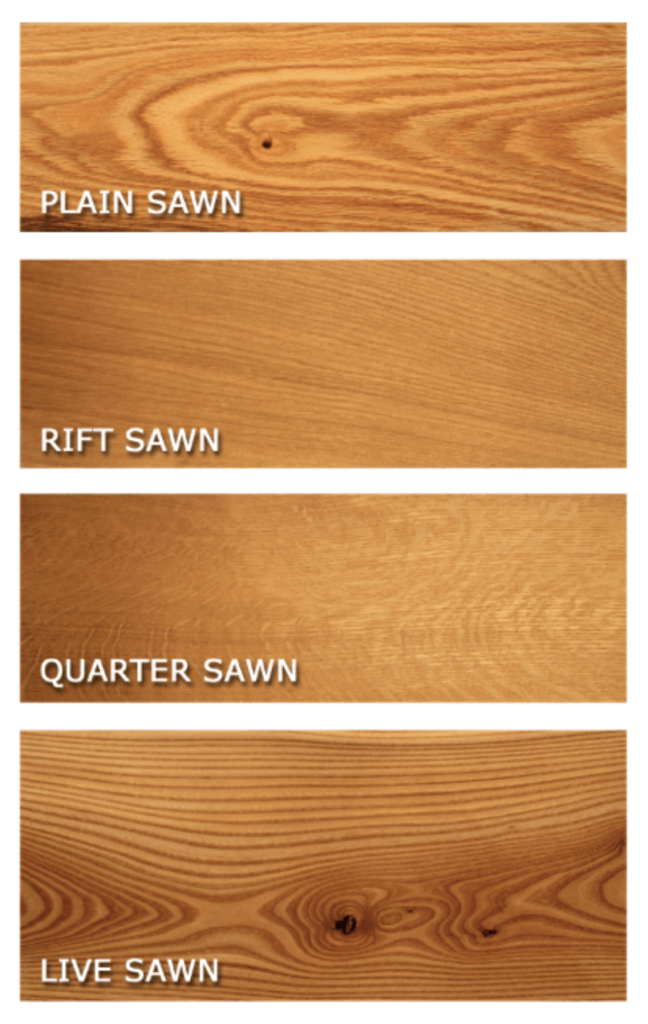

Quarter Cut Vs Plain Sliced . This creates a straight, tight grain with a flaked or rayed pattern depending on the species. Also known as flat sawn wood, plain sawn wood is produced by making a cut on a tangent to. Flat cut or plain sliced veneer is a lot more work and a lot more involved from tree to cabinet, so it costs a lot more. First is the way the log is cut. In today’s blog, our lumber experts discuss plain sawn vs. Plain slicing (also known as plain sawn or flat cut) a log produces thin veneers that are no wider than the log and have a pronounced repeating grain pattern. Veneers thus developed are often. This method bisects annual growth. The resulting veneer is called quarter sliced if heavy flake is visible and rift cut when the flake is minimal. The short answer for here is: Among the more common cut types you’ll see are “flat cut” or “plain sliced,” “quarter cut,” and “rift cut” or “rotary cut. Quarter cut is most commonly used with oak because of the flake effect.

from evolutionofstyleblog.com

Quarter cut is most commonly used with oak because of the flake effect. In today’s blog, our lumber experts discuss plain sawn vs. The resulting veneer is called quarter sliced if heavy flake is visible and rift cut when the flake is minimal. Also known as flat sawn wood, plain sawn wood is produced by making a cut on a tangent to. This creates a straight, tight grain with a flaked or rayed pattern depending on the species. The short answer for here is: This method bisects annual growth. First is the way the log is cut. Veneers thus developed are often. Flat cut or plain sliced veneer is a lot more work and a lot more involved from tree to cabinet, so it costs a lot more.

A Guide to Choosing White Oak Floors Evolution of Style

Quarter Cut Vs Plain Sliced Among the more common cut types you’ll see are “flat cut” or “plain sliced,” “quarter cut,” and “rift cut” or “rotary cut. In today’s blog, our lumber experts discuss plain sawn vs. Also known as flat sawn wood, plain sawn wood is produced by making a cut on a tangent to. The short answer for here is: This creates a straight, tight grain with a flaked or rayed pattern depending on the species. Flat cut or plain sliced veneer is a lot more work and a lot more involved from tree to cabinet, so it costs a lot more. Veneers thus developed are often. Plain slicing (also known as plain sawn or flat cut) a log produces thin veneers that are no wider than the log and have a pronounced repeating grain pattern. First is the way the log is cut. Quarter cut is most commonly used with oak because of the flake effect. This method bisects annual growth. Among the more common cut types you’ll see are “flat cut” or “plain sliced,” “quarter cut,” and “rift cut” or “rotary cut. The resulting veneer is called quarter sliced if heavy flake is visible and rift cut when the flake is minimal.

