Firing Schedule For Porcelain . Later in the article, we’ll be looking at examples of firing schedules for glasswork, firing ceramics, and metal heat treat. Firing kilns, particularly atmospheric kilns, is often a community activity in which those with less experience can learn from their more experienced peers. A kiln firing chart, also known as a cone firing chart, is a useful tool for understanding the effects of temperature on different types of clays and glazes, as well as determining what firing schedule setpoints should be used depending on the cone rating of the media you’re firing. Firing schedules are critical for functional ware, with slight differences between cone 6 and 10. Kiln firing schedules range from extremely simple to extremely complex. For example, some heat treatments for metal may only require a single step with a single setpoint, whereas firing schedules for pottery or glass can include half a dozen steps that require extremely precise inputs and outputs. By incorporating a slow ramp speed (108°f an hour) from 2050°f up to 2190°f. The following examples are offered as firing schedules that could be loaded into a controller to fire a kiln. These changes are defined by changes in the kiln atmosphere or the firing ramp.

from theartofeducation.edu

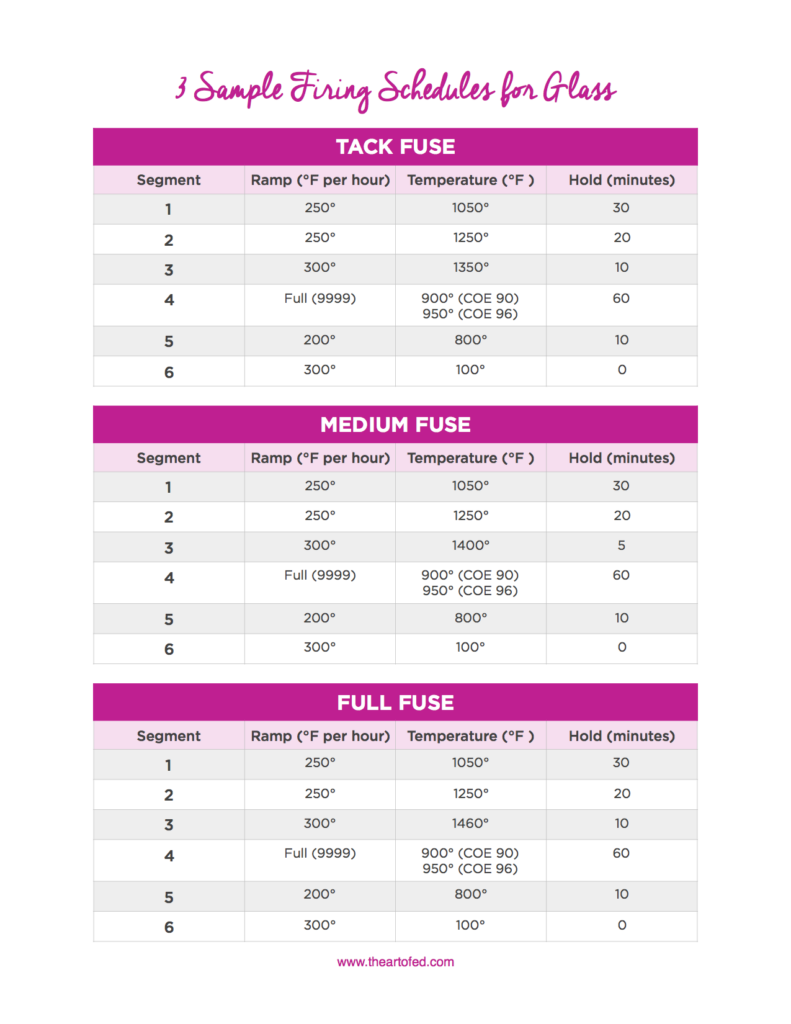

Later in the article, we’ll be looking at examples of firing schedules for glasswork, firing ceramics, and metal heat treat. Firing schedules are critical for functional ware, with slight differences between cone 6 and 10. A kiln firing chart, also known as a cone firing chart, is a useful tool for understanding the effects of temperature on different types of clays and glazes, as well as determining what firing schedule setpoints should be used depending on the cone rating of the media you’re firing. The following examples are offered as firing schedules that could be loaded into a controller to fire a kiln. By incorporating a slow ramp speed (108°f an hour) from 2050°f up to 2190°f. Kiln firing schedules range from extremely simple to extremely complex. These changes are defined by changes in the kiln atmosphere or the firing ramp. For example, some heat treatments for metal may only require a single step with a single setpoint, whereas firing schedules for pottery or glass can include half a dozen steps that require extremely precise inputs and outputs. Firing kilns, particularly atmospheric kilns, is often a community activity in which those with less experience can learn from their more experienced peers.

