Milling Table Stone . I have always used a hard arkansas to stone a table, no need to grind or dress them as they are plenty flat enough for the job. One layer contains a relatively rough silicon. It'll skate on the surface of the table and not remove. In this video, titan will explain how and why we use this stone during the. Can someone please explain what. What is a machinist stone? The best possible stone to use is a precision ground toolroom stone that's been diamond ground. If the stone is hollowed, the edge will be cutting and more likely to gouge the table. Ive heard the term stoning to take away surface defects on a milling table or the bore of a morse taper. A small stone will cut more readily and remove more steel than a large one with equally applied force on a flat surface. Product details the tyrolit machinist's stone is precision ground to an optimal flatness profile. The machinist stone is a must have tool used by all precision cnc machinist. I would stone with a fine grit stone but i would make sure that the surface of the stone is flat.

from www.walmart.com

I have always used a hard arkansas to stone a table, no need to grind or dress them as they are plenty flat enough for the job. Product details the tyrolit machinist's stone is precision ground to an optimal flatness profile. It'll skate on the surface of the table and not remove. The best possible stone to use is a precision ground toolroom stone that's been diamond ground. Ive heard the term stoning to take away surface defects on a milling table or the bore of a morse taper. If the stone is hollowed, the edge will be cutting and more likely to gouge the table. The machinist stone is a must have tool used by all precision cnc machinist. Can someone please explain what. One layer contains a relatively rough silicon. I would stone with a fine grit stone but i would make sure that the surface of the stone is flat.

