What Is Grade In Grinding Wheel . From a (soft) to z (hard), determines how tightly the bond holds the abrasive. Strong bonds, or hard grades, are recommended for soft materials, small or narrow areas of contact, or longer wheel life. Today’s discussion revolves around grinding wheels, where we’ll dissect their materials, bonds, grain sizes, grades,. Grinding wheels, regardless of their manufacturer, are made up of three main components: A to h for softer structure, i to p for moderately hard. Lower grit numbers indicate coarser abrasives suitable for material removal, while higher grit numbers result in finer finishes. Soft grade wheels are used for rapid. Aluminum oxide, silicon carbide, zirconia,.

from www.eaglesuperabrasives.com

A to h for softer structure, i to p for moderately hard. Grinding wheels, regardless of their manufacturer, are made up of three main components: Today’s discussion revolves around grinding wheels, where we’ll dissect their materials, bonds, grain sizes, grades,. Aluminum oxide, silicon carbide, zirconia,. Soft grade wheels are used for rapid. From a (soft) to z (hard), determines how tightly the bond holds the abrasive. Lower grit numbers indicate coarser abrasives suitable for material removal, while higher grit numbers result in finer finishes. Strong bonds, or hard grades, are recommended for soft materials, small or narrow areas of contact, or longer wheel life.

