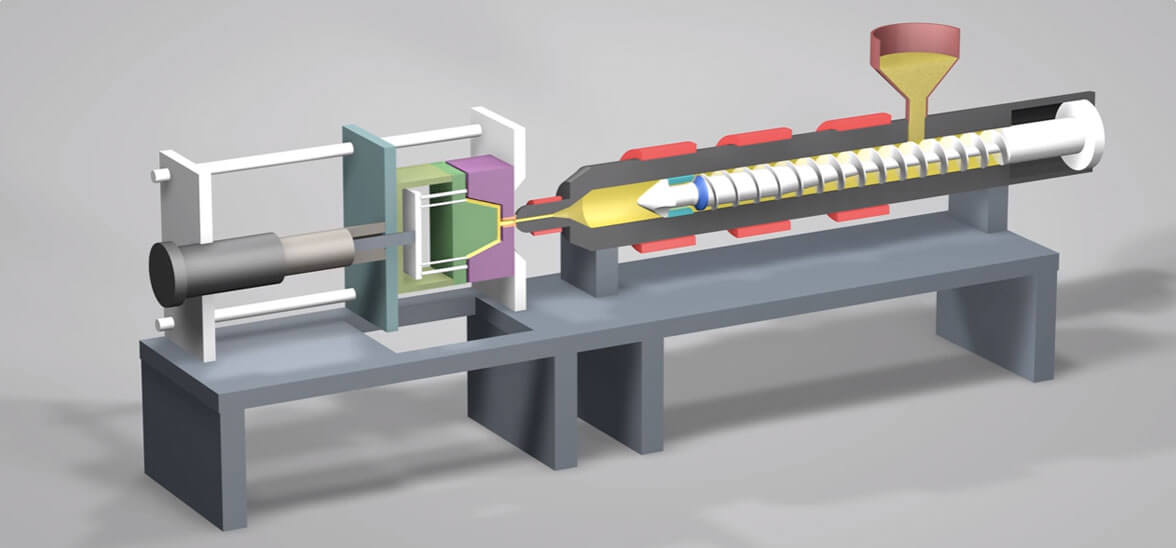

Aluminum Molding Process . We explore the benefits, applications and various related aspects of using aluminum molds in the injection molding process. This attribute drastically reduces cycle times,. Learn the types of aluminum used for aluminum molds, why plastic. Technical advances have been made, but the principle. Casting is the original and most widely used method of forming aluminum into products. Aluminum injection molding is an innovative technique based on injection molding used to produce parts (either prototypes/real. • aluminum possesses better thermal conductivity than steel, offering a more consistent mold temperature, and resin flow equating to less warpage and higher yields, improving the molding. Explore the advanced processes and innovations in aluminum molding that are revolutionizing production efficiency and precision. Aluminium is renowned for its exceptional thermal conductivity, enabling rapid heat transfer during the injection molding process.

from www.3erp.com

Explore the advanced processes and innovations in aluminum molding that are revolutionizing production efficiency and precision. Technical advances have been made, but the principle. We explore the benefits, applications and various related aspects of using aluminum molds in the injection molding process. This attribute drastically reduces cycle times,. Aluminum injection molding is an innovative technique based on injection molding used to produce parts (either prototypes/real. Learn the types of aluminum used for aluminum molds, why plastic. Aluminium is renowned for its exceptional thermal conductivity, enabling rapid heat transfer during the injection molding process. • aluminum possesses better thermal conductivity than steel, offering a more consistent mold temperature, and resin flow equating to less warpage and higher yields, improving the molding. Casting is the original and most widely used method of forming aluminum into products.

Plastic Injection Molding 3ERP

Aluminum Molding Process This attribute drastically reduces cycle times,. We explore the benefits, applications and various related aspects of using aluminum molds in the injection molding process. Learn the types of aluminum used for aluminum molds, why plastic. This attribute drastically reduces cycle times,. • aluminum possesses better thermal conductivity than steel, offering a more consistent mold temperature, and resin flow equating to less warpage and higher yields, improving the molding. Explore the advanced processes and innovations in aluminum molding that are revolutionizing production efficiency and precision. Casting is the original and most widely used method of forming aluminum into products. Technical advances have been made, but the principle. Aluminium is renowned for its exceptional thermal conductivity, enabling rapid heat transfer during the injection molding process. Aluminum injection molding is an innovative technique based on injection molding used to produce parts (either prototypes/real.