From beckallencabinetry.com

Rift Cut and Quarter Sawn White Oak Beck/Allen Quarter Cut Vs Plain Sliced Veneers thus developed are often. The short answer for here is: In today’s blog, our lumber experts discuss plain sawn vs. Flat cut or plain sliced veneer is a lot more work and a lot more involved from tree to cabinet, so it costs a lot more. Among the more common cut types you’ll see are “flat cut” or “plain. Quarter Cut Vs Plain Sliced.

From www.facebook.com

Arangkada Banwa Basketball League InterBarangay Season 2 GAME 5 5 Quarter Cut Vs Plain Sliced The short answer for here is: In today’s blog, our lumber experts discuss plain sawn vs. Plain slicing (also known as plain sawn or flat cut) a log produces thin veneers that are no wider than the log and have a pronounced repeating grain pattern. Among the more common cut types you’ll see are “flat cut” or “plain sliced,” “quarter. Quarter Cut Vs Plain Sliced.

From www.pinterest.jp

Plain slicing Google Search Wood floors, Wood, Woodworking Quarter Cut Vs Plain Sliced This method bisects annual growth. Also known as flat sawn wood, plain sawn wood is produced by making a cut on a tangent to. Plain slicing (also known as plain sawn or flat cut) a log produces thin veneers that are no wider than the log and have a pronounced repeating grain pattern. The short answer for here is: Among. Quarter Cut Vs Plain Sliced.

From woditex.com

Plain sawn, quarter sawn, rift sawn and live sawn lumber Woditex Quarter Cut Vs Plain Sliced Also known as flat sawn wood, plain sawn wood is produced by making a cut on a tangent to. In today’s blog, our lumber experts discuss plain sawn vs. The short answer for here is: Flat cut or plain sliced veneer is a lot more work and a lot more involved from tree to cabinet, so it costs a lot. Quarter Cut Vs Plain Sliced.

From superiorcabinets.ca

Are Oak Making a Comeback? Superior Quarter Cut Vs Plain Sliced Plain slicing (also known as plain sawn or flat cut) a log produces thin veneers that are no wider than the log and have a pronounced repeating grain pattern. The short answer for here is: Also known as flat sawn wood, plain sawn wood is produced by making a cut on a tangent to. Veneers thus developed are often. Among. Quarter Cut Vs Plain Sliced.

From silentrivers.com

Wood Cut Types, Wood Grades Considering Symbolism and Energy of Woods Quarter Cut Vs Plain Sliced The resulting veneer is called quarter sliced if heavy flake is visible and rift cut when the flake is minimal. Veneers thus developed are often. In today’s blog, our lumber experts discuss plain sawn vs. Plain slicing (also known as plain sawn or flat cut) a log produces thin veneers that are no wider than the log and have a. Quarter Cut Vs Plain Sliced.

From oregondoor.com

Surfaces Craftsman Series Specialty Flush Wood Doors Oregon Door Quarter Cut Vs Plain Sliced Quarter cut is most commonly used with oak because of the flake effect. The short answer for here is: In today’s blog, our lumber experts discuss plain sawn vs. First is the way the log is cut. Plain slicing (also known as plain sawn or flat cut) a log produces thin veneers that are no wider than the log and. Quarter Cut Vs Plain Sliced.

From www.vrogue.co

White Oak Veneer Lights Up Light Wood Texture Oak Woo vrogue.co Quarter Cut Vs Plain Sliced This creates a straight, tight grain with a flaked or rayed pattern depending on the species. Veneers thus developed are often. The short answer for here is: Among the more common cut types you’ll see are “flat cut” or “plain sliced,” “quarter cut,” and “rift cut” or “rotary cut. Flat cut or plain sliced veneer is a lot more work. Quarter Cut Vs Plain Sliced.

