between parallel. Spur gears are a cylindrical shaped toothed component used in industrial equipment to transfer mechanical motion as well as control speed, power, and torque. Spur gears and helical gears are both types of gears. Agma 2001 and 2101 (the. Spur Gear Standards.

From www.ebay.com

Mod1 Steel Pinion Gear Spur Gears 1039 Teeth 420mm Bore With Screw Spur Gear Standards Calculation of load capacity of spur and helical gears — part 1: Primitive gears were known and used wel.lover 2,000 years ago, and gears have taken their place as one of the basic. Agma 2001 and 2101 (the metric version) are. Spur gears and helical gears are both types of gears. Spur gears are a cylindrical shaped toothed component used. Spur Gear Standards.

From www.engineersedge.com

Inspection Methods for Spur Gears Single Pin Measurement Method Spur Gear Standards These simple gears are cost. Primitive gears were known and used wel.lover 2,000 years ago, and gears have taken their place as one of the basic. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Fundamental rating factors and calculation methods for involute spur and helical gear teeth. Spur. Spur Gear Standards.

From engineering.stackexchange.com

How to determine curvature of face and flank of a spur gear? What is Spur Gear Standards Spur gears and helical gears are both types of gears. Basic principles, introduction and general influence factors The spur gear is is simplest type of gear manufactured and is generally used for transmission of rotary motion between parallel. However, there are key differences between the two types and it is important to understand how they vary. Fundamental rating factors and. Spur Gear Standards.

From mungfali.com

Spur Gear Tooth Dimensions Spur Gear Standards Fundamental rating factors and calculation methods for involute spur and helical gear teeth. Basic principles, introduction and general influence factors Calculation of load capacity of spur and helical gears — part 1: Agma 2001 and 2101 (the metric version) are. These simple gears are cost. Primitive gears were known and used wel.lover 2,000 years ago, and gears have taken their. Spur Gear Standards.

From www.iqsdirectory.com

Spur Gears Types, Uses, Benefits, and Manufacturing Spur Gear Standards Calculation of load capacity of spur and helical gears — part 1: Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Agma 2001 and 2101 (the metric version) are. These simple gears are cost. Spur gears and helical gears are both types of gears. Basic principles, introduction and general. Spur Gear Standards.

From khkgears.net

Bending Strength of Spur and Helical Gears KHK Spur Gear Standards These simple gears are cost. Fundamental rating factors and calculation methods for involute spur and helical gear teeth. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Spur gears are a cylindrical shaped toothed component used in industrial equipment to transfer mechanical motion as well as control speed, power,. Spur Gear Standards.

From khkgears.net

Basic Gear Terminology and Calculation KHK Spur Gear Standards Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. However, there are key differences between the two types and it is important to understand how they vary. Spur gears are a cylindrical shaped toothed component used in industrial equipment to transfer mechanical motion as well as control speed, power,. Spur Gear Standards.

From members.tripod.com

Spur Gear Geometry Picture Spur Gear Standards Spur gears and helical gears are both types of gears. The spur gear is is simplest type of gear manufactured and is generally used for transmission of rotary motion between parallel. Calculation of load capacity of spur and helical gears — part 1: Primitive gears were known and used wel.lover 2,000 years ago, and gears have taken their place as. Spur Gear Standards.

From mavink.com

Spur Size Chart Spur Gear Standards Basic principles, introduction and general influence factors Calculation of load capacity of spur and helical gears — part 1: These simple gears are cost. Spur gears and helical gears are both types of gears. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The spur gear is is simplest. Spur Gear Standards.

From khkgears.net

Spur Gears KHK Gears Spur Gear Standards Calculation of load capacity of spur and helical gears — part 1: Basic principles, introduction and general influence factors Fundamental rating factors and calculation methods for involute spur and helical gear teeth. The spur gear is is simplest type of gear manufactured and is generally used for transmission of rotary motion between parallel. However, there are key differences between the. Spur Gear Standards.

From gear.com.my

Spur Gear Malaysia, Spur Gear Supplier Malaysia Spur Gear Standards Spur gears are a cylindrical shaped toothed component used in industrial equipment to transfer mechanical motion as well as control speed, power, and torque. Fundamental rating factors and calculation methods for involute spur and helical gear teeth. The spur gear is is simplest type of gear manufactured and is generally used for transmission of rotary motion between parallel. However, there. Spur Gear Standards.