Production Line Balancing Example . Discover different methods such as. This production line is unbalanced because the human resources and machine utilization is not 100%. As a production engineer, you should always work to achieve a 100% balance production line. This comprehensive guide dives deep into line balancing, exploring its business benefits, outlining practical steps for achieving a balanced production line, and. By optimizing processes, minimizing waste, and leveraging tools like takt time, work element analysis, skill matrices, workstation layout, heijunka, kanban, and natural line. Here are examples of balanced and unbalanced production lines. Line balancing in production management refers to the process of distributing work tasks and activities evenly across different workstations or production stages within a. Line balancing reduces variations within a production line. Learn how to balance your manufacturing line for optimal performance and efficiency. With a simple simulation of the line assembly operations we can identify system bottlenecks, run diferent production schedules, and evaluate. A balanced production line is stable and flexible enough to adapt to changes.

from www.slideserve.com

This comprehensive guide dives deep into line balancing, exploring its business benefits, outlining practical steps for achieving a balanced production line, and. Line balancing reduces variations within a production line. Learn how to balance your manufacturing line for optimal performance and efficiency. Discover different methods such as. By optimizing processes, minimizing waste, and leveraging tools like takt time, work element analysis, skill matrices, workstation layout, heijunka, kanban, and natural line. As a production engineer, you should always work to achieve a 100% balance production line. Line balancing in production management refers to the process of distributing work tasks and activities evenly across different workstations or production stages within a. This production line is unbalanced because the human resources and machine utilization is not 100%. A balanced production line is stable and flexible enough to adapt to changes. With a simple simulation of the line assembly operations we can identify system bottlenecks, run diferent production schedules, and evaluate.

