Eddy Current Gear Inspection . Eddy current array (eca) technology is the next stage in ect. This article compares eddy current array (eca) with phased array ultrasonic testing to clearly identify why eddyfi technologies eca technology is best suited for gear inspection in the mining sector. Eddy current testing is often used to replace chemical testing processes such as dye penetrant and magnetic particle inspection for crack testing, and cutting and acid etch testing to. Here are the top five industries that use electromagnetic testing, with specific applications covered for each one. This paper describes the use of combining combined eddy current array (eca) and alternating current field measurement (acfm) to. Eddy current testing (ect) finds applications across a wide range of industries, helping inspectors obtain critical insights into the integrity of conductive materials and components.

from www.electricity-magnetism.org

Here are the top five industries that use electromagnetic testing, with specific applications covered for each one. This article compares eddy current array (eca) with phased array ultrasonic testing to clearly identify why eddyfi technologies eca technology is best suited for gear inspection in the mining sector. Eddy current array (eca) technology is the next stage in ect. This paper describes the use of combining combined eddy current array (eca) and alternating current field measurement (acfm) to. Eddy current testing (ect) finds applications across a wide range of industries, helping inspectors obtain critical insights into the integrity of conductive materials and components. Eddy current testing is often used to replace chemical testing processes such as dye penetrant and magnetic particle inspection for crack testing, and cutting and acid etch testing to.

