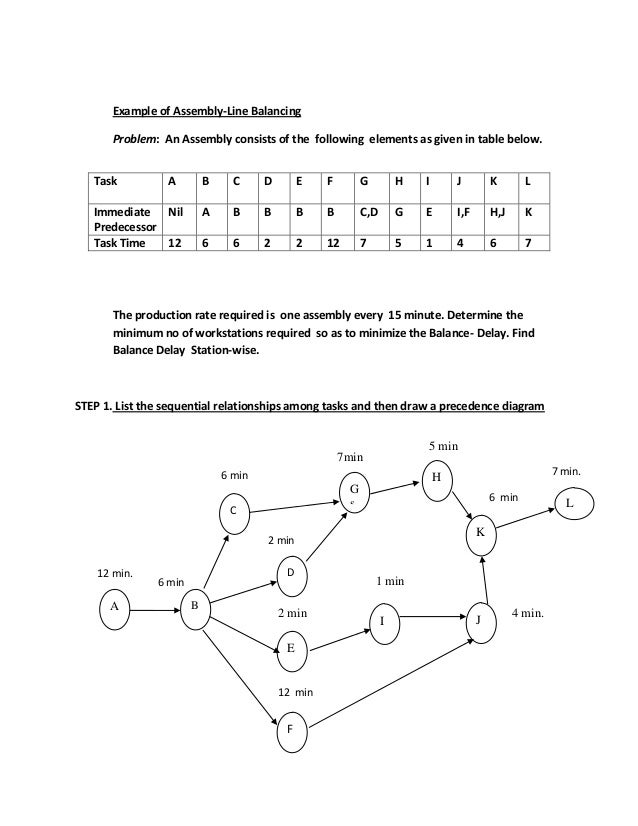

Line Balancing Example Problems . Challenges such as task duration variability and workstation imbalances, often addressed by strategies like. Objective is to minimize the imbalance between machines or personnel while meeting required output starts with the precedence relationships. Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. The document provides steps for balancing an assembly line, including determining task relationships, cycle time, number of stations, and assigning tasks based on. Problems under galb are balancing of. Effective balancing minimizes waste and ensures that production lines. The below product in a factory is assembled in an assembly line. Other assembly line balancing problems are classified into general assembly line balancing (galb).

from www.slideshare.net

Other assembly line balancing problems are classified into general assembly line balancing (galb). Problems under galb are balancing of. The below product in a factory is assembled in an assembly line. Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. The document provides steps for balancing an assembly line, including determining task relationships, cycle time, number of stations, and assigning tasks based on. Challenges such as task duration variability and workstation imbalances, often addressed by strategies like. Effective balancing minimizes waste and ensures that production lines. Objective is to minimize the imbalance between machines or personnel while meeting required output starts with the precedence relationships.

Assembly Line Balancing Example

Line Balancing Example Problems Problems under galb are balancing of. Problems under galb are balancing of. The below product in a factory is assembled in an assembly line. Other assembly line balancing problems are classified into general assembly line balancing (galb). Effective balancing minimizes waste and ensures that production lines. Objective is to minimize the imbalance between machines or personnel while meeting required output starts with the precedence relationships. Challenges such as task duration variability and workstation imbalances, often addressed by strategies like. The document provides steps for balancing an assembly line, including determining task relationships, cycle time, number of stations, and assigning tasks based on. Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills.

From www.slideserve.com

PPT Example Balance for 3 units/hour and compute theoretical min Line Balancing Example Problems Effective balancing minimizes waste and ensures that production lines. Challenges such as task duration variability and workstation imbalances, often addressed by strategies like. Objective is to minimize the imbalance between machines or personnel while meeting required output starts with the precedence relationships. Problems under galb are balancing of. Optimizing workflow on an assembly line is not as dangerous, but it. Line Balancing Example Problems.

From www.youtube.com

Modified Product Layout and Assembly Line Balancing Example YouTube Line Balancing Example Problems Objective is to minimize the imbalance between machines or personnel while meeting required output starts with the precedence relationships. Other assembly line balancing problems are classified into general assembly line balancing (galb). Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. Effective balancing minimizes waste and ensures that production lines. Problems. Line Balancing Example Problems.

From studylib.net

Line Balancing Line Balancing Example Problems Problems under galb are balancing of. Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. The document provides steps for balancing an assembly line, including determining task relationships, cycle time, number of stations, and assigning tasks based on. Objective is to minimize the imbalance between machines or personnel while meeting required. Line Balancing Example Problems.