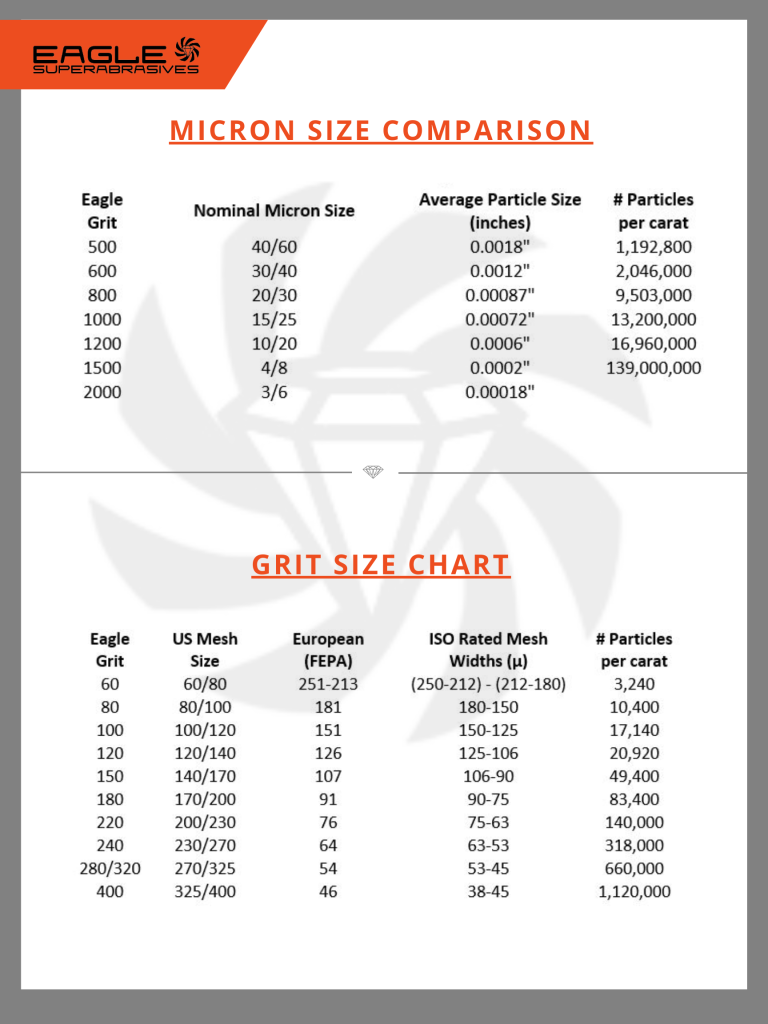

Grinding Wheel Mesh FEPA Grit Sizes

What Is Grade In Grinding Wheel Grinding wheels, regardless of their manufacturer, are made up of three main components: Soft grade wheels are used for rapid. Aluminum oxide, silicon carbide, zirconia,. Lower grit numbers indicate coarser abrasives suitable for material removal, while higher grit numbers result in finer finishes. Today’s discussion revolves around grinding wheels, where we’ll dissect their materials, bonds, grain sizes, grades,. Strong bonds, or hard grades, are recommended for soft materials, small or narrow areas of contact, or longer wheel life. From a (soft) to z (hard), determines how tightly the bond holds the abrasive. Grinding wheels, regardless of their manufacturer, are made up of three main components: A to h for softer structure, i to p for moderately hard.

From dizz.com

Grinding WheelDefinition, Material, Function, Grades, Types, Specification What Is Grade In Grinding Wheel From a (soft) to z (hard), determines how tightly the bond holds the abrasive. Strong bonds, or hard grades, are recommended for soft materials, small or narrow areas of contact, or longer wheel life. A to h for softer structure, i to p for moderately hard. Lower grit numbers indicate coarser abrasives suitable for material removal, while higher grit numbers. What Is Grade In Grinding Wheel.

From www.ebay.com.au

Professional Grade Grinding Wheel Correction Tool Set of 6 Dressers eBay What Is Grade In Grinding Wheel Lower grit numbers indicate coarser abrasives suitable for material removal, while higher grit numbers result in finer finishes. Today’s discussion revolves around grinding wheels, where we’ll dissect their materials, bonds, grain sizes, grades,. Strong bonds, or hard grades, are recommended for soft materials, small or narrow areas of contact, or longer wheel life. From a (soft) to z (hard), determines. What Is Grade In Grinding Wheel.

From www.youtube.com

grinding wheel Standard Marking System grinding wheel types Standard System Metal Cutting What Is Grade In Grinding Wheel Lower grit numbers indicate coarser abrasives suitable for material removal, while higher grit numbers result in finer finishes. Today’s discussion revolves around grinding wheels, where we’ll dissect their materials, bonds, grain sizes, grades,. A to h for softer structure, i to p for moderately hard. From a (soft) to z (hard), determines how tightly the bond holds the abrasive. Grinding. What Is Grade In Grinding Wheel.

From www.walmart.com

Professional Grade Grinding Wheel Precise Cutting for Granite Stone Marble Masonry Concrete What Is Grade In Grinding Wheel Aluminum oxide, silicon carbide, zirconia,. Strong bonds, or hard grades, are recommended for soft materials, small or narrow areas of contact, or longer wheel life. Soft grade wheels are used for rapid. Lower grit numbers indicate coarser abrasives suitable for material removal, while higher grit numbers result in finer finishes. From a (soft) to z (hard), determines how tightly the. What Is Grade In Grinding Wheel.

From learnmechanical.com

Grinding Wheel Definition, Types, Grain, Grade, Structure, Bond, Specifications, and Selection What Is Grade In Grinding Wheel Aluminum oxide, silicon carbide, zirconia,. Grinding wheels, regardless of their manufacturer, are made up of three main components: Soft grade wheels are used for rapid. Strong bonds, or hard grades, are recommended for soft materials, small or narrow areas of contact, or longer wheel life. From a (soft) to z (hard), determines how tightly the bond holds the abrasive. A. What Is Grade In Grinding Wheel.

From agrindtool.com

Grinding Wheel Speed Chart What Is Grade In Grinding Wheel A to h for softer structure, i to p for moderately hard. Today’s discussion revolves around grinding wheels, where we’ll dissect their materials, bonds, grain sizes, grades,. Aluminum oxide, silicon carbide, zirconia,. Grinding wheels, regardless of their manufacturer, are made up of three main components: Lower grit numbers indicate coarser abrasives suitable for material removal, while higher grit numbers result. What Is Grade In Grinding Wheel.

