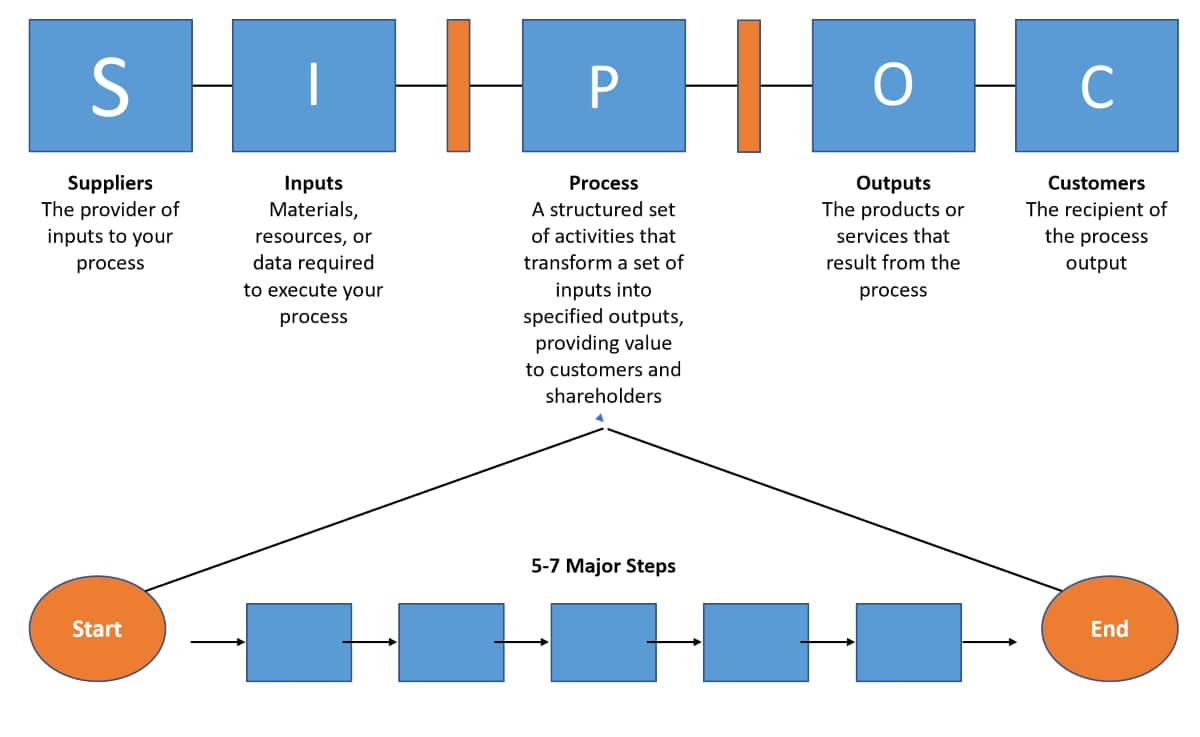

Supplier Input Process Output Customer Sipoc . Suppliers, inputs, process steps, outputs, and customers thereby offering a comprehensive visualization that aids in project scoping and stakeholder engagement. In lean six sigma and continuous improvement, a sipoc diagram is a useful tool for understanding processes. The supplier, input, process, output and customer (sipoc) matrix is one of the most important tools that must be used at the beginning of any six sigma project. In process improvement, sipoc or suppliers, inputs, process, outputs and customers (sometimes in the reversed order: A sipoc (suppliers, inputs, process, outputs, customers) diagram is a visual tool for documenting a business process from beginning to end prior to. Explore the power of sipoc (supplier, input, process, output, customer) in business process management.

from kyloot.com

In lean six sigma and continuous improvement, a sipoc diagram is a useful tool for understanding processes. In process improvement, sipoc or suppliers, inputs, process, outputs and customers (sometimes in the reversed order: Explore the power of sipoc (supplier, input, process, output, customer) in business process management. A sipoc (suppliers, inputs, process, outputs, customers) diagram is a visual tool for documenting a business process from beginning to end prior to. The supplier, input, process, output and customer (sipoc) matrix is one of the most important tools that must be used at the beginning of any six sigma project. Suppliers, inputs, process steps, outputs, and customers thereby offering a comprehensive visualization that aids in project scoping and stakeholder engagement.

