Machining Rake Angle . Concept of positive rake angle, negative rake angle and zero rake angle of a cutting tool is discussed here. Rake angle is the most important factor while. An increased rake angle can enhance the sharpness of the cutting. Larger the rake angle, smaller the cutting angle (and larger the shear angle). The rake angles may be positive, zero or negative. Rake angle affects the values of cutting angle and the shear angle. The rake angle (γ) is the angle between the rake surface and the reference plane (πr) or perpendicular surface of the workpiece. Increasing rake angle in the positive (+). One of the most important factors in machining is the geometry of the cutting tool, and one component of that is the rake angle. An increased rake angle will reduce the strength of the cutting edge. Rake angle is a cutting edge angle that has large effects on cutting resistance, chip disposal, cutting temperature and tool life. A tool’s rake angle will affect how much material can be removed, how easily chips form and break, the horsepower required to cut, and even the tool’s life. It explains classification of rake angles with diagram and their examples,. The size of the rake angle directly affects the sharpness of the cutting edge and the cutting force. Its various names based on the plane on which it is.

from www.minaprem.com

Rake angle is a cutting edge angle that has large effects on cutting resistance, chip disposal, cutting temperature and tool life. Rake angle affects the values of cutting angle and the shear angle. Rake angle is the most important factor while. One of the most important factors in machining is the geometry of the cutting tool, and one component of that is the rake angle. The size of the rake angle directly affects the sharpness of the cutting edge and the cutting force. The rake angles may be positive, zero or negative. Its various names based on the plane on which it is. The rake angle (γ) is the angle between the rake surface and the reference plane (πr) or perpendicular surface of the workpiece. Concept of positive rake angle, negative rake angle and zero rake angle of a cutting tool is discussed here. An increased rake angle can enhance the sharpness of the cutting.

