Shaft Bending Measurement . Shaft design involves calculating the dimensions and specifications for mechanical shafts used to transmit power and support axial and radial. Determine the diameter for the solid round shaft 450 mm long, as shown in figure. Shaft deflection has to be considered when designing seal grooves and extrusion gap clearance. Measurements using bonded resistance strain gages. The bending moments on a shaft can be determined by shear and bending moment diagrams. In present work, basing upon a classic measuring system at low cost composed of a displacement sensor, a lever and a shaft. We will introduce considerations that affect the accuracy of this measurement and. For pure bending, we will apply the load directly on the shaft at point c ( shown in figure 2 ), and we will measure strains in gage.

from www.mdpi.com

The bending moments on a shaft can be determined by shear and bending moment diagrams. Determine the diameter for the solid round shaft 450 mm long, as shown in figure. In present work, basing upon a classic measuring system at low cost composed of a displacement sensor, a lever and a shaft. We will introduce considerations that affect the accuracy of this measurement and. Shaft deflection has to be considered when designing seal grooves and extrusion gap clearance. Shaft design involves calculating the dimensions and specifications for mechanical shafts used to transmit power and support axial and radial. Measurements using bonded resistance strain gages. For pure bending, we will apply the load directly on the shaft at point c ( shown in figure 2 ), and we will measure strains in gage.

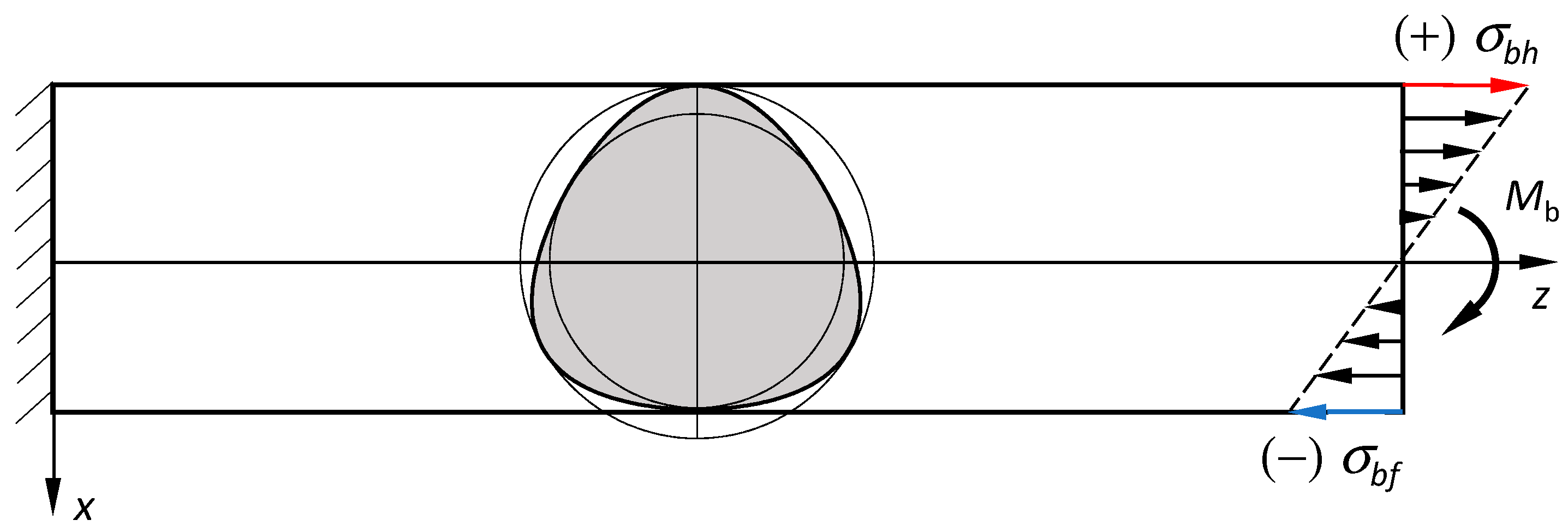

Eng Free FullText Bending and Torsional Stress Factors in Hypotrochoidal HProfiled Shafts