What is a Workflow Diagram and How to Make One? (2022)

Supplier Input Process Output Customer Sipoc A sipoc (suppliers, inputs, process, outputs, customers) diagram is a visual tool for documenting a business process from beginning to end prior to. Explore the power of sipoc (supplier, input, process, output, customer) in business process management. In process improvement, sipoc or suppliers, inputs, process, outputs and customers (sometimes in the reversed order: In lean six sigma and continuous improvement, a sipoc diagram is a useful tool for understanding processes. The supplier, input, process, output and customer (sipoc) matrix is one of the most important tools that must be used at the beginning of any six sigma project. A sipoc (suppliers, inputs, process, outputs, customers) diagram is a visual tool for documenting a business process from beginning to end prior to. Suppliers, inputs, process steps, outputs, and customers thereby offering a comprehensive visualization that aids in project scoping and stakeholder engagement.

From www.slideteam.net

Sipoc Diagram Suppliers Inputs Process Output Customers Powerpoint Supplier Input Process Output Customer Sipoc A sipoc (suppliers, inputs, process, outputs, customers) diagram is a visual tool for documenting a business process from beginning to end prior to. The supplier, input, process, output and customer (sipoc) matrix is one of the most important tools that must be used at the beginning of any six sigma project. Suppliers, inputs, process steps, outputs, and customers thereby offering. Supplier Input Process Output Customer Sipoc.

From www.qimacros.com

SIPOC Diagram Excel Supplier Input Process Output Customer Supplier Input Process Output Customer Sipoc Suppliers, inputs, process steps, outputs, and customers thereby offering a comprehensive visualization that aids in project scoping and stakeholder engagement. The supplier, input, process, output and customer (sipoc) matrix is one of the most important tools that must be used at the beginning of any six sigma project. In process improvement, sipoc or suppliers, inputs, process, outputs and customers (sometimes. Supplier Input Process Output Customer Sipoc.

From leanscape.io

Understanding SIPOC A Comprehensive Guide for Businesses Supplier Input Process Output Customer Sipoc The supplier, input, process, output and customer (sipoc) matrix is one of the most important tools that must be used at the beginning of any six sigma project. Suppliers, inputs, process steps, outputs, and customers thereby offering a comprehensive visualization that aids in project scoping and stakeholder engagement. In process improvement, sipoc or suppliers, inputs, process, outputs and customers (sometimes. Supplier Input Process Output Customer Sipoc.

From cartoondealer.com

SIPOC Process Improvement Acronym Stands For Suppliers, Inputs, Process Supplier Input Process Output Customer Sipoc Explore the power of sipoc (supplier, input, process, output, customer) in business process management. In process improvement, sipoc or suppliers, inputs, process, outputs and customers (sometimes in the reversed order: The supplier, input, process, output and customer (sipoc) matrix is one of the most important tools that must be used at the beginning of any six sigma project. A sipoc. Supplier Input Process Output Customer Sipoc.

From www.marense.com

SIPOC, Process mapping, LSS, Lean Six Sigma Supplier Input Process Output Customer Sipoc Explore the power of sipoc (supplier, input, process, output, customer) in business process management. In process improvement, sipoc or suppliers, inputs, process, outputs and customers (sometimes in the reversed order: In lean six sigma and continuous improvement, a sipoc diagram is a useful tool for understanding processes. A sipoc (suppliers, inputs, process, outputs, customers) diagram is a visual tool for. Supplier Input Process Output Customer Sipoc.

From gbu-taganskij.ru

What Is SIPOC And How To Use Its Diagram? Definition, 49 OFF Supplier Input Process Output Customer Sipoc Suppliers, inputs, process steps, outputs, and customers thereby offering a comprehensive visualization that aids in project scoping and stakeholder engagement. The supplier, input, process, output and customer (sipoc) matrix is one of the most important tools that must be used at the beginning of any six sigma project. A sipoc (suppliers, inputs, process, outputs, customers) diagram is a visual tool. Supplier Input Process Output Customer Sipoc.

From easyba.co

suppliers, inputs, process, outputs, and customers (SIPOC) Business Supplier Input Process Output Customer Sipoc Explore the power of sipoc (supplier, input, process, output, customer) in business process management. Suppliers, inputs, process steps, outputs, and customers thereby offering a comprehensive visualization that aids in project scoping and stakeholder engagement. In process improvement, sipoc or suppliers, inputs, process, outputs and customers (sometimes in the reversed order: The supplier, input, process, output and customer (sipoc) matrix is. Supplier Input Process Output Customer Sipoc.

