Tolerance Vs Control Limits . They are similar to cp and cpk, but for machines instead of. Learn the difference between control limits and specification limits in six sigma quality management. Control limits are based on process data and monitor. Cm and cmk are measures of how well a machine fits into the tolerance width. Tolerance is the total amount a dimension may vary and is the difference between the upper and lower limits. Learn how to calculate and use upper control limit (ucl) and lower control limit (lcl) to monitor, control, and improve processes with spc. With the individuals chart, the difference between the ucl and lcl is called the natural tolerance. Learn how to apply tolerances to mating parts, fit types, and important terms. It represents the range the process requires to operate with only common causes of. The classical x/r chart control limits apply to subgroup averages, and not to the results of individual items at all. Learn the difference between control limits and specification limits in quality control. Control limits are statistical boundaries that define the acceptable range of variation within a process. Control limits indicate the actual.

from www.slideserve.com

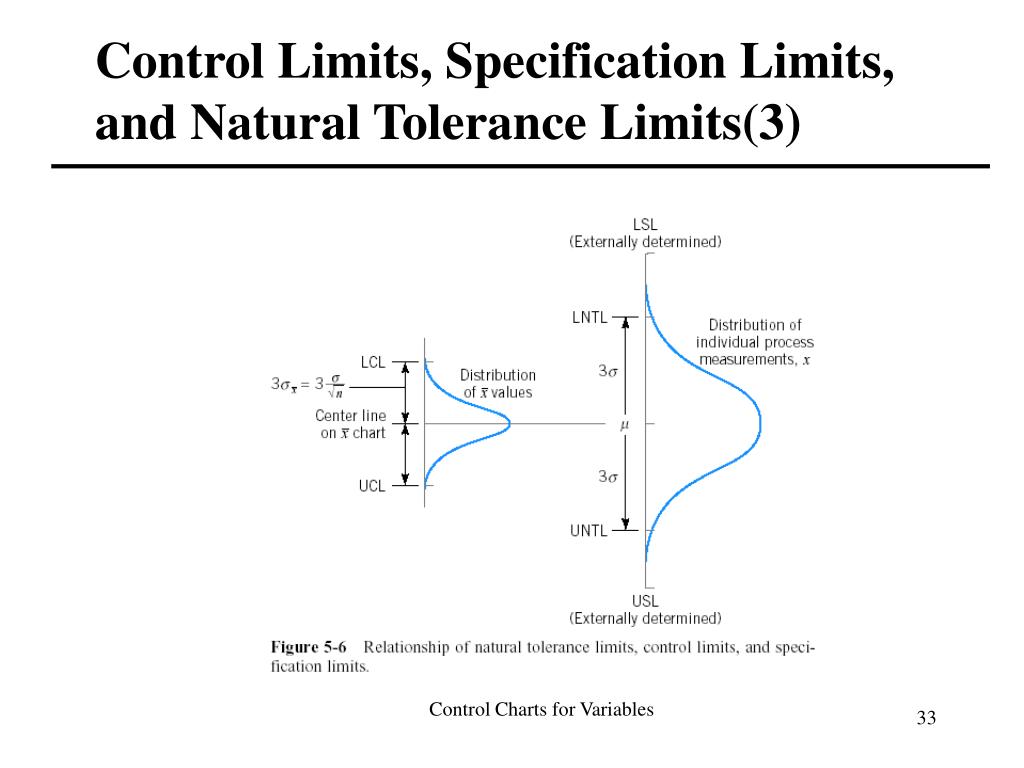

With the individuals chart, the difference between the ucl and lcl is called the natural tolerance. Learn how to calculate and use upper control limit (ucl) and lower control limit (lcl) to monitor, control, and improve processes with spc. Tolerance is the total amount a dimension may vary and is the difference between the upper and lower limits. Learn the difference between control limits and specification limits in quality control. Control limits indicate the actual. Learn the difference between control limits and specification limits in six sigma quality management. Cm and cmk are measures of how well a machine fits into the tolerance width. Learn how to apply tolerances to mating parts, fit types, and important terms. It represents the range the process requires to operate with only common causes of. Control limits are based on process data and monitor.

