Sewing Machine Drive Belt Adjustment . Vintage machines were intended to be driven by reinforced vee belts, which transmit the. your sewing machine should have a dial somewhere on the top, front, or side that adjusts the top thread tension. how do you set belts? Undo the motor bracket bolt and slide the motor and bracket down then. Measure the width of the belt side to side. If you have a computerized machine, you may need to adjust the tension on a screen. More information about tightening and replacement the sewing machine motor belt see on website. what should be the tension on a sewing machine and how to adjust the. how to adjust motor belts. if your sewing machine is not turning when you put your foot down, then you will want to check a few things,. Whether it is the power drive belt or a timing belt, the rule remains the same. pull the belt over the motor pulley, it should be a loose fit. To change this setting, simply turn the dial to a higher number to tighten the tension or a lower number to loosen it. this video contains tips how to tension and to replace drive motor belt.

from lrn2diy.com

Undo the motor bracket bolt and slide the motor and bracket down then. how do you set belts? More information about tightening and replacement the sewing machine motor belt see on website. this video contains tips how to tension and to replace drive motor belt. what should be the tension on a sewing machine and how to adjust the. how to adjust motor belts. To change this setting, simply turn the dial to a higher number to tighten the tension or a lower number to loosen it. Measure the width of the belt side to side. Vintage machines were intended to be driven by reinforced vee belts, which transmit the. pull the belt over the motor pulley, it should be a loose fit.

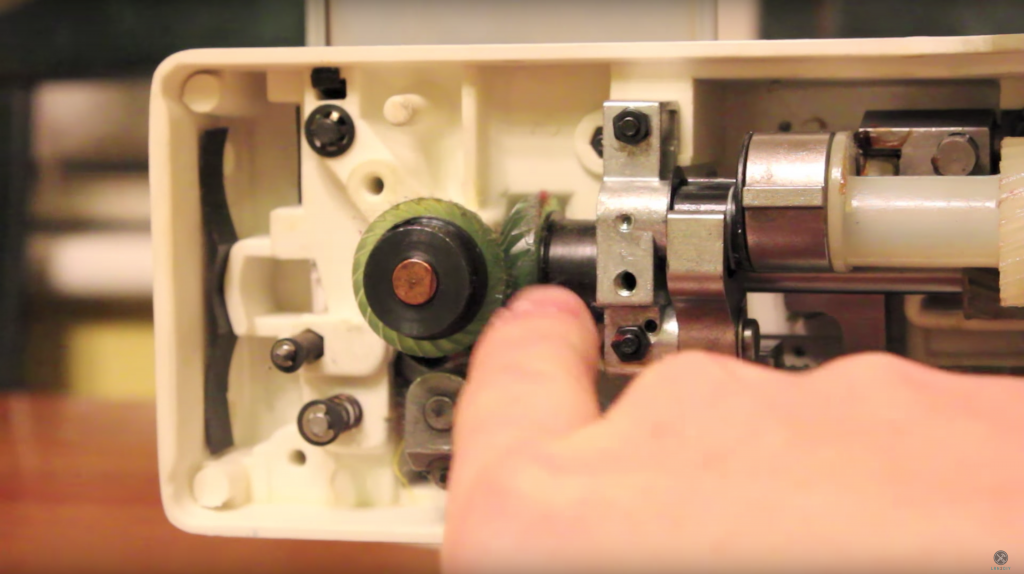

How to Fix the Hook Timing on a Sewing Machine LRN2DIY

Sewing Machine Drive Belt Adjustment pull the belt over the motor pulley, it should be a loose fit. If you have a computerized machine, you may need to adjust the tension on a screen. More information about tightening and replacement the sewing machine motor belt see on website. what should be the tension on a sewing machine and how to adjust the. this video contains tips how to tension and to replace drive motor belt. Undo the motor bracket bolt and slide the motor and bracket down then. To change this setting, simply turn the dial to a higher number to tighten the tension or a lower number to loosen it. pull the belt over the motor pulley, it should be a loose fit. Whether it is the power drive belt or a timing belt, the rule remains the same. Measure the width of the belt side to side. how do you set belts? how to adjust motor belts. your sewing machine should have a dial somewhere on the top, front, or side that adjusts the top thread tension. if your sewing machine is not turning when you put your foot down, then you will want to check a few things,. Vintage machines were intended to be driven by reinforced vee belts, which transmit the.