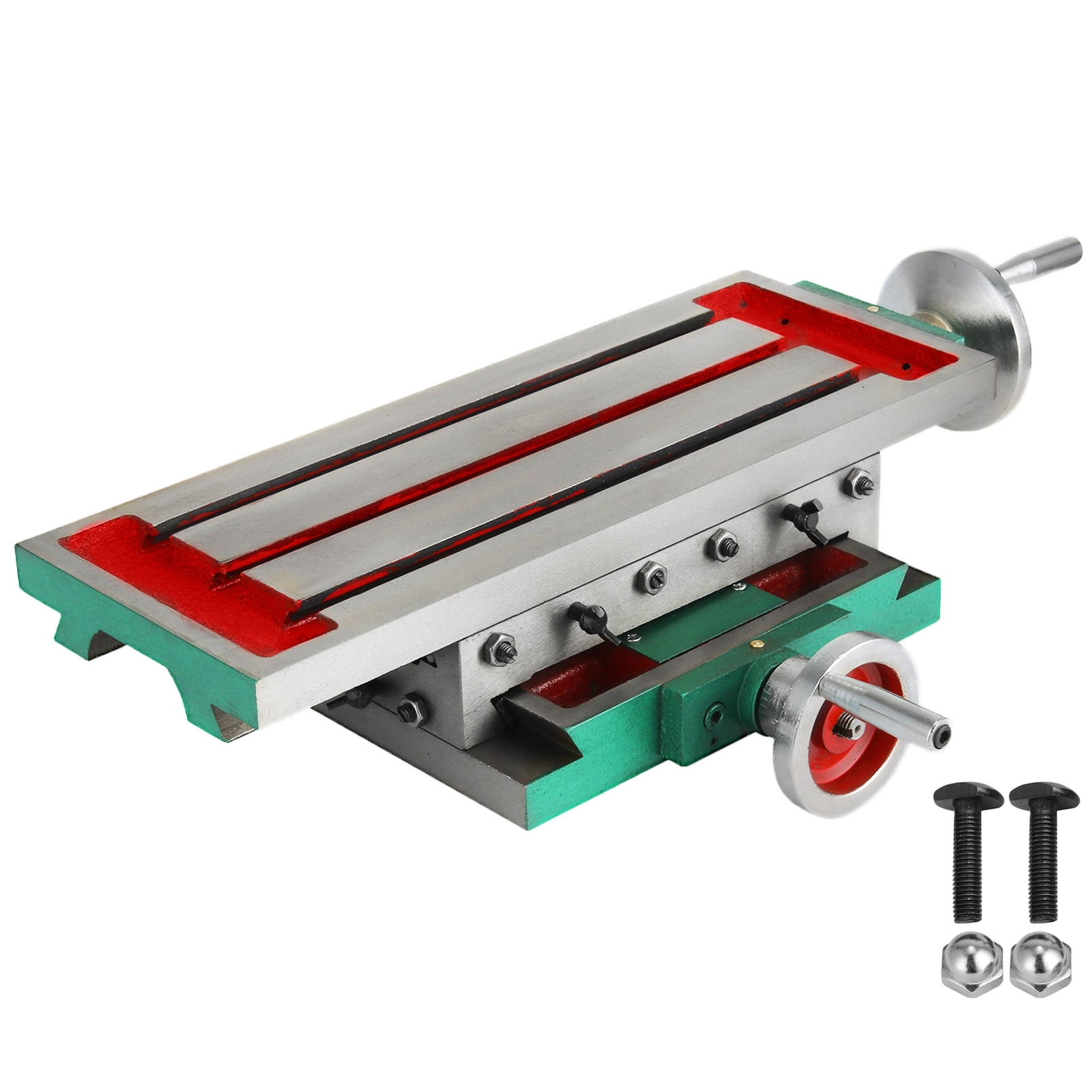

VEVOR Milling Working Table 17.7 X 6.7 inch, Compound Milling Machine

Milling Table Stone One layer contains a relatively rough silicon. I have always used a hard arkansas to stone a table, no need to grind or dress them as they are plenty flat enough for the job. If the stone is hollowed, the edge will be cutting and more likely to gouge the table. A small stone will cut more readily and remove more steel than a large one with equally applied force on a flat surface. In this video, titan will explain how and why we use this stone during the. The best possible stone to use is a precision ground toolroom stone that's been diamond ground. Can someone please explain what. I would stone with a fine grit stone but i would make sure that the surface of the stone is flat. Product details the tyrolit machinist's stone is precision ground to an optimal flatness profile. Ive heard the term stoning to take away surface defects on a milling table or the bore of a morse taper. The machinist stone is a must have tool used by all precision cnc machinist. It'll skate on the surface of the table and not remove. What is a machinist stone? One layer contains a relatively rough silicon.

From www.yuriystoys.com

Large Table Assembly for X2 Mini Mill Yuriy's Toys Milling Table Stone I would stone with a fine grit stone but i would make sure that the surface of the stone is flat. A small stone will cut more readily and remove more steel than a large one with equally applied force on a flat surface. Ive heard the term stoning to take away surface defects on a milling table or the. Milling Table Stone.

From uk.vevor.com

VEVOR VEVOR Milling Table 17.7×6.7Inch Compound Slide Milling Table Milling Table Stone If the stone is hollowed, the edge will be cutting and more likely to gouge the table. What is a machinist stone? Product details the tyrolit machinist's stone is precision ground to an optimal flatness profile. In this video, titan will explain how and why we use this stone during the. I would stone with a fine grit stone but. Milling Table Stone.

From www.walmart.com

VEVOR Milling Working Table 17.7 X 6.7 inch, Compound Milling Machine Milling Table Stone A small stone will cut more readily and remove more steel than a large one with equally applied force on a flat surface. The best possible stone to use is a precision ground toolroom stone that's been diamond ground. Product details the tyrolit machinist's stone is precision ground to an optimal flatness profile. The machinist stone is a must have. Milling Table Stone.

From uk.vevor.com

VEVOR VEVOR Milling Table 17.7×6.7Inch Compound Slide Milling Table Milling Table Stone In this video, titan will explain how and why we use this stone during the. One layer contains a relatively rough silicon. The machinist stone is a must have tool used by all precision cnc machinist. I have always used a hard arkansas to stone a table, no need to grind or dress them as they are plenty flat enough. Milling Table Stone.

