Thermoplastic Bonding . Fusion bonding or welding involves heating and melting of the thermoplastic surfaces and pressing the surfaces together for joint. This review paper summarizes the current bonding processes being practiced for the fabrication of thermoplastic microfluidic devices,. Thermoplastic adhesives can be applied as a molten liquid to encapsulate the fabric and then harden by cooling. Fusion bonding of thermoplastic composites can reduce overall manufacturing cost and is expected to replace traditional joining and assembly. The present work is concerned with adhesive bonding of thermoplastic composites used in general aerospace applications, including polyphenylene sulfide (pps), polyetherimide (pei) and.

from www.semanticscholar.org

Fusion bonding or welding involves heating and melting of the thermoplastic surfaces and pressing the surfaces together for joint. The present work is concerned with adhesive bonding of thermoplastic composites used in general aerospace applications, including polyphenylene sulfide (pps), polyetherimide (pei) and. This review paper summarizes the current bonding processes being practiced for the fabrication of thermoplastic microfluidic devices,. Thermoplastic adhesives can be applied as a molten liquid to encapsulate the fabric and then harden by cooling. Fusion bonding of thermoplastic composites can reduce overall manufacturing cost and is expected to replace traditional joining and assembly.

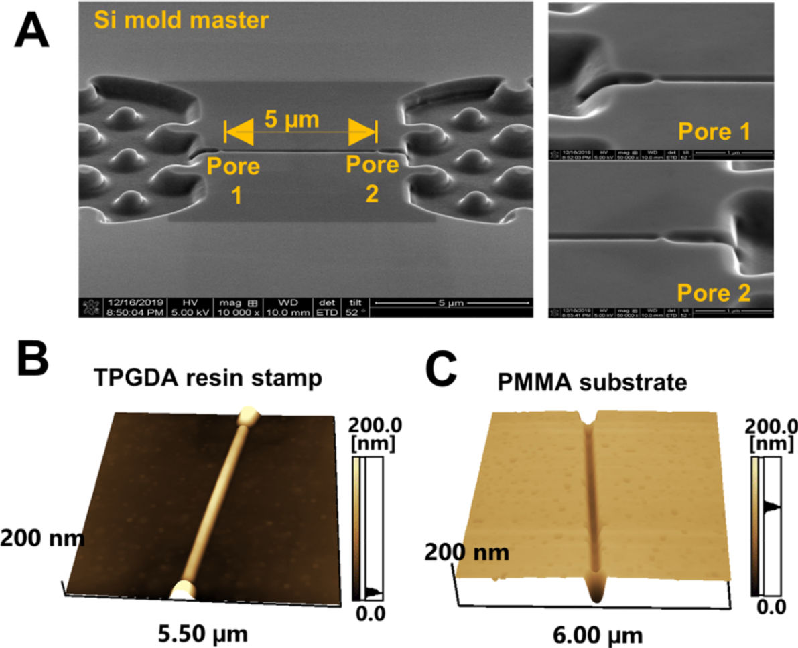

Figure 1 from Tailoring Thermoplastic InPlane Nanopore Size by Thermal

Thermoplastic Bonding The present work is concerned with adhesive bonding of thermoplastic composites used in general aerospace applications, including polyphenylene sulfide (pps), polyetherimide (pei) and. Fusion bonding or welding involves heating and melting of the thermoplastic surfaces and pressing the surfaces together for joint. The present work is concerned with adhesive bonding of thermoplastic composites used in general aerospace applications, including polyphenylene sulfide (pps), polyetherimide (pei) and. This review paper summarizes the current bonding processes being practiced for the fabrication of thermoplastic microfluidic devices,. Thermoplastic adhesives can be applied as a molten liquid to encapsulate the fabric and then harden by cooling. Fusion bonding of thermoplastic composites can reduce overall manufacturing cost and is expected to replace traditional joining and assembly.

From www.veryst.com

FTIR microscopy analysis of thermoplastic solvent bonding Veryst Thermoplastic Bonding Thermoplastic adhesives can be applied as a molten liquid to encapsulate the fabric and then harden by cooling. The present work is concerned with adhesive bonding of thermoplastic composites used in general aerospace applications, including polyphenylene sulfide (pps), polyetherimide (pei) and. Fusion bonding or welding involves heating and melting of the thermoplastic surfaces and pressing the surfaces together for joint.. Thermoplastic Bonding.