From www.sparkyabrasives.com

Understanding Grinding Wheel Hardness Sparky Abrasives What Is Grade In Grinding Wheel Strong bonds, or hard grades, are recommended for soft materials, small or narrow areas of contact, or longer wheel life. Soft grade wheels are used for rapid. A to h for softer structure, i to p for moderately hard. Lower grit numbers indicate coarser abrasives suitable for material removal, while higher grit numbers result in finer finishes. Today’s discussion revolves. What Is Grade In Grinding Wheel.

From www.delungrinding.com

China grinding wheel grade chart manufacturers, grinding wheel grade chart suppliers, grinding What Is Grade In Grinding Wheel A to h for softer structure, i to p for moderately hard. Strong bonds, or hard grades, are recommended for soft materials, small or narrow areas of contact, or longer wheel life. Grinding wheels, regardless of their manufacturer, are made up of three main components: Lower grit numbers indicate coarser abrasives suitable for material removal, while higher grit numbers result. What Is Grade In Grinding Wheel.

From www.pinterest.com

5 in. 60 Grit Grinding Wheel Grind, Used wheels, Grit What Is Grade In Grinding Wheel Aluminum oxide, silicon carbide, zirconia,. Lower grit numbers indicate coarser abrasives suitable for material removal, while higher grit numbers result in finer finishes. Strong bonds, or hard grades, are recommended for soft materials, small or narrow areas of contact, or longer wheel life. Today’s discussion revolves around grinding wheels, where we’ll dissect their materials, bonds, grain sizes, grades,. Soft grade. What Is Grade In Grinding Wheel.

From www.tradeindia.com

Diamond Abrasive Grade 5mm Thick 5 Inch Round Grinding Wheel at Best Price in Bengaluru V R What Is Grade In Grinding Wheel Aluminum oxide, silicon carbide, zirconia,. Soft grade wheels are used for rapid. Strong bonds, or hard grades, are recommended for soft materials, small or narrow areas of contact, or longer wheel life. Lower grit numbers indicate coarser abrasives suitable for material removal, while higher grit numbers result in finer finishes. A to h for softer structure, i to p for. What Is Grade In Grinding Wheel.

From mechanicalsphere.blogspot.com

Mechanical Minds KNOW HOW TO DECODE GRADE OF GRINDING WHEEL What Is Grade In Grinding Wheel Strong bonds, or hard grades, are recommended for soft materials, small or narrow areas of contact, or longer wheel life. From a (soft) to z (hard), determines how tightly the bond holds the abrasive. A to h for softer structure, i to p for moderately hard. Lower grit numbers indicate coarser abrasives suitable for material removal, while higher grit numbers. What Is Grade In Grinding Wheel.

From www.residencestyle.com

How to Choose From the Different Types of Grinding Wheels? » Residence Style What Is Grade In Grinding Wheel Grinding wheels, regardless of their manufacturer, are made up of three main components: From a (soft) to z (hard), determines how tightly the bond holds the abrasive. A to h for softer structure, i to p for moderately hard. Strong bonds, or hard grades, are recommended for soft materials, small or narrow areas of contact, or longer wheel life. Soft. What Is Grade In Grinding Wheel.

From www.delungrinding.com

China grinding wheel grade chart manufacturers, grinding wheel grade chart suppliers, grinding What Is Grade In Grinding Wheel Aluminum oxide, silicon carbide, zirconia,. Soft grade wheels are used for rapid. Strong bonds, or hard grades, are recommended for soft materials, small or narrow areas of contact, or longer wheel life. From a (soft) to z (hard), determines how tightly the bond holds the abrasive. Today’s discussion revolves around grinding wheels, where we’ll dissect their materials, bonds, grain sizes,. What Is Grade In Grinding Wheel.