From auctionresource.com

Sears Compound Milling Table Lot 4396, November Shop and Misc Milling Table Stone One layer contains a relatively rough silicon. What is a machinist stone? Ive heard the term stoning to take away surface defects on a milling table or the bore of a morse taper. The machinist stone is a must have tool used by all precision cnc machinist. I have always used a hard arkansas to stone a table, no need. Milling Table Stone.

From brunei.desertcart.com

Buy ROMYIX Milling Table 17.7×6.7Inch Compound Slide Milling Table 30KG Milling Table Stone In this video, titan will explain how and why we use this stone during the. Ive heard the term stoning to take away surface defects on a milling table or the bore of a morse taper. I would stone with a fine grit stone but i would make sure that the surface of the stone is flat. Can someone please. Milling Table Stone.

From www.dgmfmoldclamps.com

45° Adjustable Angle Plate for Milling Machine Supplier Milling Table Stone What is a machinist stone? The machinist stone is a must have tool used by all precision cnc machinist. I would stone with a fine grit stone but i would make sure that the surface of the stone is flat. One layer contains a relatively rough silicon. Product details the tyrolit machinist's stone is precision ground to an optimal flatness. Milling Table Stone.

From www.indiamart.com

Hammer Tone Mid Grey APEX Rotary Milling Table, For Use In Metalworking Milling Table Stone A small stone will cut more readily and remove more steel than a large one with equally applied force on a flat surface. In this video, titan will explain how and why we use this stone during the. It'll skate on the surface of the table and not remove. The best possible stone to use is a precision ground toolroom. Milling Table Stone.

From www.vevor.com

Vevor Cross Milling Work Slide Table Bench Drilling Milling Machine 6"x Milling Table Stone Product details the tyrolit machinist's stone is precision ground to an optimal flatness profile. Can someone please explain what. I have always used a hard arkansas to stone a table, no need to grind or dress them as they are plenty flat enough for the job. I would stone with a fine grit stone but i would make sure that. Milling Table Stone.

From www.rollerauction.com

XW Axis Milling Table Roller Auctions Milling Table Stone A small stone will cut more readily and remove more steel than a large one with equally applied force on a flat surface. The best possible stone to use is a precision ground toolroom stone that's been diamond ground. In this video, titan will explain how and why we use this stone during the. The machinist stone is a must. Milling Table Stone.

From www.vevor.com

VEVOR Tilting Milling Table 10x7inch Tilting Angle Milling Machine 090 Milling Table Stone I would stone with a fine grit stone but i would make sure that the surface of the stone is flat. In this video, titan will explain how and why we use this stone during the. A small stone will cut more readily and remove more steel than a large one with equally applied force on a flat surface. I. Milling Table Stone.

From xlmachine.en.made-in-china.com

Swivel Milling Head Rotary Table Universal Milling Machine X6436 Milling Table Stone The machinist stone is a must have tool used by all precision cnc machinist. Ive heard the term stoning to take away surface defects on a milling table or the bore of a morse taper. A small stone will cut more readily and remove more steel than a large one with equally applied force on a flat surface. Product details. Milling Table Stone.

From topdrillpress.com

15 Best Milling Table For Drill Presses In 2024 Milling Table Stone Product details the tyrolit machinist's stone is precision ground to an optimal flatness profile. I have always used a hard arkansas to stone a table, no need to grind or dress them as they are plenty flat enough for the job. The best possible stone to use is a precision ground toolroom stone that's been diamond ground. I would stone. Milling Table Stone.

From www.aliexpress.com

1Set 7x5 In Tilting Milling Table Adjustable Rotary Worktable Machine W Milling Table Stone If the stone is hollowed, the edge will be cutting and more likely to gouge the table. A small stone will cut more readily and remove more steel than a large one with equally applied force on a flat surface. What is a machinist stone? Product details the tyrolit machinist's stone is precision ground to an optimal flatness profile. It'll. Milling Table Stone.

From auctionresource.com

Sears Compound Milling Table Lot 4396, November Shop and Misc Milling Table Stone What is a machinist stone? Ive heard the term stoning to take away surface defects on a milling table or the bore of a morse taper. It'll skate on the surface of the table and not remove. One layer contains a relatively rough silicon. The best possible stone to use is a precision ground toolroom stone that's been diamond ground.. Milling Table Stone.