From www.slideserve.com

PPT Assembly Line Balancing PowerPoint Presentation, free download Line Balancing Example Problems Effective balancing minimizes waste and ensures that production lines. Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. The document provides steps for balancing an assembly line, including determining task relationships, cycle time, number of stations, and assigning tasks based on. Other assembly line balancing problems are classified into general assembly. Line Balancing Example Problems.

From www.slideserve.com

PPT 10 Min. PowerPoint Presentation, free download ID5534368 Line Balancing Example Problems Challenges such as task duration variability and workstation imbalances, often addressed by strategies like. Other assembly line balancing problems are classified into general assembly line balancing (galb). Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. Objective is to minimize the imbalance between machines or personnel while meeting required output starts. Line Balancing Example Problems.

From www.researchgate.net

Assembly line balancing problem. Download Scientific Diagram Line Balancing Example Problems Problems under galb are balancing of. The below product in a factory is assembled in an assembly line. The document provides steps for balancing an assembly line, including determining task relationships, cycle time, number of stations, and assigning tasks based on. Objective is to minimize the imbalance between machines or personnel while meeting required output starts with the precedence relationships.. Line Balancing Example Problems.

From www.youtube.com

Operations Layout Assembly Line Balancing I YouTube Line Balancing Example Problems The document provides steps for balancing an assembly line, including determining task relationships, cycle time, number of stations, and assigning tasks based on. Objective is to minimize the imbalance between machines or personnel while meeting required output starts with the precedence relationships. The below product in a factory is assembled in an assembly line. Problems under galb are balancing of.. Line Balancing Example Problems.

From www.slideshare.net

Assembly Line Balancing Example Line Balancing Example Problems Problems under galb are balancing of. Effective balancing minimizes waste and ensures that production lines. Objective is to minimize the imbalance between machines or personnel while meeting required output starts with the precedence relationships. Challenges such as task duration variability and workstation imbalances, often addressed by strategies like. The below product in a factory is assembled in an assembly line.. Line Balancing Example Problems.

From www.chegg.com

Solved Q4. Consider the assembly line balancing problem Line Balancing Example Problems Effective balancing minimizes waste and ensures that production lines. The below product in a factory is assembled in an assembly line. Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. Challenges such as task duration variability and workstation imbalances, often addressed by strategies like. Problems under galb are balancing of. Other. Line Balancing Example Problems.

From www.slideserve.com

PPT Line Balancing Problem PowerPoint Presentation, free download Line Balancing Example Problems Effective balancing minimizes waste and ensures that production lines. Problems under galb are balancing of. The document provides steps for balancing an assembly line, including determining task relationships, cycle time, number of stations, and assigning tasks based on. Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. Objective is to minimize. Line Balancing Example Problems.

From www.slideserve.com

PPT Assembly Line Balancing PowerPoint Presentation, free download Line Balancing Example Problems Other assembly line balancing problems are classified into general assembly line balancing (galb). Effective balancing minimizes waste and ensures that production lines. Challenges such as task duration variability and workstation imbalances, often addressed by strategies like. Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. The below product in a factory. Line Balancing Example Problems.

From zh.scribd.com

Examples Line Balancing Applied Mathematics Mathematics Line Balancing Example Problems Effective balancing minimizes waste and ensures that production lines. Objective is to minimize the imbalance between machines or personnel while meeting required output starts with the precedence relationships. Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. Challenges such as task duration variability and workstation imbalances, often addressed by strategies like.. Line Balancing Example Problems.

From www.slideserve.com

PPT Chapter 7 Assembly Line Balancing PowerPoint Presentation, free Line Balancing Example Problems Problems under galb are balancing of. Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. Objective is to minimize the imbalance between machines or personnel while meeting required output starts with the precedence relationships. Other assembly line balancing problems are classified into general assembly line balancing (galb). Challenges such as task. Line Balancing Example Problems.

From www.slideshare.net

Assembly Line Balancing Example Line Balancing Example Problems The document provides steps for balancing an assembly line, including determining task relationships, cycle time, number of stations, and assigning tasks based on. Effective balancing minimizes waste and ensures that production lines. Problems under galb are balancing of. Other assembly line balancing problems are classified into general assembly line balancing (galb). Challenges such as task duration variability and workstation imbalances,. Line Balancing Example Problems.

