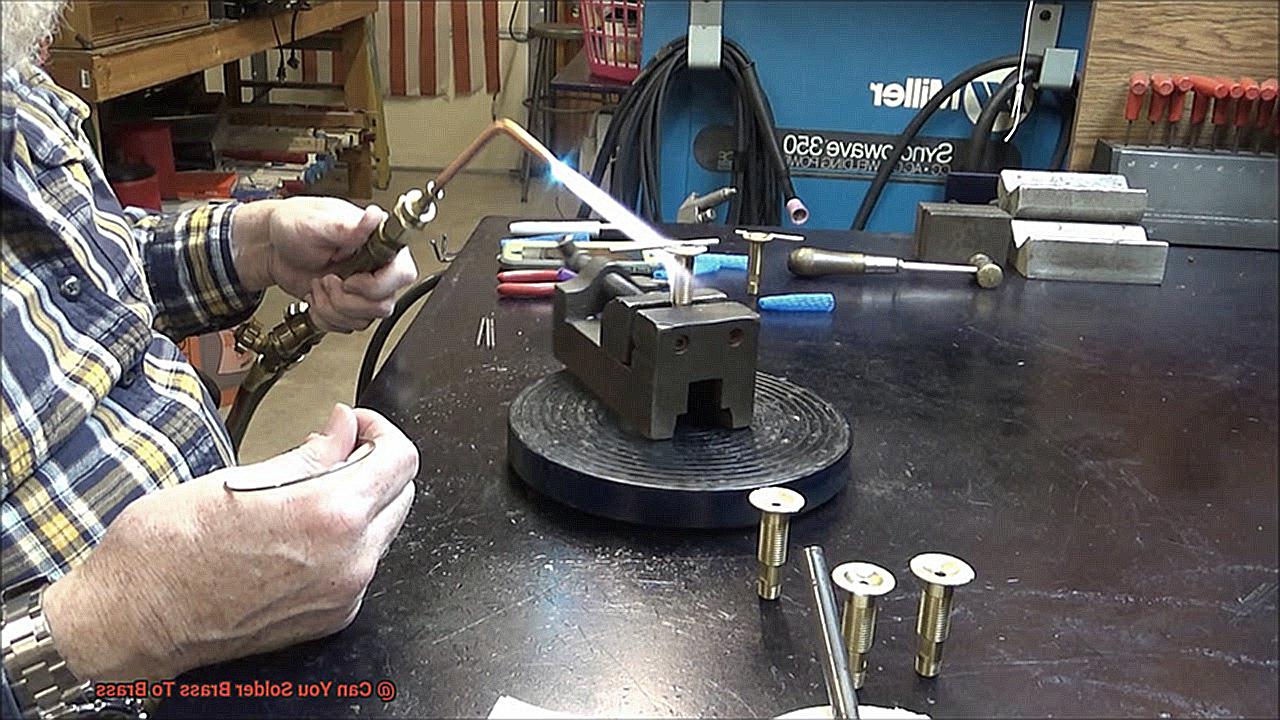

Wire Solder To Brass . To do it effectively, you should know. How do you weld brass to brass? We will walk you through the process. It involves melting an alloy, usually made of lead and tin, and using it to fill the joint between two pieces of metal, such as a brass wire. The good news is you don’t need many expensive parts or tools to start soldering copper and brass together. You just need to use the right type of solder and make sure that both pieces of brass are clean and free of any debris or oxides. It is possible to solder brass effectively. This as result of new. This is a question that many people may ask and the answer is yes, you can solder brass to brass. It is very possible to tig braze as well as solder brass to brass. Learn how to solder brass like a pro with this complete guide, from selecting the right materials to getting a clean solder joint. Make sure the surfaces of the project are clean and fit together tightly. Use the correct solder for brass and a low heat flame torch. Soldering brass doesn’t have to be complicated. But there are a few things you need to know before you try it.

from www.theweldguru.com

But there are a few things you need to know before you try it. This guide will walk you through the basics of soldering brass wire, so you can get started on your next project! We have the truth about soldering brass. I found your article while searching to see if i could solder #38 awg or #42 awg magnet wire to brass. Soldering brass doesn’t have to be complicated. In fact, all you really need is some. To do it effectively, you should know. It involves melting an alloy, usually made of lead and tin, and using it to fill the joint between two pieces of metal, such as a brass wire. It is possible to solder brass effectively. It is very possible to tig braze as well as solder brass to brass.