Shaft Bending Measurement In present work, basing upon a classic measuring system at low cost composed of a displacement sensor, a lever and a shaft. Determine the diameter for the solid round shaft 450 mm long, as shown in figure. In present work, basing upon a classic measuring system at low cost composed of a displacement sensor, a lever and a shaft. Measurements using bonded resistance strain gages. The bending moments on a shaft can be determined by shear and bending moment diagrams. Shaft deflection has to be considered when designing seal grooves and extrusion gap clearance. For pure bending, we will apply the load directly on the shaft at point c ( shown in figure 2 ), and we will measure strains in gage. Shaft design involves calculating the dimensions and specifications for mechanical shafts used to transmit power and support axial and radial. We will introduce considerations that affect the accuracy of this measurement and.

From www.youtube.com

Design of Shafts subjected to Bending Moment only Shafts Machine Design YouTube Shaft Bending Measurement In present work, basing upon a classic measuring system at low cost composed of a displacement sensor, a lever and a shaft. Shaft deflection has to be considered when designing seal grooves and extrusion gap clearance. Shaft design involves calculating the dimensions and specifications for mechanical shafts used to transmit power and support axial and radial. We will introduce considerations. Shaft Bending Measurement.

From brabon.org

shaft alignment bearing load Brabon Engineering Services Shaft Bending Measurement The bending moments on a shaft can be determined by shear and bending moment diagrams. Determine the diameter for the solid round shaft 450 mm long, as shown in figure. Measurements using bonded resistance strain gages. Shaft design involves calculating the dimensions and specifications for mechanical shafts used to transmit power and support axial and radial. Shaft deflection has to. Shaft Bending Measurement.

From simutechgroup.com

Torsional Vibration Measurements Testing & Analysis Consulting Shaft Bending Measurement Shaft deflection has to be considered when designing seal grooves and extrusion gap clearance. In present work, basing upon a classic measuring system at low cost composed of a displacement sensor, a lever and a shaft. For pure bending, we will apply the load directly on the shaft at point c ( shown in figure 2 ), and we will. Shaft Bending Measurement.

From www.researchgate.net

Schematic diagram of the shaft bending deformation. Download Scientific Diagram Shaft Bending Measurement Shaft deflection has to be considered when designing seal grooves and extrusion gap clearance. We will introduce considerations that affect the accuracy of this measurement and. Measurements using bonded resistance strain gages. Determine the diameter for the solid round shaft 450 mm long, as shown in figure. For pure bending, we will apply the load directly on the shaft at. Shaft Bending Measurement.

From www.slideserve.com

PPT Shaft Design PowerPoint Presentation, free download ID3955524 Shaft Bending Measurement We will introduce considerations that affect the accuracy of this measurement and. Shaft design involves calculating the dimensions and specifications for mechanical shafts used to transmit power and support axial and radial. The bending moments on a shaft can be determined by shear and bending moment diagrams. For pure bending, we will apply the load directly on the shaft at. Shaft Bending Measurement.

From planm8.io

How to Conduct a Crankshaft Deflection Measurement Shaft Bending Measurement For pure bending, we will apply the load directly on the shaft at point c ( shown in figure 2 ), and we will measure strains in gage. Shaft deflection has to be considered when designing seal grooves and extrusion gap clearance. Shaft design involves calculating the dimensions and specifications for mechanical shafts used to transmit power and support axial. Shaft Bending Measurement.

From www.researchgate.net

Method used to calculate lead/lag shaft deflection along the Y axis of... Download Scientific Shaft Bending Measurement Determine the diameter for the solid round shaft 450 mm long, as shown in figure. We will introduce considerations that affect the accuracy of this measurement and. The bending moments on a shaft can be determined by shear and bending moment diagrams. Shaft deflection has to be considered when designing seal grooves and extrusion gap clearance. For pure bending, we. Shaft Bending Measurement.