From www.youtube.com

04 Assembly Line Balancing YouTube Line Balancing Example Problems Other assembly line balancing problems are classified into general assembly line balancing (galb). Challenges such as task duration variability and workstation imbalances, often addressed by strategies like. Objective is to minimize the imbalance between machines or personnel while meeting required output starts with the precedence relationships. The document provides steps for balancing an assembly line, including determining task relationships, cycle. Line Balancing Example Problems.

From www.youtube.com

Line balancing problem method 3 YouTube Line Balancing Example Problems Effective balancing minimizes waste and ensures that production lines. Challenges such as task duration variability and workstation imbalances, often addressed by strategies like. Other assembly line balancing problems are classified into general assembly line balancing (galb). The below product in a factory is assembled in an assembly line. Objective is to minimize the imbalance between machines or personnel while meeting. Line Balancing Example Problems.

From www.academia.edu

(DOC) LINE BALANCING Assembly Line Balancing Problem Linh Ngô Line Balancing Example Problems Other assembly line balancing problems are classified into general assembly line balancing (galb). Effective balancing minimizes waste and ensures that production lines. The document provides steps for balancing an assembly line, including determining task relationships, cycle time, number of stations, and assigning tasks based on. Optimizing workflow on an assembly line is not as dangerous, but it requires a similar. Line Balancing Example Problems.

From www.slideserve.com

PPT Line Balancing in Operations Management PowerPoint Presentation Line Balancing Example Problems Problems under galb are balancing of. Challenges such as task duration variability and workstation imbalances, often addressed by strategies like. Other assembly line balancing problems are classified into general assembly line balancing (galb). Effective balancing minimizes waste and ensures that production lines. The document provides steps for balancing an assembly line, including determining task relationships, cycle time, number of stations,. Line Balancing Example Problems.

From www.slideserve.com

PPT Line Balancing Problem PowerPoint Presentation, free download Line Balancing Example Problems Other assembly line balancing problems are classified into general assembly line balancing (galb). Challenges such as task duration variability and workstation imbalances, often addressed by strategies like. Objective is to minimize the imbalance between machines or personnel while meeting required output starts with the precedence relationships. The document provides steps for balancing an assembly line, including determining task relationships, cycle. Line Balancing Example Problems.

From slidetodoc.com

Line Balancing Example problem Golf Club mfgassy firm Line Balancing Example Problems Challenges such as task duration variability and workstation imbalances, often addressed by strategies like. Effective balancing minimizes waste and ensures that production lines. The document provides steps for balancing an assembly line, including determining task relationships, cycle time, number of stations, and assigning tasks based on. The below product in a factory is assembled in an assembly line. Objective is. Line Balancing Example Problems.

From template.mapadapalavra.ba.gov.br

Line Balancing Template Line Balancing Example Problems The document provides steps for balancing an assembly line, including determining task relationships, cycle time, number of stations, and assigning tasks based on. Problems under galb are balancing of. The below product in a factory is assembled in an assembly line. Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. Challenges. Line Balancing Example Problems.

From www.chegg.com

Solved 1. Assembly Line Balancing (10+5+5+5+5 points) (a) Line Balancing Example Problems Other assembly line balancing problems are classified into general assembly line balancing (galb). Problems under galb are balancing of. The document provides steps for balancing an assembly line, including determining task relationships, cycle time, number of stations, and assigning tasks based on. Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills.. Line Balancing Example Problems.

From www.chegg.com

Solved Assembly Line Balancing Example The daily output for Line Balancing Example Problems The document provides steps for balancing an assembly line, including determining task relationships, cycle time, number of stations, and assigning tasks based on. Other assembly line balancing problems are classified into general assembly line balancing (galb). The below product in a factory is assembled in an assembly line. Challenges such as task duration variability and workstation imbalances, often addressed by. Line Balancing Example Problems.

From www.slideserve.com

PPT Line Balancing in Operations Management PowerPoint Presentation Line Balancing Example Problems Effective balancing minimizes waste and ensures that production lines. The document provides steps for balancing an assembly line, including determining task relationships, cycle time, number of stations, and assigning tasks based on. Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. Other assembly line balancing problems are classified into general assembly. Line Balancing Example Problems.

