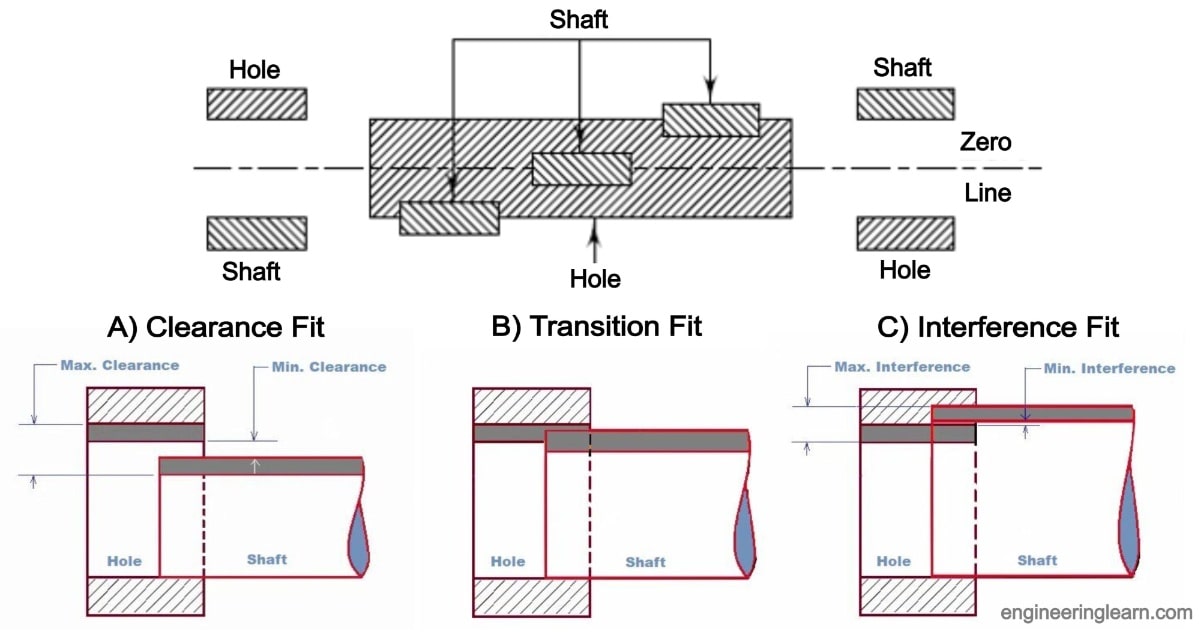

Fitting Definition In Engineering . A fit system is a way of specifying how much clearance or interference there is between two parts that are supposed to fit together. Fit is the general term used to signify the relative degree of tightness or looseness of assembled parts, which decides the relative movement. The three types of fits are clearance fit, interference fit, and transition fit. Interference fits are ideal for situations where a permanent and tight connection between components is required. In engineering, a fit refers to the clearance between two mating parts. Limits are the extreme boundaries of acceptable dimensions and fits determine. The choice of an engineering fit determines whether the. A hole is a component’s internal feature that is cylindrical or not, while a shaft is a component’s external feature that is cylindrical or not. Tolerance in engineering or engineering tolerance is the acceptable variation in a specific measurement from the base. What are limits and fits? Dive deep into the world of fitting:

from engineeringlearn.com

The three types of fits are clearance fit, interference fit, and transition fit. Tolerance in engineering or engineering tolerance is the acceptable variation in a specific measurement from the base. The choice of an engineering fit determines whether the. Limits are the extreme boundaries of acceptable dimensions and fits determine. A hole is a component’s internal feature that is cylindrical or not, while a shaft is a component’s external feature that is cylindrical or not. A fit system is a way of specifying how much clearance or interference there is between two parts that are supposed to fit together. Dive deep into the world of fitting: Fit is the general term used to signify the relative degree of tightness or looseness of assembled parts, which decides the relative movement. What are limits and fits? Interference fits are ideal for situations where a permanent and tight connection between components is required.

