Iron Casting Mold . Processes with reusable molds and processes with expendable molds. This series follows a cast iron or steel product through the metal casting process in a traditional foundry. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Find out the materials and methods for different casting methods, such as sand casting, investment casting, and die casting. Foundry pattern making is the process of designing and creating a mold. Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. Learn the six steps involved in creating custom molds for metal casting, from designing the pattern to applying the refractory coating. It is made by melting iron and adding carbon and other elements to the molten metal, which is then poured into a mold to cool and solidify. Iron melts at 2750°f and. Metal casting comes in two main categories: The resulting material has a crystalline structure that is highly resistant to wear and deformation. Every good ductile iron casting is the result of a good pattern.

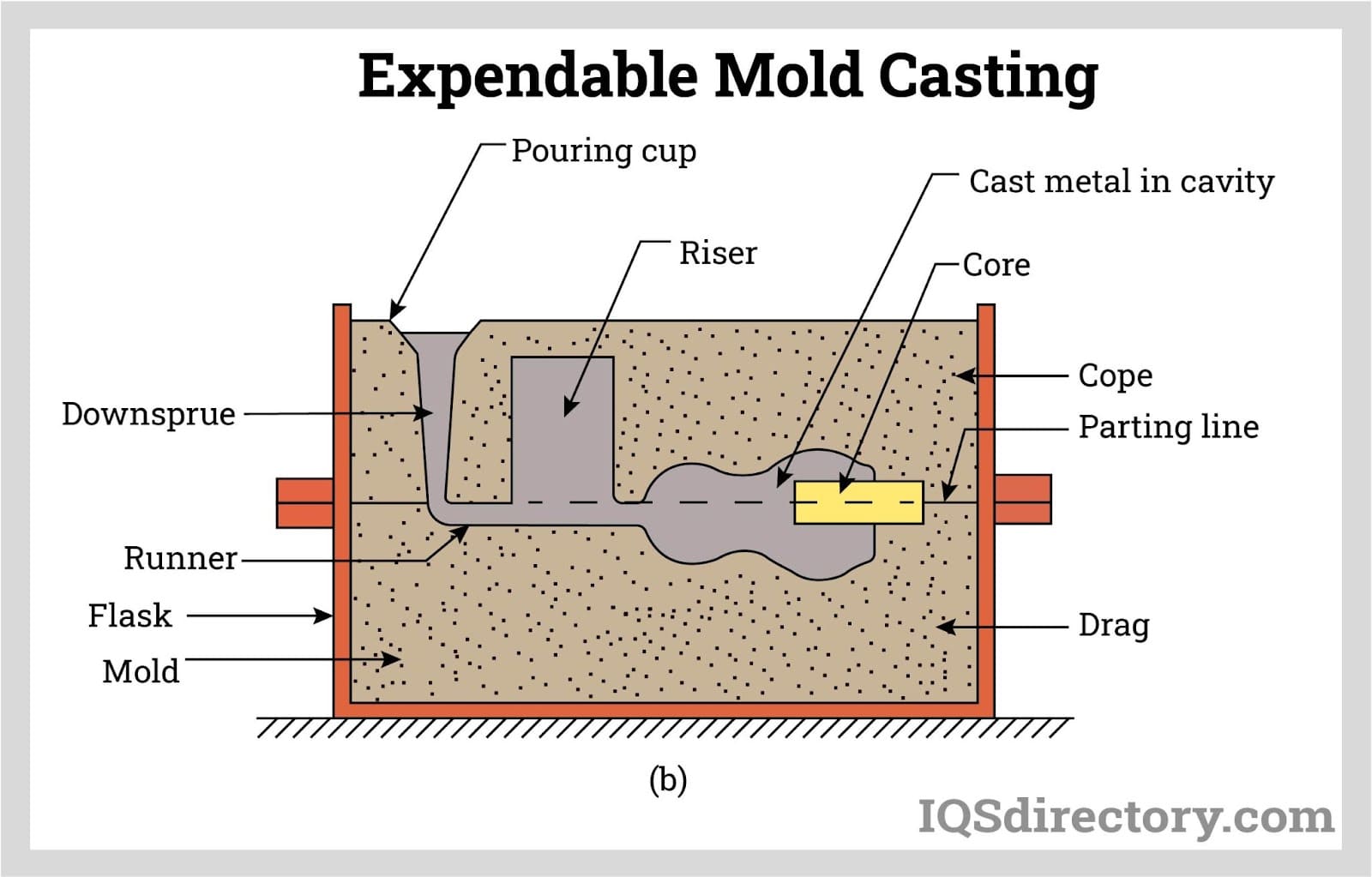

from www.iqsdirectory.com

It is made by melting iron and adding carbon and other elements to the molten metal, which is then poured into a mold to cool and solidify. Learn the six steps involved in creating custom molds for metal casting, from designing the pattern to applying the refractory coating. This series follows a cast iron or steel product through the metal casting process in a traditional foundry. Metal casting comes in two main categories: Processes with reusable molds and processes with expendable molds. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. The resulting material has a crystalline structure that is highly resistant to wear and deformation. Every good ductile iron casting is the result of a good pattern. Find out the materials and methods for different casting methods, such as sand casting, investment casting, and die casting. Iron melts at 2750°f and.