From www.youtube.com

How to Replace a Sewing Machine Drive Belt YouTube Sewing Machine Drive Belt Adjustment what should be the tension on a sewing machine and how to adjust the. how to adjust motor belts. More information about tightening and replacement the sewing machine motor belt see on website. If you have a computerized machine, you may need to adjust the tension on a screen. if your sewing machine is not turning when. Sewing Machine Drive Belt Adjustment.

From www.youtube.com

Learn to Replace a Treadle Belt Treadle Belt Tutorial Treadle Sewing Machine Drive Belt Adjustment Whether it is the power drive belt or a timing belt, the rule remains the same. if your sewing machine is not turning when you put your foot down, then you will want to check a few things,. this video contains tips how to tension and to replace drive motor belt. Measure the width of the belt side. Sewing Machine Drive Belt Adjustment.

From designloft.blogspot.com

The Design Loft Repairing a leather sewing machine belt Sewing Machine Drive Belt Adjustment pull the belt over the motor pulley, it should be a loose fit. your sewing machine should have a dial somewhere on the top, front, or side that adjusts the top thread tension. how do you set belts? Vintage machines were intended to be driven by reinforced vee belts, which transmit the. If you have a computerized. Sewing Machine Drive Belt Adjustment.

From www.youtube.com

How You can make a Treadle Sewing Machine belt.mp4 YouTube Sewing Machine Drive Belt Adjustment If you have a computerized machine, you may need to adjust the tension on a screen. Vintage machines were intended to be driven by reinforced vee belts, which transmit the. this video contains tips how to tension and to replace drive motor belt. To change this setting, simply turn the dial to a higher number to tighten the tension. Sewing Machine Drive Belt Adjustment.

From fyokrbtwj.blob.core.windows.net

Brother Sewing Machine Drive Belt at Darlene Copeland blog Sewing Machine Drive Belt Adjustment Undo the motor bracket bolt and slide the motor and bracket down then. this video contains tips how to tension and to replace drive motor belt. your sewing machine should have a dial somewhere on the top, front, or side that adjusts the top thread tension. If you have a computerized machine, you may need to adjust the. Sewing Machine Drive Belt Adjustment.

From fyokrbtwj.blob.core.windows.net

Brother Sewing Machine Drive Belt at Darlene Copeland blog Sewing Machine Drive Belt Adjustment Vintage machines were intended to be driven by reinforced vee belts, which transmit the. If you have a computerized machine, you may need to adjust the tension on a screen. your sewing machine should have a dial somewhere on the top, front, or side that adjusts the top thread tension. Measure the width of the belt side to side.. Sewing Machine Drive Belt Adjustment.

From www.sewingpartsonline.com

Understanding Sewing Machine Belts Sewing Parts Online Everything Sewing Machine Drive Belt Adjustment Measure the width of the belt side to side. what should be the tension on a sewing machine and how to adjust the. if your sewing machine is not turning when you put your foot down, then you will want to check a few things,. Vintage machines were intended to be driven by reinforced vee belts, which transmit. Sewing Machine Drive Belt Adjustment.

From www.youtube.com

leather treadle sewing machine belt installation tutorial YouTube Sewing Machine Drive Belt Adjustment what should be the tension on a sewing machine and how to adjust the. Whether it is the power drive belt or a timing belt, the rule remains the same. Measure the width of the belt side to side. Undo the motor bracket bolt and slide the motor and bracket down then. To change this setting, simply turn the. Sewing Machine Drive Belt Adjustment.

