Laser Cleaning Epoxy . laser cleaning is based on laser ablation—the process of removing material mainly from a solid surface by irradiating it with a laser beam. Relying on laser cleaning technology, our cleaning solutions are tailored uniquely for epoxy surfaces. the purpose of this study was to determine the cleaning performance of epoxy paint according to process. Every material is composed of different molecular bonds that determine a specific ablation threshold—that is, the energy required to overcome the binding energy of the contaminant layer and. in this paper, the performance of two pulsed laser sources (70 w and 1,000 w) are compared after the removal of.

from www.emag.com

the purpose of this study was to determine the cleaning performance of epoxy paint according to process. laser cleaning is based on laser ablation—the process of removing material mainly from a solid surface by irradiating it with a laser beam. in this paper, the performance of two pulsed laser sources (70 w and 1,000 w) are compared after the removal of. Relying on laser cleaning technology, our cleaning solutions are tailored uniquely for epoxy surfaces. Every material is composed of different molecular bonds that determine a specific ablation threshold—that is, the energy required to overcome the binding energy of the contaminant layer and.

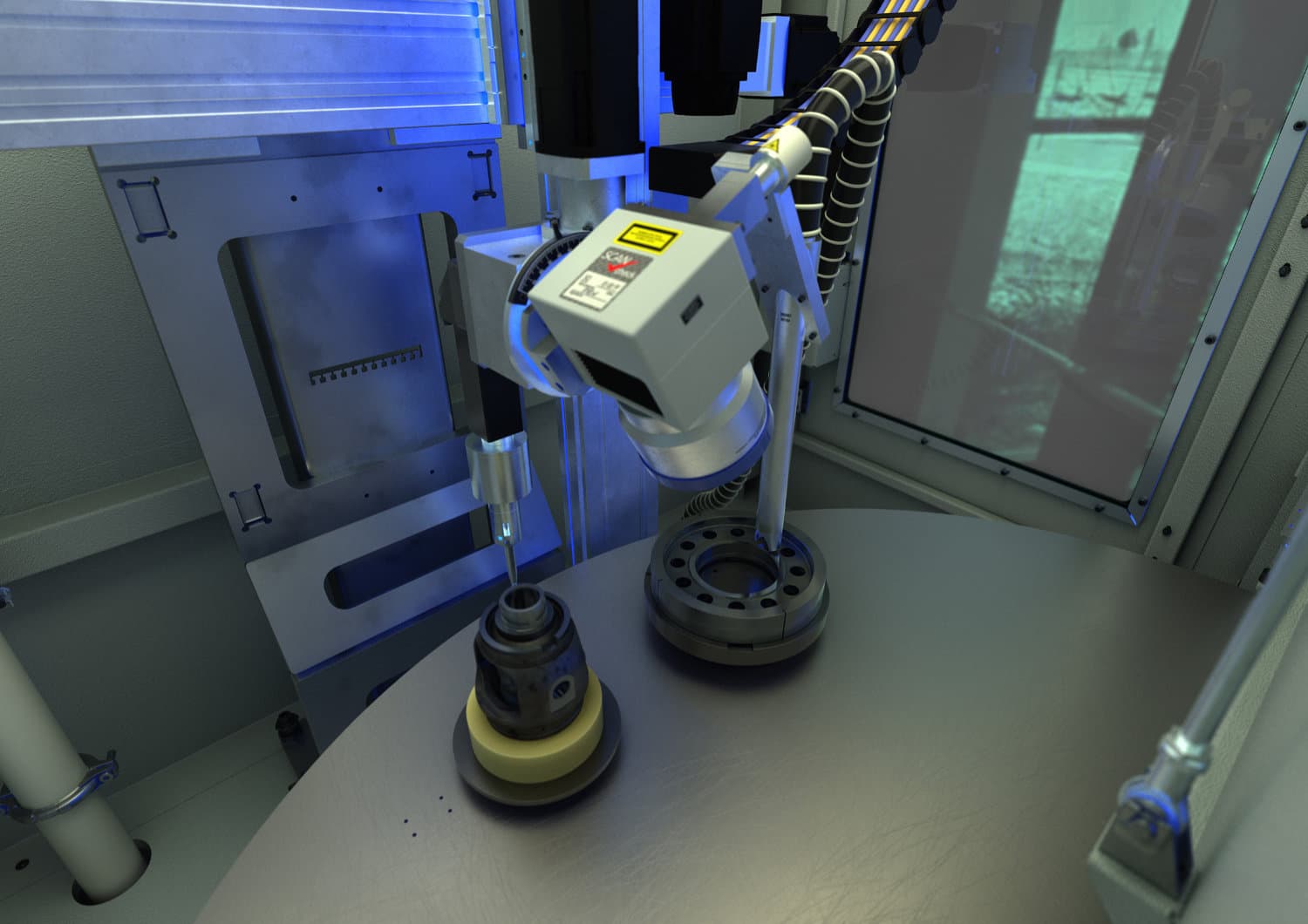

Laser cleaning with the LC 42 from EMAG LaserTec EMAG Group

Laser Cleaning Epoxy Every material is composed of different molecular bonds that determine a specific ablation threshold—that is, the energy required to overcome the binding energy of the contaminant layer and. laser cleaning is based on laser ablation—the process of removing material mainly from a solid surface by irradiating it with a laser beam. Relying on laser cleaning technology, our cleaning solutions are tailored uniquely for epoxy surfaces. the purpose of this study was to determine the cleaning performance of epoxy paint according to process. in this paper, the performance of two pulsed laser sources (70 w and 1,000 w) are compared after the removal of. Every material is composed of different molecular bonds that determine a specific ablation threshold—that is, the energy required to overcome the binding energy of the contaminant layer and.

From www.lasersystemseurope.com

The basics of laser cleaning Laser Systems Europe Laser Cleaning Epoxy in this paper, the performance of two pulsed laser sources (70 w and 1,000 w) are compared after the removal of. the purpose of this study was to determine the cleaning performance of epoxy paint according to process. laser cleaning is based on laser ablation—the process of removing material mainly from a solid surface by irradiating it. Laser Cleaning Epoxy.