From www.scribd.com

SupplierInputProcessOutputCustomer (SIPOC) PDF Supply Chain Supplier Input Process Output Customer Sipoc Suppliers, inputs, process steps, outputs, and customers thereby offering a comprehensive visualization that aids in project scoping and stakeholder engagement. In process improvement, sipoc or suppliers, inputs, process, outputs and customers (sometimes in the reversed order: A sipoc (suppliers, inputs, process, outputs, customers) diagram is a visual tool for documenting a business process from beginning to end prior to. In. Supplier Input Process Output Customer Sipoc.

From www.techiequality.com

SIPOC Template Manufacturing Sector SIPOC Diagram Example Supplier Input Process Output Customer Sipoc Suppliers, inputs, process steps, outputs, and customers thereby offering a comprehensive visualization that aids in project scoping and stakeholder engagement. Explore the power of sipoc (supplier, input, process, output, customer) in business process management. A sipoc (suppliers, inputs, process, outputs, customers) diagram is a visual tool for documenting a business process from beginning to end prior to. In lean six. Supplier Input Process Output Customer Sipoc.

From www.dreamstime.com

SIPOC Process Improvement Acronym Stands for Suppliers, Inputs, Process Supplier Input Process Output Customer Sipoc The supplier, input, process, output and customer (sipoc) matrix is one of the most important tools that must be used at the beginning of any six sigma project. Suppliers, inputs, process steps, outputs, and customers thereby offering a comprehensive visualization that aids in project scoping and stakeholder engagement. In process improvement, sipoc or suppliers, inputs, process, outputs and customers (sometimes. Supplier Input Process Output Customer Sipoc.

From www.surajmech.com

SIPOC Diagram / Supplier Input Process Output Customer Supplier Input Process Output Customer Sipoc The supplier, input, process, output and customer (sipoc) matrix is one of the most important tools that must be used at the beginning of any six sigma project. Suppliers, inputs, process steps, outputs, and customers thereby offering a comprehensive visualization that aids in project scoping and stakeholder engagement. Explore the power of sipoc (supplier, input, process, output, customer) in business. Supplier Input Process Output Customer Sipoc.

From fullyexpanded.com

SIPOC SupplierInputProcessOutputCustomer meaning, definition Supplier Input Process Output Customer Sipoc In process improvement, sipoc or suppliers, inputs, process, outputs and customers (sometimes in the reversed order: Explore the power of sipoc (supplier, input, process, output, customer) in business process management. A sipoc (suppliers, inputs, process, outputs, customers) diagram is a visual tool for documenting a business process from beginning to end prior to. The supplier, input, process, output and customer. Supplier Input Process Output Customer Sipoc.

From www.slideshare.net

Sipoc Block Diagram 9 3 09 Supplier Input Process Output Customer Sipoc In process improvement, sipoc or suppliers, inputs, process, outputs and customers (sometimes in the reversed order: Explore the power of sipoc (supplier, input, process, output, customer) in business process management. The supplier, input, process, output and customer (sipoc) matrix is one of the most important tools that must be used at the beginning of any six sigma project. In lean. Supplier Input Process Output Customer Sipoc.

From online.visual-paradigm.com

SIPOC (Suppliers, Inputs, Process, Outputs, Customers) Archimate Supplier Input Process Output Customer Sipoc In process improvement, sipoc or suppliers, inputs, process, outputs and customers (sometimes in the reversed order: The supplier, input, process, output and customer (sipoc) matrix is one of the most important tools that must be used at the beginning of any six sigma project. Explore the power of sipoc (supplier, input, process, output, customer) in business process management. Suppliers, inputs,. Supplier Input Process Output Customer Sipoc.

From sipoc.info

Inputs SIPOC Diagrams Supplier Input Process Output Customer Sipoc In process improvement, sipoc or suppliers, inputs, process, outputs and customers (sometimes in the reversed order: A sipoc (suppliers, inputs, process, outputs, customers) diagram is a visual tool for documenting a business process from beginning to end prior to. Explore the power of sipoc (supplier, input, process, output, customer) in business process management. In lean six sigma and continuous improvement,. Supplier Input Process Output Customer Sipoc.

From eldonkao.com

Using the SIPOC Diagram Template Included — Eldon Kao Supplier Input Process Output Customer Sipoc Suppliers, inputs, process steps, outputs, and customers thereby offering a comprehensive visualization that aids in project scoping and stakeholder engagement. A sipoc (suppliers, inputs, process, outputs, customers) diagram is a visual tool for documenting a business process from beginning to end prior to. The supplier, input, process, output and customer (sipoc) matrix is one of the most important tools that. Supplier Input Process Output Customer Sipoc.