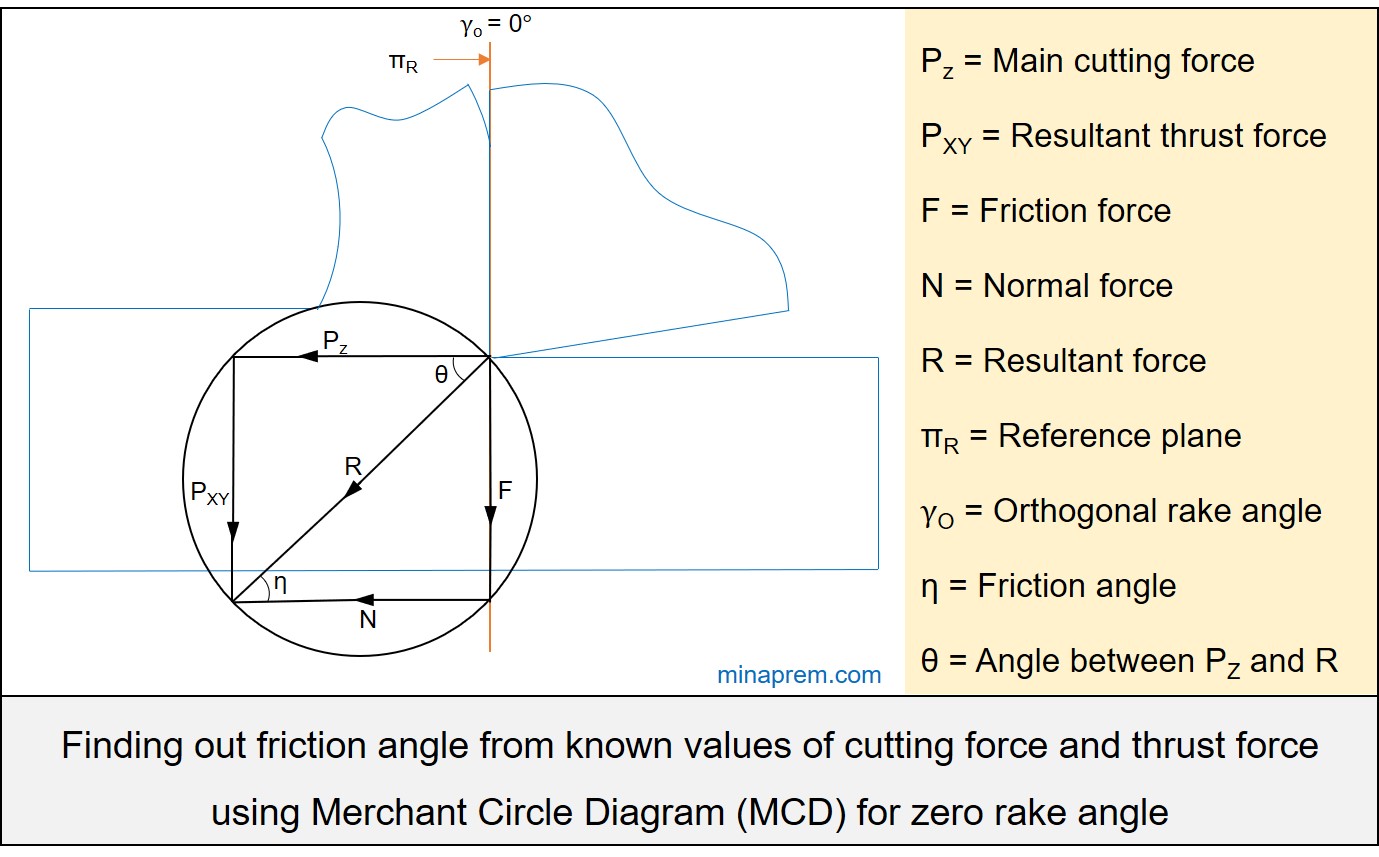

Coefficient of friction from cutting force and thrust force for zero

Machining Rake Angle Rake angle is the most important factor while. Rake angle is a cutting edge angle that has large effects on cutting resistance, chip disposal, cutting temperature and tool life. A tool’s rake angle will affect how much material can be removed, how easily chips form and break, the horsepower required to cut, and even the tool’s life. An increased rake angle will reduce the strength of the cutting edge. One of the most important factors in machining is the geometry of the cutting tool, and one component of that is the rake angle. The size of the rake angle directly affects the sharpness of the cutting edge and the cutting force. Larger the rake angle, smaller the cutting angle (and larger the shear angle). Rake angle is the most important factor while. Rake angle affects the values of cutting angle and the shear angle. An increased rake angle can enhance the sharpness of the cutting. Increasing rake angle in the positive (+). Concept of positive rake angle, negative rake angle and zero rake angle of a cutting tool is discussed here. The rake angle (γ) is the angle between the rake surface and the reference plane (πr) or perpendicular surface of the workpiece. It explains classification of rake angles with diagram and their examples,. Its various names based on the plane on which it is. The rake angles may be positive, zero or negative.

From www.minaprem.com

What is Rake Surface of Cutting Tool? Machining Principles Machining Rake Angle Rake angle affects the values of cutting angle and the shear angle. It explains classification of rake angles with diagram and their examples,. The size of the rake angle directly affects the sharpness of the cutting edge and the cutting force. Increasing rake angle in the positive (+). A tool’s rake angle will affect how much material can be removed,. Machining Rake Angle.

From slideplayer.com

Lathe. ppt download Machining Rake Angle Rake angle affects the values of cutting angle and the shear angle. The size of the rake angle directly affects the sharpness of the cutting edge and the cutting force. Larger the rake angle, smaller the cutting angle (and larger the shear angle). Rake angle is a cutting edge angle that has large effects on cutting resistance, chip disposal, cutting. Machining Rake Angle.

From www.hobby-machinist.com

Rake angles The HobbyMachinist Forums Machining Rake Angle Larger the rake angle, smaller the cutting angle (and larger the shear angle). A tool’s rake angle will affect how much material can be removed, how easily chips form and break, the horsepower required to cut, and even the tool’s life. It explains classification of rake angles with diagram and their examples,. Increasing rake angle in the positive (+). The. Machining Rake Angle.

From www.performers.hk

Tool_Geometry Machining Rake Angle The size of the rake angle directly affects the sharpness of the cutting edge and the cutting force. One of the most important factors in machining is the geometry of the cutting tool, and one component of that is the rake angle. The rake angles may be positive, zero or negative. It explains classification of rake angles with diagram and. Machining Rake Angle.