From www.emag.com

Laser Cleaning Perfect Solutions from EMAG LaserTec Laser Cleaning Epoxy Relying on laser cleaning technology, our cleaning solutions are tailored uniquely for epoxy surfaces. Every material is composed of different molecular bonds that determine a specific ablation threshold—that is, the energy required to overcome the binding energy of the contaminant layer and. laser cleaning is based on laser ablation—the process of removing material mainly from a solid surface by. Laser Cleaning Epoxy.

From www.youtube.com

Three minutes to teach you how to correctly use HanTenCNC laser Laser Cleaning Epoxy in this paper, the performance of two pulsed laser sources (70 w and 1,000 w) are compared after the removal of. Relying on laser cleaning technology, our cleaning solutions are tailored uniquely for epoxy surfaces. laser cleaning is based on laser ablation—the process of removing material mainly from a solid surface by irradiating it with a laser beam.. Laser Cleaning Epoxy.

From www.laserswipecleaning.com

CARBONIZED LAYERS Removal with Laser Swipe2Clean Laser surface Laser Cleaning Epoxy laser cleaning is based on laser ablation—the process of removing material mainly from a solid surface by irradiating it with a laser beam. the purpose of this study was to determine the cleaning performance of epoxy paint according to process. in this paper, the performance of two pulsed laser sources (70 w and 1,000 w) are compared. Laser Cleaning Epoxy.

From exosvauka.blob.core.windows.net

Laser Ablation Cleaning System at Vera Flores blog Laser Cleaning Epoxy in this paper, the performance of two pulsed laser sources (70 w and 1,000 w) are compared after the removal of. Every material is composed of different molecular bonds that determine a specific ablation threshold—that is, the energy required to overcome the binding energy of the contaminant layer and. the purpose of this study was to determine the. Laser Cleaning Epoxy.

From www.punchlistzero.com

Laser Cleaning How it Works, Machines, and Alternatives Punchlist Zero Laser Cleaning Epoxy the purpose of this study was to determine the cleaning performance of epoxy paint according to process. Relying on laser cleaning technology, our cleaning solutions are tailored uniquely for epoxy surfaces. Every material is composed of different molecular bonds that determine a specific ablation threshold—that is, the energy required to overcome the binding energy of the contaminant layer and.. Laser Cleaning Epoxy.