How to Fuse Glass in Your Ceramics Kiln The Art of Education University

Firing Schedule For Porcelain The following examples are offered as firing schedules that could be loaded into a controller to fire a kiln. Later in the article, we’ll be looking at examples of firing schedules for glasswork, firing ceramics, and metal heat treat. The following examples are offered as firing schedules that could be loaded into a controller to fire a kiln. These changes are defined by changes in the kiln atmosphere or the firing ramp. Firing kilns, particularly atmospheric kilns, is often a community activity in which those with less experience can learn from their more experienced peers. For example, some heat treatments for metal may only require a single step with a single setpoint, whereas firing schedules for pottery or glass can include half a dozen steps that require extremely precise inputs and outputs. By incorporating a slow ramp speed (108°f an hour) from 2050°f up to 2190°f. Kiln firing schedules range from extremely simple to extremely complex. Firing schedules are critical for functional ware, with slight differences between cone 6 and 10. A kiln firing chart, also known as a cone firing chart, is a useful tool for understanding the effects of temperature on different types of clays and glazes, as well as determining what firing schedule setpoints should be used depending on the cone rating of the media you’re firing.

From www.oxfordclay.co.uk

How to Fire Bisque and Stoneware Kiln Firing Schedule — Oxford Clay Firing Schedule For Porcelain Later in the article, we’ll be looking at examples of firing schedules for glasswork, firing ceramics, and metal heat treat. Firing schedules are critical for functional ware, with slight differences between cone 6 and 10. Kiln firing schedules range from extremely simple to extremely complex. By incorporating a slow ramp speed (108°f an hour) from 2050°f up to 2190°f. These. Firing Schedule For Porcelain.

From wiki.glazy.org

Firing Schedule General Theory and Documentation Firing Schedules Firing Schedule For Porcelain By incorporating a slow ramp speed (108°f an hour) from 2050°f up to 2190°f. These changes are defined by changes in the kiln atmosphere or the firing ramp. Later in the article, we’ll be looking at examples of firing schedules for glasswork, firing ceramics, and metal heat treat. For example, some heat treatments for metal may only require a single. Firing Schedule For Porcelain.

From www.pinterest.com

Firing schedule Pottery kiln, Kiln, Ceramics Firing Schedule For Porcelain Firing kilns, particularly atmospheric kilns, is often a community activity in which those with less experience can learn from their more experienced peers. Later in the article, we’ll be looking at examples of firing schedules for glasswork, firing ceramics, and metal heat treat. The following examples are offered as firing schedules that could be loaded into a controller to fire. Firing Schedule For Porcelain.

From www.kilncontrol.com

Kiln Firing Schedules for Glass, Ceramics and Heat Treat Firing Schedule For Porcelain Later in the article, we’ll be looking at examples of firing schedules for glasswork, firing ceramics, and metal heat treat. By incorporating a slow ramp speed (108°f an hour) from 2050°f up to 2190°f. Firing kilns, particularly atmospheric kilns, is often a community activity in which those with less experience can learn from their more experienced peers. These changes are. Firing Schedule For Porcelain.

From ceramicartsnetwork.org

Kiln Firing Chart Firing Schedule For Porcelain Later in the article, we’ll be looking at examples of firing schedules for glasswork, firing ceramics, and metal heat treat. Kiln firing schedules range from extremely simple to extremely complex. Firing schedules are critical for functional ware, with slight differences between cone 6 and 10. These changes are defined by changes in the kiln atmosphere or the firing ramp. By. Firing Schedule For Porcelain.

From ceramicartsnetwork.org

Cone 6 Pottery Glazes and Firing Tips for Creating Exciting Surfaces in Firing Schedule For Porcelain Firing schedules are critical for functional ware, with slight differences between cone 6 and 10. By incorporating a slow ramp speed (108°f an hour) from 2050°f up to 2190°f. For example, some heat treatments for metal may only require a single step with a single setpoint, whereas firing schedules for pottery or glass can include half a dozen steps that. Firing Schedule For Porcelain.