From www.youtube.com

Bridgeport Vertical Milling Machine Table 1070 mm x 230 mm YouTube Milling Table Stone Product details the tyrolit machinist's stone is precision ground to an optimal flatness profile. What is a machinist stone? I have always used a hard arkansas to stone a table, no need to grind or dress them as they are plenty flat enough for the job. One layer contains a relatively rough silicon. If the stone is hollowed, the edge. Milling Table Stone.

From www.vevor.com

VEVOR Tilting Milling Table 10x7inch Tilting Angle Milling Machine 045 Milling Table Stone One layer contains a relatively rough silicon. It'll skate on the surface of the table and not remove. What is a machinist stone? A small stone will cut more readily and remove more steel than a large one with equally applied force on a flat surface. I would stone with a fine grit stone but i would make sure that. Milling Table Stone.

From www.vevor.com

VEVOR Tilting Milling Table 10x7inch Tilting Angle Milling Machine 090 Milling Table Stone A small stone will cut more readily and remove more steel than a large one with equally applied force on a flat surface. One layer contains a relatively rough silicon. It'll skate on the surface of the table and not remove. Can someone please explain what. Ive heard the term stoning to take away surface defects on a milling table. Milling Table Stone.

From www.pinterest.com

OrangeA Milling Working Table 17.7 X 6.7 Inch Worktable Compound Slide Milling Table Stone The machinist stone is a must have tool used by all precision cnc machinist. It'll skate on the surface of the table and not remove. Can someone please explain what. If the stone is hollowed, the edge will be cutting and more likely to gouge the table. A small stone will cut more readily and remove more steel than a. Milling Table Stone.

From pelatools.com

Buy Milling table at Pela Tools Milling Table Stone I have always used a hard arkansas to stone a table, no need to grind or dress them as they are plenty flat enough for the job. In this video, titan will explain how and why we use this stone during the. Ive heard the term stoning to take away surface defects on a milling table or the bore of. Milling Table Stone.

From www.desertcart.ae

Buy MultifunctionWorktable Milling Working Cross Table Milling Machine Milling Table Stone What is a machinist stone? Ive heard the term stoning to take away surface defects on a milling table or the bore of a morse taper. Product details the tyrolit machinist's stone is precision ground to an optimal flatness profile. A small stone will cut more readily and remove more steel than a large one with equally applied force on. Milling Table Stone.

From www.dreamstime.com

Archaeology Abrasion Marks On Rock Milling Table In Australia Milling Table Stone If the stone is hollowed, the edge will be cutting and more likely to gouge the table. The best possible stone to use is a precision ground toolroom stone that's been diamond ground. Can someone please explain what. In this video, titan will explain how and why we use this stone during the. What is a machinist stone? Product details. Milling Table Stone.

From www.stonecontact.com

Maccha Stone Mill Small Stone Mill,Flour Milling Stone for Home Use Milling Table Stone Ive heard the term stoning to take away surface defects on a milling table or the bore of a morse taper. The machinist stone is a must have tool used by all precision cnc machinist. I would stone with a fine grit stone but i would make sure that the surface of the stone is flat. Product details the tyrolit. Milling Table Stone.

From www.webco.me

AMYAMY Compound Slide Table / Worktable Milling Working Cross Table Milling Table Stone In this video, titan will explain how and why we use this stone during the. Can someone please explain what. The machinist stone is a must have tool used by all precision cnc machinist. If the stone is hollowed, the edge will be cutting and more likely to gouge the table. It'll skate on the surface of the table and. Milling Table Stone.

From brunei.desertcart.com

Buy VEVOR Milling Table 17.7×6.7Inch Compound Slide Milling Table Milling Table Stone The best possible stone to use is a precision ground toolroom stone that's been diamond ground. I would stone with a fine grit stone but i would make sure that the surface of the stone is flat. If the stone is hollowed, the edge will be cutting and more likely to gouge the table. It'll skate on the surface of. Milling Table Stone.