From www.youtube.com

Laser Cleaning Compilation Part 2 Satisfying Surface Removals YouTube Laser Cleaning Epoxy in this paper, the performance of two pulsed laser sources (70 w and 1,000 w) are compared after the removal of. laser cleaning is based on laser ablation—the process of removing material mainly from a solid surface by irradiating it with a laser beam. the purpose of this study was to determine the cleaning performance of epoxy. Laser Cleaning Epoxy.

From laserlightray.com

Can you laser engrave epoxy resin? Laser Light Ray Laser Cleaning Epoxy laser cleaning is based on laser ablation—the process of removing material mainly from a solid surface by irradiating it with a laser beam. the purpose of this study was to determine the cleaning performance of epoxy paint according to process. in this paper, the performance of two pulsed laser sources (70 w and 1,000 w) are compared. Laser Cleaning Epoxy.

From www.p-laser.com

How does laser cleaning work PLaser Laser Cleaning Epoxy Every material is composed of different molecular bonds that determine a specific ablation threshold—that is, the energy required to overcome the binding energy of the contaminant layer and. the purpose of this study was to determine the cleaning performance of epoxy paint according to process. Relying on laser cleaning technology, our cleaning solutions are tailored uniquely for epoxy surfaces.. Laser Cleaning Epoxy.

From www.sdqy-laser.com

China Customized Laser Cleaning Epoxy Suppliers, Manufacturers Laser Cleaning Epoxy in this paper, the performance of two pulsed laser sources (70 w and 1,000 w) are compared after the removal of. Relying on laser cleaning technology, our cleaning solutions are tailored uniquely for epoxy surfaces. the purpose of this study was to determine the cleaning performance of epoxy paint according to process. laser cleaning is based on. Laser Cleaning Epoxy.

From www.emag.com

Laser cleaning with the LC 42 from EMAG LaserTec EMAG Group Laser Cleaning Epoxy Relying on laser cleaning technology, our cleaning solutions are tailored uniquely for epoxy surfaces. the purpose of this study was to determine the cleaning performance of epoxy paint according to process. in this paper, the performance of two pulsed laser sources (70 w and 1,000 w) are compared after the removal of. Every material is composed of different. Laser Cleaning Epoxy.

From laserresearch.net

LASER OPTICS CLEANING KITOPTIMIZES ENGRAVING & ETCHING PERFORMANCE Laser Cleaning Epoxy Relying on laser cleaning technology, our cleaning solutions are tailored uniquely for epoxy surfaces. Every material is composed of different molecular bonds that determine a specific ablation threshold—that is, the energy required to overcome the binding energy of the contaminant layer and. in this paper, the performance of two pulsed laser sources (70 w and 1,000 w) are compared. Laser Cleaning Epoxy.

From www.laser-master.com

How Laser Cleaning Works Laser Master Laser Cleaning Epoxy the purpose of this study was to determine the cleaning performance of epoxy paint according to process. Every material is composed of different molecular bonds that determine a specific ablation threshold—that is, the energy required to overcome the binding energy of the contaminant layer and. in this paper, the performance of two pulsed laser sources (70 w and. Laser Cleaning Epoxy.

From www.sltl.com

A Complete Guide on Laser Cleaning Applications SLTL Group® Laser Cleaning Epoxy Every material is composed of different molecular bonds that determine a specific ablation threshold—that is, the energy required to overcome the binding energy of the contaminant layer and. Relying on laser cleaning technology, our cleaning solutions are tailored uniquely for epoxy surfaces. the purpose of this study was to determine the cleaning performance of epoxy paint according to process.. Laser Cleaning Epoxy.

From www.alliedscientificpro.com

Laser Cleaning Machines LaserBlast TM Portable Laser Cleaning System Laser Cleaning Epoxy the purpose of this study was to determine the cleaning performance of epoxy paint according to process. laser cleaning is based on laser ablation—the process of removing material mainly from a solid surface by irradiating it with a laser beam. Every material is composed of different molecular bonds that determine a specific ablation threshold—that is, the energy required. Laser Cleaning Epoxy.

From blog.laserax.com

Laserax's Versatile Handheld Laser Cleaner Laser Cleaning Epoxy laser cleaning is based on laser ablation—the process of removing material mainly from a solid surface by irradiating it with a laser beam. in this paper, the performance of two pulsed laser sources (70 w and 1,000 w) are compared after the removal of. the purpose of this study was to determine the cleaning performance of epoxy. Laser Cleaning Epoxy.