From offersteels.com

3003 5052 Aluminum SheetDiamond Tread Plate Factory price Aluminum Molding Process Aluminum injection molding is an innovative technique based on injection molding used to produce parts (either prototypes/real. Technical advances have been made, but the principle. This attribute drastically reduces cycle times,. Aluminium is renowned for its exceptional thermal conductivity, enabling rapid heat transfer during the injection molding process. Casting is the original and most widely used method of forming aluminum. Aluminum Molding Process.

From ecfpmould.com

What`s the injection molding Shanghai Henglian Industrial Co., Ltd. Aluminum Molding Process Aluminium is renowned for its exceptional thermal conductivity, enabling rapid heat transfer during the injection molding process. • aluminum possesses better thermal conductivity than steel, offering a more consistent mold temperature, and resin flow equating to less warpage and higher yields, improving the molding. Aluminum injection molding is an innovative technique based on injection molding used to produce parts (either. Aluminum Molding Process.

From www.dreamstime.com

Processing of Aluminum Parts for Injection Molding for Mechanical Aluminum Molding Process Learn the types of aluminum used for aluminum molds, why plastic. Aluminum injection molding is an innovative technique based on injection molding used to produce parts (either prototypes/real. This attribute drastically reduces cycle times,. Technical advances have been made, but the principle. Explore the advanced processes and innovations in aluminum molding that are revolutionizing production efficiency and precision. Casting is. Aluminum Molding Process.

From www.protolabs.com

Overmolding & Insert Molding Parts with Metal Inserts Aluminum Molding Process Aluminum injection molding is an innovative technique based on injection molding used to produce parts (either prototypes/real. • aluminum possesses better thermal conductivity than steel, offering a more consistent mold temperature, and resin flow equating to less warpage and higher yields, improving the molding. Casting is the original and most widely used method of forming aluminum into products. Aluminium is. Aluminum Molding Process.

From www.micronsolutions.com

Thermoset Vs. Thermoplastic Injection Molding A Comparison Aluminum Molding Process Explore the advanced processes and innovations in aluminum molding that are revolutionizing production efficiency and precision. • aluminum possesses better thermal conductivity than steel, offering a more consistent mold temperature, and resin flow equating to less warpage and higher yields, improving the molding. We explore the benefits, applications and various related aspects of using aluminum molds in the injection molding. Aluminum Molding Process.

From www.mimsupplier.com

Metal Injection Molding MIM Supplier Aluminum Molding Process Aluminum injection molding is an innovative technique based on injection molding used to produce parts (either prototypes/real. We explore the benefits, applications and various related aspects of using aluminum molds in the injection molding process. Learn the types of aluminum used for aluminum molds, why plastic. Explore the advanced processes and innovations in aluminum molding that are revolutionizing production efficiency. Aluminum Molding Process.

From learnmech.com

Compression molding Process Advantages and Disadvantages Aluminum Molding Process Technical advances have been made, but the principle. Explore the advanced processes and innovations in aluminum molding that are revolutionizing production efficiency and precision. Aluminium is renowned for its exceptional thermal conductivity, enabling rapid heat transfer during the injection molding process. This attribute drastically reduces cycle times,. Casting is the original and most widely used method of forming aluminum into. Aluminum Molding Process.

From novastevensville.com

Molding Manufacturing Creating the World's Most Useful Products Aluminum Molding Process This attribute drastically reduces cycle times,. Explore the advanced processes and innovations in aluminum molding that are revolutionizing production efficiency and precision. Technical advances have been made, but the principle. Learn the types of aluminum used for aluminum molds, why plastic. • aluminum possesses better thermal conductivity than steel, offering a more consistent mold temperature, and resin flow equating to. Aluminum Molding Process.