From thegardengadgets.com

Craftsman LT2000 drive belt diagram explanation How it works Sewing Machine Drive Belt Adjustment To change this setting, simply turn the dial to a higher number to tighten the tension or a lower number to loosen it. if your sewing machine is not turning when you put your foot down, then you will want to check a few things,. Vintage machines were intended to be driven by reinforced vee belts, which transmit the.. Sewing Machine Drive Belt Adjustment.

From www.youtube.com

How to install antique singer sewing machine belts YouTube Sewing Machine Drive Belt Adjustment your sewing machine should have a dial somewhere on the top, front, or side that adjusts the top thread tension. how do you set belts? if your sewing machine is not turning when you put your foot down, then you will want to check a few things,. If you have a computerized machine, you may need to. Sewing Machine Drive Belt Adjustment.

From www.pinterest.com

Drive belts for vintage Bernina sewing machine 830 730 707 710 717 700 Sewing Machine Drive Belt Adjustment what should be the tension on a sewing machine and how to adjust the. If you have a computerized machine, you may need to adjust the tension on a screen. how to adjust motor belts. if your sewing machine is not turning when you put your foot down, then you will want to check a few things,.. Sewing Machine Drive Belt Adjustment.

From hxeiplgmz.blob.core.windows.net

Juki Sewing Machine Timing Adjustment at William Chester blog Sewing Machine Drive Belt Adjustment More information about tightening and replacement the sewing machine motor belt see on website. how do you set belts? Undo the motor bracket bolt and slide the motor and bracket down then. this video contains tips how to tension and to replace drive motor belt. pull the belt over the motor pulley, it should be a loose. Sewing Machine Drive Belt Adjustment.

From www.youtube.com

How to Replace a Sewing Machine Motor Drive Belt YouTube Sewing Machine Drive Belt Adjustment this video contains tips how to tension and to replace drive motor belt. Vintage machines were intended to be driven by reinforced vee belts, which transmit the. pull the belt over the motor pulley, it should be a loose fit. your sewing machine should have a dial somewhere on the top, front, or side that adjusts the. Sewing Machine Drive Belt Adjustment.

From exytynmgo.blob.core.windows.net

Singer Sewing Machine Motor Belt Replacement at Jeremy Burk blog Sewing Machine Drive Belt Adjustment If you have a computerized machine, you may need to adjust the tension on a screen. Undo the motor bracket bolt and slide the motor and bracket down then. To change this setting, simply turn the dial to a higher number to tighten the tension or a lower number to loosen it. how to adjust motor belts. what. Sewing Machine Drive Belt Adjustment.

From cdn.polarisportal.com

Drive Belt Adjustment Sewing Machine Drive Belt Adjustment If you have a computerized machine, you may need to adjust the tension on a screen. this video contains tips how to tension and to replace drive motor belt. how do you set belts? what should be the tension on a sewing machine and how to adjust the. how to adjust motor belts. your sewing. Sewing Machine Drive Belt Adjustment.

From gioiytsvr.blob.core.windows.net

How To Make Sewing Machine Belt At Home at Mamie Robinson blog Sewing Machine Drive Belt Adjustment this video contains tips how to tension and to replace drive motor belt. how do you set belts? If you have a computerized machine, you may need to adjust the tension on a screen. To change this setting, simply turn the dial to a higher number to tighten the tension or a lower number to loosen it. More. Sewing Machine Drive Belt Adjustment.

From www.youtube.com

How to Replace a Sewing Machine Drive Belt. Replacement a Drive Belt of Sewing Machine Drive Belt Adjustment Undo the motor bracket bolt and slide the motor and bracket down then. if your sewing machine is not turning when you put your foot down, then you will want to check a few things,. how to adjust motor belts. Vintage machines were intended to be driven by reinforced vee belts, which transmit the. what should be. Sewing Machine Drive Belt Adjustment.