From studylib.net

Line Balancing Line Balancing Example Problems Other assembly line balancing problems are classified into general assembly line balancing (galb). Objective is to minimize the imbalance between machines or personnel while meeting required output starts with the precedence relationships. Effective balancing minimizes waste and ensures that production lines. The document provides steps for balancing an assembly line, including determining task relationships, cycle time, number of stations, and. Line Balancing Example Problems.

From www.youtube.com

What is Line Balancing YouTube Line Balancing Example Problems Other assembly line balancing problems are classified into general assembly line balancing (galb). Objective is to minimize the imbalance between machines or personnel while meeting required output starts with the precedence relationships. Effective balancing minimizes waste and ensures that production lines. Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. The. Line Balancing Example Problems.

From www.slideserve.com

PPT Line Balancing in Operations Management PowerPoint Presentation Line Balancing Example Problems Challenges such as task duration variability and workstation imbalances, often addressed by strategies like. Objective is to minimize the imbalance between machines or personnel while meeting required output starts with the precedence relationships. Effective balancing minimizes waste and ensures that production lines. Problems under galb are balancing of. Optimizing workflow on an assembly line is not as dangerous, but it. Line Balancing Example Problems.

From www.mdpi.com

JOItmC Free FullText Simple Assembly Line Balancing Problem Type 2 Line Balancing Example Problems Challenges such as task duration variability and workstation imbalances, often addressed by strategies like. Objective is to minimize the imbalance between machines or personnel while meeting required output starts with the precedence relationships. The below product in a factory is assembled in an assembly line. Optimizing workflow on an assembly line is not as dangerous, but it requires a similar. Line Balancing Example Problems.

From www.chegg.com

Solved Line Balancing Exercise (20 Points) SCM 300 LINE Line Balancing Example Problems Challenges such as task duration variability and workstation imbalances, often addressed by strategies like. The document provides steps for balancing an assembly line, including determining task relationships, cycle time, number of stations, and assigning tasks based on. Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. The below product in a. Line Balancing Example Problems.

From www.slideserve.com

PPT Line Balancing Problem PowerPoint Presentation, free download Line Balancing Example Problems Effective balancing minimizes waste and ensures that production lines. Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. Objective is to minimize the imbalance between machines or personnel while meeting required output starts with the precedence relationships. Challenges such as task duration variability and workstation imbalances, often addressed by strategies like.. Line Balancing Example Problems.

From www.slideserve.com

PPT Manual Assembly Lines PowerPoint Presentation, free download ID Line Balancing Example Problems Other assembly line balancing problems are classified into general assembly line balancing (galb). Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. The below product in a factory is assembled in an assembly line. The document provides steps for balancing an assembly line, including determining task relationships, cycle time, number of. Line Balancing Example Problems.

From www.youtube.com

𝐋𝐢𝐧𝐞 𝐁𝐚𝐥𝐚𝐧𝐜𝐢𝐧𝐠 Production Line Balancing ? Assembly Line Balancing Line Balancing Example Problems Objective is to minimize the imbalance between machines or personnel while meeting required output starts with the precedence relationships. Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. Challenges such as task duration variability and workstation imbalances, often addressed by strategies like. Problems under galb are balancing of. The document provides. Line Balancing Example Problems.

From www.youtube.com

Line Balancing Example YouTube Line Balancing Example Problems Other assembly line balancing problems are classified into general assembly line balancing (galb). Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. Objective is to minimize the imbalance between machines or personnel while meeting required output starts with the precedence relationships. Effective balancing minimizes waste and ensures that production lines. Problems. Line Balancing Example Problems.

From www.youtube.com

Introduction to Line Balancing Problems using SPT (Part 1) YouTube Line Balancing Example Problems The below product in a factory is assembled in an assembly line. Challenges such as task duration variability and workstation imbalances, often addressed by strategies like. Other assembly line balancing problems are classified into general assembly line balancing (galb). Optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. Problems under galb. Line Balancing Example Problems.

From slidetodoc.com

Line Balancing Example problem Golf Club mfgassy firm Line Balancing Example Problems Objective is to minimize the imbalance between machines or personnel while meeting required output starts with the precedence relationships. The document provides steps for balancing an assembly line, including determining task relationships, cycle time, number of stations, and assigning tasks based on. Other assembly line balancing problems are classified into general assembly line balancing (galb). Challenges such as task duration. Line Balancing Example Problems.