Can You Solder Brass To Brass? The Welding Guru

Wire Solder To Brass Make sure the surfaces of the project are clean and fit together tightly. We will walk you through the process. To do it effectively, you should know. It involves melting an alloy, usually made of lead and tin, and using it to fill the joint between two pieces of metal, such as a brass wire. This as result of new. But there are a few things you need to know before you try it. I found your article while searching to see if i could solder #38 awg or #42 awg magnet wire to brass. Soldering brass doesn’t have to be complicated. It is possible to solder brass effectively. In fact, all you really need is some. This is a question that many people may ask and the answer is yes, you can solder brass to brass. How do you weld brass to brass? You just need to use the right type of solder and make sure that both pieces of brass are clean and free of any debris or oxides. This guide will walk you through the basics of soldering brass wire, so you can get started on your next project! The good news is you don’t need many expensive parts or tools to start soldering copper and brass together. Use the correct solder for brass and a low heat flame torch.

From albionfireandice.co.uk

jewellers solder bronze / copper / brass Wire Solder To Brass Soldering brass doesn’t have to be complicated. It involves melting an alloy, usually made of lead and tin, and using it to fill the joint between two pieces of metal, such as a brass wire. It is possible to solder brass effectively. This is a question that many people may ask and the answer is yes, you can solder brass. Wire Solder To Brass.

From blog.thepipingmart.com

How to Solder Brass with a Soldering Iron Wire Solder To Brass Soldering brass doesn’t have to be complicated. How do you weld brass to brass? The good news is you don’t need many expensive parts or tools to start soldering copper and brass together. But there are a few things you need to know before you try it. We will walk you through the process. It is possible to solder brass. Wire Solder To Brass.

From blog.thepipingmart.com

How to Solder Brass Wire A StepByStep Guide Wire Solder To Brass To do it effectively, you should know. Use the correct solder for brass and a low heat flame torch. This guide will walk you through the basics of soldering brass wire, so you can get started on your next project! It is possible to solder brass effectively. It is very possible to tig braze as well as solder brass to. Wire Solder To Brass.

From www.industrialmetalsupply.com

How to Solder Brass and Copper Wire Solder To Brass We have the truth about soldering brass. It is possible to solder brass effectively. This is a question that many people may ask and the answer is yes, you can solder brass to brass. Soldering brass doesn’t have to be complicated. But there are a few things you need to know before you try it. Make sure the surfaces of. Wire Solder To Brass.

From blog.thepipingmart.com

How to Solder Brass to Stainless Steel Wire Solder To Brass Learn how to solder brass like a pro with this complete guide, from selecting the right materials to getting a clean solder joint. How do you weld brass to brass? You just need to use the right type of solder and make sure that both pieces of brass are clean and free of any debris or oxides. We will walk. Wire Solder To Brass.

From www.makeuseof.com

How to Solder Two or More Wires Together Wire Solder To Brass You just need to use the right type of solder and make sure that both pieces of brass are clean and free of any debris or oxides. To do it effectively, you should know. This is a question that many people may ask and the answer is yes, you can solder brass to brass. Learn how to solder brass like. Wire Solder To Brass.

From www.theweldguru.com

Can You Solder Brass Effectively? The Welding Guru Wire Solder To Brass Make sure the surfaces of the project are clean and fit together tightly. This guide will walk you through the basics of soldering brass wire, so you can get started on your next project! The good news is you don’t need many expensive parts or tools to start soldering copper and brass together. You just need to use the right. Wire Solder To Brass.

From weldingtrends.com

Can You Solder Brass To Brass? How To Solder It! Wire Solder To Brass Make sure the surfaces of the project are clean and fit together tightly. The good news is you don’t need many expensive parts or tools to start soldering copper and brass together. It is possible to solder brass effectively. This is a question that many people may ask and the answer is yes, you can solder brass to brass. You. Wire Solder To Brass.

From www.thespruce.com

How to Solder Wires Wire Solder To Brass We have the truth about soldering brass. You just need to use the right type of solder and make sure that both pieces of brass are clean and free of any debris or oxides. Soldering brass doesn’t have to be complicated. In fact, all you really need is some. This guide will walk you through the basics of soldering brass. Wire Solder To Brass.

From www.youtube.com

How to Solder Brass and Copper YouTube Wire Solder To Brass Make sure the surfaces of the project are clean and fit together tightly. The good news is you don’t need many expensive parts or tools to start soldering copper and brass together. This as result of new. To do it effectively, you should know. You just need to use the right type of solder and make sure that both pieces. Wire Solder To Brass.

From weldingmastermind.com

Can You Solder Brass Effectively? Here’s the Truth. Welding Mastermind Wire Solder To Brass We have the truth about soldering brass. You just need to use the right type of solder and make sure that both pieces of brass are clean and free of any debris or oxides. To do it effectively, you should know. Make sure the surfaces of the project are clean and fit together tightly. This as result of new. I. Wire Solder To Brass.