PPT Introduction PowerPoint Presentation, free download ID515945

Tolerance Vs Control Limits With the individuals chart, the difference between the ucl and lcl is called the natural tolerance. Learn how to apply tolerances to mating parts, fit types, and important terms. Learn the difference between control limits and specification limits in quality control. With the individuals chart, the difference between the ucl and lcl is called the natural tolerance. The classical x/r chart control limits apply to subgroup averages, and not to the results of individual items at all. Learn the difference between control limits and specification limits in six sigma quality management. It represents the range the process requires to operate with only common causes of. Control limits indicate the actual. Learn how to calculate and use upper control limit (ucl) and lower control limit (lcl) to monitor, control, and improve processes with spc. Control limits are based on process data and monitor. Tolerance is the total amount a dimension may vary and is the difference between the upper and lower limits. Control limits are statistical boundaries that define the acceptable range of variation within a process. They are similar to cp and cpk, but for machines instead of. Cm and cmk are measures of how well a machine fits into the tolerance width.

From www.slideserve.com

PPT Control Chart (continued) PowerPoint Presentation, free download Tolerance Vs Control Limits Learn how to calculate and use upper control limit (ucl) and lower control limit (lcl) to monitor, control, and improve processes with spc. Control limits are based on process data and monitor. Tolerance is the total amount a dimension may vary and is the difference between the upper and lower limits. Learn the difference between control limits and specification limits. Tolerance Vs Control Limits.

From www.bostoncenterless.com

Metric Tolerance Chart for ISO 2862 Round Bar Tolerances Tolerance Vs Control Limits Learn the difference between control limits and specification limits in quality control. Control limits are based on process data and monitor. Tolerance is the total amount a dimension may vary and is the difference between the upper and lower limits. They are similar to cp and cpk, but for machines instead of. Control limits are statistical boundaries that define the. Tolerance Vs Control Limits.

From www.vrogue.co

Best 5 Difference Between Control Limits And Specific vrogue.co Tolerance Vs Control Limits The classical x/r chart control limits apply to subgroup averages, and not to the results of individual items at all. Learn how to apply tolerances to mating parts, fit types, and important terms. Learn the difference between control limits and specification limits in quality control. Learn the difference between control limits and specification limits in six sigma quality management. They. Tolerance Vs Control Limits.

From cyntegrity.com

Quality Tolerance Limits versus Key Risk Indicators Cyntegrity Tolerance Vs Control Limits Control limits indicate the actual. With the individuals chart, the difference between the ucl and lcl is called the natural tolerance. Learn how to calculate and use upper control limit (ucl) and lower control limit (lcl) to monitor, control, and improve processes with spc. It represents the range the process requires to operate with only common causes of. Learn the. Tolerance Vs Control Limits.

From www.youtube.com

LIMITS FITS AND TOLERANCES What is limit fit & tolerance and its need Tolerance Vs Control Limits Control limits are statistical boundaries that define the acceptable range of variation within a process. Tolerance is the total amount a dimension may vary and is the difference between the upper and lower limits. Learn how to apply tolerances to mating parts, fit types, and important terms. It represents the range the process requires to operate with only common causes. Tolerance Vs Control Limits.

From www.slideserve.com

PPT Chapter 8 Project Quality Management PowerPoint Presentation Tolerance Vs Control Limits Control limits indicate the actual. Tolerance is the total amount a dimension may vary and is the difference between the upper and lower limits. Learn how to calculate and use upper control limit (ucl) and lower control limit (lcl) to monitor, control, and improve processes with spc. Learn the difference between control limits and specification limits in quality control. They. Tolerance Vs Control Limits.

From werk24.io

Tolerances IT Grades, General Tolerances Tolerance Vs Control Limits Cm and cmk are measures of how well a machine fits into the tolerance width. Learn the difference between control limits and specification limits in quality control. Tolerance is the total amount a dimension may vary and is the difference between the upper and lower limits. Learn how to apply tolerances to mating parts, fit types, and important terms. Learn. Tolerance Vs Control Limits.