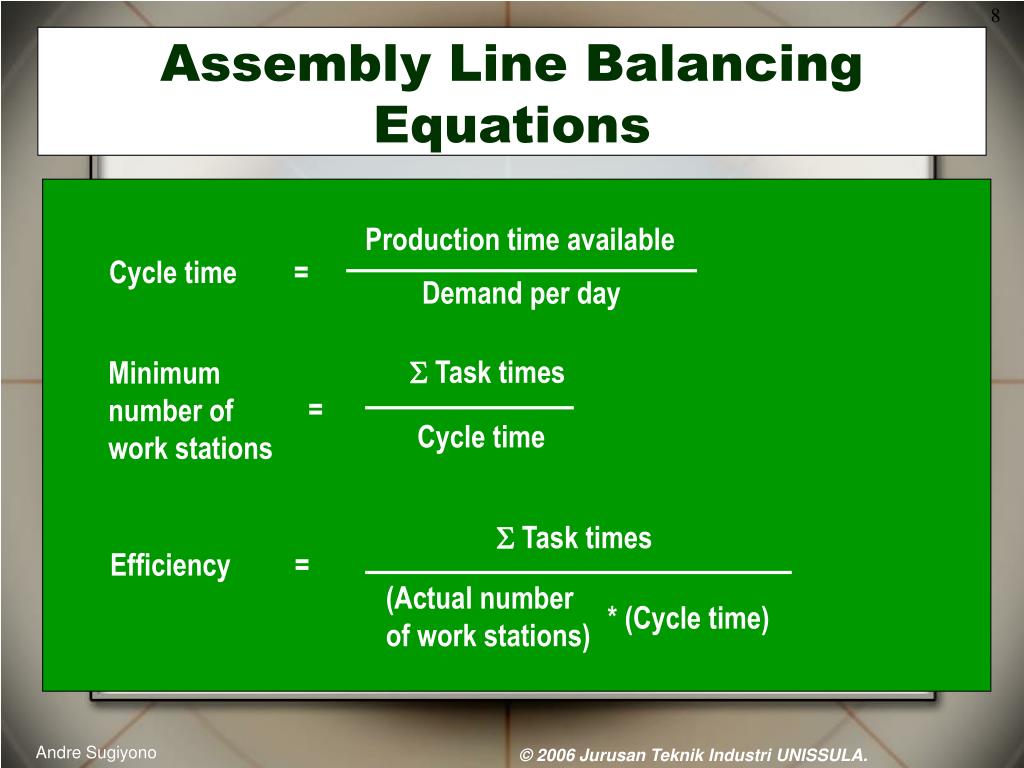

PPT Chapter 7 Assembly Line Balancing PowerPoint Presentation, free

Production Line Balancing Example This comprehensive guide dives deep into line balancing, exploring its business benefits, outlining practical steps for achieving a balanced production line, and. By optimizing processes, minimizing waste, and leveraging tools like takt time, work element analysis, skill matrices, workstation layout, heijunka, kanban, and natural line. Here are examples of balanced and unbalanced production lines. This production line is unbalanced because the human resources and machine utilization is not 100%. As a production engineer, you should always work to achieve a 100% balance production line. A balanced production line is stable and flexible enough to adapt to changes. Line balancing reduces variations within a production line. This comprehensive guide dives deep into line balancing, exploring its business benefits, outlining practical steps for achieving a balanced production line, and. Line balancing in production management refers to the process of distributing work tasks and activities evenly across different workstations or production stages within a. With a simple simulation of the line assembly operations we can identify system bottlenecks, run diferent production schedules, and evaluate. Learn how to balance your manufacturing line for optimal performance and efficiency. Discover different methods such as.

From www.researchgate.net

Assembly line balancing problem. Download Scientific Diagram Production Line Balancing Example As a production engineer, you should always work to achieve a 100% balance production line. Here are examples of balanced and unbalanced production lines. Learn how to balance your manufacturing line for optimal performance and efficiency. Line balancing in production management refers to the process of distributing work tasks and activities evenly across different workstations or production stages within a.. Production Line Balancing Example.

From www.youtube.com

Modified Product Layout and Assembly Line Balancing Example YouTube Production Line Balancing Example By optimizing processes, minimizing waste, and leveraging tools like takt time, work element analysis, skill matrices, workstation layout, heijunka, kanban, and natural line. This comprehensive guide dives deep into line balancing, exploring its business benefits, outlining practical steps for achieving a balanced production line, and. Learn how to balance your manufacturing line for optimal performance and efficiency. A balanced production. Production Line Balancing Example.

From www.scribd.com

Line Balancing Ppt Inventory Production And Manufacturing Production Line Balancing Example Line balancing in production management refers to the process of distributing work tasks and activities evenly across different workstations or production stages within a. With a simple simulation of the line assembly operations we can identify system bottlenecks, run diferent production schedules, and evaluate. By optimizing processes, minimizing waste, and leveraging tools like takt time, work element analysis, skill matrices,. Production Line Balancing Example.

From www.slideshare.net

Assembly Line Balancing Example Production Line Balancing Example This comprehensive guide dives deep into line balancing, exploring its business benefits, outlining practical steps for achieving a balanced production line, and. Learn how to balance your manufacturing line for optimal performance and efficiency. Line balancing in production management refers to the process of distributing work tasks and activities evenly across different workstations or production stages within a. With a. Production Line Balancing Example.

From www.slideserve.com

PPT Assembly Line Balancing PowerPoint Presentation, free download Production Line Balancing Example Line balancing reduces variations within a production line. With a simple simulation of the line assembly operations we can identify system bottlenecks, run diferent production schedules, and evaluate. Here are examples of balanced and unbalanced production lines. A balanced production line is stable and flexible enough to adapt to changes. This production line is unbalanced because the human resources and. Production Line Balancing Example.

From www.slideserve.com

PPT Product layout PowerPoint Presentation, free download ID526491 Production Line Balancing Example Discover different methods such as. This comprehensive guide dives deep into line balancing, exploring its business benefits, outlining practical steps for achieving a balanced production line, and. Line balancing reduces variations within a production line. As a production engineer, you should always work to achieve a 100% balance production line. Here are examples of balanced and unbalanced production lines. By. Production Line Balancing Example.

From www.slideshare.net

Assembly Line Balancing Example PDF Production Line Balancing Example Discover different methods such as. By optimizing processes, minimizing waste, and leveraging tools like takt time, work element analysis, skill matrices, workstation layout, heijunka, kanban, and natural line. A balanced production line is stable and flexible enough to adapt to changes. This comprehensive guide dives deep into line balancing, exploring its business benefits, outlining practical steps for achieving a balanced. Production Line Balancing Example.