From wiki.glazy.org

Crystalline Glazed Firing Schedules Firing Schedules Glazy Ceramics Firing Schedule For Porcelain By incorporating a slow ramp speed (108°f an hour) from 2050°f up to 2190°f. Later in the article, we’ll be looking at examples of firing schedules for glasswork, firing ceramics, and metal heat treat. Firing schedules are critical for functional ware, with slight differences between cone 6 and 10. Kiln firing schedules range from extremely simple to extremely complex. Firing. Firing Schedule For Porcelain.

From wiki.glazy.org

Highfire Firing Schedules Firing Schedules Glazy Ceramics Wiki Firing Schedule For Porcelain A kiln firing chart, also known as a cone firing chart, is a useful tool for understanding the effects of temperature on different types of clays and glazes, as well as determining what firing schedule setpoints should be used depending on the cone rating of the media you’re firing. Firing schedules are critical for functional ware, with slight differences between. Firing Schedule For Porcelain.

From labbyag.es

Noritake Czr Porcelain Firing Chart Labb by AG Firing Schedule For Porcelain Kiln firing schedules range from extremely simple to extremely complex. A kiln firing chart, also known as a cone firing chart, is a useful tool for understanding the effects of temperature on different types of clays and glazes, as well as determining what firing schedule setpoints should be used depending on the cone rating of the media you’re firing. Firing. Firing Schedule For Porcelain.

From www.kilncontrol.com

Kiln Firing Schedules for Glass, Ceramics and Heat Treat Firing Schedule For Porcelain For example, some heat treatments for metal may only require a single step with a single setpoint, whereas firing schedules for pottery or glass can include half a dozen steps that require extremely precise inputs and outputs. Kiln firing schedules range from extremely simple to extremely complex. By incorporating a slow ramp speed (108°f an hour) from 2050°f up to. Firing Schedule For Porcelain.

From community.ceramicartsdaily.org

Bisque 04 and Glaze 5 Firing Schedule Feedback Studio Operations and Firing Schedule For Porcelain A kiln firing chart, also known as a cone firing chart, is a useful tool for understanding the effects of temperature on different types of clays and glazes, as well as determining what firing schedule setpoints should be used depending on the cone rating of the media you’re firing. Later in the article, we’ll be looking at examples of firing. Firing Schedule For Porcelain.

From talk.makeict.org

Glaze Fire complete 3/30/18 Kiln Firing Notices MakeICT Firing Schedule For Porcelain Firing schedules are critical for functional ware, with slight differences between cone 6 and 10. A kiln firing chart, also known as a cone firing chart, is a useful tool for understanding the effects of temperature on different types of clays and glazes, as well as determining what firing schedule setpoints should be used depending on the cone rating of. Firing Schedule For Porcelain.

From www.pinterest.co.uk

Skutt Kiln Firing Log Kiln firing, Kiln, Pottery kiln Firing Schedule For Porcelain These changes are defined by changes in the kiln atmosphere or the firing ramp. Kiln firing schedules range from extremely simple to extremely complex. Later in the article, we’ll be looking at examples of firing schedules for glasswork, firing ceramics, and metal heat treat. A kiln firing chart, also known as a cone firing chart, is a useful tool for. Firing Schedule For Porcelain.

From www.kilncontrol.com

Kiln Firing Schedules for Glass, Ceramics and Heat Treat Firing Schedule For Porcelain These changes are defined by changes in the kiln atmosphere or the firing ramp. For example, some heat treatments for metal may only require a single step with a single setpoint, whereas firing schedules for pottery or glass can include half a dozen steps that require extremely precise inputs and outputs. Firing schedules are critical for functional ware, with slight. Firing Schedule For Porcelain.

From www.kilncontrol.com

Kiln Firing Schedules for Glass, Ceramics and Heat Treat Firing Schedule For Porcelain For example, some heat treatments for metal may only require a single step with a single setpoint, whereas firing schedules for pottery or glass can include half a dozen steps that require extremely precise inputs and outputs. Kiln firing schedules range from extremely simple to extremely complex. The following examples are offered as firing schedules that could be loaded into. Firing Schedule For Porcelain.