From blog.thepipingmart.com

How to Solder Brass Pipe An Overview Wire Solder To Brass We have the truth about soldering brass. I found your article while searching to see if i could solder #38 awg or #42 awg magnet wire to brass. It is very possible to tig braze as well as solder brass to brass. This guide will walk you through the basics of soldering brass wire, so you can get started on. Wire Solder To Brass.

From weldingmastermind.com

Can You Solder Brass Effectively? Here’s the Truth. Welding Mastermind Wire Solder To Brass It involves melting an alloy, usually made of lead and tin, and using it to fill the joint between two pieces of metal, such as a brass wire. We have the truth about soldering brass. To do it effectively, you should know. This as result of new. This is a question that many people may ask and the answer is. Wire Solder To Brass.

From www.youtube.com

tutorial how to soldering brass YouTube Wire Solder To Brass But there are a few things you need to know before you try it. This is a question that many people may ask and the answer is yes, you can solder brass to brass. To do it effectively, you should know. This as result of new. Make sure the surfaces of the project are clean and fit together tightly. I. Wire Solder To Brass.

From www.youtube.com

How to Solder Brass YouTube Wire Solder To Brass How do you weld brass to brass? Make sure the surfaces of the project are clean and fit together tightly. The good news is you don’t need many expensive parts or tools to start soldering copper and brass together. This as result of new. In fact, all you really need is some. This guide will walk you through the basics. Wire Solder To Brass.

From www.etsy.com

Brass Wire Solder 20 Gauge Choose Your Length Etsy Wire Solder To Brass I found your article while searching to see if i could solder #38 awg or #42 awg magnet wire to brass. To do it effectively, you should know. This guide will walk you through the basics of soldering brass wire, so you can get started on your next project! It involves melting an alloy, usually made of lead and tin,. Wire Solder To Brass.

From www.instructables.com

Brass and Copper Soldering 12 Steps (with Pictures) Instructables Wire Solder To Brass We will walk you through the process. In fact, all you really need is some. This as result of new. Use the correct solder for brass and a low heat flame torch. We have the truth about soldering brass. How do you weld brass to brass? Learn how to solder brass like a pro with this complete guide, from selecting. Wire Solder To Brass.

From www.instructables.com

The Ultimate Wire Soldering Guide for Beginners 5 Steps (with Wire Solder To Brass To do it effectively, you should know. We will walk you through the process. You just need to use the right type of solder and make sure that both pieces of brass are clean and free of any debris or oxides. Soldering brass doesn’t have to be complicated. It is possible to solder brass effectively. In fact, all you really. Wire Solder To Brass.

From albionfireandice.co.uk

Jewellers Solder Brass, Bronze and Copper Solder UK Wire Solder To Brass Soldering brass doesn’t have to be complicated. You just need to use the right type of solder and make sure that both pieces of brass are clean and free of any debris or oxides. This is a question that many people may ask and the answer is yes, you can solder brass to brass. We will walk you through the. Wire Solder To Brass.

From www.youtube.com

Soldering brass wire YouTube Wire Solder To Brass Use the correct solder for brass and a low heat flame torch. Learn how to solder brass like a pro with this complete guide, from selecting the right materials to getting a clean solder joint. It is possible to solder brass effectively. I found your article while searching to see if i could solder #38 awg or #42 awg magnet. Wire Solder To Brass.

From www.dreamstime.com

Soldering Tools. Solder Wire, Iron and Brass Wool on White Table Stock Wire Solder To Brass This is a question that many people may ask and the answer is yes, you can solder brass to brass. This guide will walk you through the basics of soldering brass wire, so you can get started on your next project! In fact, all you really need is some. We will walk you through the process. Use the correct solder. Wire Solder To Brass.

From electronicshacks.com

3 Steps to Solder Wires to Connectors ElectronicsHacks Wire Solder To Brass You just need to use the right type of solder and make sure that both pieces of brass are clean and free of any debris or oxides. To do it effectively, you should know. Make sure the surfaces of the project are clean and fit together tightly. I found your article while searching to see if i could solder #38. Wire Solder To Brass.

From www.youtube.com

How To Solder Intro/Joining Stranded Wires Part 1 YouTube Wire Solder To Brass The good news is you don’t need many expensive parts or tools to start soldering copper and brass together. How do you weld brass to brass? We have the truth about soldering brass. Make sure the surfaces of the project are clean and fit together tightly. Use the correct solder for brass and a low heat flame torch. We will. Wire Solder To Brass.