Iron Castings Types, Applications, Process, and Benefits

Iron Casting Mold Find out the materials and methods for different casting methods, such as sand casting, investment casting, and die casting. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Foundry pattern making is the process of designing and creating a mold. Processes with reusable molds and processes with expendable molds. Iron melts at 2750°f and. Learn the six steps involved in creating custom molds for metal casting, from designing the pattern to applying the refractory coating. It is made by melting iron and adding carbon and other elements to the molten metal, which is then poured into a mold to cool and solidify. This series follows a cast iron or steel product through the metal casting process in a traditional foundry. Metal casting comes in two main categories: Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. Find out the materials and methods for different casting methods, such as sand casting, investment casting, and die casting. Every good ductile iron casting is the result of a good pattern. The resulting material has a crystalline structure that is highly resistant to wear and deformation.

From www.youtube.com

Casting Iron Mold for Ingots! 2000°+ (MattMakes Mold Part 1/4) YouTube Iron Casting Mold To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Learn the six steps involved in creating custom molds for metal casting, from designing the pattern to applying the refractory coating. Processes with reusable molds and processes with expendable molds. Foundry pattern making. Iron Casting Mold.

From www.steel-foundry.com

Gray Iron Shell Mold Casting Steel Casting Factory Grey Iron Iron Casting Mold Every good ductile iron casting is the result of a good pattern. Learn the six steps involved in creating custom molds for metal casting, from designing the pattern to applying the refractory coating. It is made by melting iron and adding carbon and other elements to the molten metal, which is then poured into a mold to cool and solidify.. Iron Casting Mold.

From ar.inspiredpencil.com

Cast Iron Process Iron Casting Mold Iron melts at 2750°f and. Processes with reusable molds and processes with expendable molds. The resulting material has a crystalline structure that is highly resistant to wear and deformation. Metal casting comes in two main categories: To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a. Iron Casting Mold.

From pmcsupplies.com

Cast Iron Ingot Molds For Pouring Gold Silver Copper Brass Aluminum Iron Casting Mold This series follows a cast iron or steel product through the metal casting process in a traditional foundry. Processes with reusable molds and processes with expendable molds. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Find out the materials and methods. Iron Casting Mold.

From www.iqsdirectory.com

Iron Castings Types, Applications, Process, and Benefits Iron Casting Mold Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. It is made by melting iron and adding carbon and other elements to the molten metal, which is then poured into a mold to cool and solidify. The resulting material has a crystalline structure that is highly resistant to wear. Iron Casting Mold.

From www.steel-foundry.com

Shell Mold Casting of Ductile Cast Iron Steel Casting Factory Grey Iron Casting Mold Iron melts at 2750°f and. Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. This series follows a cast iron or steel product through the metal casting process in a traditional foundry. Foundry pattern making is the process of designing and creating a mold. To successfully cast metal, you’ll. Iron Casting Mold.

From www.dreamstime.com

Molten Metal Iron Casting in Metal Mold Stock Photo Image of factory Iron Casting Mold Every good ductile iron casting is the result of a good pattern. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Processes with reusable molds and processes with expendable molds. Find out the materials and methods for different casting methods, such as. Iron Casting Mold.

From www.steel-foundry.com

Grey Iron & Ductile Iron Shell Mold Casting Foundry Cast Iron Casting Iron Casting Mold The resulting material has a crystalline structure that is highly resistant to wear and deformation. Metal casting comes in two main categories: Learn the six steps involved in creating custom molds for metal casting, from designing the pattern to applying the refractory coating. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold. Iron Casting Mold.

From buntyllc.com

Custom Metal Casting Molds Bunty LLC Iron Casting Mold Iron melts at 2750°f and. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Processes with reusable molds and processes with expendable molds. It is made by melting iron and adding carbon and other elements to the molten metal, which is then. Iron Casting Mold.