From www.veryst.com

FTIR microscopy analysis of thermoplastic solvent bonding Veryst Thermoplastic Bonding The present work is concerned with adhesive bonding of thermoplastic composites used in general aerospace applications, including polyphenylene sulfide (pps), polyetherimide (pei) and. Fusion bonding of thermoplastic composites can reduce overall manufacturing cost and is expected to replace traditional joining and assembly. Thermoplastic adhesives can be applied as a molten liquid to encapsulate the fabric and then harden by cooling.. Thermoplastic Bonding.

From radiofrequencywelding.com

Thermoplastic Foam Bonding Services RF Foam Bonding Thermoplastic Bonding Thermoplastic adhesives can be applied as a molten liquid to encapsulate the fabric and then harden by cooling. The present work is concerned with adhesive bonding of thermoplastic composites used in general aerospace applications, including polyphenylene sulfide (pps), polyetherimide (pei) and. Fusion bonding of thermoplastic composites can reduce overall manufacturing cost and is expected to replace traditional joining and assembly.. Thermoplastic Bonding.

From pubs.acs.org

Controlled Thermal Imidization of Thermoplastic Polyimide for Temporary Thermoplastic Bonding Fusion bonding of thermoplastic composites can reduce overall manufacturing cost and is expected to replace traditional joining and assembly. Thermoplastic adhesives can be applied as a molten liquid to encapsulate the fabric and then harden by cooling. The present work is concerned with adhesive bonding of thermoplastic composites used in general aerospace applications, including polyphenylene sulfide (pps), polyetherimide (pei) and.. Thermoplastic Bonding.

From www.researchgate.net

Manufacturing toughened thermoplastic tapes and bonding DCB samples Thermoplastic Bonding Fusion bonding or welding involves heating and melting of the thermoplastic surfaces and pressing the surfaces together for joint. This review paper summarizes the current bonding processes being practiced for the fabrication of thermoplastic microfluidic devices,. The present work is concerned with adhesive bonding of thermoplastic composites used in general aerospace applications, including polyphenylene sulfide (pps), polyetherimide (pei) and. Thermoplastic. Thermoplastic Bonding.

From blogs.rsc.org

The Name is Bond Heat Bond Using a Heated Lamination Press for Thermoplastic Bonding Thermoplastic adhesives can be applied as a molten liquid to encapsulate the fabric and then harden by cooling. Fusion bonding or welding involves heating and melting of the thermoplastic surfaces and pressing the surfaces together for joint. The present work is concerned with adhesive bonding of thermoplastic composites used in general aerospace applications, including polyphenylene sulfide (pps), polyetherimide (pei) and.. Thermoplastic Bonding.

From www.semanticscholar.org

Figure 1 from Tailoring Thermoplastic InPlane Nanopore Size by Thermal Thermoplastic Bonding Thermoplastic adhesives can be applied as a molten liquid to encapsulate the fabric and then harden by cooling. Fusion bonding of thermoplastic composites can reduce overall manufacturing cost and is expected to replace traditional joining and assembly. The present work is concerned with adhesive bonding of thermoplastic composites used in general aerospace applications, including polyphenylene sulfide (pps), polyetherimide (pei) and.. Thermoplastic Bonding.

From www.weldmaster.com

Thermoplastic Welding & Bonding Machines, Plastic Weld Thermoplastic Bonding Thermoplastic adhesives can be applied as a molten liquid to encapsulate the fabric and then harden by cooling. This review paper summarizes the current bonding processes being practiced for the fabrication of thermoplastic microfluidic devices,. Fusion bonding or welding involves heating and melting of the thermoplastic surfaces and pressing the surfaces together for joint. The present work is concerned with. Thermoplastic Bonding.

From www.researchgate.net

(a) Schematics showing the procedures for solvent bonding for Thermoplastic Bonding Fusion bonding or welding involves heating and melting of the thermoplastic surfaces and pressing the surfaces together for joint. The present work is concerned with adhesive bonding of thermoplastic composites used in general aerospace applications, including polyphenylene sulfide (pps), polyetherimide (pei) and. Thermoplastic adhesives can be applied as a molten liquid to encapsulate the fabric and then harden by cooling.. Thermoplastic Bonding.

From www.eatonhand.com

Trauma Percutaneous Pin Stabilization with Thermoplastic Bonding Thermoplastic Bonding Thermoplastic adhesives can be applied as a molten liquid to encapsulate the fabric and then harden by cooling. The present work is concerned with adhesive bonding of thermoplastic composites used in general aerospace applications, including polyphenylene sulfide (pps), polyetherimide (pei) and. This review paper summarizes the current bonding processes being practiced for the fabrication of thermoplastic microfluidic devices,. Fusion bonding. Thermoplastic Bonding.