From www.gkseries.com

In an orthogonal machining with a single point cutting tool of rake Machining Rake Angle Larger the rake angle, smaller the cutting angle (and larger the shear angle). The size of the rake angle directly affects the sharpness of the cutting edge and the cutting force. The rake angle (γ) is the angle between the rake surface and the reference plane (πr) or perpendicular surface of the workpiece. Rake angle is a cutting edge angle. Machining Rake Angle.

From www.youtube.com

Differences between Rake Angle and Clearance Angle. YouTube Machining Rake Angle The size of the rake angle directly affects the sharpness of the cutting edge and the cutting force. The rake angle (γ) is the angle between the rake surface and the reference plane (πr) or perpendicular surface of the workpiece. Concept of positive rake angle, negative rake angle and zero rake angle of a cutting tool is discussed here. A. Machining Rake Angle.

From www.indiamart.com

Variable Rake Angle Shearing Machine at Rs 980000 हाइड्रोलिक शेयरिंग Machining Rake Angle An increased rake angle will reduce the strength of the cutting edge. The rake angles may be positive, zero or negative. Rake angle is a cutting edge angle that has large effects on cutting resistance, chip disposal, cutting temperature and tool life. Concept of positive rake angle, negative rake angle and zero rake angle of a cutting tool is discussed. Machining Rake Angle.

From learnmechanical.com

Rake Angle Definition, Importance, and Types (Positive, Negative, Zero Machining Rake Angle Larger the rake angle, smaller the cutting angle (and larger the shear angle). One of the most important factors in machining is the geometry of the cutting tool, and one component of that is the rake angle. Rake angle is the most important factor while. Increasing rake angle in the positive (+). The rake angles may be positive, zero or. Machining Rake Angle.

From www.ctemag.com

Rake angles make or break facemilling Cutting Tool Engineering Machining Rake Angle An increased rake angle can enhance the sharpness of the cutting. Rake angle is the most important factor while. One of the most important factors in machining is the geometry of the cutting tool, and one component of that is the rake angle. The size of the rake angle directly affects the sharpness of the cutting edge and the cutting. Machining Rake Angle.

From www.riansclub.com

Rake Angle Types Of Rake Angle, Advantages, And Disadvantages Machining Rake Angle An increased rake angle will reduce the strength of the cutting edge. An increased rake angle can enhance the sharpness of the cutting. The size of the rake angle directly affects the sharpness of the cutting edge and the cutting force. Increasing rake angle in the positive (+). It explains classification of rake angles with diagram and their examples,. Rake. Machining Rake Angle.

From toolnotes.com

Lathe Tools and Toolholders ToolNotes Machining Rake Angle Larger the rake angle, smaller the cutting angle (and larger the shear angle). An increased rake angle can enhance the sharpness of the cutting. Rake angle affects the values of cutting angle and the shear angle. Rake angle is the most important factor while. It explains classification of rake angles with diagram and their examples,. Concept of positive rake angle,. Machining Rake Angle.

From www.mdpi.com

Metals Free FullText Effect of Machining Conditions on Temperature Machining Rake Angle Rake angle affects the values of cutting angle and the shear angle. Increasing rake angle in the positive (+). The size of the rake angle directly affects the sharpness of the cutting edge and the cutting force. An increased rake angle will reduce the strength of the cutting edge. Concept of positive rake angle, negative rake angle and zero rake. Machining Rake Angle.

From www.mdpi.com

Micromachines Free FullText Experimental Study on the Minimum Machining Rake Angle Larger the rake angle, smaller the cutting angle (and larger the shear angle). An increased rake angle can enhance the sharpness of the cutting. Its various names based on the plane on which it is. The rake angles may be positive, zero or negative. The rake angle (γ) is the angle between the rake surface and the reference plane (πr). Machining Rake Angle.

From www.minaprem.com

Coefficient of friction from cutting force and thrust force for zero Machining Rake Angle An increased rake angle will reduce the strength of the cutting edge. Concept of positive rake angle, negative rake angle and zero rake angle of a cutting tool is discussed here. Rake angle is the most important factor while. Rake angle is a cutting edge angle that has large effects on cutting resistance, chip disposal, cutting temperature and tool life.. Machining Rake Angle.