From www.dreamstime.com

SIPOC Process Improvement Acronym Stands for Suppliers, Inputs, Process Supplier Input Process Output Customer Sipoc The supplier, input, process, output and customer (sipoc) matrix is one of the most important tools that must be used at the beginning of any six sigma project. In lean six sigma and continuous improvement, a sipoc diagram is a useful tool for understanding processes. Suppliers, inputs, process steps, outputs, and customers thereby offering a comprehensive visualization that aids in. Supplier Input Process Output Customer Sipoc.

From www.vecteezy.com

SIPOC model stands for Suppliers, Inputs, Process, Outputs and Customer Supplier Input Process Output Customer Sipoc In process improvement, sipoc or suppliers, inputs, process, outputs and customers (sometimes in the reversed order: Suppliers, inputs, process steps, outputs, and customers thereby offering a comprehensive visualization that aids in project scoping and stakeholder engagement. A sipoc (suppliers, inputs, process, outputs, customers) diagram is a visual tool for documenting a business process from beginning to end prior to. The. Supplier Input Process Output Customer Sipoc.

From www.dreamstime.com

SIPOC Supplier Input Process Output Customer Infographics Stock Supplier Input Process Output Customer Sipoc Suppliers, inputs, process steps, outputs, and customers thereby offering a comprehensive visualization that aids in project scoping and stakeholder engagement. A sipoc (suppliers, inputs, process, outputs, customers) diagram is a visual tool for documenting a business process from beginning to end prior to. In lean six sigma and continuous improvement, a sipoc diagram is a useful tool for understanding processes.. Supplier Input Process Output Customer Sipoc.

From www.dreamstime.com

SIPOC Concept. Supplier Input Process Output Customer Stock Vector Supplier Input Process Output Customer Sipoc A sipoc (suppliers, inputs, process, outputs, customers) diagram is a visual tool for documenting a business process from beginning to end prior to. In lean six sigma and continuous improvement, a sipoc diagram is a useful tool for understanding processes. The supplier, input, process, output and customer (sipoc) matrix is one of the most important tools that must be used. Supplier Input Process Output Customer Sipoc.

From mychartguide.com

SIPOC Diagram Suppliers, Inputs, Process, Outputs, Customers My Supplier Input Process Output Customer Sipoc In lean six sigma and continuous improvement, a sipoc diagram is a useful tool for understanding processes. Explore the power of sipoc (supplier, input, process, output, customer) in business process management. A sipoc (suppliers, inputs, process, outputs, customers) diagram is a visual tool for documenting a business process from beginning to end prior to. Suppliers, inputs, process steps, outputs, and. Supplier Input Process Output Customer Sipoc.

From dokumen.tips

(PDF) SIPOC Diagram Edraw Max · Suppliers Inputs Process Outputs Supplier Input Process Output Customer Sipoc A sipoc (suppliers, inputs, process, outputs, customers) diagram is a visual tool for documenting a business process from beginning to end prior to. Suppliers, inputs, process steps, outputs, and customers thereby offering a comprehensive visualization that aids in project scoping and stakeholder engagement. The supplier, input, process, output and customer (sipoc) matrix is one of the most important tools that. Supplier Input Process Output Customer Sipoc.

From cartoondealer.com

SIPOC Process Improvement Acronym Stands For Suppliers, Inputs, Process Supplier Input Process Output Customer Sipoc Explore the power of sipoc (supplier, input, process, output, customer) in business process management. The supplier, input, process, output and customer (sipoc) matrix is one of the most important tools that must be used at the beginning of any six sigma project. In process improvement, sipoc or suppliers, inputs, process, outputs and customers (sometimes in the reversed order: In lean. Supplier Input Process Output Customer Sipoc.

From www.ba-guru.com

SIPOC Diagram How to bring Suppliers and Customers together Business Supplier Input Process Output Customer Sipoc A sipoc (suppliers, inputs, process, outputs, customers) diagram is a visual tool for documenting a business process from beginning to end prior to. Suppliers, inputs, process steps, outputs, and customers thereby offering a comprehensive visualization that aids in project scoping and stakeholder engagement. In lean six sigma and continuous improvement, a sipoc diagram is a useful tool for understanding processes.. Supplier Input Process Output Customer Sipoc.