From www.slideserve.com

PPT Statistical Process Control (SPC) PowerPoint Presentation, free Tolerance Vs Control Limits Learn the difference between control limits and specification limits in quality control. Control limits are based on process data and monitor. Tolerance is the total amount a dimension may vary and is the difference between the upper and lower limits. The classical x/r chart control limits apply to subgroup averages, and not to the results of individual items at all.. Tolerance Vs Control Limits.

From werk24.io

Tolerances IT Grades, General Tolerances Tolerance Vs Control Limits It represents the range the process requires to operate with only common causes of. They are similar to cp and cpk, but for machines instead of. Learn how to apply tolerances to mating parts, fit types, and important terms. Tolerance is the total amount a dimension may vary and is the difference between the upper and lower limits. Learn the. Tolerance Vs Control Limits.

From www.youtube.com

Difference between Tolerance and Allowance Limits Fits Tolerances Tolerance Vs Control Limits With the individuals chart, the difference between the ucl and lcl is called the natural tolerance. Control limits are statistical boundaries that define the acceptable range of variation within a process. Control limits are based on process data and monitor. Learn how to calculate and use upper control limit (ucl) and lower control limit (lcl) to monitor, control, and improve. Tolerance Vs Control Limits.

From www.slideserve.com

PPT Introduction PowerPoint Presentation, free download ID515945 Tolerance Vs Control Limits It represents the range the process requires to operate with only common causes of. Tolerance is the total amount a dimension may vary and is the difference between the upper and lower limits. Learn how to apply tolerances to mating parts, fit types, and important terms. Control limits are statistical boundaries that define the acceptable range of variation within a. Tolerance Vs Control Limits.

From www.slideserve.com

PPT Fits and Tolerances PowerPoint Presentation, free download ID Tolerance Vs Control Limits Learn the difference between control limits and specification limits in six sigma quality management. Control limits indicate the actual. Learn how to calculate and use upper control limit (ucl) and lower control limit (lcl) to monitor, control, and improve processes with spc. They are similar to cp and cpk, but for machines instead of. Learn the difference between control limits. Tolerance Vs Control Limits.

From www.researchgate.net

2 Specification Limit Vs. Control Limits Download Scientific Diagram Tolerance Vs Control Limits With the individuals chart, the difference between the ucl and lcl is called the natural tolerance. Control limits are statistical boundaries that define the acceptable range of variation within a process. Control limits indicate the actual. The classical x/r chart control limits apply to subgroup averages, and not to the results of individual items at all. It represents the range. Tolerance Vs Control Limits.

From www.slideserve.com

PPT Six Sigma Quality PowerPoint Presentation, free download ID6453509 Tolerance Vs Control Limits Learn the difference between control limits and specification limits in quality control. With the individuals chart, the difference between the ucl and lcl is called the natural tolerance. Control limits are based on process data and monitor. Control limits indicate the actual. Learn how to calculate and use upper control limit (ucl) and lower control limit (lcl) to monitor, control,. Tolerance Vs Control Limits.

From www.slideserve.com

PPT Introduction PowerPoint Presentation, free download ID515945 Tolerance Vs Control Limits Learn how to apply tolerances to mating parts, fit types, and important terms. Learn the difference between control limits and specification limits in quality control. Tolerance is the total amount a dimension may vary and is the difference between the upper and lower limits. The classical x/r chart control limits apply to subgroup averages, and not to the results of. Tolerance Vs Control Limits.

From www.youtube.com

Control Limit Vs Specification Limit Difference between Control Tolerance Vs Control Limits With the individuals chart, the difference between the ucl and lcl is called the natural tolerance. Learn how to calculate and use upper control limit (ucl) and lower control limit (lcl) to monitor, control, and improve processes with spc. Learn how to apply tolerances to mating parts, fit types, and important terms. Control limits are statistical boundaries that define the. Tolerance Vs Control Limits.