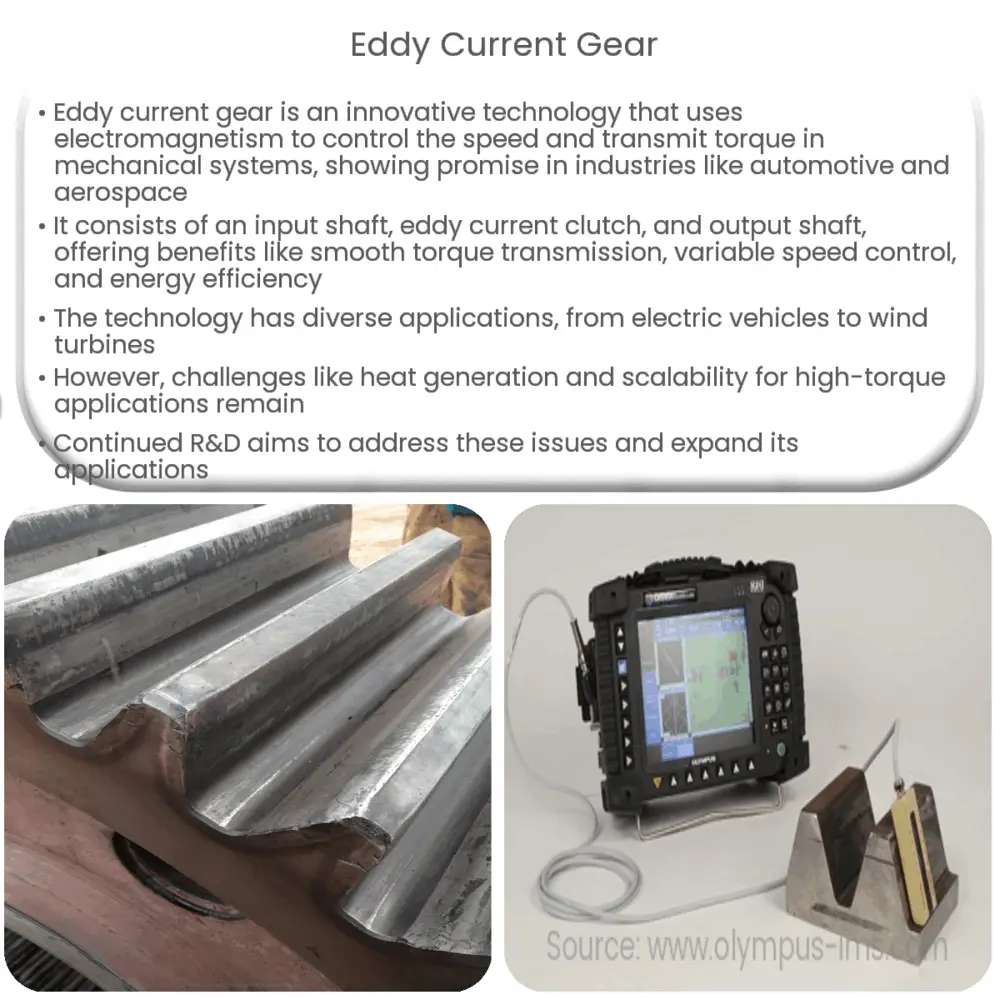

Eddy current gear How it works, Application & Advantages

Eddy Current Gear Inspection Eddy current testing is often used to replace chemical testing processes such as dye penetrant and magnetic particle inspection for crack testing, and cutting and acid etch testing to. Here are the top five industries that use electromagnetic testing, with specific applications covered for each one. Eddy current testing (ect) finds applications across a wide range of industries, helping inspectors obtain critical insights into the integrity of conductive materials and components. This article compares eddy current array (eca) with phased array ultrasonic testing to clearly identify why eddyfi technologies eca technology is best suited for gear inspection in the mining sector. This paper describes the use of combining combined eddy current array (eca) and alternating current field measurement (acfm) to. Eddy current testing is often used to replace chemical testing processes such as dye penetrant and magnetic particle inspection for crack testing, and cutting and acid etch testing to. Eddy current array (eca) technology is the next stage in ect.

From www.specializednde.ca

Eddy Current Testing Specialized NDE Ontario Eddy Current Testing Eddy Current Gear Inspection Here are the top five industries that use electromagnetic testing, with specific applications covered for each one. Eddy current testing (ect) finds applications across a wide range of industries, helping inspectors obtain critical insights into the integrity of conductive materials and components. Eddy current array (eca) technology is the next stage in ect. This article compares eddy current array (eca). Eddy Current Gear Inspection.

From www.electricity-magnetism.org

Eddy current gear How it works, Application & Advantages Eddy Current Gear Inspection This paper describes the use of combining combined eddy current array (eca) and alternating current field measurement (acfm) to. Eddy current array (eca) technology is the next stage in ect. Here are the top five industries that use electromagnetic testing, with specific applications covered for each one. Eddy current testing (ect) finds applications across a wide range of industries, helping. Eddy Current Gear Inspection.

From www.youtube.com

High Frequency Eddy Current Inspection YouTube Eddy Current Gear Inspection Eddy current array (eca) technology is the next stage in ect. Eddy current testing (ect) finds applications across a wide range of industries, helping inspectors obtain critical insights into the integrity of conductive materials and components. This article compares eddy current array (eca) with phased array ultrasonic testing to clearly identify why eddyfi technologies eca technology is best suited for. Eddy Current Gear Inspection.

From www.youtube.com

Gear Blank Eddy Current Inspection Machine YouTube Eddy Current Gear Inspection Here are the top five industries that use electromagnetic testing, with specific applications covered for each one. This article compares eddy current array (eca) with phased array ultrasonic testing to clearly identify why eddyfi technologies eca technology is best suited for gear inspection in the mining sector. Eddy current array (eca) technology is the next stage in ect. Eddy current. Eddy Current Gear Inspection.

From www.qualitymag.com

What Is Eddy Current Testing? 20161101 Quality Magazine Eddy Current Gear Inspection Here are the top five industries that use electromagnetic testing, with specific applications covered for each one. Eddy current array (eca) technology is the next stage in ect. Eddy current testing (ect) finds applications across a wide range of industries, helping inspectors obtain critical insights into the integrity of conductive materials and components. This paper describes the use of combining. Eddy Current Gear Inspection.

From www.youtube.com

The system for eddy current testing of aircraft wheels SMARTSCAN Eddy Current Gear Inspection Here are the top five industries that use electromagnetic testing, with specific applications covered for each one. This article compares eddy current array (eca) with phased array ultrasonic testing to clearly identify why eddyfi technologies eca technology is best suited for gear inspection in the mining sector. This paper describes the use of combining combined eddy current array (eca) and. Eddy Current Gear Inspection.

From atslab.com

Eddy Current Inspections Applied Technical Services Eddy Current Gear Inspection Here are the top five industries that use electromagnetic testing, with specific applications covered for each one. Eddy current testing is often used to replace chemical testing processes such as dye penetrant and magnetic particle inspection for crack testing, and cutting and acid etch testing to. This paper describes the use of combining combined eddy current array (eca) and alternating. Eddy Current Gear Inspection.