From www.dreamstime.com

Molten Metal Pour from Ladle into Sand Mold. Iron Casting Process in Iron Casting Mold Iron melts at 2750°f and. Metal casting comes in two main categories: Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. The resulting material has a crystalline structure that is highly resistant to wear and deformation. Learn the six steps involved in creating custom molds for metal casting, from. Iron Casting Mold.

From www.clinchrivercasting.com

Molding NoBake Iron Foundry Clinch River Casting Iron Casting Mold This series follows a cast iron or steel product through the metal casting process in a traditional foundry. Learn the six steps involved in creating custom molds for metal casting, from designing the pattern to applying the refractory coating. Foundry pattern making is the process of designing and creating a mold. The resulting material has a crystalline structure that is. Iron Casting Mold.

From samamachinery.en.made-in-china.com

China Casting, Iron Casting, Sand Casting, Shell Mold Casting with Iron Casting Mold Find out the materials and methods for different casting methods, such as sand casting, investment casting, and die casting. Iron melts at 2750°f and. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Make sure the frame comes in 2 parts and. Iron Casting Mold.

From www.indiamart.com

CAST IRON Casting Mold at Rs 1800/piece in Aurangabad ID 2850586206173 Iron Casting Mold Find out the materials and methods for different casting methods, such as sand casting, investment casting, and die casting. Foundry pattern making is the process of designing and creating a mold. Iron melts at 2750°f and. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a. Iron Casting Mold.

From www.steel-foundry.com

Ductile Iron Shell Mold Casting Steel Casting Factory Grey Iron Iron Casting Mold Iron melts at 2750°f and. Metal casting comes in two main categories: Learn the six steps involved in creating custom molds for metal casting, from designing the pattern to applying the refractory coating. It is made by melting iron and adding carbon and other elements to the molten metal, which is then poured into a mold to cool and solidify.. Iron Casting Mold.

From www.youtube.com

The Basic Permanent Mold Casting Process YouTube Iron Casting Mold Learn the six steps involved in creating custom molds for metal casting, from designing the pattern to applying the refractory coating. Metal casting comes in two main categories: This series follows a cast iron or steel product through the metal casting process in a traditional foundry. Foundry pattern making is the process of designing and creating a mold. Every good. Iron Casting Mold.

From www.alamy.com

Metal casting process in foundry, liquid metal pouring from container Iron Casting Mold Processes with reusable molds and processes with expendable molds. Foundry pattern making is the process of designing and creating a mold. Learn the six steps involved in creating custom molds for metal casting, from designing the pattern to applying the refractory coating. Find out the materials and methods for different casting methods, such as sand casting, investment casting, and die. Iron Casting Mold.

From www.lifestylecasted.com

China Iron Casting Molds Suppliers, Manufacturers, Factory Discount Iron Casting Mold Processes with reusable molds and processes with expendable molds. Every good ductile iron casting is the result of a good pattern. It is made by melting iron and adding carbon and other elements to the molten metal, which is then poured into a mold to cool and solidify. The resulting material has a crystalline structure that is highly resistant to. Iron Casting Mold.

From www.dreamstime.com

Iron Casting Parts Housing Pump or Blower Casting by Green Sand or Iron Casting Mold Find out the materials and methods for different casting methods, such as sand casting, investment casting, and die casting. Every good ductile iron casting is the result of a good pattern. Metal casting comes in two main categories: Foundry pattern making is the process of designing and creating a mold. Processes with reusable molds and processes with expendable molds. The. Iron Casting Mold.

From www.clinchrivercasting.com

Molding Clinch River Casting NoBake Casting Foundry Iron Casting Mold Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. This series follows a cast iron or steel product through the metal casting process in a traditional foundry. Every good ductile iron casting is the result of a good pattern. Find out the materials and methods for different casting methods,. Iron Casting Mold.

From dakotafoundry.com

Capabilities at Dakota Foundry Grey Iron & Ductile Iron Castings Iron Casting Mold Every good ductile iron casting is the result of a good pattern. Foundry pattern making is the process of designing and creating a mold. Learn the six steps involved in creating custom molds for metal casting, from designing the pattern to applying the refractory coating. This series follows a cast iron or steel product through the metal casting process in. Iron Casting Mold.

From startup-buzz.com

The Beginner’s Guide to Permanent Mold Casting Startup Buzz Iron Casting Mold Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. The resulting material has a crystalline structure that is highly resistant to wear and deformation. Processes with reusable molds and processes with expendable molds. It is made by melting iron and adding carbon and other elements to the molten metal,. Iron Casting Mold.