From www.slideserve.com

PPT LIMITS, FITS, TOLERANCES & SURFACE ROUGHNESS PowerPoint Tolerance Vs Control Limits Learn how to apply tolerances to mating parts, fit types, and important terms. With the individuals chart, the difference between the ucl and lcl is called the natural tolerance. Control limits indicate the actual. The classical x/r chart control limits apply to subgroup averages, and not to the results of individual items at all. Learn the difference between control limits. Tolerance Vs Control Limits.

From www.slideserve.com

PPT PROCESS CAPABILITY PowerPoint Presentation, free download ID Tolerance Vs Control Limits Control limits are statistical boundaries that define the acceptable range of variation within a process. Control limits are based on process data and monitor. With the individuals chart, the difference between the ucl and lcl is called the natural tolerance. Learn how to apply tolerances to mating parts, fit types, and important terms. Learn how to calculate and use upper. Tolerance Vs Control Limits.

From isssp.org

Statistical Tolerance Intervals Definition, Use, and Calculation Tolerance Vs Control Limits Control limits are based on process data and monitor. Learn how to calculate and use upper control limit (ucl) and lower control limit (lcl) to monitor, control, and improve processes with spc. Learn the difference between control limits and specification limits in six sigma quality management. They are similar to cp and cpk, but for machines instead of. Cm and. Tolerance Vs Control Limits.

From www.slideserve.com

PPT Tolerances PowerPoint Presentation, free download ID481230 Tolerance Vs Control Limits Cm and cmk are measures of how well a machine fits into the tolerance width. Learn how to apply tolerances to mating parts, fit types, and important terms. Learn the difference between control limits and specification limits in quality control. With the individuals chart, the difference between the ucl and lcl is called the natural tolerance. Control limits are based. Tolerance Vs Control Limits.

From www.latestquality.com

What Is the Difference Between Control Limits and Specification Limits Tolerance Vs Control Limits Learn how to apply tolerances to mating parts, fit types, and important terms. Control limits are statistical boundaries that define the acceptable range of variation within a process. Learn the difference between control limits and specification limits in six sigma quality management. Tolerance is the total amount a dimension may vary and is the difference between the upper and lower. Tolerance Vs Control Limits.

From www.slideserve.com

PPT Tolerances PowerPoint Presentation, free download ID481230 Tolerance Vs Control Limits Learn how to apply tolerances to mating parts, fit types, and important terms. Tolerance is the total amount a dimension may vary and is the difference between the upper and lower limits. Control limits are statistical boundaries that define the acceptable range of variation within a process. Learn how to calculate and use upper control limit (ucl) and lower control. Tolerance Vs Control Limits.

From www.slideserve.com

PPT CHAPTER (2) Dimensions, Tolerances, And Surfaces PowerPoint Tolerance Vs Control Limits The classical x/r chart control limits apply to subgroup averages, and not to the results of individual items at all. Learn how to calculate and use upper control limit (ucl) and lower control limit (lcl) to monitor, control, and improve processes with spc. With the individuals chart, the difference between the ucl and lcl is called the natural tolerance. They. Tolerance Vs Control Limits.

From www.mcgill.ca

Principles of Tolerancing Engineering Design McGill University Tolerance Vs Control Limits With the individuals chart, the difference between the ucl and lcl is called the natural tolerance. Control limits are statistical boundaries that define the acceptable range of variation within a process. Cm and cmk are measures of how well a machine fits into the tolerance width. Learn how to apply tolerances to mating parts, fit types, and important terms. Tolerance. Tolerance Vs Control Limits.

From www.slideserve.com

PPT Tolerances PowerPoint Presentation ID5812015 Tolerance Vs Control Limits With the individuals chart, the difference between the ucl and lcl is called the natural tolerance. They are similar to cp and cpk, but for machines instead of. Control limits indicate the actual. The classical x/r chart control limits apply to subgroup averages, and not to the results of individual items at all. Tolerance is the total amount a dimension. Tolerance Vs Control Limits.