From www.laser-master.com

Laser Cleaning Best Soot Remover solution for Wood Laser Master Laser Cleaning Epoxy Relying on laser cleaning technology, our cleaning solutions are tailored uniquely for epoxy surfaces. Every material is composed of different molecular bonds that determine a specific ablation threshold—that is, the energy required to overcome the binding energy of the contaminant layer and. laser cleaning is based on laser ablation—the process of removing material mainly from a solid surface by. Laser Cleaning Epoxy.

From www.epoxyandconcreteflooringla.com

How to Clean Epoxy Floors Laser Cleaning Epoxy Every material is composed of different molecular bonds that determine a specific ablation threshold—that is, the energy required to overcome the binding energy of the contaminant layer and. laser cleaning is based on laser ablation—the process of removing material mainly from a solid surface by irradiating it with a laser beam. the purpose of this study was to. Laser Cleaning Epoxy.

From www.sfxlyxc.com

SFX Laser Cleaner 2000w Metal Rust Removal Laser Cleaning Machine Fiber Laser Cleaning Epoxy Relying on laser cleaning technology, our cleaning solutions are tailored uniquely for epoxy surfaces. the purpose of this study was to determine the cleaning performance of epoxy paint according to process. laser cleaning is based on laser ablation—the process of removing material mainly from a solid surface by irradiating it with a laser beam. in this paper,. Laser Cleaning Epoxy.

From www.youtube.com

【レーザークリーニング除去事例⑥】金属上のエポキシ樹脂をクリーニング YouTube Laser Cleaning Epoxy the purpose of this study was to determine the cleaning performance of epoxy paint according to process. laser cleaning is based on laser ablation—the process of removing material mainly from a solid surface by irradiating it with a laser beam. Every material is composed of different molecular bonds that determine a specific ablation threshold—that is, the energy required. Laser Cleaning Epoxy.

From www.laser-master.com

LASER CLEANING How it works Laser Master Laser Cleaning Epoxy the purpose of this study was to determine the cleaning performance of epoxy paint according to process. laser cleaning is based on laser ablation—the process of removing material mainly from a solid surface by irradiating it with a laser beam. Every material is composed of different molecular bonds that determine a specific ablation threshold—that is, the energy required. Laser Cleaning Epoxy.

From www.youtube.com

How to Clean Epoxy Tools YouTube Laser Cleaning Epoxy the purpose of this study was to determine the cleaning performance of epoxy paint according to process. in this paper, the performance of two pulsed laser sources (70 w and 1,000 w) are compared after the removal of. Relying on laser cleaning technology, our cleaning solutions are tailored uniquely for epoxy surfaces. Every material is composed of different. Laser Cleaning Epoxy.

From www.youtube.com

Laser Cleaning Demo YouTube Laser Cleaning Epoxy Every material is composed of different molecular bonds that determine a specific ablation threshold—that is, the energy required to overcome the binding energy of the contaminant layer and. laser cleaning is based on laser ablation—the process of removing material mainly from a solid surface by irradiating it with a laser beam. in this paper, the performance of two. Laser Cleaning Epoxy.

From www.youtube.com

Demystifying 8 cleaning modes of pulse laser cleaning machine YouTube Laser Cleaning Epoxy Relying on laser cleaning technology, our cleaning solutions are tailored uniquely for epoxy surfaces. laser cleaning is based on laser ablation—the process of removing material mainly from a solid surface by irradiating it with a laser beam. Every material is composed of different molecular bonds that determine a specific ablation threshold—that is, the energy required to overcome the binding. Laser Cleaning Epoxy.

From makinamx.com

Makina® LASER CLEANING Laser Cleaning Epoxy laser cleaning is based on laser ablation—the process of removing material mainly from a solid surface by irradiating it with a laser beam. in this paper, the performance of two pulsed laser sources (70 w and 1,000 w) are compared after the removal of. Relying on laser cleaning technology, our cleaning solutions are tailored uniquely for epoxy surfaces.. Laser Cleaning Epoxy.