3 Types of Fits Clearance Fit, Interference Fit, Transition Fit

Fitting Definition In Engineering In engineering, a fit refers to the clearance between two mating parts. The three types of fits are clearance fit, interference fit, and transition fit. Fit is the general term used to signify the relative degree of tightness or looseness of assembled parts, which decides the relative movement. A fit system is a way of specifying how much clearance or interference there is between two parts that are supposed to fit together. What are limits and fits? A hole is a component’s internal feature that is cylindrical or not, while a shaft is a component’s external feature that is cylindrical or not. Limits are the extreme boundaries of acceptable dimensions and fits determine. Dive deep into the world of fitting: The choice of an engineering fit determines whether the. In engineering, a fit refers to the clearance between two mating parts. Tolerance in engineering or engineering tolerance is the acceptable variation in a specific measurement from the base. Interference fits are ideal for situations where a permanent and tight connection between components is required.

From varsity.taalct.co.za

Mechanical Engineering Fitting & Turning Varsity Fitting Definition In Engineering The choice of an engineering fit determines whether the. The three types of fits are clearance fit, interference fit, and transition fit. Limits are the extreme boundaries of acceptable dimensions and fits determine. A fit system is a way of specifying how much clearance or interference there is between two parts that are supposed to fit together. Fit is the. Fitting Definition In Engineering.

From www.rapiddirect.com

Types of Fits How to Choose the Right Fits in Engineering RapidDirect Fitting Definition In Engineering Dive deep into the world of fitting: The choice of an engineering fit determines whether the. A hole is a component’s internal feature that is cylindrical or not, while a shaft is a component’s external feature that is cylindrical or not. Tolerance in engineering or engineering tolerance is the acceptable variation in a specific measurement from the base. Fit is. Fitting Definition In Engineering.

From www.youtube.com

How to read piping isometric drawing, Pipe fitter training, Watch the Fitting Definition In Engineering A hole is a component’s internal feature that is cylindrical or not, while a shaft is a component’s external feature that is cylindrical or not. Dive deep into the world of fitting: In engineering, a fit refers to the clearance between two mating parts. Interference fits are ideal for situations where a permanent and tight connection between components is required.. Fitting Definition In Engineering.

From themechanicalengineering.com

Types of Fit Clearance Fit, Transition Fit, and Interference Fit Fitting Definition In Engineering What are limits and fits? In engineering, a fit refers to the clearance between two mating parts. Dive deep into the world of fitting: A fit system is a way of specifying how much clearance or interference there is between two parts that are supposed to fit together. Interference fits are ideal for situations where a permanent and tight connection. Fitting Definition In Engineering.

From hxeolbyzs.blob.core.windows.net

Machine Tool Fitter Definition at June Petrie blog Fitting Definition In Engineering Tolerance in engineering or engineering tolerance is the acceptable variation in a specific measurement from the base. The choice of an engineering fit determines whether the. The three types of fits are clearance fit, interference fit, and transition fit. Interference fits are ideal for situations where a permanent and tight connection between components is required. In engineering, a fit refers. Fitting Definition In Engineering.

From www.youtube.com

Northlink College Fitting and Turning YouTube Fitting Definition In Engineering Limits are the extreme boundaries of acceptable dimensions and fits determine. Dive deep into the world of fitting: A hole is a component’s internal feature that is cylindrical or not, while a shaft is a component’s external feature that is cylindrical or not. What are limits and fits? Fit is the general term used to signify the relative degree of. Fitting Definition In Engineering.

From www.maharashtradirectory.com

Pipes and Pipe Fittings, Maharashtra, India. Fitting Definition In Engineering The three types of fits are clearance fit, interference fit, and transition fit. Interference fits are ideal for situations where a permanent and tight connection between components is required. The choice of an engineering fit determines whether the. A fit system is a way of specifying how much clearance or interference there is between two parts that are supposed to. Fitting Definition In Engineering.