From www.youtube.com

example of bending stress, bending in shafts YouTube Shaft Bending Measurement The bending moments on a shaft can be determined by shear and bending moment diagrams. Shaft deflection has to be considered when designing seal grooves and extrusion gap clearance. Determine the diameter for the solid round shaft 450 mm long, as shown in figure. Measurements using bonded resistance strain gages. In present work, basing upon a classic measuring system at. Shaft Bending Measurement.

From www.youtube.com

Design of shaft subjected to twisting moment and bending moment PART 1 YouTube Shaft Bending Measurement Shaft design involves calculating the dimensions and specifications for mechanical shafts used to transmit power and support axial and radial. Measurements using bonded resistance strain gages. For pure bending, we will apply the load directly on the shaft at point c ( shown in figure 2 ), and we will measure strains in gage. Determine the diameter for the solid. Shaft Bending Measurement.

From www.researchgate.net

(A) For stiffness measurements of the kinocilium shaft in bending,... Download Scientific Diagram Shaft Bending Measurement For pure bending, we will apply the load directly on the shaft at point c ( shown in figure 2 ), and we will measure strains in gage. Shaft deflection has to be considered when designing seal grooves and extrusion gap clearance. Measurements using bonded resistance strain gages. Shaft design involves calculating the dimensions and specifications for mechanical shafts used. Shaft Bending Measurement.

From www.reddit.com

Bending moment in a gear shaft r/MechanicalEngineering Shaft Bending Measurement We will introduce considerations that affect the accuracy of this measurement and. In present work, basing upon a classic measuring system at low cost composed of a displacement sensor, a lever and a shaft. The bending moments on a shaft can be determined by shear and bending moment diagrams. For pure bending, we will apply the load directly on the. Shaft Bending Measurement.

From www.cesdb.com

MITCalc Shafts Shafts Design and Calculation Spreadsheet Shaft Bending Measurement Shaft design involves calculating the dimensions and specifications for mechanical shafts used to transmit power and support axial and radial. Measurements using bonded resistance strain gages. We will introduce considerations that affect the accuracy of this measurement and. For pure bending, we will apply the load directly on the shaft at point c ( shown in figure 2 ), and. Shaft Bending Measurement.

From www.youtube.com

shaft subjected to combined bending and twisting moment YouTube Shaft Bending Measurement In present work, basing upon a classic measuring system at low cost composed of a displacement sensor, a lever and a shaft. Measurements using bonded resistance strain gages. Shaft design involves calculating the dimensions and specifications for mechanical shafts used to transmit power and support axial and radial. We will introduce considerations that affect the accuracy of this measurement and.. Shaft Bending Measurement.

From www.researchgate.net

6. Prototype Shaft Bending Moment Diagram Download Scientific Diagram Shaft Bending Measurement The bending moments on a shaft can be determined by shear and bending moment diagrams. Shaft deflection has to be considered when designing seal grooves and extrusion gap clearance. Determine the diameter for the solid round shaft 450 mm long, as shown in figure. Measurements using bonded resistance strain gages. Shaft design involves calculating the dimensions and specifications for mechanical. Shaft Bending Measurement.

From www.mathworks.com

Shaft with torsional and bending compliance MATLAB Shaft Bending Measurement The bending moments on a shaft can be determined by shear and bending moment diagrams. Shaft design involves calculating the dimensions and specifications for mechanical shafts used to transmit power and support axial and radial. Shaft deflection has to be considered when designing seal grooves and extrusion gap clearance. Measurements using bonded resistance strain gages. In present work, basing upon. Shaft Bending Measurement.

From www.youtube.com

DTI to measure deflection of splined shaft YouTube Shaft Bending Measurement Measurements using bonded resistance strain gages. We will introduce considerations that affect the accuracy of this measurement and. The bending moments on a shaft can be determined by shear and bending moment diagrams. For pure bending, we will apply the load directly on the shaft at point c ( shown in figure 2 ), and we will measure strains in. Shaft Bending Measurement.

From www.researchgate.net

Shaft displacement due to shrink fitting and bending load (a)... Download Scientific Diagram Shaft Bending Measurement The bending moments on a shaft can be determined by shear and bending moment diagrams. Measurements using bonded resistance strain gages. For pure bending, we will apply the load directly on the shaft at point c ( shown in figure 2 ), and we will measure strains in gage. Shaft deflection has to be considered when designing seal grooves and. Shaft Bending Measurement.