From mechanicalsphere.blogspot.com

Mechanical Minds KNOW HOW TO DECODE GRADE OF GRINDING WHEEL What Is Grade In Grinding Wheel Strong bonds, or hard grades, are recommended for soft materials, small or narrow areas of contact, or longer wheel life. Today’s discussion revolves around grinding wheels, where we’ll dissect their materials, bonds, grain sizes, grades,. Soft grade wheels are used for rapid. A to h for softer structure, i to p for moderately hard. Lower grit numbers indicate coarser abrasives. What Is Grade In Grinding Wheel.

From www.youtube.com

Grinding Wheel Selection Grinding Methods Types of Grinding Grinding Machines Grinding What Is Grade In Grinding Wheel Strong bonds, or hard grades, are recommended for soft materials, small or narrow areas of contact, or longer wheel life. Grinding wheels, regardless of their manufacturer, are made up of three main components: A to h for softer structure, i to p for moderately hard. From a (soft) to z (hard), determines how tightly the bond holds the abrasive. Aluminum. What Is Grade In Grinding Wheel.

From www.eaglesuperabrasives.com

Grinding Wheel Mesh FEPA Grit Sizes What Is Grade In Grinding Wheel Grinding wheels, regardless of their manufacturer, are made up of three main components: Aluminum oxide, silicon carbide, zirconia,. Soft grade wheels are used for rapid. A to h for softer structure, i to p for moderately hard. Today’s discussion revolves around grinding wheels, where we’ll dissect their materials, bonds, grain sizes, grades,. From a (soft) to z (hard), determines how. What Is Grade In Grinding Wheel.

From www.forturetools.com

How to read a grinding wheel's specification Forture Tools What Is Grade In Grinding Wheel Strong bonds, or hard grades, are recommended for soft materials, small or narrow areas of contact, or longer wheel life. From a (soft) to z (hard), determines how tightly the bond holds the abrasive. Today’s discussion revolves around grinding wheels, where we’ll dissect their materials, bonds, grain sizes, grades,. A to h for softer structure, i to p for moderately. What Is Grade In Grinding Wheel.

From finemetalworking.com

Surface Grinding Wheels Types and Specification What Is Grade In Grinding Wheel Today’s discussion revolves around grinding wheels, where we’ll dissect their materials, bonds, grain sizes, grades,. Grinding wheels, regardless of their manufacturer, are made up of three main components: Strong bonds, or hard grades, are recommended for soft materials, small or narrow areas of contact, or longer wheel life. A to h for softer structure, i to p for moderately hard.. What Is Grade In Grinding Wheel.

From www.youtube.com

grinding wheel specifications explained (English) YouTube What Is Grade In Grinding Wheel Aluminum oxide, silicon carbide, zirconia,. Soft grade wheels are used for rapid. Strong bonds, or hard grades, are recommended for soft materials, small or narrow areas of contact, or longer wheel life. Lower grit numbers indicate coarser abrasives suitable for material removal, while higher grit numbers result in finer finishes. From a (soft) to z (hard), determines how tightly the. What Is Grade In Grinding Wheel.

From www.indiamart.com

NORTON,CUMI Grinding Wheels, For Heavy Duty Work, ABRASIVE Grade ABRASIVE at Rs 45/piece in What Is Grade In Grinding Wheel Aluminum oxide, silicon carbide, zirconia,. Soft grade wheels are used for rapid. Strong bonds, or hard grades, are recommended for soft materials, small or narrow areas of contact, or longer wheel life. Grinding wheels, regardless of their manufacturer, are made up of three main components: Lower grit numbers indicate coarser abrasives suitable for material removal, while higher grit numbers result. What Is Grade In Grinding Wheel.

From www.shakedeal.com

How to choose the right grinding wheel? What Is Grade In Grinding Wheel Grinding wheels, regardless of their manufacturer, are made up of three main components: A to h for softer structure, i to p for moderately hard. Today’s discussion revolves around grinding wheels, where we’ll dissect their materials, bonds, grain sizes, grades,. Strong bonds, or hard grades, are recommended for soft materials, small or narrow areas of contact, or longer wheel life.. What Is Grade In Grinding Wheel.