From kyloot.com

What is a Workflow Diagram and How to Make One? (2022) Supplier Input Process Output Customer Sipoc In lean six sigma and continuous improvement, a sipoc diagram is a useful tool for understanding processes. Explore the power of sipoc (supplier, input, process, output, customer) in business process management. In process improvement, sipoc or suppliers, inputs, process, outputs and customers (sometimes in the reversed order: The supplier, input, process, output and customer (sipoc) matrix is one of the. Supplier Input Process Output Customer Sipoc.

From www.pinterest.com

SIPOC Suppliers, Inputs, Process, Outputs, Customers GoLeanSixSigma Supplier Input Process Output Customer Sipoc Explore the power of sipoc (supplier, input, process, output, customer) in business process management. A sipoc (suppliers, inputs, process, outputs, customers) diagram is a visual tool for documenting a business process from beginning to end prior to. In lean six sigma and continuous improvement, a sipoc diagram is a useful tool for understanding processes. In process improvement, sipoc or suppliers,. Supplier Input Process Output Customer Sipoc.

From www.slideteam.net

Customer Supplier Model With Inputs And Outputs Template Presentation Supplier Input Process Output Customer Sipoc A sipoc (suppliers, inputs, process, outputs, customers) diagram is a visual tool for documenting a business process from beginning to end prior to. Explore the power of sipoc (supplier, input, process, output, customer) in business process management. Suppliers, inputs, process steps, outputs, and customers thereby offering a comprehensive visualization that aids in project scoping and stakeholder engagement. In process improvement,. Supplier Input Process Output Customer Sipoc.

From www.researchgate.net

SIPOC (see online version for colours) Supplier(s) Inputs/Req'ts Supplier Input Process Output Customer Sipoc In process improvement, sipoc or suppliers, inputs, process, outputs and customers (sometimes in the reversed order: The supplier, input, process, output and customer (sipoc) matrix is one of the most important tools that must be used at the beginning of any six sigma project. A sipoc (suppliers, inputs, process, outputs, customers) diagram is a visual tool for documenting a business. Supplier Input Process Output Customer Sipoc.

From www.tpsearchtool.com

Sipoc Model Suppliers Inputs Process Outputs Customers Powerpoint Images Supplier Input Process Output Customer Sipoc Explore the power of sipoc (supplier, input, process, output, customer) in business process management. In lean six sigma and continuous improvement, a sipoc diagram is a useful tool for understanding processes. Suppliers, inputs, process steps, outputs, and customers thereby offering a comprehensive visualization that aids in project scoping and stakeholder engagement. The supplier, input, process, output and customer (sipoc) matrix. Supplier Input Process Output Customer Sipoc.

From www.youtube.com

SIPOC Diagram Suppliers, Input, Process, Output, and Customers Supplier Input Process Output Customer Sipoc Explore the power of sipoc (supplier, input, process, output, customer) in business process management. The supplier, input, process, output and customer (sipoc) matrix is one of the most important tools that must be used at the beginning of any six sigma project. In process improvement, sipoc or suppliers, inputs, process, outputs and customers (sometimes in the reversed order: A sipoc. Supplier Input Process Output Customer Sipoc.

From brunofuga.adv.br

Inputs And Outputs Sales brunofuga.adv.br Supplier Input Process Output Customer Sipoc In process improvement, sipoc or suppliers, inputs, process, outputs and customers (sometimes in the reversed order: The supplier, input, process, output and customer (sipoc) matrix is one of the most important tools that must be used at the beginning of any six sigma project. Suppliers, inputs, process steps, outputs, and customers thereby offering a comprehensive visualization that aids in project. Supplier Input Process Output Customer Sipoc.

From sanet.st

Sipoc Supplier, Input, Process, Output, Customer SoftArchive Supplier Input Process Output Customer Sipoc In process improvement, sipoc or suppliers, inputs, process, outputs and customers (sometimes in the reversed order: In lean six sigma and continuous improvement, a sipoc diagram is a useful tool for understanding processes. Suppliers, inputs, process steps, outputs, and customers thereby offering a comprehensive visualization that aids in project scoping and stakeholder engagement. Explore the power of sipoc (supplier, input,. Supplier Input Process Output Customer Sipoc.

From cartoondealer.com

SIPOC Process Improvement Acronym Stands For Suppliers, Inputs, Process Supplier Input Process Output Customer Sipoc The supplier, input, process, output and customer (sipoc) matrix is one of the most important tools that must be used at the beginning of any six sigma project. In process improvement, sipoc or suppliers, inputs, process, outputs and customers (sometimes in the reversed order: In lean six sigma and continuous improvement, a sipoc diagram is a useful tool for understanding. Supplier Input Process Output Customer Sipoc.