From www.lifestylecasted.com

China Iron Casting Molds Suppliers, Manufacturers, Factory Discount Iron Casting Mold Metal casting comes in two main categories: Iron melts at 2750°f and. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Find out the materials and methods for different casting methods, such as sand casting, investment casting, and die casting. Every good. Iron Casting Mold.

From www.youtube.com

Casting an iron wheel iron casting mold making YouTube Iron Casting Mold It is made by melting iron and adding carbon and other elements to the molten metal, which is then poured into a mold to cool and solidify. The resulting material has a crystalline structure that is highly resistant to wear and deformation. Foundry pattern making is the process of designing and creating a mold. Metal casting comes in two main. Iron Casting Mold.

From www.hrmetalcasting.com

The metal pattern/mold for automatic iron casting production line Iron Casting Mold To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Foundry pattern making is the process of designing and creating a mold. Learn the six steps involved in creating custom molds for metal casting, from designing the pattern to applying the refractory coating.. Iron Casting Mold.

From www.steel-foundry.com

Grey Iron Casting Machinery Part by Investment Casting Steel Casting Iron Casting Mold The resulting material has a crystalline structure that is highly resistant to wear and deformation. Learn the six steps involved in creating custom molds for metal casting, from designing the pattern to applying the refractory coating. Iron melts at 2750°f and. Find out the materials and methods for different casting methods, such as sand casting, investment casting, and die casting.. Iron Casting Mold.

From www.iqsdirectory.com

Iron Castings Types, Applications, Process, and Benefits Iron Casting Mold Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. Processes with reusable molds and processes with expendable molds. The resulting material has a crystalline structure that is highly resistant to wear and deformation. This series follows a cast iron or steel product through the metal casting process in a. Iron Casting Mold.

From www.reliance-foundry.com

Ask a Metallurgist Wrought Iron vs Cast Iron Metal Casting Blog Iron Casting Mold Foundry pattern making is the process of designing and creating a mold. Processes with reusable molds and processes with expendable molds. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Iron melts at 2750°f and. Make sure the frame comes in 2. Iron Casting Mold.

From www.iqsdirectory.com

Permanent Mold Castings What Is It? How Does It Work? Advantages Iron Casting Mold The resulting material has a crystalline structure that is highly resistant to wear and deformation. Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly. Iron Casting Mold.

From www.steel-foundry.com

Ductile Iron Shell Mold Casting Steel Casting Factory Grey Iron Iron Casting Mold The resulting material has a crystalline structure that is highly resistant to wear and deformation. Iron melts at 2750°f and. It is made by melting iron and adding carbon and other elements to the molten metal, which is then poured into a mold to cool and solidify. Every good ductile iron casting is the result of a good pattern. Learn. Iron Casting Mold.

From www.alibaba.com

High Quality Mold Making Iron Casting Aluminum Sand Casting Mould Buy Iron Casting Mold Every good ductile iron casting is the result of a good pattern. Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. Foundry pattern making is the process of designing and creating a mold. This series follows a cast iron or steel product through the metal casting process in a. Iron Casting Mold.

From www.dreamstime.com

The Liquid Metal or Cast Iron Poured into Molds. Metal Casting Process Iron Casting Mold Foundry pattern making is the process of designing and creating a mold. Learn the six steps involved in creating custom molds for metal casting, from designing the pattern to applying the refractory coating. Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. Find out the materials and methods for. Iron Casting Mold.

From www.thecrucible.org

Metal Casting 101 Learn To Cast Metal [Types & Processes] Iron Casting Mold Processes with reusable molds and processes with expendable molds. Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. Every good ductile iron casting is the result of a good pattern. Find out the materials and methods for different casting methods, such as sand casting, investment casting, and die casting.. Iron Casting Mold.

From www.westend61.de

Crop of group of professional male artisans working in weathered Iron Casting Mold Every good ductile iron casting is the result of a good pattern. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Find out the materials and methods for different casting methods, such as sand casting, investment casting, and die casting. Foundry pattern. Iron Casting Mold.

From statementsltd.com

Compare Price iron casting mold on Iron Casting Mold Processes with reusable molds and processes with expendable molds. It is made by melting iron and adding carbon and other elements to the molten metal, which is then poured into a mold to cool and solidify. Learn the six steps involved in creating custom molds for metal casting, from designing the pattern to applying the refractory coating. Foundry pattern making. Iron Casting Mold.

From statementsltd.com

Compare Price iron casting mold on Iron Casting Mold Find out the materials and methods for different casting methods, such as sand casting, investment casting, and die casting. Processes with reusable molds and processes with expendable molds. The resulting material has a crystalline structure that is highly resistant to wear and deformation. It is made by melting iron and adding carbon and other elements to the molten metal, which. Iron Casting Mold.