From www.slideserve.com

PPT Curve Fitting PowerPoint Presentation, free download ID5389966 Fitting Definition In Engineering A hole is a component’s internal feature that is cylindrical or not, while a shaft is a component’s external feature that is cylindrical or not. Tolerance in engineering or engineering tolerance is the acceptable variation in a specific measurement from the base. Dive deep into the world of fitting: Interference fits are ideal for situations where a permanent and tight. Fitting Definition In Engineering.

From www.multyskill.co.za

Mechanical Fitting Course Multi Skill Training Centre Fitting Definition In Engineering Dive deep into the world of fitting: A fit system is a way of specifying how much clearance or interference there is between two parts that are supposed to fit together. Fit is the general term used to signify the relative degree of tightness or looseness of assembled parts, which decides the relative movement. A hole is a component’s internal. Fitting Definition In Engineering.

From www.educationalstuffs.in

FITTING Parts of file, materials, classification of files Fitting Definition In Engineering The three types of fits are clearance fit, interference fit, and transition fit. Interference fits are ideal for situations where a permanent and tight connection between components is required. A fit system is a way of specifying how much clearance or interference there is between two parts that are supposed to fit together. Limits are the extreme boundaries of acceptable. Fitting Definition In Engineering.

From oilandgaselectricalandinstrumentation.blogspot.com

OIL AND GAS ELECTRICAL AND INSTRUMENTATION ENGINEERING CABLE TRAY Fitting Definition In Engineering Dive deep into the world of fitting: Fit is the general term used to signify the relative degree of tightness or looseness of assembled parts, which decides the relative movement. In engineering, a fit refers to the clearance between two mating parts. Limits are the extreme boundaries of acceptable dimensions and fits determine. What are limits and fits? A fit. Fitting Definition In Engineering.

From www.enggarena.net

3 Types of Fits Clearance Fit, Transition Fit And Interference Fit Fitting Definition In Engineering Fit is the general term used to signify the relative degree of tightness or looseness of assembled parts, which decides the relative movement. Dive deep into the world of fitting: In engineering, a fit refers to the clearance between two mating parts. The choice of an engineering fit determines whether the. The three types of fits are clearance fit, interference. Fitting Definition In Engineering.

From www.youtube.com

Точение штуцера(turning fitting) YouTube Fitting Definition In Engineering Dive deep into the world of fitting: Tolerance in engineering or engineering tolerance is the acceptable variation in a specific measurement from the base. Interference fits are ideal for situations where a permanent and tight connection between components is required. A fit system is a way of specifying how much clearance or interference there is between two parts that are. Fitting Definition In Engineering.

From dictionary.langeek.co

Definition & Meaning of "Pipe fitter" LanGeek Fitting Definition In Engineering Dive deep into the world of fitting: Tolerance in engineering or engineering tolerance is the acceptable variation in a specific measurement from the base. A fit system is a way of specifying how much clearance or interference there is between two parts that are supposed to fit together. Limits are the extreme boundaries of acceptable dimensions and fits determine. Fit. Fitting Definition In Engineering.

From wallpapersafari.com

🔥 [50+] Engineering Wallpapers 1080p WallpaperSafari Fitting Definition In Engineering The three types of fits are clearance fit, interference fit, and transition fit. A hole is a component’s internal feature that is cylindrical or not, while a shaft is a component’s external feature that is cylindrical or not. What are limits and fits? Fit is the general term used to signify the relative degree of tightness or looseness of assembled. Fitting Definition In Engineering.

From www.youtube.com

Fittings 101 NPT & NPTF YouTube Fitting Definition In Engineering The three types of fits are clearance fit, interference fit, and transition fit. Tolerance in engineering or engineering tolerance is the acceptable variation in a specific measurement from the base. Fit is the general term used to signify the relative degree of tightness or looseness of assembled parts, which decides the relative movement. Interference fits are ideal for situations where. Fitting Definition In Engineering.