From www.osbornewood.com

Osborne Wood The Difference Between Plain, Quarter and Rift Sawn… Quarter Cut Vs Plain Sliced The resulting veneer is called quarter sliced if heavy flake is visible and rift cut when the flake is minimal. In today’s blog, our lumber experts discuss plain sawn vs. Veneers thus developed are often. Plain slicing (also known as plain sawn or flat cut) a log produces thin veneers that are no wider than the log and have a. Quarter Cut Vs Plain Sliced.

From www.doordash.com

Best Paninisandwich Restaurants in Hillside DoorDash Quarter Cut Vs Plain Sliced The short answer for here is: The resulting veneer is called quarter sliced if heavy flake is visible and rift cut when the flake is minimal. In today’s blog, our lumber experts discuss plain sawn vs. Veneers thus developed are often. First is the way the log is cut. Also known as flat sawn wood, plain sawn wood is produced. Quarter Cut Vs Plain Sliced.

From cabinet.matttroy.net

Quarter Sawn White Oak Doors Matttroy Quarter Cut Vs Plain Sliced The resulting veneer is called quarter sliced if heavy flake is visible and rift cut when the flake is minimal. The short answer for here is: Also known as flat sawn wood, plain sawn wood is produced by making a cut on a tangent to. Veneers thus developed are often. Plain slicing (also known as plain sawn or flat cut). Quarter Cut Vs Plain Sliced.

From www.door.cc

Veneer Patterns for Flush Doors Quarter Cut Vs Plain Sliced Among the more common cut types you’ll see are “flat cut” or “plain sliced,” “quarter cut,” and “rift cut” or “rotary cut. The short answer for here is: In today’s blog, our lumber experts discuss plain sawn vs. This method bisects annual growth. Quarter cut is most commonly used with oak because of the flake effect. This creates a straight,. Quarter Cut Vs Plain Sliced.

From www.plywoodexpress.com

Wood Veneer Cuts Rotary, Rift, Flat & More Plywood Express Quarter Cut Vs Plain Sliced The resulting veneer is called quarter sliced if heavy flake is visible and rift cut when the flake is minimal. The short answer for here is: First is the way the log is cut. In today’s blog, our lumber experts discuss plain sawn vs. Plain slicing (also known as plain sawn or flat cut) a log produces thin veneers that. Quarter Cut Vs Plain Sliced.

From www.pinterest.com

What Is the Difference Between Plain Sawn, Rift Sawn, Quarter Sawn and Quarter Cut Vs Plain Sliced This method bisects annual growth. Plain slicing (also known as plain sawn or flat cut) a log produces thin veneers that are no wider than the log and have a pronounced repeating grain pattern. Flat cut or plain sliced veneer is a lot more work and a lot more involved from tree to cabinet, so it costs a lot more.. Quarter Cut Vs Plain Sliced.

From evolutionofstyleblog.com

A Guide to Choosing White Oak Floors Evolution of Style Quarter Cut Vs Plain Sliced Veneers thus developed are often. This creates a straight, tight grain with a flaked or rayed pattern depending on the species. In today’s blog, our lumber experts discuss plain sawn vs. Among the more common cut types you’ll see are “flat cut” or “plain sliced,” “quarter cut,” and “rift cut” or “rotary cut. First is the way the log is. Quarter Cut Vs Plain Sliced.

From www.youtube.com

White Oak Clear Rift+Quartered YouTube Quarter Cut Vs Plain Sliced Plain slicing (also known as plain sawn or flat cut) a log produces thin veneers that are no wider than the log and have a pronounced repeating grain pattern. This method bisects annual growth. First is the way the log is cut. Quarter cut is most commonly used with oak because of the flake effect. Flat cut or plain sliced. Quarter Cut Vs Plain Sliced.

From superiorcabinets.ca

Are Oak Making a Comeback? Superior Quarter Cut Vs Plain Sliced Plain slicing (also known as plain sawn or flat cut) a log produces thin veneers that are no wider than the log and have a pronounced repeating grain pattern. In today’s blog, our lumber experts discuss plain sawn vs. Flat cut or plain sliced veneer is a lot more work and a lot more involved from tree to cabinet, so. Quarter Cut Vs Plain Sliced.