From www.scribd.com

Advances in Fusion Bonding Techniques For Joining Thermoplastic Matrix Thermoplastic Bonding Fusion bonding or welding involves heating and melting of the thermoplastic surfaces and pressing the surfaces together for joint. This review paper summarizes the current bonding processes being practiced for the fabrication of thermoplastic microfluidic devices,. Fusion bonding of thermoplastic composites can reduce overall manufacturing cost and is expected to replace traditional joining and assembly. The present work is concerned. Thermoplastic Bonding.

From www.slideshare.net

Plastic Thermoplastic Bonding Fusion bonding of thermoplastic composites can reduce overall manufacturing cost and is expected to replace traditional joining and assembly. Fusion bonding or welding involves heating and melting of the thermoplastic surfaces and pressing the surfaces together for joint. The present work is concerned with adhesive bonding of thermoplastic composites used in general aerospace applications, including polyphenylene sulfide (pps), polyetherimide (pei). Thermoplastic Bonding.

From eatonhand.com

Trauma Percutaneous Pin Stabilization with Thermoplastic Bonding Thermoplastic Bonding Fusion bonding or welding involves heating and melting of the thermoplastic surfaces and pressing the surfaces together for joint. Thermoplastic adhesives can be applied as a molten liquid to encapsulate the fabric and then harden by cooling. Fusion bonding of thermoplastic composites can reduce overall manufacturing cost and is expected to replace traditional joining and assembly. This review paper summarizes. Thermoplastic Bonding.

From www.youtube.com

Thermoplastics and Thermosetting plastics Polymer Chemistry YouTube Thermoplastic Bonding This review paper summarizes the current bonding processes being practiced for the fabrication of thermoplastic microfluidic devices,. The present work is concerned with adhesive bonding of thermoplastic composites used in general aerospace applications, including polyphenylene sulfide (pps), polyetherimide (pei) and. Fusion bonding of thermoplastic composites can reduce overall manufacturing cost and is expected to replace traditional joining and assembly. Fusion. Thermoplastic Bonding.

From www.iqsdirectory.com

Plastic Trim Types, Extrusion Methods, Applications, and Benefits Thermoplastic Bonding Fusion bonding of thermoplastic composites can reduce overall manufacturing cost and is expected to replace traditional joining and assembly. This review paper summarizes the current bonding processes being practiced for the fabrication of thermoplastic microfluidic devices,. Thermoplastic adhesives can be applied as a molten liquid to encapsulate the fabric and then harden by cooling. The present work is concerned with. Thermoplastic Bonding.

From exoighysx.blob.core.windows.net

Thermoplastic Bonding Films at Stephen Crooms blog Thermoplastic Bonding This review paper summarizes the current bonding processes being practiced for the fabrication of thermoplastic microfluidic devices,. Fusion bonding of thermoplastic composites can reduce overall manufacturing cost and is expected to replace traditional joining and assembly. Thermoplastic adhesives can be applied as a molten liquid to encapsulate the fabric and then harden by cooling. Fusion bonding or welding involves heating. Thermoplastic Bonding.

From www.eatonhand.com

Trauma Percutaneous Pin Stabilization with Thermoplastic Bonding Thermoplastic Bonding The present work is concerned with adhesive bonding of thermoplastic composites used in general aerospace applications, including polyphenylene sulfide (pps), polyetherimide (pei) and. Fusion bonding or welding involves heating and melting of the thermoplastic surfaces and pressing the surfaces together for joint. Fusion bonding of thermoplastic composites can reduce overall manufacturing cost and is expected to replace traditional joining and. Thermoplastic Bonding.

From www.eatonhand.com

Trauma Percutaneous Pin Stabilization with Thermoplastic Bonding Thermoplastic Bonding This review paper summarizes the current bonding processes being practiced for the fabrication of thermoplastic microfluidic devices,. Fusion bonding of thermoplastic composites can reduce overall manufacturing cost and is expected to replace traditional joining and assembly. Thermoplastic adhesives can be applied as a molten liquid to encapsulate the fabric and then harden by cooling. The present work is concerned with. Thermoplastic Bonding.