From www.p-laser.com

How does laser cleaning work? PLaser Laser Cleaning Epoxy Relying on laser cleaning technology, our cleaning solutions are tailored uniquely for epoxy surfaces. Every material is composed of different molecular bonds that determine a specific ablation threshold—that is, the energy required to overcome the binding energy of the contaminant layer and. laser cleaning is based on laser ablation—the process of removing material mainly from a solid surface by. Laser Cleaning Epoxy.

From cleanersadvisor.com

A Detailed Guide on How to Clean Epoxy Floors Cleaners Advisor Laser Cleaning Epoxy Relying on laser cleaning technology, our cleaning solutions are tailored uniquely for epoxy surfaces. laser cleaning is based on laser ablation—the process of removing material mainly from a solid surface by irradiating it with a laser beam. Every material is composed of different molecular bonds that determine a specific ablation threshold—that is, the energy required to overcome the binding. Laser Cleaning Epoxy.

From www.mdpi.com

Photonics Free FullText Substrate Cleaning Threshold for Various Laser Cleaning Epoxy in this paper, the performance of two pulsed laser sources (70 w and 1,000 w) are compared after the removal of. Every material is composed of different molecular bonds that determine a specific ablation threshold—that is, the energy required to overcome the binding energy of the contaminant layer and. the purpose of this study was to determine the. Laser Cleaning Epoxy.

From selfoy.com

How Do Laser Cleaning Machines Work? 4 Things To Know Laser Cleaning Epoxy the purpose of this study was to determine the cleaning performance of epoxy paint according to process. laser cleaning is based on laser ablation—the process of removing material mainly from a solid surface by irradiating it with a laser beam. Relying on laser cleaning technology, our cleaning solutions are tailored uniquely for epoxy surfaces. Every material is composed. Laser Cleaning Epoxy.

From www.emag.com

Laser cleaning with the LC 42 from EMAG LaserTec EMAG Group Laser Cleaning Epoxy the purpose of this study was to determine the cleaning performance of epoxy paint according to process. Every material is composed of different molecular bonds that determine a specific ablation threshold—that is, the energy required to overcome the binding energy of the contaminant layer and. laser cleaning is based on laser ablation—the process of removing material mainly from. Laser Cleaning Epoxy.

From www.technologycatalogue.com

Laser Cleaning Technology Catalogue Laser Cleaning Epoxy Every material is composed of different molecular bonds that determine a specific ablation threshold—that is, the energy required to overcome the binding energy of the contaminant layer and. the purpose of this study was to determine the cleaning performance of epoxy paint according to process. in this paper, the performance of two pulsed laser sources (70 w and. Laser Cleaning Epoxy.

From adapt-laser.com

How Laser Cleaning Works Adapt Laser Laser Cleaning Epoxy the purpose of this study was to determine the cleaning performance of epoxy paint according to process. Relying on laser cleaning technology, our cleaning solutions are tailored uniquely for epoxy surfaces. Every material is composed of different molecular bonds that determine a specific ablation threshold—that is, the energy required to overcome the binding energy of the contaminant layer and.. Laser Cleaning Epoxy.

From www.youtube.com

Top 10 Best Laser Cleaning Machine Review 2022 Best Handheld Laser Laser Cleaning Epoxy Relying on laser cleaning technology, our cleaning solutions are tailored uniquely for epoxy surfaces. Every material is composed of different molecular bonds that determine a specific ablation threshold—that is, the energy required to overcome the binding energy of the contaminant layer and. in this paper, the performance of two pulsed laser sources (70 w and 1,000 w) are compared. Laser Cleaning Epoxy.

From www.youtube.com

How To Clean Up Epoxy Resin YouTube Laser Cleaning Epoxy Relying on laser cleaning technology, our cleaning solutions are tailored uniquely for epoxy surfaces. Every material is composed of different molecular bonds that determine a specific ablation threshold—that is, the energy required to overcome the binding energy of the contaminant layer and. the purpose of this study was to determine the cleaning performance of epoxy paint according to process.. Laser Cleaning Epoxy.

From sdcnclaser.com

2022 Industrial laser cleaning machine selection guide Laser Cleaning Epoxy laser cleaning is based on laser ablation—the process of removing material mainly from a solid surface by irradiating it with a laser beam. the purpose of this study was to determine the cleaning performance of epoxy paint according to process. in this paper, the performance of two pulsed laser sources (70 w and 1,000 w) are compared. Laser Cleaning Epoxy.