From www.researchgate.net

A simplified inplane model of the shaft bending fatigue testing... Download Scientific Diagram Shaft Bending Measurement Determine the diameter for the solid round shaft 450 mm long, as shown in figure. Shaft deflection has to be considered when designing seal grooves and extrusion gap clearance. In present work, basing upon a classic measuring system at low cost composed of a displacement sensor, a lever and a shaft. The bending moments on a shaft can be determined. Shaft Bending Measurement.

From www.iims.org.uk

Engine Crankshaft Deflection Measurement Guide IIMS Shaft Bending Measurement In present work, basing upon a classic measuring system at low cost composed of a displacement sensor, a lever and a shaft. Shaft deflection has to be considered when designing seal grooves and extrusion gap clearance. Measurements using bonded resistance strain gages. Shaft design involves calculating the dimensions and specifications for mechanical shafts used to transmit power and support axial. Shaft Bending Measurement.

From www.researchgate.net

Shaft bending stress measurement as a function of blade position Download Scientific Diagram Shaft Bending Measurement In present work, basing upon a classic measuring system at low cost composed of a displacement sensor, a lever and a shaft. The bending moments on a shaft can be determined by shear and bending moment diagrams. Determine the diameter for the solid round shaft 450 mm long, as shown in figure. Shaft design involves calculating the dimensions and specifications. Shaft Bending Measurement.

From www.youtube.com

Follow Lesson 11 Shafts Bending Moment YouTube Shaft Bending Measurement We will introduce considerations that affect the accuracy of this measurement and. For pure bending, we will apply the load directly on the shaft at point c ( shown in figure 2 ), and we will measure strains in gage. Shaft design involves calculating the dimensions and specifications for mechanical shafts used to transmit power and support axial and radial.. Shaft Bending Measurement.

From www.youtube.com

Lesson 11 Shafts Bending Moment YouTube Shaft Bending Measurement We will introduce considerations that affect the accuracy of this measurement and. Measurements using bonded resistance strain gages. In present work, basing upon a classic measuring system at low cost composed of a displacement sensor, a lever and a shaft. The bending moments on a shaft can be determined by shear and bending moment diagrams. Shaft design involves calculating the. Shaft Bending Measurement.

From www.researchgate.net

Schematic of the setup used to measure the oarshaft’s deflection from... Download Scientific Shaft Bending Measurement Determine the diameter for the solid round shaft 450 mm long, as shown in figure. The bending moments on a shaft can be determined by shear and bending moment diagrams. Shaft design involves calculating the dimensions and specifications for mechanical shafts used to transmit power and support axial and radial. In present work, basing upon a classic measuring system at. Shaft Bending Measurement.

From www.researchgate.net

Shaft Dimensions and Material Properties for Bending/Torsion Analysis... Download Table Shaft Bending Measurement The bending moments on a shaft can be determined by shear and bending moment diagrams. Determine the diameter for the solid round shaft 450 mm long, as shown in figure. Shaft design involves calculating the dimensions and specifications for mechanical shafts used to transmit power and support axial and radial. For pure bending, we will apply the load directly on. Shaft Bending Measurement.

From www.slideserve.com

PPT Design of Shaft PowerPoint Presentation, free download ID9464321 Shaft Bending Measurement In present work, basing upon a classic measuring system at low cost composed of a displacement sensor, a lever and a shaft. Determine the diameter for the solid round shaft 450 mm long, as shown in figure. The bending moments on a shaft can be determined by shear and bending moment diagrams. Shaft deflection has to be considered when designing. Shaft Bending Measurement.

From askltd.co.jp

Shafts ASK Shaft Bending Measurement Determine the diameter for the solid round shaft 450 mm long, as shown in figure. Shaft deflection has to be considered when designing seal grooves and extrusion gap clearance. For pure bending, we will apply the load directly on the shaft at point c ( shown in figure 2 ), and we will measure strains in gage. Shaft design involves. Shaft Bending Measurement.