From www.veryst.com

FTIR microscopy analysis of thermoplastic solvent bonding Veryst Thermoplastic Bonding Fusion bonding of thermoplastic composites can reduce overall manufacturing cost and is expected to replace traditional joining and assembly. The present work is concerned with adhesive bonding of thermoplastic composites used in general aerospace applications, including polyphenylene sulfide (pps), polyetherimide (pei) and. Thermoplastic adhesives can be applied as a molten liquid to encapsulate the fabric and then harden by cooling.. Thermoplastic Bonding.

From www.pinterest.com

Design Guide for Bonding Rubber & Thermoplastic Elastomers Design Thermoplastic Bonding Fusion bonding or welding involves heating and melting of the thermoplastic surfaces and pressing the surfaces together for joint. The present work is concerned with adhesive bonding of thermoplastic composites used in general aerospace applications, including polyphenylene sulfide (pps), polyetherimide (pei) and. Fusion bonding of thermoplastic composites can reduce overall manufacturing cost and is expected to replace traditional joining and. Thermoplastic Bonding.

From blogs.rsc.org

The Name is Bond Heat Bond Using a Heated Lamination Press for Thermoplastic Bonding Fusion bonding or welding involves heating and melting of the thermoplastic surfaces and pressing the surfaces together for joint. Fusion bonding of thermoplastic composites can reduce overall manufacturing cost and is expected to replace traditional joining and assembly. This review paper summarizes the current bonding processes being practiced for the fabrication of thermoplastic microfluidic devices,. The present work is concerned. Thermoplastic Bonding.

From www.eatonhand.com

Trauma Percutaneous Pin Stabilization with Thermoplastic Bonding Thermoplastic Bonding The present work is concerned with adhesive bonding of thermoplastic composites used in general aerospace applications, including polyphenylene sulfide (pps), polyetherimide (pei) and. Fusion bonding of thermoplastic composites can reduce overall manufacturing cost and is expected to replace traditional joining and assembly. Fusion bonding or welding involves heating and melting of the thermoplastic surfaces and pressing the surfaces together for. Thermoplastic Bonding.

From radiofrequencywelding.com

Thermoplastic Foam Bonding Services RF Foam Bonding Thermoplastic Bonding Fusion bonding or welding involves heating and melting of the thermoplastic surfaces and pressing the surfaces together for joint. Fusion bonding of thermoplastic composites can reduce overall manufacturing cost and is expected to replace traditional joining and assembly. Thermoplastic adhesives can be applied as a molten liquid to encapsulate the fabric and then harden by cooling. This review paper summarizes. Thermoplastic Bonding.

From eatonhand.com

Trauma Percutaneous Pin Stabilization with Thermoplastic Bonding Thermoplastic Bonding The present work is concerned with adhesive bonding of thermoplastic composites used in general aerospace applications, including polyphenylene sulfide (pps), polyetherimide (pei) and. Fusion bonding or welding involves heating and melting of the thermoplastic surfaces and pressing the surfaces together for joint. Fusion bonding of thermoplastic composites can reduce overall manufacturing cost and is expected to replace traditional joining and. Thermoplastic Bonding.

From www.themadething.com

Bonding metal and thermoplastic without adhesive Thermoplastic Bonding This review paper summarizes the current bonding processes being practiced for the fabrication of thermoplastic microfluidic devices,. Fusion bonding or welding involves heating and melting of the thermoplastic surfaces and pressing the surfaces together for joint. Fusion bonding of thermoplastic composites can reduce overall manufacturing cost and is expected to replace traditional joining and assembly. Thermoplastic adhesives can be applied. Thermoplastic Bonding.

From www.linkedin.com

More sustainable Adhesive Bonding of Thermoplastic Composites Thermoplastic Bonding The present work is concerned with adhesive bonding of thermoplastic composites used in general aerospace applications, including polyphenylene sulfide (pps), polyetherimide (pei) and. Fusion bonding or welding involves heating and melting of the thermoplastic surfaces and pressing the surfaces together for joint. Thermoplastic adhesives can be applied as a molten liquid to encapsulate the fabric and then harden by cooling.. Thermoplastic Bonding.

From www.mdpi.com

Micromachines Free FullText Bonding Strategies for Thermoplastics Thermoplastic Bonding The present work is concerned with adhesive bonding of thermoplastic composites used in general aerospace applications, including polyphenylene sulfide (pps), polyetherimide (pei) and. Fusion bonding of thermoplastic composites can reduce overall manufacturing cost and is expected to replace traditional joining and assembly. This review paper summarizes the current bonding processes being practiced for the fabrication of thermoplastic microfluidic devices,. Thermoplastic. Thermoplastic Bonding.