From www.tcsndt.com.au

Eddy Current Testing TCS NDT Eddy Current Gear Inspection This article compares eddy current array (eca) with phased array ultrasonic testing to clearly identify why eddyfi technologies eca technology is best suited for gear inspection in the mining sector. Eddy current array (eca) technology is the next stage in ect. Eddy current testing is often used to replace chemical testing processes such as dye penetrant and magnetic particle inspection. Eddy Current Gear Inspection.

From industrial.evidentscientific.com.cn

Eddy Current Array Gear Tooth Surface Inspection for the Mining Industry Eddy Current Gear Inspection This article compares eddy current array (eca) with phased array ultrasonic testing to clearly identify why eddyfi technologies eca technology is best suited for gear inspection in the mining sector. Here are the top five industries that use electromagnetic testing, with specific applications covered for each one. Eddy current testing (ect) finds applications across a wide range of industries, helping. Eddy Current Gear Inspection.

From www.bwxt.com

Eddy Current Inspection BWX Technologies, Inc. People Strong Eddy Current Gear Inspection Eddy current testing (ect) finds applications across a wide range of industries, helping inspectors obtain critical insights into the integrity of conductive materials and components. This article compares eddy current array (eca) with phased array ultrasonic testing to clearly identify why eddyfi technologies eca technology is best suited for gear inspection in the mining sector. Here are the top five. Eddy Current Gear Inspection.

From pragmandt.com

Technologies Eddy Current Pragma NDT Eddy Current Gear Inspection Here are the top five industries that use electromagnetic testing, with specific applications covered for each one. Eddy current testing (ect) finds applications across a wide range of industries, helping inspectors obtain critical insights into the integrity of conductive materials and components. This article compares eddy current array (eca) with phased array ultrasonic testing to clearly identify why eddyfi technologies. Eddy Current Gear Inspection.

From www.slideserve.com

PPT Basic Principles of the Eddy Current Inspection Technique Eddy Current Gear Inspection Eddy current testing is often used to replace chemical testing processes such as dye penetrant and magnetic particle inspection for crack testing, and cutting and acid etch testing to. This paper describes the use of combining combined eddy current array (eca) and alternating current field measurement (acfm) to. Here are the top five industries that use electromagnetic testing, with specific. Eddy Current Gear Inspection.

From www.pine-environmental.com

Eddy Current Inspection Pine Environmental Eddy Current Gear Inspection Eddy current testing (ect) finds applications across a wide range of industries, helping inspectors obtain critical insights into the integrity of conductive materials and components. Eddy current array (eca) technology is the next stage in ect. This article compares eddy current array (eca) with phased array ultrasonic testing to clearly identify why eddyfi technologies eca technology is best suited for. Eddy Current Gear Inspection.

From dxobsbges.blob.core.windows.net

Eddy Current Weld Inspection Procedure at Joseph Wheeler blog Eddy Current Gear Inspection Eddy current array (eca) technology is the next stage in ect. Here are the top five industries that use electromagnetic testing, with specific applications covered for each one. Eddy current testing is often used to replace chemical testing processes such as dye penetrant and magnetic particle inspection for crack testing, and cutting and acid etch testing to. This paper describes. Eddy Current Gear Inspection.

From www.nde-solutions.com

Eddy Current Testing NDE Solutions Eddy Current Gear Inspection Eddy current testing (ect) finds applications across a wide range of industries, helping inspectors obtain critical insights into the integrity of conductive materials and components. Eddy current testing is often used to replace chemical testing processes such as dye penetrant and magnetic particle inspection for crack testing, and cutting and acid etch testing to. Here are the top five industries. Eddy Current Gear Inspection.

From www.aviationpros.com

Eddy current inspection(2) From Praxair Surface Technologies Eddy Current Gear Inspection This article compares eddy current array (eca) with phased array ultrasonic testing to clearly identify why eddyfi technologies eca technology is best suited for gear inspection in the mining sector. This paper describes the use of combining combined eddy current array (eca) and alternating current field measurement (acfm) to. Eddy current testing (ect) finds applications across a wide range of. Eddy Current Gear Inspection.