From www.3erp.com

Plastic Injection Molding 3ERP Aluminum Molding Process This attribute drastically reduces cycle times,. Aluminum injection molding is an innovative technique based on injection molding used to produce parts (either prototypes/real. Learn the types of aluminum used for aluminum molds, why plastic. Technical advances have been made, but the principle. We explore the benefits, applications and various related aspects of using aluminum molds in the injection molding process.. Aluminum Molding Process.

From www.tekna.com

Metal Injection Molding Tekna Aluminum Molding Process Learn the types of aluminum used for aluminum molds, why plastic. Technical advances have been made, but the principle. • aluminum possesses better thermal conductivity than steel, offering a more consistent mold temperature, and resin flow equating to less warpage and higher yields, improving the molding. This attribute drastically reduces cycle times,. We explore the benefits, applications and various related. Aluminum Molding Process.

From www.pinterest.cl

Injection molding the manufacturing & design guide 3D Hubs 3d Hubs Aluminum Molding Process Aluminium is renowned for its exceptional thermal conductivity, enabling rapid heat transfer during the injection molding process. Learn the types of aluminum used for aluminum molds, why plastic. Aluminum injection molding is an innovative technique based on injection molding used to produce parts (either prototypes/real. Casting is the original and most widely used method of forming aluminum into products. •. Aluminum Molding Process.

From www.petermanfirm.com

Injection Molding 101 How It Works Aluminum Molding Process Technical advances have been made, but the principle. Aluminium is renowned for its exceptional thermal conductivity, enabling rapid heat transfer during the injection molding process. We explore the benefits, applications and various related aspects of using aluminum molds in the injection molding process. Learn the types of aluminum used for aluminum molds, why plastic. This attribute drastically reduces cycle times,.. Aluminum Molding Process.

From yisong888.en.made-in-china.com

Aluminium Casting Mould for Rotational Moulding Process China Aluminum Molding Process Learn the types of aluminum used for aluminum molds, why plastic. This attribute drastically reduces cycle times,. Technical advances have been made, but the principle. Aluminium is renowned for its exceptional thermal conductivity, enabling rapid heat transfer during the injection molding process. Explore the advanced processes and innovations in aluminum molding that are revolutionizing production efficiency and precision. We explore. Aluminum Molding Process.

From icomold.com

Aluminum Molds for Plastic Injection Molding Aluminum Molding Process We explore the benefits, applications and various related aspects of using aluminum molds in the injection molding process. This attribute drastically reduces cycle times,. Technical advances have been made, but the principle. Explore the advanced processes and innovations in aluminum molding that are revolutionizing production efficiency and precision. Learn the types of aluminum used for aluminum molds, why plastic. •. Aluminum Molding Process.

From www.ace-mold.com

Why Aluminium Mold For Plastic Injection Advantages and Benefits Aluminum Molding Process Learn the types of aluminum used for aluminum molds, why plastic. Aluminum injection molding is an innovative technique based on injection molding used to produce parts (either prototypes/real. Aluminium is renowned for its exceptional thermal conductivity, enabling rapid heat transfer during the injection molding process. Explore the advanced processes and innovations in aluminum molding that are revolutionizing production efficiency and. Aluminum Molding Process.

From www.sunrise-metal.com

Die Cast Aluminum Mold Sunrise Metal Aluminium Die Casting Expert Aluminum Molding Process Aluminum injection molding is an innovative technique based on injection molding used to produce parts (either prototypes/real. Casting is the original and most widely used method of forming aluminum into products. Technical advances have been made, but the principle. Explore the advanced processes and innovations in aluminum molding that are revolutionizing production efficiency and precision. This attribute drastically reduces cycle. Aluminum Molding Process.

From www.linkedin.com

Aluminum Casting Process and Common Applications Aluminum Molding Process Explore the advanced processes and innovations in aluminum molding that are revolutionizing production efficiency and precision. Aluminum injection molding is an innovative technique based on injection molding used to produce parts (either prototypes/real. This attribute drastically reduces cycle times,. Learn the types of aluminum used for aluminum molds, why plastic. We explore the benefits, applications and various related aspects of. Aluminum Molding Process.