From forturetools.com

Five characteristics of a grinding wheel you have to know Forture Tools What Is Grade In Grinding Wheel A to h for softer structure, i to p for moderately hard. Strong bonds, or hard grades, are recommended for soft materials, small or narrow areas of contact, or longer wheel life. Aluminum oxide, silicon carbide, zirconia,. From a (soft) to z (hard), determines how tightly the bond holds the abrasive. Lower grit numbers indicate coarser abrasives suitable for material. What Is Grade In Grinding Wheel.

From www.youtube.com

Standard Marking System of Grinding Wheel Designation of Grinding Wheel YouTube What Is Grade In Grinding Wheel A to h for softer structure, i to p for moderately hard. Grinding wheels, regardless of their manufacturer, are made up of three main components: Strong bonds, or hard grades, are recommended for soft materials, small or narrow areas of contact, or longer wheel life. Lower grit numbers indicate coarser abrasives suitable for material removal, while higher grit numbers result. What Is Grade In Grinding Wheel.

From www.homedepot.ca

Forney Industries Bench Grinding Wheel, 6 inch x 3/4 inch x 1 inch The Home Depot Canada What Is Grade In Grinding Wheel Aluminum oxide, silicon carbide, zirconia,. Grinding wheels, regardless of their manufacturer, are made up of three main components: Soft grade wheels are used for rapid. Today’s discussion revolves around grinding wheels, where we’ll dissect their materials, bonds, grain sizes, grades,. A to h for softer structure, i to p for moderately hard. Strong bonds, or hard grades, are recommended for. What Is Grade In Grinding Wheel.

From www.extremeabrasives.com

Cutting and Grinding Wheels Application Guide Archives Extreme Abrasives Extreme Abrasives What Is Grade In Grinding Wheel Aluminum oxide, silicon carbide, zirconia,. Lower grit numbers indicate coarser abrasives suitable for material removal, while higher grit numbers result in finer finishes. Soft grade wheels are used for rapid. From a (soft) to z (hard), determines how tightly the bond holds the abrasive. Grinding wheels, regardless of their manufacturer, are made up of three main components: Today’s discussion revolves. What Is Grade In Grinding Wheel.

From forturetools.com

Grit chart of grinding wheels Forture Tools What Is Grade In Grinding Wheel A to h for softer structure, i to p for moderately hard. Aluminum oxide, silicon carbide, zirconia,. Grinding wheels, regardless of their manufacturer, are made up of three main components: Soft grade wheels are used for rapid. Today’s discussion revolves around grinding wheels, where we’ll dissect their materials, bonds, grain sizes, grades,. Lower grit numbers indicate coarser abrasives suitable for. What Is Grade In Grinding Wheel.

From www.bibielle.co.uk

Bibielle UK Grinding Wheels What Is Grade In Grinding Wheel Grinding wheels, regardless of their manufacturer, are made up of three main components: Aluminum oxide, silicon carbide, zirconia,. From a (soft) to z (hard), determines how tightly the bond holds the abrasive. A to h for softer structure, i to p for moderately hard. Lower grit numbers indicate coarser abrasives suitable for material removal, while higher grit numbers result in. What Is Grade In Grinding Wheel.

From www.farmacologiaactual.com

Order online NEW GENERAL INDUSTRIAL DIAMOND GRINDING WHEEL 180 GRIT 1/8" WIDE X 5" USA MADE What Is Grade In Grinding Wheel Soft grade wheels are used for rapid. Lower grit numbers indicate coarser abrasives suitable for material removal, while higher grit numbers result in finer finishes. Today’s discussion revolves around grinding wheels, where we’ll dissect their materials, bonds, grain sizes, grades,. Strong bonds, or hard grades, are recommended for soft materials, small or narrow areas of contact, or longer wheel life.. What Is Grade In Grinding Wheel.