From ndtblog-us.fujifilm.com

Complete Guide to Eddy Current Testing Fujifilm NDT Eddy Current Gear Inspection Here are the top five industries that use electromagnetic testing, with specific applications covered for each one. This article compares eddy current array (eca) with phased array ultrasonic testing to clearly identify why eddyfi technologies eca technology is best suited for gear inspection in the mining sector. Eddy current testing (ect) finds applications across a wide range of industries, helping. Eddy Current Gear Inspection.

From www.triquestndt.com

Pulsed Eddy Current Inspection (PEC) Eddy Current Gear Inspection Eddy current testing (ect) finds applications across a wide range of industries, helping inspectors obtain critical insights into the integrity of conductive materials and components. Eddy current testing is often used to replace chemical testing processes such as dye penetrant and magnetic particle inspection for crack testing, and cutting and acid etch testing to. This paper describes the use of. Eddy Current Gear Inspection.

From www.politicalfunda.com

Eddy Current Inspection (ECI) Eddy Current Non Destructive Testing Eddy Current Gear Inspection This paper describes the use of combining combined eddy current array (eca) and alternating current field measurement (acfm) to. Eddy current testing (ect) finds applications across a wide range of industries, helping inspectors obtain critical insights into the integrity of conductive materials and components. Eddy current testing is often used to replace chemical testing processes such as dye penetrant and. Eddy Current Gear Inspection.

From www.nomogroup.com

Inspections under the Eddy Current technique NOMO Eddy Current Gear Inspection Eddy current testing is often used to replace chemical testing processes such as dye penetrant and magnetic particle inspection for crack testing, and cutting and acid etch testing to. This article compares eddy current array (eca) with phased array ultrasonic testing to clearly identify why eddyfi technologies eca technology is best suited for gear inspection in the mining sector. Eddy. Eddy Current Gear Inspection.

From www.qualitymag.com

What Is Eddy Current Testing? 20161101 Quality Magazine Eddy Current Gear Inspection Here are the top five industries that use electromagnetic testing, with specific applications covered for each one. Eddy current testing (ect) finds applications across a wide range of industries, helping inspectors obtain critical insights into the integrity of conductive materials and components. Eddy current testing is often used to replace chemical testing processes such as dye penetrant and magnetic particle. Eddy Current Gear Inspection.

From thermalprocessing.com

Advanced Robotics Combined with Eddy Current Testing Offers Eddy Current Gear Inspection This paper describes the use of combining combined eddy current array (eca) and alternating current field measurement (acfm) to. This article compares eddy current array (eca) with phased array ultrasonic testing to clearly identify why eddyfi technologies eca technology is best suited for gear inspection in the mining sector. Eddy current testing is often used to replace chemical testing processes. Eddy Current Gear Inspection.

From www.youtube.com

Eddy Current Edge Inspection with Video Endoscope YouTube Eddy Current Gear Inspection This article compares eddy current array (eca) with phased array ultrasonic testing to clearly identify why eddyfi technologies eca technology is best suited for gear inspection in the mining sector. Eddy current testing is often used to replace chemical testing processes such as dye penetrant and magnetic particle inspection for crack testing, and cutting and acid etch testing to. This. Eddy Current Gear Inspection.

From www.researchgate.net

(PDF) Eddy Current Testing Basics Eddy Current Gear Inspection Eddy current testing is often used to replace chemical testing processes such as dye penetrant and magnetic particle inspection for crack testing, and cutting and acid etch testing to. Eddy current array (eca) technology is the next stage in ect. This paper describes the use of combining combined eddy current array (eca) and alternating current field measurement (acfm) to. This. Eddy Current Gear Inspection.

From www.aviationpros.com

Eddy current inspection(2) Aviation Pros Eddy Current Gear Inspection Here are the top five industries that use electromagnetic testing, with specific applications covered for each one. Eddy current testing is often used to replace chemical testing processes such as dye penetrant and magnetic particle inspection for crack testing, and cutting and acid etch testing to. Eddy current array (eca) technology is the next stage in ect. This paper describes. Eddy Current Gear Inspection.

From www.youtube.com

inar Optimizing Weld Inspection With eddy current GE YouTube Eddy Current Gear Inspection This article compares eddy current array (eca) with phased array ultrasonic testing to clearly identify why eddyfi technologies eca technology is best suited for gear inspection in the mining sector. Eddy current testing (ect) finds applications across a wide range of industries, helping inspectors obtain critical insights into the integrity of conductive materials and components. Eddy current array (eca) technology. Eddy Current Gear Inspection.