From www.youtube.com

Episode 3 BONDING OF THERMOPLASTICS The 7 Steps of the Ultrasonic Bond Thermoplastic Bonding Fusion bonding of thermoplastic composites can reduce overall manufacturing cost and is expected to replace traditional joining and assembly. Fusion bonding or welding involves heating and melting of the thermoplastic surfaces and pressing the surfaces together for joint. This review paper summarizes the current bonding processes being practiced for the fabrication of thermoplastic microfluidic devices,. The present work is concerned. Thermoplastic Bonding.

From eatonhand.com

Trauma Percutaneous Pin Stabilization with Thermoplastic Bonding Thermoplastic Bonding Thermoplastic adhesives can be applied as a molten liquid to encapsulate the fabric and then harden by cooling. This review paper summarizes the current bonding processes being practiced for the fabrication of thermoplastic microfluidic devices,. Fusion bonding or welding involves heating and melting of the thermoplastic surfaces and pressing the surfaces together for joint. Fusion bonding of thermoplastic composites can. Thermoplastic Bonding.

From e-hand.com

Trauma Percutaneous Pin Stabilization with Thermoplastic Bonding Thermoplastic Bonding The present work is concerned with adhesive bonding of thermoplastic composites used in general aerospace applications, including polyphenylene sulfide (pps), polyetherimide (pei) and. Fusion bonding or welding involves heating and melting of the thermoplastic surfaces and pressing the surfaces together for joint. This review paper summarizes the current bonding processes being practiced for the fabrication of thermoplastic microfluidic devices,. Thermoplastic. Thermoplastic Bonding.

From www.researchgate.net

SEM micrographs showing bonding of thermoplastic polymer (up Thermoplastic Bonding Thermoplastic adhesives can be applied as a molten liquid to encapsulate the fabric and then harden by cooling. The present work is concerned with adhesive bonding of thermoplastic composites used in general aerospace applications, including polyphenylene sulfide (pps), polyetherimide (pei) and. Fusion bonding of thermoplastic composites can reduce overall manufacturing cost and is expected to replace traditional joining and assembly.. Thermoplastic Bonding.

From www.e-hand.com

Trauma Percutaneous Pin Stabilization with Thermoplastic Bonding Thermoplastic Bonding Thermoplastic adhesives can be applied as a molten liquid to encapsulate the fabric and then harden by cooling. This review paper summarizes the current bonding processes being practiced for the fabrication of thermoplastic microfluidic devices,. Fusion bonding of thermoplastic composites can reduce overall manufacturing cost and is expected to replace traditional joining and assembly. The present work is concerned with. Thermoplastic Bonding.

From pubs.rsc.org

Bonding of thermoplastic microfluidics by using dry adhesive tape RSC Thermoplastic Bonding Thermoplastic adhesives can be applied as a molten liquid to encapsulate the fabric and then harden by cooling. The present work is concerned with adhesive bonding of thermoplastic composites used in general aerospace applications, including polyphenylene sulfide (pps), polyetherimide (pei) and. This review paper summarizes the current bonding processes being practiced for the fabrication of thermoplastic microfluidic devices,. Fusion bonding. Thermoplastic Bonding.

From eatonhand.com

Trauma Percutaneous Pin Stabilization with Thermoplastic Bonding Thermoplastic Bonding Fusion bonding or welding involves heating and melting of the thermoplastic surfaces and pressing the surfaces together for joint. Fusion bonding of thermoplastic composites can reduce overall manufacturing cost and is expected to replace traditional joining and assembly. The present work is concerned with adhesive bonding of thermoplastic composites used in general aerospace applications, including polyphenylene sulfide (pps), polyetherimide (pei). Thermoplastic Bonding.

From eatonhand.com

Trauma Percutaneous Pin Stabilization with Thermoplastic Bonding Thermoplastic Bonding The present work is concerned with adhesive bonding of thermoplastic composites used in general aerospace applications, including polyphenylene sulfide (pps), polyetherimide (pei) and. Fusion bonding of thermoplastic composites can reduce overall manufacturing cost and is expected to replace traditional joining and assembly. This review paper summarizes the current bonding processes being practiced for the fabrication of thermoplastic microfluidic devices,. Thermoplastic. Thermoplastic Bonding.