From engineeringlearn.com

Types of Extrusion Process Working, Advantages & Disadvantages Aluminum Molding Process Explore the advanced processes and innovations in aluminum molding that are revolutionizing production efficiency and precision. Learn the types of aluminum used for aluminum molds, why plastic. This attribute drastically reduces cycle times,. We explore the benefits, applications and various related aspects of using aluminum molds in the injection molding process. Casting is the original and most widely used method. Aluminum Molding Process.

From www.kemalmfg.com

Aluminum Injection Molding in Product Manufacturing Kemal Aluminum Molding Process Aluminium is renowned for its exceptional thermal conductivity, enabling rapid heat transfer during the injection molding process. Explore the advanced processes and innovations in aluminum molding that are revolutionizing production efficiency and precision. Aluminum injection molding is an innovative technique based on injection molding used to produce parts (either prototypes/real. This attribute drastically reduces cycle times,. Technical advances have been. Aluminum Molding Process.

From www.gabrian.com

What is Aluminum Die Casting? 5 Things You Need to Know Aluminum Molding Process Aluminium is renowned for its exceptional thermal conductivity, enabling rapid heat transfer during the injection molding process. Casting is the original and most widely used method of forming aluminum into products. This attribute drastically reduces cycle times,. Aluminum injection molding is an innovative technique based on injection molding used to produce parts (either prototypes/real. Technical advances have been made, but. Aluminum Molding Process.

From riversofsteel.com

Aluminum Casting Session — Rivers of Steel Aluminum Molding Process Learn the types of aluminum used for aluminum molds, why plastic. Technical advances have been made, but the principle. • aluminum possesses better thermal conductivity than steel, offering a more consistent mold temperature, and resin flow equating to less warpage and higher yields, improving the molding. We explore the benefits, applications and various related aspects of using aluminum molds in. Aluminum Molding Process.

From www.arptech.com.au

Injection Moulding Process Explained ArpTechBlog Aluminum Molding Process We explore the benefits, applications and various related aspects of using aluminum molds in the injection molding process. Aluminium is renowned for its exceptional thermal conductivity, enabling rapid heat transfer during the injection molding process. This attribute drastically reduces cycle times,. Casting is the original and most widely used method of forming aluminum into products. • aluminum possesses better thermal. Aluminum Molding Process.

From www.iqsdirectory.com

Polyurethane Molding What Is It? How Does It Work? Uses, Types Of Aluminum Molding Process We explore the benefits, applications and various related aspects of using aluminum molds in the injection molding process. Learn the types of aluminum used for aluminum molds, why plastic. Aluminum injection molding is an innovative technique based on injection molding used to produce parts (either prototypes/real. This attribute drastically reduces cycle times,. • aluminum possesses better thermal conductivity than steel,. Aluminum Molding Process.

From www.pinterest.com

Injection moulding explained Mould design, Injection moulding process Aluminum Molding Process • aluminum possesses better thermal conductivity than steel, offering a more consistent mold temperature, and resin flow equating to less warpage and higher yields, improving the molding. Aluminium is renowned for its exceptional thermal conductivity, enabling rapid heat transfer during the injection molding process. We explore the benefits, applications and various related aspects of using aluminum molds in the injection. Aluminum Molding Process.

From www.adtcmold.com

Injection mold principle and structure knowledge Aluminum Molding Process Explore the advanced processes and innovations in aluminum molding that are revolutionizing production efficiency and precision. • aluminum possesses better thermal conductivity than steel, offering a more consistent mold temperature, and resin flow equating to less warpage and higher yields, improving the molding. Learn the types of aluminum used for aluminum molds, why plastic. Aluminium is renowned for its exceptional. Aluminum Molding Process.

From www.inal.com

Aluminium Extrusion Process INAL Aluminum Molding Process We explore the benefits, applications and various related aspects of using aluminum molds in the injection molding process. Aluminum injection molding is an innovative technique based on injection molding used to produce parts (either prototypes/real. • aluminum possesses better thermal conductivity than steel, offering a more consistent mold temperature, and resin flow equating to less warpage and higher yields, improving. Aluminum Molding Process.