From www.pinterest.es

Jubilee Creative a division of The Glass Galleria, Inc. Glass fusing Firing Schedule For Porcelain Later in the article, we’ll be looking at examples of firing schedules for glasswork, firing ceramics, and metal heat treat. Firing kilns, particularly atmospheric kilns, is often a community activity in which those with less experience can learn from their more experienced peers. The following examples are offered as firing schedules that could be loaded into a controller to fire. Firing Schedule For Porcelain.

From www.bisqueimports.com

Warm Glass Firing Schedules Firing Schedule For Porcelain Firing schedules are critical for functional ware, with slight differences between cone 6 and 10. A kiln firing chart, also known as a cone firing chart, is a useful tool for understanding the effects of temperature on different types of clays and glazes, as well as determining what firing schedule setpoints should be used depending on the cone rating of. Firing Schedule For Porcelain.

From www.youtube.com

How to Read a Firing Schedule and Program a Fast Glaze Fire into your Firing Schedule For Porcelain These changes are defined by changes in the kiln atmosphere or the firing ramp. Kiln firing schedules range from extremely simple to extremely complex. Firing kilns, particularly atmospheric kilns, is often a community activity in which those with less experience can learn from their more experienced peers. For example, some heat treatments for metal may only require a single step. Firing Schedule For Porcelain.

From www.pinterest.com

When It Comes to Pottery, These Are the Firing Schedules to Know Firing Schedule For Porcelain Firing schedules are critical for functional ware, with slight differences between cone 6 and 10. A kiln firing chart, also known as a cone firing chart, is a useful tool for understanding the effects of temperature on different types of clays and glazes, as well as determining what firing schedule setpoints should be used depending on the cone rating of. Firing Schedule For Porcelain.

From www.pinterest.com.au

Kiln Firing Chart Poster Pottery Pottery kiln, Beginner pottery Firing Schedule For Porcelain These changes are defined by changes in the kiln atmosphere or the firing ramp. By incorporating a slow ramp speed (108°f an hour) from 2050°f up to 2190°f. The following examples are offered as firing schedules that could be loaded into a controller to fire a kiln. For example, some heat treatments for metal may only require a single step. Firing Schedule For Porcelain.

From guidefixjana.z19.web.core.windows.net

Manual Kiln Firing Schedule Firing Schedule For Porcelain Later in the article, we’ll be looking at examples of firing schedules for glasswork, firing ceramics, and metal heat treat. These changes are defined by changes in the kiln atmosphere or the firing ramp. For example, some heat treatments for metal may only require a single step with a single setpoint, whereas firing schedules for pottery or glass can include. Firing Schedule For Porcelain.

From www.gc.dental

GC Initial® LiSi Veneering Ceramic GC America Firing Schedule For Porcelain Firing kilns, particularly atmospheric kilns, is often a community activity in which those with less experience can learn from their more experienced peers. By incorporating a slow ramp speed (108°f an hour) from 2050°f up to 2190°f. These changes are defined by changes in the kiln atmosphere or the firing ramp. Firing schedules are critical for functional ware, with slight. Firing Schedule For Porcelain.

From www.drkclay.com

SH Firing Schedule(s) drkclay Firing Schedule For Porcelain These changes are defined by changes in the kiln atmosphere or the firing ramp. The following examples are offered as firing schedules that could be loaded into a controller to fire a kiln. Firing schedules are critical for functional ware, with slight differences between cone 6 and 10. A kiln firing chart, also known as a cone firing chart, is. Firing Schedule For Porcelain.

From www.pinterest.com

A Bisque Firing Schedule to Help Prevent Glaze Faults Bisque pottery Firing Schedule For Porcelain Kiln firing schedules range from extremely simple to extremely complex. A kiln firing chart, also known as a cone firing chart, is a useful tool for understanding the effects of temperature on different types of clays and glazes, as well as determining what firing schedule setpoints should be used depending on the cone rating of the media you’re firing. For. Firing Schedule For Porcelain.

From theartofeducation.edu

How to Fuse Glass in Your Ceramics Kiln The Art of Education University Firing Schedule For Porcelain A kiln firing chart, also known as a cone firing chart, is a useful tool for understanding the effects of temperature on different types of clays and glazes, as well as determining what firing schedule setpoints should be used depending on the cone rating of the media you’re firing. For example, some heat treatments for metal may only require a. Firing Schedule For Porcelain.