From www.cobanengineering.com

Back Rake, Side Rake, Rake angle, wedge angle and flank angles,the Machining Rake Angle The rake angle (γ) is the angle between the rake surface and the reference plane (πr) or perpendicular surface of the workpiece. A tool’s rake angle will affect how much material can be removed, how easily chips form and break, the horsepower required to cut, and even the tool’s life. Its various names based on the plane on which it. Machining Rake Angle.

From www.youtube.com

Single Point Cutting Tool Nomenclature, Tool Signature, Side Rake Machining Rake Angle Increasing rake angle in the positive (+). One of the most important factors in machining is the geometry of the cutting tool, and one component of that is the rake angle. Rake angle is the most important factor while. Rake angle is a cutting edge angle that has large effects on cutting resistance, chip disposal, cutting temperature and tool life.. Machining Rake Angle.

From www.minaprem.com

Concept of Positive Rake, Negative Rake and Zero Rake Angle Machining Rake Angle The size of the rake angle directly affects the sharpness of the cutting edge and the cutting force. Larger the rake angle, smaller the cutting angle (and larger the shear angle). Rake angle affects the values of cutting angle and the shear angle. Its various names based on the plane on which it is. It explains classification of rake angles. Machining Rake Angle.

From www.minaprem.com

Why brittle materials are machined with tools having negative rake? Machining Rake Angle An increased rake angle will reduce the strength of the cutting edge. Concept of positive rake angle, negative rake angle and zero rake angle of a cutting tool is discussed here. A tool’s rake angle will affect how much material can be removed, how easily chips form and break, the horsepower required to cut, and even the tool’s life. Increasing. Machining Rake Angle.

From www.minaprem.com

Maximum Rake Angle of Cutting Tool Its Advantages in Tool Grinding Machining Rake Angle Concept of positive rake angle, negative rake angle and zero rake angle of a cutting tool is discussed here. The rake angle (γ) is the angle between the rake surface and the reference plane (πr) or perpendicular surface of the workpiece. Its various names based on the plane on which it is. The rake angles may be positive, zero or. Machining Rake Angle.

From toolnotes.com

Lathe Tools and Toolholders ToolNotes Machining Rake Angle It explains classification of rake angles with diagram and their examples,. An increased rake angle can enhance the sharpness of the cutting. A tool’s rake angle will affect how much material can be removed, how easily chips form and break, the horsepower required to cut, and even the tool’s life. Increasing rake angle in the positive (+). Larger the rake. Machining Rake Angle.

From www.difference.minaprem.com

Difference Between Rake Angle and Clearance Angle Machining Rake Angle It explains classification of rake angles with diagram and their examples,. One of the most important factors in machining is the geometry of the cutting tool, and one component of that is the rake angle. Rake angle affects the values of cutting angle and the shear angle. Larger the rake angle, smaller the cutting angle (and larger the shear angle).. Machining Rake Angle.

From www.minaprem.com

Concept of Positive Rake, Negative Rake and Zero Rake Angle Machining Rake Angle One of the most important factors in machining is the geometry of the cutting tool, and one component of that is the rake angle. Concept of positive rake angle, negative rake angle and zero rake angle of a cutting tool is discussed here. The rake angle (γ) is the angle between the rake surface and the reference plane (πr) or. Machining Rake Angle.

From www.mmc-carbide.com

Rake Angle Technical Info/Cutting Formula MITSUBISHI MATERIALS Machining Rake Angle An increased rake angle will reduce the strength of the cutting edge. An increased rake angle can enhance the sharpness of the cutting. The rake angles may be positive, zero or negative. Its various names based on the plane on which it is. Rake angle is a cutting edge angle that has large effects on cutting resistance, chip disposal, cutting. Machining Rake Angle.

From www.manufacturingguide.com

Positive and negative rake angle in milling Find suppliers, processes Machining Rake Angle Rake angle is a cutting edge angle that has large effects on cutting resistance, chip disposal, cutting temperature and tool life. One of the most important factors in machining is the geometry of the cutting tool, and one component of that is the rake angle. It explains classification of rake angles with diagram and their examples,. Its various names based. Machining Rake Angle.

From www.youtube.com

Differences between Positive Rake Angle and Negative Rake Angle Machining Rake Angle Concept of positive rake angle, negative rake angle and zero rake angle of a cutting tool is discussed here. It explains classification of rake angles with diagram and their examples,. Increasing rake angle in the positive (+). One of the most important factors in machining is the geometry of the cutting tool, and one component of that is the rake. Machining Rake Angle.