From www.youtube.com

Assembly Line BalancingSolved ExampleOperations Management YouTube Production Line Balancing Example As a production engineer, you should always work to achieve a 100% balance production line. Line balancing reduces variations within a production line. Learn how to balance your manufacturing line for optimal performance and efficiency. With a simple simulation of the line assembly operations we can identify system bottlenecks, run diferent production schedules, and evaluate. By optimizing processes, minimizing waste,. Production Line Balancing Example.

From www.slideserve.com

PPT Assembly Line Balancing PowerPoint Presentation, free download Production Line Balancing Example As a production engineer, you should always work to achieve a 100% balance production line. This comprehensive guide dives deep into line balancing, exploring its business benefits, outlining practical steps for achieving a balanced production line, and. By optimizing processes, minimizing waste, and leveraging tools like takt time, work element analysis, skill matrices, workstation layout, heijunka, kanban, and natural line.. Production Line Balancing Example.

From mungfali.com

Line Balancing Diagram Production Line Balancing Example Line balancing reduces variations within a production line. As a production engineer, you should always work to achieve a 100% balance production line. With a simple simulation of the line assembly operations we can identify system bottlenecks, run diferent production schedules, and evaluate. Line balancing in production management refers to the process of distributing work tasks and activities evenly across. Production Line Balancing Example.

From template.mapadapalavra.ba.gov.br

Line Balancing Template Production Line Balancing Example Here are examples of balanced and unbalanced production lines. With a simple simulation of the line assembly operations we can identify system bottlenecks, run diferent production schedules, and evaluate. Learn how to balance your manufacturing line for optimal performance and efficiency. A balanced production line is stable and flexible enough to adapt to changes. As a production engineer, you should. Production Line Balancing Example.

From www.slideserve.com

PPT Line Balancing in Operations Management PowerPoint Presentation Production Line Balancing Example Here are examples of balanced and unbalanced production lines. This comprehensive guide dives deep into line balancing, exploring its business benefits, outlining practical steps for achieving a balanced production line, and. Learn how to balance your manufacturing line for optimal performance and efficiency. Discover different methods such as. By optimizing processes, minimizing waste, and leveraging tools like takt time, work. Production Line Balancing Example.

From www.mdpi.com

JOItmC Free FullText Simple Assembly Line Balancing Problem Type 2 Production Line Balancing Example As a production engineer, you should always work to achieve a 100% balance production line. Here are examples of balanced and unbalanced production lines. Line balancing reduces variations within a production line. A balanced production line is stable and flexible enough to adapt to changes. With a simple simulation of the line assembly operations we can identify system bottlenecks, run. Production Line Balancing Example.

From www.intechopen.com

Assembly Line Balancing and Sequencing IntechOpen Production Line Balancing Example With a simple simulation of the line assembly operations we can identify system bottlenecks, run diferent production schedules, and evaluate. Line balancing reduces variations within a production line. Here are examples of balanced and unbalanced production lines. By optimizing processes, minimizing waste, and leveraging tools like takt time, work element analysis, skill matrices, workstation layout, heijunka, kanban, and natural line.. Production Line Balancing Example.

From www.slideserve.com

PPT Line Balancing PowerPoint Presentation ID203412 Production Line Balancing Example A balanced production line is stable and flexible enough to adapt to changes. Line balancing reduces variations within a production line. Discover different methods such as. Learn how to balance your manufacturing line for optimal performance and efficiency. This comprehensive guide dives deep into line balancing, exploring its business benefits, outlining practical steps for achieving a balanced production line, and.. Production Line Balancing Example.

From www.slideserve.com

PPT Assembly Line Balancing PowerPoint Presentation, free download Production Line Balancing Example With a simple simulation of the line assembly operations we can identify system bottlenecks, run diferent production schedules, and evaluate. Discover different methods such as. Line balancing in production management refers to the process of distributing work tasks and activities evenly across different workstations or production stages within a. A balanced production line is stable and flexible enough to adapt. Production Line Balancing Example.