From www.youtube.com

Tolerance, Limits and Fits YouTube Tolerance Vs Control Limits They are similar to cp and cpk, but for machines instead of. Tolerance is the total amount a dimension may vary and is the difference between the upper and lower limits. Learn the difference between control limits and specification limits in quality control. Learn the difference between control limits and specification limits in six sigma quality management. Control limits indicate. Tolerance Vs Control Limits.

From www.slideserve.com

PPT CHAPTER (2) Dimensions, Tolerances, And Surfaces PowerPoint Tolerance Vs Control Limits The classical x/r chart control limits apply to subgroup averages, and not to the results of individual items at all. It represents the range the process requires to operate with only common causes of. Cm and cmk are measures of how well a machine fits into the tolerance width. They are similar to cp and cpk, but for machines instead. Tolerance Vs Control Limits.

From www.aquaportail.com

Limite de tolérance définition et explications Tolerance Vs Control Limits Learn the difference between control limits and specification limits in six sigma quality management. Learn how to calculate and use upper control limit (ucl) and lower control limit (lcl) to monitor, control, and improve processes with spc. Control limits are based on process data and monitor. Control limits are statistical boundaries that define the acceptable range of variation within a. Tolerance Vs Control Limits.

From www.smlease.com

GD&T Basics Introduction to Geometric Dimension and Tolerance Tolerance Vs Control Limits Learn the difference between control limits and specification limits in quality control. They are similar to cp and cpk, but for machines instead of. The classical x/r chart control limits apply to subgroup averages, and not to the results of individual items at all. Learn how to calculate and use upper control limit (ucl) and lower control limit (lcl) to. Tolerance Vs Control Limits.

From www.benchmarksixsigma.com

Control Limits vs Specification Limits We ask and you answer! The Tolerance Vs Control Limits Tolerance is the total amount a dimension may vary and is the difference between the upper and lower limits. With the individuals chart, the difference between the ucl and lcl is called the natural tolerance. Learn the difference between control limits and specification limits in six sigma quality management. The classical x/r chart control limits apply to subgroup averages, and. Tolerance Vs Control Limits.

From www.slideserve.com

PPT Statistical Process Control (SPC) PowerPoint Presentation, free Tolerance Vs Control Limits Learn how to apply tolerances to mating parts, fit types, and important terms. Control limits indicate the actual. It represents the range the process requires to operate with only common causes of. Learn how to calculate and use upper control limit (ucl) and lower control limit (lcl) to monitor, control, and improve processes with spc. Cm and cmk are measures. Tolerance Vs Control Limits.

From www.pinterest.com

SPC chart utilizingthetolerancelimits Tolerance, Chart, Simplify Tolerance Vs Control Limits They are similar to cp and cpk, but for machines instead of. With the individuals chart, the difference between the ucl and lcl is called the natural tolerance. Learn the difference between control limits and specification limits in quality control. Control limits indicate the actual. Cm and cmk are measures of how well a machine fits into the tolerance width.. Tolerance Vs Control Limits.

From www.slideserve.com

PPT Chapter 5a Process Capability PowerPoint Presentation, free Tolerance Vs Control Limits They are similar to cp and cpk, but for machines instead of. Cm and cmk are measures of how well a machine fits into the tolerance width. Control limits indicate the actual. Control limits are based on process data and monitor. The classical x/r chart control limits apply to subgroup averages, and not to the results of individual items at. Tolerance Vs Control Limits.

From www.youtube.com

Tolerance VS Specification YouTube Tolerance Vs Control Limits Learn the difference between control limits and specification limits in quality control. Control limits are statistical boundaries that define the acceptable range of variation within a process. Learn how to calculate and use upper control limit (ucl) and lower control limit (lcl) to monitor, control, and improve processes with spc. They are similar to cp and cpk, but for machines. Tolerance Vs Control Limits.

From www.slideserve.com

PPT Fits and Tolerances PowerPoint Presentation, free download ID Tolerance Vs Control Limits With the individuals chart, the difference between the ucl and lcl is called the natural tolerance. Learn the difference between control limits and specification limits in six sigma quality management. Learn the difference between control limits and specification limits in quality control. It represents the range the process requires to operate with only common causes of. The classical x/r chart. Tolerance Vs Control Limits.