From m2engineering.co.za

Fitting & Turning M2 Engineering Fitting Definition In Engineering A fit system is a way of specifying how much clearance or interference there is between two parts that are supposed to fit together. The choice of an engineering fit determines whether the. Limits are the extreme boundaries of acceptable dimensions and fits determine. Interference fits are ideal for situations where a permanent and tight connection between components is required.. Fitting Definition In Engineering.

From engineeringlearn.com

3 Types of Fits Clearance Fit, Interference Fit, Transition Fit Fitting Definition In Engineering A hole is a component’s internal feature that is cylindrical or not, while a shaft is a component’s external feature that is cylindrical or not. Fit is the general term used to signify the relative degree of tightness or looseness of assembled parts, which decides the relative movement. The choice of an engineering fit determines whether the. In engineering, a. Fitting Definition In Engineering.

From www.youtube.com

Tools used in Fitting Shop YouTube Fitting Definition In Engineering A hole is a component’s internal feature that is cylindrical or not, while a shaft is a component’s external feature that is cylindrical or not. A fit system is a way of specifying how much clearance or interference there is between two parts that are supposed to fit together. In engineering, a fit refers to the clearance between two mating. Fitting Definition In Engineering.

From hxeolbyzs.blob.core.windows.net

Machine Tool Fitter Definition at June Petrie blog Fitting Definition In Engineering Tolerance in engineering or engineering tolerance is the acceptable variation in a specific measurement from the base. In engineering, a fit refers to the clearance between two mating parts. What are limits and fits? A hole is a component’s internal feature that is cylindrical or not, while a shaft is a component’s external feature that is cylindrical or not. The. Fitting Definition In Engineering.

From www.ikonet.com

house > plumbing > fittings > examples of fittings image Visual Fitting Definition In Engineering A fit system is a way of specifying how much clearance or interference there is between two parts that are supposed to fit together. Tolerance in engineering or engineering tolerance is the acceptable variation in a specific measurement from the base. A hole is a component’s internal feature that is cylindrical or not, while a shaft is a component’s external. Fitting Definition In Engineering.

From worksol.pl

Work for an Industrial pipeline fitter in Poland Worksol Fitting Definition In Engineering The choice of an engineering fit determines whether the. Dive deep into the world of fitting: Fit is the general term used to signify the relative degree of tightness or looseness of assembled parts, which decides the relative movement. A fit system is a way of specifying how much clearance or interference there is between two parts that are supposed. Fitting Definition In Engineering.

From www.youtube.com

[English] Types of Pipe Fittings YouTube Fitting Definition In Engineering The choice of an engineering fit determines whether the. Fit is the general term used to signify the relative degree of tightness or looseness of assembled parts, which decides the relative movement. Dive deep into the world of fitting: A fit system is a way of specifying how much clearance or interference there is between two parts that are supposed. Fitting Definition In Engineering.

From hxeolbyzs.blob.core.windows.net

Machine Tool Fitter Definition at June Petrie blog Fitting Definition In Engineering The three types of fits are clearance fit, interference fit, and transition fit. Limits are the extreme boundaries of acceptable dimensions and fits determine. Interference fits are ideal for situations where a permanent and tight connection between components is required. A fit system is a way of specifying how much clearance or interference there is between two parts that are. Fitting Definition In Engineering.

From m2engineering.co.za

Fitting & Turning M2 Engineering Fitting Definition In Engineering A hole is a component’s internal feature that is cylindrical or not, while a shaft is a component’s external feature that is cylindrical or not. Limits are the extreme boundaries of acceptable dimensions and fits determine. Interference fits are ideal for situations where a permanent and tight connection between components is required. In engineering, a fit refers to the clearance. Fitting Definition In Engineering.

From hydraulicfitting.cn

Japanese Hydraulic Fitting Definition, Types, and Difference Fitting Definition In Engineering In engineering, a fit refers to the clearance between two mating parts. A fit system is a way of specifying how much clearance or interference there is between two parts that are supposed to fit together. Interference fits are ideal for situations where a permanent and tight connection between components is required. A hole is a component’s internal feature that. Fitting Definition In Engineering.