From www.semanticscholar.org

Figure 1 from Assembly line balancing using simulation technique in a Production Line Balancing Example A balanced production line is stable and flexible enough to adapt to changes. Line balancing in production management refers to the process of distributing work tasks and activities evenly across different workstations or production stages within a. Line balancing reduces variations within a production line. This comprehensive guide dives deep into line balancing, exploring its business benefits, outlining practical steps. Production Line Balancing Example.

From www.youtube.com

What is Line Balancing YouTube Production Line Balancing Example Line balancing in production management refers to the process of distributing work tasks and activities evenly across different workstations or production stages within a. A balanced production line is stable and flexible enough to adapt to changes. Line balancing reduces variations within a production line. This comprehensive guide dives deep into line balancing, exploring its business benefits, outlining practical steps. Production Line Balancing Example.

From www.youtube.com

04 Assembly Line Balancing YouTube Production Line Balancing Example This comprehensive guide dives deep into line balancing, exploring its business benefits, outlining practical steps for achieving a balanced production line, and. Discover different methods such as. Line balancing reduces variations within a production line. This production line is unbalanced because the human resources and machine utilization is not 100%. By optimizing processes, minimizing waste, and leveraging tools like takt. Production Line Balancing Example.

From www.proplanner.com

Line Balancing Software Generates Assignment of Tasks to Operator Production Line Balancing Example Learn how to balance your manufacturing line for optimal performance and efficiency. Line balancing in production management refers to the process of distributing work tasks and activities evenly across different workstations or production stages within a. With a simple simulation of the line assembly operations we can identify system bottlenecks, run diferent production schedules, and evaluate. As a production engineer,. Production Line Balancing Example.

From www.smlease.com

What is production Line Balancing and How to implement it? Production Line Balancing Example Here are examples of balanced and unbalanced production lines. Line balancing reduces variations within a production line. A balanced production line is stable and flexible enough to adapt to changes. By optimizing processes, minimizing waste, and leveraging tools like takt time, work element analysis, skill matrices, workstation layout, heijunka, kanban, and natural line. Discover different methods such as. This production. Production Line Balancing Example.

From www.proplanner.com

Assembly Process Planning Proplanner Production Line Balancing Example A balanced production line is stable and flexible enough to adapt to changes. As a production engineer, you should always work to achieve a 100% balance production line. This comprehensive guide dives deep into line balancing, exploring its business benefits, outlining practical steps for achieving a balanced production line, and. With a simple simulation of the line assembly operations we. Production Line Balancing Example.

From www.youtube.com

Operations Layout Assembly Line Balancing I YouTube Production Line Balancing Example Learn how to balance your manufacturing line for optimal performance and efficiency. A balanced production line is stable and flexible enough to adapt to changes. Discover different methods such as. By optimizing processes, minimizing waste, and leveraging tools like takt time, work element analysis, skill matrices, workstation layout, heijunka, kanban, and natural line. Line balancing reduces variations within a production. Production Line Balancing Example.

From www.onlineclothingstudy.com

Line Balancing Tool Based on Operator Skill Matrix Production Line Balancing Example Line balancing reduces variations within a production line. Here are examples of balanced and unbalanced production lines. A balanced production line is stable and flexible enough to adapt to changes. Learn how to balance your manufacturing line for optimal performance and efficiency. This production line is unbalanced because the human resources and machine utilization is not 100%. With a simple. Production Line Balancing Example.

From www.slideshare.net

Assembly Line Balancing Example Production Line Balancing Example By optimizing processes, minimizing waste, and leveraging tools like takt time, work element analysis, skill matrices, workstation layout, heijunka, kanban, and natural line. Learn how to balance your manufacturing line for optimal performance and efficiency. This production line is unbalanced because the human resources and machine utilization is not 100%. A balanced production line is stable and flexible enough to. Production Line Balancing Example.

From www.slideserve.com

PPT Product layout PowerPoint Presentation, free download ID526491 Production Line Balancing Example With a simple simulation of the line assembly operations we can identify system bottlenecks, run diferent production schedules, and evaluate. A balanced production line is stable and flexible enough to adapt to changes. Discover different methods such as. Line balancing reduces variations within a production line. By optimizing processes, minimizing waste, and leveraging tools like takt time, work element analysis,. Production Line Balancing Example.