From manuallibsculpt.z21.web.core.windows.net

Solder For Electrical Wiring Wire Solder To Brass You just need to use the right type of solder and make sure that both pieces of brass are clean and free of any debris or oxides. In fact, all you really need is some. How do you weld brass to brass? It is very possible to tig braze as well as solder brass to brass. It is possible to. Wire Solder To Brass.

From sfjs.net

Brass Wire Solder Santa Fe Jewelers Supply Santa Fe Jewelers Supply Wire Solder To Brass Use the correct solder for brass and a low heat flame torch. This is a question that many people may ask and the answer is yes, you can solder brass to brass. We will walk you through the process. But there are a few things you need to know before you try it. It is possible to solder brass effectively.. Wire Solder To Brass.

From www.youtube.com

Soldering Wires to Wires Soldering Basics Soldering for Beginners Wire Solder To Brass The good news is you don’t need many expensive parts or tools to start soldering copper and brass together. But there are a few things you need to know before you try it. We will walk you through the process. I found your article while searching to see if i could solder #38 awg or #42 awg magnet wire to. Wire Solder To Brass.

From www.supercheapauto.com.au

How to Solder Wires Wire Joining Supercheap Auto Wire Solder To Brass I found your article while searching to see if i could solder #38 awg or #42 awg magnet wire to brass. How do you weld brass to brass? We have the truth about soldering brass. Soldering brass doesn’t have to be complicated. This guide will walk you through the basics of soldering brass wire, so you can get started on. Wire Solder To Brass.

From www.theweldguru.com

Can You Solder Brass To Brass? The Welding Guru Wire Solder To Brass It involves melting an alloy, usually made of lead and tin, and using it to fill the joint between two pieces of metal, such as a brass wire. Use the correct solder for brass and a low heat flame torch. In fact, all you really need is some. Soldering brass doesn’t have to be complicated. Learn how to solder brass. Wire Solder To Brass.

From albionfireandice.co.uk

Jewellers Solder Brass, Bronze and Copper Solder UK Wire Solder To Brass Learn how to solder brass like a pro with this complete guide, from selecting the right materials to getting a clean solder joint. This as result of new. The good news is you don’t need many expensive parts or tools to start soldering copper and brass together. It is possible to solder brass effectively. It involves melting an alloy, usually. Wire Solder To Brass.

From www.industrialmetalsupply.com

How to Solder Brass and Copper Wire Solder To Brass It involves melting an alloy, usually made of lead and tin, and using it to fill the joint between two pieces of metal, such as a brass wire. We have the truth about soldering brass. We will walk you through the process. To do it effectively, you should know. This as result of new. This guide will walk you through. Wire Solder To Brass.

From www.youtube.com

HOW TO SOLDER BRASS YouTube Wire Solder To Brass But there are a few things you need to know before you try it. It is possible to solder brass effectively. It is very possible to tig braze as well as solder brass to brass. Make sure the surfaces of the project are clean and fit together tightly. To do it effectively, you should know. This guide will walk you. Wire Solder To Brass.

From joimviwua.blob.core.windows.net

Soldering Wire For Brass at Richard Reed blog Wire Solder To Brass We will walk you through the process. Make sure the surfaces of the project are clean and fit together tightly. Learn how to solder brass like a pro with this complete guide, from selecting the right materials to getting a clean solder joint. But there are a few things you need to know before you try it. Soldering brass doesn’t. Wire Solder To Brass.

From www.electronicsandyou.com

How to Solder Wires Together Correctly Like a Pro (Easy Tips and Tricks) Wire Solder To Brass It is possible to solder brass effectively. In fact, all you really need is some. But there are a few things you need to know before you try it. The good news is you don’t need many expensive parts or tools to start soldering copper and brass together. We have the truth about soldering brass. I found your article while. Wire Solder To Brass.

From www.thespruce.com

How to Solder Wires Wire Solder To Brass This as result of new. This guide will walk you through the basics of soldering brass wire, so you can get started on your next project! Soldering brass doesn’t have to be complicated. How do you weld brass to brass? Learn how to solder brass like a pro with this complete guide, from selecting the right materials to getting a. Wire Solder To Brass.

From www.theweldguru.com

Can You Solder Brass Effectively? The Welding Guru Wire Solder To Brass How do you weld brass to brass? You just need to use the right type of solder and make sure that both pieces of brass are clean and free of any debris or oxides. Learn how to solder brass like a pro with this complete guide, from selecting the right materials to getting a clean solder joint. Soldering brass doesn’t. Wire Solder To Brass.