From www.kroger.com

Norton Fine Grade Grinding Wheel, 6 x 3/4 in Kroger What Is Grade In Grinding Wheel Lower grit numbers indicate coarser abrasives suitable for material removal, while higher grit numbers result in finer finishes. From a (soft) to z (hard), determines how tightly the bond holds the abrasive. Strong bonds, or hard grades, are recommended for soft materials, small or narrow areas of contact, or longer wheel life. A to h for softer structure, i to. What Is Grade In Grinding Wheel.

From testbook.com

Grinding MCQ [Free PDF] Objective Question Answer for Grinding Quiz Download Now! What Is Grade In Grinding Wheel A to h for softer structure, i to p for moderately hard. Soft grade wheels are used for rapid. Aluminum oxide, silicon carbide, zirconia,. From a (soft) to z (hard), determines how tightly the bond holds the abrasive. Lower grit numbers indicate coarser abrasives suitable for material removal, while higher grit numbers result in finer finishes. Today’s discussion revolves around. What Is Grade In Grinding Wheel.

From www.grainger.com

NORTON Type 6 Aluminum Oxide Straight Cup Grinding Wheel, 5 in, 1 1/2 in Thickness, 60 Abrasive What Is Grade In Grinding Wheel Strong bonds, or hard grades, are recommended for soft materials, small or narrow areas of contact, or longer wheel life. Lower grit numbers indicate coarser abrasives suitable for material removal, while higher grit numbers result in finer finishes. Aluminum oxide, silicon carbide, zirconia,. Today’s discussion revolves around grinding wheels, where we’ll dissect their materials, bonds, grain sizes, grades,. A to. What Is Grade In Grinding Wheel.

From www.ediamondtools.com

Diamond Grinding Wheels for Concrete Grinding Polishing EDiamondTools What Is Grade In Grinding Wheel A to h for softer structure, i to p for moderately hard. Strong bonds, or hard grades, are recommended for soft materials, small or narrow areas of contact, or longer wheel life. Today’s discussion revolves around grinding wheels, where we’ll dissect their materials, bonds, grain sizes, grades,. Aluminum oxide, silicon carbide, zirconia,. Soft grade wheels are used for rapid. From. What Is Grade In Grinding Wheel.

From www.mscdirect.com

Norton Surface Grinding Wheel 12" Dia, 11/2" Thick, 5" Hole, 46 Grit, I Hardness 00391128 What Is Grade In Grinding Wheel Today’s discussion revolves around grinding wheels, where we’ll dissect their materials, bonds, grain sizes, grades,. Lower grit numbers indicate coarser abrasives suitable for material removal, while higher grit numbers result in finer finishes. From a (soft) to z (hard), determines how tightly the bond holds the abrasive. A to h for softer structure, i to p for moderately hard. Aluminum. What Is Grade In Grinding Wheel.

From www.forturetools.com

Abrasives grit size Forture Tools What Is Grade In Grinding Wheel Aluminum oxide, silicon carbide, zirconia,. Lower grit numbers indicate coarser abrasives suitable for material removal, while higher grit numbers result in finer finishes. Grinding wheels, regardless of their manufacturer, are made up of three main components: From a (soft) to z (hard), determines how tightly the bond holds the abrasive. Today’s discussion revolves around grinding wheels, where we’ll dissect their. What Is Grade In Grinding Wheel.

From www.pinnaxis.com

Grinding WheelDefinition, Material, Grit, Grades,, 56 OFF What Is Grade In Grinding Wheel Grinding wheels, regardless of their manufacturer, are made up of three main components: From a (soft) to z (hard), determines how tightly the bond holds the abrasive. Lower grit numbers indicate coarser abrasives suitable for material removal, while higher grit numbers result in finer finishes. A to h for softer structure, i to p for moderately hard. Soft grade wheels. What Is Grade In Grinding Wheel.