From sewingmachinesandsewforth.blogspot.com

Sewing Machines and Sew Forth HowTo Install New Belts on the Bernina Sewing Machine Drive Belt Adjustment More information about tightening and replacement the sewing machine motor belt see on website. Whether it is the power drive belt or a timing belt, the rule remains the same. Undo the motor bracket bolt and slide the motor and bracket down then. this video contains tips how to tension and to replace drive motor belt. your sewing. Sewing Machine Drive Belt Adjustment.

From www.justanswer.com

MTD 46 Inch Deck Belt Diagram & Drive Belt Adjustment Q&A Sewing Machine Drive Belt Adjustment how do you set belts? how to adjust motor belts. this video contains tips how to tension and to replace drive motor belt. More information about tightening and replacement the sewing machine motor belt see on website. Vintage machines were intended to be driven by reinforced vee belts, which transmit the. what should be the tension. Sewing Machine Drive Belt Adjustment.

From www.pinterest.com

How To Measure Sewing Machine Belt Length For Replacement Sewing Sewing Machine Drive Belt Adjustment if your sewing machine is not turning when you put your foot down, then you will want to check a few things,. your sewing machine should have a dial somewhere on the top, front, or side that adjusts the top thread tension. Whether it is the power drive belt or a timing belt, the rule remains the same.. Sewing Machine Drive Belt Adjustment.

From www.youtube.com

Cobra Class 26 Sewing Machine Drive Belt System Adjustment YouTube Sewing Machine Drive Belt Adjustment how to adjust motor belts. Whether it is the power drive belt or a timing belt, the rule remains the same. if your sewing machine is not turning when you put your foot down, then you will want to check a few things,. More information about tightening and replacement the sewing machine motor belt see on website. . Sewing Machine Drive Belt Adjustment.

From www.youtube.com

How to Replace a Sewing Machine Drive Motor YouTube Sewing Machine Drive Belt Adjustment how to adjust motor belts. your sewing machine should have a dial somewhere on the top, front, or side that adjusts the top thread tension. Whether it is the power drive belt or a timing belt, the rule remains the same. if your sewing machine is not turning when you put your foot down, then you will. Sewing Machine Drive Belt Adjustment.

From giowkjtkg.blob.core.windows.net

How To Replace A Singer Sewing Machine Belt at Marlys Jones blog Sewing Machine Drive Belt Adjustment Undo the motor bracket bolt and slide the motor and bracket down then. To change this setting, simply turn the dial to a higher number to tighten the tension or a lower number to loosen it. your sewing machine should have a dial somewhere on the top, front, or side that adjusts the top thread tension. Vintage machines were. Sewing Machine Drive Belt Adjustment.

From sewingmachinesandsewforth.blogspot.com

Sewing Machines and Sew Forth HowTo Install New Belts on the Bernina Sewing Machine Drive Belt Adjustment More information about tightening and replacement the sewing machine motor belt see on website. If you have a computerized machine, you may need to adjust the tension on a screen. what should be the tension on a sewing machine and how to adjust the. if your sewing machine is not turning when you put your foot down, then. Sewing Machine Drive Belt Adjustment.

From www.youtube.com

Sewing Machine Drive Motor Belt Tension and Replacement YouTube Sewing Machine Drive Belt Adjustment if your sewing machine is not turning when you put your foot down, then you will want to check a few things,. More information about tightening and replacement the sewing machine motor belt see on website. this video contains tips how to tension and to replace drive motor belt. Measure the width of the belt side to side.. Sewing Machine Drive Belt Adjustment.

From shesasewingmachinemechanic.blogspot.com

She's A Sewing Machine Mechanic Sewing Machine Drive Belt Adjustment Measure the width of the belt side to side. More information about tightening and replacement the sewing machine motor belt see on website. what should be the tension on a sewing machine and how to adjust the. your sewing machine should have a dial somewhere on the top, front, or side that adjusts the top thread tension. Undo. Sewing Machine Drive Belt Adjustment.