From www.youtube.com

ASSEMBLY LINE BALANCING Tutorial 2 LeanSeekho YouTube Production Line Balancing Example By optimizing processes, minimizing waste, and leveraging tools like takt time, work element analysis, skill matrices, workstation layout, heijunka, kanban, and natural line. Line balancing in production management refers to the process of distributing work tasks and activities evenly across different workstations or production stages within a. As a production engineer, you should always work to achieve a 100% balance. Production Line Balancing Example.

From www.smlease.com

What is production Line Balancing and How to implement it? Production Line Balancing Example Learn how to balance your manufacturing line for optimal performance and efficiency. A balanced production line is stable and flexible enough to adapt to changes. By optimizing processes, minimizing waste, and leveraging tools like takt time, work element analysis, skill matrices, workstation layout, heijunka, kanban, and natural line. Discover different methods such as. With a simple simulation of the line. Production Line Balancing Example.

From studiousguy.com

Operations Management StudiousGuy Production Line Balancing Example With a simple simulation of the line assembly operations we can identify system bottlenecks, run diferent production schedules, and evaluate. A balanced production line is stable and flexible enough to adapt to changes. Learn how to balance your manufacturing line for optimal performance and efficiency. This comprehensive guide dives deep into line balancing, exploring its business benefits, outlining practical steps. Production Line Balancing Example.

From www.slideserve.com

PPT Assembly Line Balance PowerPoint Presentation, free download ID Production Line Balancing Example Line balancing in production management refers to the process of distributing work tasks and activities evenly across different workstations or production stages within a. With a simple simulation of the line assembly operations we can identify system bottlenecks, run diferent production schedules, and evaluate. Here are examples of balanced and unbalanced production lines. By optimizing processes, minimizing waste, and leveraging. Production Line Balancing Example.

From www.youtube.com

𝐋𝐢𝐧𝐞 𝐁𝐚𝐥𝐚𝐧𝐜𝐢𝐧𝐠 Production Line Balancing ? Assembly Line Balancing Production Line Balancing Example As a production engineer, you should always work to achieve a 100% balance production line. By optimizing processes, minimizing waste, and leveraging tools like takt time, work element analysis, skill matrices, workstation layout, heijunka, kanban, and natural line. This comprehensive guide dives deep into line balancing, exploring its business benefits, outlining practical steps for achieving a balanced production line, and.. Production Line Balancing Example.

From enginexi.com

Line Balancing How to do it (With Example) / Assembly Line Production Line Balancing Example With a simple simulation of the line assembly operations we can identify system bottlenecks, run diferent production schedules, and evaluate. Line balancing in production management refers to the process of distributing work tasks and activities evenly across different workstations or production stages within a. By optimizing processes, minimizing waste, and leveraging tools like takt time, work element analysis, skill matrices,. Production Line Balancing Example.

From www.slideserve.com

PPT Chapter 7 Assembly Line Balancing PowerPoint Presentation, free Production Line Balancing Example Learn how to balance your manufacturing line for optimal performance and efficiency. With a simple simulation of the line assembly operations we can identify system bottlenecks, run diferent production schedules, and evaluate. Here are examples of balanced and unbalanced production lines. This production line is unbalanced because the human resources and machine utilization is not 100%. As a production engineer,. Production Line Balancing Example.

From www.chegg.com

Solved Assembly Line Balancing Example The daily output for Production Line Balancing Example With a simple simulation of the line assembly operations we can identify system bottlenecks, run diferent production schedules, and evaluate. Line balancing reduces variations within a production line. Learn how to balance your manufacturing line for optimal performance and efficiency. By optimizing processes, minimizing waste, and leveraging tools like takt time, work element analysis, skill matrices, workstation layout, heijunka, kanban,. Production Line Balancing Example.

From www.powerarena.com

Line Balancer PowerArena Production Line Balancing Example This comprehensive guide dives deep into line balancing, exploring its business benefits, outlining practical steps for achieving a balanced production line, and. With a simple simulation of the line assembly operations we can identify system bottlenecks, run diferent production schedules, and evaluate. Here are examples of balanced and unbalanced production lines. Line balancing in production management refers to the process. Production Line Balancing Example.