From www.indiamart.com

Iron Unique Precision Rotary Milling Table Horizontal & Vertical at Rs Milling Table Stone Ive heard the term stoning to take away surface defects on a milling table or the bore of a morse taper. I would stone with a fine grit stone but i would make sure that the surface of the stone is flat. In this video, titan will explain how and why we use this stone during the. Can someone please. Milling Table Stone.

From www.youtube.com

Cheap Milling Table YouTube Milling Table Stone I have always used a hard arkansas to stone a table, no need to grind or dress them as they are plenty flat enough for the job. I would stone with a fine grit stone but i would make sure that the surface of the stone is flat. In this video, titan will explain how and why we use this. Milling Table Stone.

From www.mcmachinetools.com

แท่นมิลลิ่ง/MILLING TABLE Milling Table Stone Can someone please explain what. Ive heard the term stoning to take away surface defects on a milling table or the bore of a morse taper. In this video, titan will explain how and why we use this stone during the. Product details the tyrolit machinist's stone is precision ground to an optimal flatness profile. The machinist stone is a. Milling Table Stone.

From www.lazada.co.th

โต๊ะมิลลิ่งแกนX แกนY (Milling Table) MEGA รุ่นSTZX7025ASP1 Lazada.co.th Milling Table Stone A small stone will cut more readily and remove more steel than a large one with equally applied force on a flat surface. If the stone is hollowed, the edge will be cutting and more likely to gouge the table. Product details the tyrolit machinist's stone is precision ground to an optimal flatness profile. I have always used a hard. Milling Table Stone.

From www.aliexpress.com

7inchTiltingMillingTableAdjustableAngleWorkingTableHigh Milling Table Stone Product details the tyrolit machinist's stone is precision ground to an optimal flatness profile. What is a machinist stone? If the stone is hollowed, the edge will be cutting and more likely to gouge the table. The best possible stone to use is a precision ground toolroom stone that's been diamond ground. The machinist stone is a must have tool. Milling Table Stone.

From mdaprecision.com

Lathe Milling Table MDA Precision Milling Table Stone The machinist stone is a must have tool used by all precision cnc machinist. If the stone is hollowed, the edge will be cutting and more likely to gouge the table. It'll skate on the surface of the table and not remove. The best possible stone to use is a precision ground toolroom stone that's been diamond ground. Can someone. Milling Table Stone.

From www.vevor.com.au

VEVOR 178x125mm Tilting Milling Table Angle Plates Clean Precise Milling Table Stone The machinist stone is a must have tool used by all precision cnc machinist. In this video, titan will explain how and why we use this stone during the. If the stone is hollowed, the edge will be cutting and more likely to gouge the table. Can someone please explain what. What is a machinist stone? Product details the tyrolit. Milling Table Stone.

From gainjoys.en.made-in-china.com

Gainjoys Diamond Stone Milling Wheel Thread Matcha Stone Mill China Milling Table Stone If the stone is hollowed, the edge will be cutting and more likely to gouge the table. A small stone will cut more readily and remove more steel than a large one with equally applied force on a flat surface. It'll skate on the surface of the table and not remove. The best possible stone to use is a precision. Milling Table Stone.

From www.pinterest.com

Milling Table 18 Compound milling table Milling table, Metal shop Milling Table Stone One layer contains a relatively rough silicon. Can someone please explain what. If the stone is hollowed, the edge will be cutting and more likely to gouge the table. The machinist stone is a must have tool used by all precision cnc machinist. Product details the tyrolit machinist's stone is precision ground to an optimal flatness profile. A small stone. Milling Table Stone.

From www.manomano.co.uk

VEVOR Milling Table 17.7×6.7Inch Compound Slide Milling Table Milling Table Stone I would stone with a fine grit stone but i would make sure that the surface of the stone is flat. The machinist stone is a must have tool used by all precision cnc machinist. Ive heard the term stoning to take away surface defects on a milling table or the bore of a morse taper. A small stone will. Milling Table Stone.