From iminco.net

Mechanical Fitter Turner Operator Roma QLD iMINCO Mining Training Fitting Definition In Engineering Dive deep into the world of fitting: A fit system is a way of specifying how much clearance or interference there is between two parts that are supposed to fit together. Interference fits are ideal for situations where a permanent and tight connection between components is required. The three types of fits are clearance fit, interference fit, and transition fit.. Fitting Definition In Engineering.

From www.s10forum.com

anyone recognize thise fittings diagram??? S10 Forum Fitting Definition In Engineering Interference fits are ideal for situations where a permanent and tight connection between components is required. In engineering, a fit refers to the clearance between two mating parts. The three types of fits are clearance fit, interference fit, and transition fit. Dive deep into the world of fitting: Tolerance in engineering or engineering tolerance is the acceptable variation in a. Fitting Definition In Engineering.

From www.youtube.com

Fitting Theory Practice Mechanical Engineering YouTube Fitting Definition In Engineering The three types of fits are clearance fit, interference fit, and transition fit. What are limits and fits? In engineering, a fit refers to the clearance between two mating parts. A fit system is a way of specifying how much clearance or interference there is between two parts that are supposed to fit together. Interference fits are ideal for situations. Fitting Definition In Engineering.

From www.realfittings.com

Applications of High Pressure Fitting Real Engineering Fitting Definition In Engineering The choice of an engineering fit determines whether the. In engineering, a fit refers to the clearance between two mating parts. Tolerance in engineering or engineering tolerance is the acceptable variation in a specific measurement from the base. Dive deep into the world of fitting: What are limits and fits? Fit is the general term used to signify the relative. Fitting Definition In Engineering.

From www.educationalstuffs.in

FITTING Parts of file, materials, classification of files Fitting Definition In Engineering Limits are the extreme boundaries of acceptable dimensions and fits determine. Dive deep into the world of fitting: A hole is a component’s internal feature that is cylindrical or not, while a shaft is a component’s external feature that is cylindrical or not. Fit is the general term used to signify the relative degree of tightness or looseness of assembled. Fitting Definition In Engineering.

From varsity.taalct.co.za

Mechanical Engineering Fitting & Turning Varsity Fitting Definition In Engineering A fit system is a way of specifying how much clearance or interference there is between two parts that are supposed to fit together. The three types of fits are clearance fit, interference fit, and transition fit. In engineering, a fit refers to the clearance between two mating parts. The choice of an engineering fit determines whether the. Limits are. Fitting Definition In Engineering.

From fittertraining.com

Pipe Schedule thickness chart Pipe fittings' dimension chart Fitter Fitting Definition In Engineering In engineering, a fit refers to the clearance between two mating parts. The three types of fits are clearance fit, interference fit, and transition fit. A fit system is a way of specifying how much clearance or interference there is between two parts that are supposed to fit together. Limits are the extreme boundaries of acceptable dimensions and fits determine.. Fitting Definition In Engineering.

From www.youtube.com

आईटीआई फिटर FITTER TYPS OF FILE FULL DITAILS iti trade fitter full Fitting Definition In Engineering Tolerance in engineering or engineering tolerance is the acceptable variation in a specific measurement from the base. Interference fits are ideal for situations where a permanent and tight connection between components is required. The three types of fits are clearance fit, interference fit, and transition fit. Limits are the extreme boundaries of acceptable dimensions and fits determine. The choice of. Fitting Definition In Engineering.

From wallpapersafari.com

Mechanical Engineering Wallpaper WallpaperSafari Fitting Definition In Engineering Interference fits are ideal for situations where a permanent and tight connection between components is required. A hole is a component’s internal feature that is cylindrical or not, while a shaft is a component’s external feature that is cylindrical or not. Fit is the general term used to signify the relative degree of tightness or looseness of assembled parts, which. Fitting Definition In Engineering.