From www.themachinedesign.com

Single Point Cutting Tool Nomenclature, Geometry The Machine Design Machining Rake Angle An increased rake angle can enhance the sharpness of the cutting. Its various names based on the plane on which it is. Larger the rake angle, smaller the cutting angle (and larger the shear angle). The rake angles may be positive, zero or negative. One of the most important factors in machining is the geometry of the cutting tool, and. Machining Rake Angle.

From www.machinemfg.com

Lathe Cutting Tool Angles Selection Principle MachineMFG Machining Rake Angle Concept of positive rake angle, negative rake angle and zero rake angle of a cutting tool is discussed here. An increased rake angle will reduce the strength of the cutting edge. Rake angle affects the values of cutting angle and the shear angle. Its various names based on the plane on which it is. One of the most important factors. Machining Rake Angle.

From huanatools.com

Positive Angle Inserts VS Negative Angle Inserts Huana Tools Machining Rake Angle Concept of positive rake angle, negative rake angle and zero rake angle of a cutting tool is discussed here. One of the most important factors in machining is the geometry of the cutting tool, and one component of that is the rake angle. The size of the rake angle directly affects the sharpness of the cutting edge and the cutting. Machining Rake Angle.

From www.researchgate.net

End mill fabrication of various rake angles and clearance angles Machining Rake Angle Rake angle affects the values of cutting angle and the shear angle. Its various names based on the plane on which it is. The rake angles may be positive, zero or negative. Rake angle is the most important factor while. The rake angle (γ) is the angle between the rake surface and the reference plane (πr) or perpendicular surface of. Machining Rake Angle.

From huanatools.com

Positive Angle Inserts VS Negative Angle Inserts Huana Tools Machining Rake Angle An increased rake angle can enhance the sharpness of the cutting. Its various names based on the plane on which it is. The rake angle (γ) is the angle between the rake surface and the reference plane (πr) or perpendicular surface of the workpiece. Concept of positive rake angle, negative rake angle and zero rake angle of a cutting tool. Machining Rake Angle.

From www.smartlathe.com

Components Of A Lathe Cutting Tool Machining Rake Angle It explains classification of rake angles with diagram and their examples,. Concept of positive rake angle, negative rake angle and zero rake angle of a cutting tool is discussed here. Increasing rake angle in the positive (+). The rake angles may be positive, zero or negative. One of the most important factors in machining is the geometry of the cutting. Machining Rake Angle.

From www.chegg.com

Solved In a machining operation that approximates orthogonal Machining Rake Angle An increased rake angle will reduce the strength of the cutting edge. Rake angle affects the values of cutting angle and the shear angle. The rake angle (γ) is the angle between the rake surface and the reference plane (πr) or perpendicular surface of the workpiece. It explains classification of rake angles with diagram and their examples,. Rake angle is. Machining Rake Angle.

From www.ukocarbide.com

How Important to Know Each Part of the CNC Lath Tool? Machining Rake Angle It explains classification of rake angles with diagram and their examples,. The rake angles may be positive, zero or negative. Rake angle is a cutting edge angle that has large effects on cutting resistance, chip disposal, cutting temperature and tool life. An increased rake angle can enhance the sharpness of the cutting. An increased rake angle will reduce the strength. Machining Rake Angle.

From www.caebay.com

Post 2 Rake Angle Influence CAEbay Machining Rake Angle An increased rake angle will reduce the strength of the cutting edge. The rake angles may be positive, zero or negative. Increasing rake angle in the positive (+). Larger the rake angle, smaller the cutting angle (and larger the shear angle). An increased rake angle can enhance the sharpness of the cutting. The size of the rake angle directly affects. Machining Rake Angle.

From www.minaprem.com

Determine shear angle from orthogonal rake angle and chip thickness ratio Machining Rake Angle Increasing rake angle in the positive (+). One of the most important factors in machining is the geometry of the cutting tool, and one component of that is the rake angle. Rake angle affects the values of cutting angle and the shear angle. Rake angle is the most important factor while. Larger the rake angle, smaller the cutting angle (and. Machining Rake Angle.