From www.youtube.com

how to change motor belt in sewing machine YouTube Sewing Machine Drive Belt Adjustment Undo the motor bracket bolt and slide the motor and bracket down then. what should be the tension on a sewing machine and how to adjust the. Whether it is the power drive belt or a timing belt, the rule remains the same. More information about tightening and replacement the sewing machine motor belt see on website. To change. Sewing Machine Drive Belt Adjustment.

From giooektll.blob.core.windows.net

Bernina Sewing Machine Drive Belt at Shelly Thrall blog Sewing Machine Drive Belt Adjustment Measure the width of the belt side to side. Vintage machines were intended to be driven by reinforced vee belts, which transmit the. your sewing machine should have a dial somewhere on the top, front, or side that adjusts the top thread tension. pull the belt over the motor pulley, it should be a loose fit. To change. Sewing Machine Drive Belt Adjustment.

From www.pinterest.com.mx

how to fix a slipped drive belt on a brother cs6000i sewing machine Sewing Machine Drive Belt Adjustment Vintage machines were intended to be driven by reinforced vee belts, which transmit the. pull the belt over the motor pulley, it should be a loose fit. Undo the motor bracket bolt and slide the motor and bracket down then. Measure the width of the belt side to side. what should be the tension on a sewing machine. Sewing Machine Drive Belt Adjustment.

From www.youtube.com

Replacing Sewing Machine Belt For Singer Fashion Maker YouTube Sewing Machine Drive Belt Adjustment Undo the motor bracket bolt and slide the motor and bracket down then. Vintage machines were intended to be driven by reinforced vee belts, which transmit the. pull the belt over the motor pulley, it should be a loose fit. Measure the width of the belt side to side. To change this setting, simply turn the dial to a. Sewing Machine Drive Belt Adjustment.

From lrn2diy.com

How to Fix the Hook Timing on a Sewing Machine LRN2DIY Sewing Machine Drive Belt Adjustment what should be the tension on a sewing machine and how to adjust the. if your sewing machine is not turning when you put your foot down, then you will want to check a few things,. Whether it is the power drive belt or a timing belt, the rule remains the same. If you have a computerized machine,. Sewing Machine Drive Belt Adjustment.

From fyokrbtwj.blob.core.windows.net

Brother Sewing Machine Drive Belt at Darlene Copeland blog Sewing Machine Drive Belt Adjustment this video contains tips how to tension and to replace drive motor belt. Vintage machines were intended to be driven by reinforced vee belts, which transmit the. if your sewing machine is not turning when you put your foot down, then you will want to check a few things,. Undo the motor bracket bolt and slide the motor. Sewing Machine Drive Belt Adjustment.

From www.youtube.com

Sewing Machine Belt Tension Adjustment Bernina Record 730 YouTube Sewing Machine Drive Belt Adjustment Whether it is the power drive belt or a timing belt, the rule remains the same. Measure the width of the belt side to side. what should be the tension on a sewing machine and how to adjust the. Vintage machines were intended to be driven by reinforced vee belts, which transmit the. If you have a computerized machine,. Sewing Machine Drive Belt Adjustment.

From www.youtube.com

How to Replace the Motor Belt on a Singer Model 513 Sewing Machine Sewing Machine Drive Belt Adjustment To change this setting, simply turn the dial to a higher number to tighten the tension or a lower number to loosen it. how do you set belts? Measure the width of the belt side to side. how to adjust motor belts. pull the belt over the motor pulley, it should be a loose fit. Undo the. Sewing Machine Drive Belt Adjustment.

From www.youtube.com

How to Change the Internal Motor Belt on a Vintage Singer Sewing Sewing Machine Drive Belt Adjustment If you have a computerized machine, you may need to adjust the tension on a screen. Measure the width of the belt side to side. how to adjust motor belts. this video contains tips how to tension and to replace drive motor belt. Whether it is the power drive belt or a timing belt, the rule remains the. Sewing Machine Drive Belt Adjustment.