From www.researchgate.net

(a) Captured image of bend radius measurement in a customized LABVIEW... Download Scientific Shaft Bending Measurement Determine the diameter for the solid round shaft 450 mm long, as shown in figure. The bending moments on a shaft can be determined by shear and bending moment diagrams. For pure bending, we will apply the load directly on the shaft at point c ( shown in figure 2 ), and we will measure strains in gage. Shaft deflection. Shaft Bending Measurement.

From www.civilology.com

Table1Measurementofbendingdimensions2 Civilology Shaft Bending Measurement The bending moments on a shaft can be determined by shear and bending moment diagrams. Determine the diameter for the solid round shaft 450 mm long, as shown in figure. Measurements using bonded resistance strain gages. We will introduce considerations that affect the accuracy of this measurement and. In present work, basing upon a classic measuring system at low cost. Shaft Bending Measurement.

From www.civilology.com

Table1Measurementofbendingdimensions5 Civilology Shaft Bending Measurement We will introduce considerations that affect the accuracy of this measurement and. Shaft deflection has to be considered when designing seal grooves and extrusion gap clearance. In present work, basing upon a classic measuring system at low cost composed of a displacement sensor, a lever and a shaft. Shaft design involves calculating the dimensions and specifications for mechanical shafts used. Shaft Bending Measurement.

From extrudesign.com

How to calculate Shaft Diameter under Twisting and Bending Moment? Shaft Bending Measurement The bending moments on a shaft can be determined by shear and bending moment diagrams. Measurements using bonded resistance strain gages. We will introduce considerations that affect the accuracy of this measurement and. Shaft deflection has to be considered when designing seal grooves and extrusion gap clearance. Shaft design involves calculating the dimensions and specifications for mechanical shafts used to. Shaft Bending Measurement.

From www.civilology.com

Table1Measurementofbendingdimensions8 Civilology Shaft Bending Measurement In present work, basing upon a classic measuring system at low cost composed of a displacement sensor, a lever and a shaft. For pure bending, we will apply the load directly on the shaft at point c ( shown in figure 2 ), and we will measure strains in gage. Shaft deflection has to be considered when designing seal grooves. Shaft Bending Measurement.

From dokumen.tips

(PDF) A COMPARISON OF SHAFT DEFLECTION MEASUREMENTS … · A COMPARISON OF SHAFT DEFLECTION Shaft Bending Measurement Determine the diameter for the solid round shaft 450 mm long, as shown in figure. The bending moments on a shaft can be determined by shear and bending moment diagrams. In present work, basing upon a classic measuring system at low cost composed of a displacement sensor, a lever and a shaft. We will introduce considerations that affect the accuracy. Shaft Bending Measurement.

From extrudesign.com

How to calculate Shaft Diameter under Twisting and Bending Moment? Shaft Bending Measurement For pure bending, we will apply the load directly on the shaft at point c ( shown in figure 2 ), and we will measure strains in gage. Shaft design involves calculating the dimensions and specifications for mechanical shafts used to transmit power and support axial and radial. Shaft deflection has to be considered when designing seal grooves and extrusion. Shaft Bending Measurement.

From www.researchgate.net

Shaft bending unbalance force. Download Scientific Diagram Shaft Bending Measurement The bending moments on a shaft can be determined by shear and bending moment diagrams. In present work, basing upon a classic measuring system at low cost composed of a displacement sensor, a lever and a shaft. Shaft deflection has to be considered when designing seal grooves and extrusion gap clearance. Shaft design involves calculating the dimensions and specifications for. Shaft Bending Measurement.

From www.mdpi.com

Eng Free FullText Bending and Torsional Stress Factors in Hypotrochoidal HProfiled Shafts Shaft Bending Measurement For pure bending, we will apply the load directly on the shaft at point c ( shown in figure 2 ), and we will measure strains in gage. We will introduce considerations that affect the accuracy of this measurement and. In present work, basing upon a classic measuring system at low cost composed of a displacement sensor, a lever and. Shaft Bending Measurement.