From www.pinterest.com

Kiln Firing Schedules and Profiles Kiln firing, Kiln, Pottery Firing Schedule For Porcelain These changes are defined by changes in the kiln atmosphere or the firing ramp. Later in the article, we’ll be looking at examples of firing schedules for glasswork, firing ceramics, and metal heat treat. The following examples are offered as firing schedules that could be loaded into a controller to fire a kiln. By incorporating a slow ramp speed (108°f. Firing Schedule For Porcelain.

From potterykey.com

What Are The Best Pottery Firing Techniques Pottery Key Firing Schedule For Porcelain For example, some heat treatments for metal may only require a single step with a single setpoint, whereas firing schedules for pottery or glass can include half a dozen steps that require extremely precise inputs and outputs. Firing schedules are critical for functional ware, with slight differences between cone 6 and 10. These changes are defined by changes in the. Firing Schedule For Porcelain.

From www.kilncontrol.com

Kiln Firing Schedules for Glass, Ceramics and Heat Treat Firing Schedule For Porcelain Firing schedules are critical for functional ware, with slight differences between cone 6 and 10. For example, some heat treatments for metal may only require a single step with a single setpoint, whereas firing schedules for pottery or glass can include half a dozen steps that require extremely precise inputs and outputs. By incorporating a slow ramp speed (108°f an. Firing Schedule For Porcelain.

From conomo.helpapp.co

ceramco 2 firing chart Conomo.helpapp.co Firing Schedule For Porcelain Kiln firing schedules range from extremely simple to extremely complex. Firing schedules are critical for functional ware, with slight differences between cone 6 and 10. Firing kilns, particularly atmospheric kilns, is often a community activity in which those with less experience can learn from their more experienced peers. For example, some heat treatments for metal may only require a single. Firing Schedule For Porcelain.

From www.pinterest.com

Pin on Clay Firing Schedule For Porcelain These changes are defined by changes in the kiln atmosphere or the firing ramp. Kiln firing schedules range from extremely simple to extremely complex. Firing schedules are critical for functional ware, with slight differences between cone 6 and 10. For example, some heat treatments for metal may only require a single step with a single setpoint, whereas firing schedules for. Firing Schedule For Porcelain.

From www.kilncontrol.com

Kiln Firing Chart for Pottery and Ceramics [Infographic] Firing Schedule For Porcelain Kiln firing schedules range from extremely simple to extremely complex. For example, some heat treatments for metal may only require a single step with a single setpoint, whereas firing schedules for pottery or glass can include half a dozen steps that require extremely precise inputs and outputs. By incorporating a slow ramp speed (108°f an hour) from 2050°f up to. Firing Schedule For Porcelain.

From www.researchgate.net

Firing schedules of the veneering porcelains according to... Download Firing Schedule For Porcelain Firing kilns, particularly atmospheric kilns, is often a community activity in which those with less experience can learn from their more experienced peers. These changes are defined by changes in the kiln atmosphere or the firing ramp. Firing schedules are critical for functional ware, with slight differences between cone 6 and 10. Later in the article, we’ll be looking at. Firing Schedule For Porcelain.

From www.researchgate.net

(PDF) Determination of the firing schedule for a self glazing porcelain Firing Schedule For Porcelain By incorporating a slow ramp speed (108°f an hour) from 2050°f up to 2190°f. These changes are defined by changes in the kiln atmosphere or the firing ramp. Firing kilns, particularly atmospheric kilns, is often a community activity in which those with less experience can learn from their more experienced peers. For example, some heat treatments for metal may only. Firing Schedule For Porcelain.

From diagramparthomophiles.z13.web.core.windows.net

Manual Kiln Firing Schedule Firing Schedule For Porcelain The following examples are offered as firing schedules that could be loaded into a controller to fire a kiln. A kiln firing chart, also known as a cone firing chart, is a useful tool for understanding the effects of temperature on different types of clays and glazes, as well as determining what firing schedule setpoints should be used depending on. Firing Schedule For Porcelain.

From www.pinterest.se

Drop Out Mold firing schedule for glass to drape through (With images Firing Schedule For Porcelain Firing schedules are critical for functional ware, with slight differences between cone 6 and 10. Later in the article, we’ll be looking at examples of firing schedules for glasswork, firing ceramics, and metal heat treat. Firing kilns, particularly atmospheric kilns, is often a community activity in which those with less experience can learn from their more experienced peers. Kiln firing. Firing Schedule For Porcelain.