From www.twi-global.com

Eddy Current Testing A Definitive Guide (Includes Eddy Current Array Eddy Current Gear Inspection This paper describes the use of combining combined eddy current array (eca) and alternating current field measurement (acfm) to. Eddy current testing is often used to replace chemical testing processes such as dye penetrant and magnetic particle inspection for crack testing, and cutting and acid etch testing to. Eddy current array (eca) technology is the next stage in ect. Here. Eddy Current Gear Inspection.

From www.youtube.com

Pulsed Eddy Current Inspection for CUI YouTube Eddy Current Gear Inspection Here are the top five industries that use electromagnetic testing, with specific applications covered for each one. Eddy current testing (ect) finds applications across a wide range of industries, helping inspectors obtain critical insights into the integrity of conductive materials and components. This paper describes the use of combining combined eddy current array (eca) and alternating current field measurement (acfm). Eddy Current Gear Inspection.

From www.aviationpros.com

UniWest’s New MultiChannel Eddy Current Inspection Instrument Provides Eddy Current Gear Inspection Here are the top five industries that use electromagnetic testing, with specific applications covered for each one. This article compares eddy current array (eca) with phased array ultrasonic testing to clearly identify why eddyfi technologies eca technology is best suited for gear inspection in the mining sector. This paper describes the use of combining combined eddy current array (eca) and. Eddy Current Gear Inspection.

From ndtsupply.com

Eddy Current Advanced Rohmann Systems EloWheel RPT17 Wheel Rim Eddy Current Gear Inspection Here are the top five industries that use electromagnetic testing, with specific applications covered for each one. This paper describes the use of combining combined eddy current array (eca) and alternating current field measurement (acfm) to. This article compares eddy current array (eca) with phased array ultrasonic testing to clearly identify why eddyfi technologies eca technology is best suited for. Eddy Current Gear Inspection.

From www.youtube.com

227 Eddy Current Inspection Inline Integration YouTube Eddy Current Gear Inspection Eddy current array (eca) technology is the next stage in ect. Eddy current testing is often used to replace chemical testing processes such as dye penetrant and magnetic particle inspection for crack testing, and cutting and acid etch testing to. This paper describes the use of combining combined eddy current array (eca) and alternating current field measurement (acfm) to. Here. Eddy Current Gear Inspection.

From tecscan.ca

Automated Eddy Current Testing Systems TecScan Eddy Current Gear Inspection Eddy current testing is often used to replace chemical testing processes such as dye penetrant and magnetic particle inspection for crack testing, and cutting and acid etch testing to. Eddy current array (eca) technology is the next stage in ect. This article compares eddy current array (eca) with phased array ultrasonic testing to clearly identify why eddyfi technologies eca technology. Eddy Current Gear Inspection.

From present5.com

EDDY CURRENT TESTING Introduction l l This Eddy Current Gear Inspection Here are the top five industries that use electromagnetic testing, with specific applications covered for each one. This paper describes the use of combining combined eddy current array (eca) and alternating current field measurement (acfm) to. Eddy current array (eca) technology is the next stage in ect. Eddy current testing (ect) finds applications across a wide range of industries, helping. Eddy Current Gear Inspection.

From www.qualitymag.com

What Is Eddy Current Testing? 20161101 Quality Magazine Eddy Current Gear Inspection Here are the top five industries that use electromagnetic testing, with specific applications covered for each one. This paper describes the use of combining combined eddy current array (eca) and alternating current field measurement (acfm) to. Eddy current array (eca) technology is the next stage in ect. This article compares eddy current array (eca) with phased array ultrasonic testing to. Eddy Current Gear Inspection.

From www.youtube.com

Eddy Current Bore Hole Inspection YouTube Eddy Current Gear Inspection Eddy current testing is often used to replace chemical testing processes such as dye penetrant and magnetic particle inspection for crack testing, and cutting and acid etch testing to. Eddy current array (eca) technology is the next stage in ect. This paper describes the use of combining combined eddy current array (eca) and alternating current field measurement (acfm) to. This. Eddy Current Gear Inspection.