From www.finemim.com

Metal Injection Molding MIM Process FineMIM Aluminum Molding Process Learn the types of aluminum used for aluminum molds, why plastic. We explore the benefits, applications and various related aspects of using aluminum molds in the injection molding process. Aluminum injection molding is an innovative technique based on injection molding used to produce parts (either prototypes/real. This attribute drastically reduces cycle times,. Explore the advanced processes and innovations in aluminum. Aluminum Molding Process.

From www.jiangsutech.com

Metal Injection Molding (MIM) Process China Metal Parts Manufacturer Aluminum Molding Process Aluminum injection molding is an innovative technique based on injection molding used to produce parts (either prototypes/real. Explore the advanced processes and innovations in aluminum molding that are revolutionizing production efficiency and precision. We explore the benefits, applications and various related aspects of using aluminum molds in the injection molding process. Technical advances have been made, but the principle. Learn. Aluminum Molding Process.

From www.empcasting.com

What is the Posttreatment of Aluminum Casting? EMP Tech Co.,Ltd Aluminum Molding Process • aluminum possesses better thermal conductivity than steel, offering a more consistent mold temperature, and resin flow equating to less warpage and higher yields, improving the molding. Learn the types of aluminum used for aluminum molds, why plastic. Aluminium is renowned for its exceptional thermal conductivity, enabling rapid heat transfer during the injection molding process. This attribute drastically reduces cycle. Aluminum Molding Process.

From www.youtube.com

Aluminium Extrusion Process AMS GIA Extrusion Press YouTube Aluminum Molding Process This attribute drastically reduces cycle times,. Explore the advanced processes and innovations in aluminum molding that are revolutionizing production efficiency and precision. Technical advances have been made, but the principle. • aluminum possesses better thermal conductivity than steel, offering a more consistent mold temperature, and resin flow equating to less warpage and higher yields, improving the molding. Casting is the. Aluminum Molding Process.

From www.aluminumsandcastingfoundry.com

Molding Aluminum Molding Process Learn the types of aluminum used for aluminum molds, why plastic. • aluminum possesses better thermal conductivity than steel, offering a more consistent mold temperature, and resin flow equating to less warpage and higher yields, improving the molding. Aluminium is renowned for its exceptional thermal conductivity, enabling rapid heat transfer during the injection molding process. Aluminum injection molding is an. Aluminum Molding Process.

From themechanicalengineering.com

Injection Molding Definition, Construction, Working Process Aluminum Molding Process This attribute drastically reduces cycle times,. Aluminium is renowned for its exceptional thermal conductivity, enabling rapid heat transfer during the injection molding process. We explore the benefits, applications and various related aspects of using aluminum molds in the injection molding process. Casting is the original and most widely used method of forming aluminum into products. • aluminum possesses better thermal. Aluminum Molding Process.

From www.pinterest.com

Heatsink Aluminum molding, Aluminium extrusion, Tile trim Aluminum Molding Process Aluminum injection molding is an innovative technique based on injection molding used to produce parts (either prototypes/real. This attribute drastically reduces cycle times,. Explore the advanced processes and innovations in aluminum molding that are revolutionizing production efficiency and precision. Aluminium is renowned for its exceptional thermal conductivity, enabling rapid heat transfer during the injection molding process. Technical advances have been. Aluminum Molding Process.

From www.youtube.com

Shell Molding Expandable Mold Casting Processes YouTube Aluminum Molding Process This attribute drastically reduces cycle times,. Aluminium is renowned for its exceptional thermal conductivity, enabling rapid heat transfer during the injection molding process. Learn the types of aluminum used for aluminum molds, why plastic. Explore the advanced processes and innovations in aluminum molding that are revolutionizing production efficiency and precision. • aluminum possesses better thermal conductivity than steel, offering a. Aluminum Molding Process.

From www.museoinclusivo.com

Aluminum Moulding Profiles An Overview of their Manufacturing Aluminum Molding Process Technical advances have been made, but the principle. • aluminum possesses better thermal conductivity than steel, offering a more consistent mold temperature, and resin flow equating to less warpage and higher yields, improving the molding. Aluminum injection molding is an innovative technique based on injection molding used to produce parts (either prototypes/real. Learn the types of aluminum used for aluminum. Aluminum Molding Process.