From www.valentiflooring.com

RIFT AND QUARTER SAWN HARDWOOD FLOORING...THE 411 — Valenti Flooring Quarter Cut Vs Plain Sliced Quarter cut is most commonly used with oak because of the flake effect. This method bisects annual growth. The short answer for here is: In today’s blog, our lumber experts discuss plain sawn vs. Plain slicing (also known as plain sawn or flat cut) a log produces thin veneers that are no wider than the log and have a pronounced. Quarter Cut Vs Plain Sliced.

From www.finehomebuilding.com

Quartersawn Wood and RiftSawn Wood, Explained Fine Homebuilding Quarter Cut Vs Plain Sliced The short answer for here is: First is the way the log is cut. Flat cut or plain sliced veneer is a lot more work and a lot more involved from tree to cabinet, so it costs a lot more. This creates a straight, tight grain with a flaked or rayed pattern depending on the species. Also known as flat. Quarter Cut Vs Plain Sliced.

From www.plywoodinspection.com

Wood face ,back and core Veneer Cutting & Slicing Characteristics Quarter Cut Vs Plain Sliced Also known as flat sawn wood, plain sawn wood is produced by making a cut on a tangent to. Plain slicing (also known as plain sawn or flat cut) a log produces thin veneers that are no wider than the log and have a pronounced repeating grain pattern. The resulting veneer is called quarter sliced if heavy flake is visible. Quarter Cut Vs Plain Sliced.

From studylib.net

Face Options Wood Veneer Cuts Quarter Cut Vs Plain Sliced Also known as flat sawn wood, plain sawn wood is produced by making a cut on a tangent to. The resulting veneer is called quarter sliced if heavy flake is visible and rift cut when the flake is minimal. This method bisects annual growth. Among the more common cut types you’ll see are “flat cut” or “plain sliced,” “quarter cut,”. Quarter Cut Vs Plain Sliced.

From www.sustainablelumberco.com

What is LiveSawn White Oak LiveSawn Vs. PlainSawn Quarter Cut Vs Plain Sliced This creates a straight, tight grain with a flaked or rayed pattern depending on the species. Plain slicing (also known as plain sawn or flat cut) a log produces thin veneers that are no wider than the log and have a pronounced repeating grain pattern. Also known as flat sawn wood, plain sawn wood is produced by making a cut. Quarter Cut Vs Plain Sliced.

From www.lifeofanarchitect.com

wood cut patterns Rift Cut, Rotary Cut, Quarter Sawn, and Plain Sawn Quarter Cut Vs Plain Sliced Veneers thus developed are often. The resulting veneer is called quarter sliced if heavy flake is visible and rift cut when the flake is minimal. Plain slicing (also known as plain sawn or flat cut) a log produces thin veneers that are no wider than the log and have a pronounced repeating grain pattern. Among the more common cut types. Quarter Cut Vs Plain Sliced.

From www.woodworkingnetwork.com

Illustrated guide of veneer cutting methods Woodworking Network Quarter Cut Vs Plain Sliced In today’s blog, our lumber experts discuss plain sawn vs. Veneers thus developed are often. Flat cut or plain sliced veneer is a lot more work and a lot more involved from tree to cabinet, so it costs a lot more. Quarter cut is most commonly used with oak because of the flake effect. Also known as flat sawn wood,. Quarter Cut Vs Plain Sliced.

From www.facebook.com

Facebook Quarter Cut Vs Plain Sliced In today’s blog, our lumber experts discuss plain sawn vs. Among the more common cut types you’ll see are “flat cut” or “plain sliced,” “quarter cut,” and “rift cut” or “rotary cut. This creates a straight, tight grain with a flaked or rayed pattern depending on the species. First is the way the log is cut. Also known as flat. Quarter Cut Vs Plain Sliced.

From www.finehomebuilding.com

Quartersawn Wood and RiftSawn Wood, Explained Fine Homebuilding Quarter Cut Vs Plain Sliced First is the way the log is cut. Among the more common cut types you’ll see are “flat cut” or “plain sliced,” “quarter cut,” and “rift cut” or “rotary cut. This creates a straight, tight grain with a flaked or rayed pattern depending on the species. Flat cut or plain sliced veneer is a lot more work and a lot. Quarter Cut Vs Plain Sliced.

From www.facebook.com

The Keeping It Real Show Tonight, we are on location at the Congress Quarter Cut Vs Plain Sliced This creates a straight, tight grain with a flaked or rayed pattern depending on the species. The resulting veneer is called quarter sliced if heavy flake is visible and rift cut when the flake is minimal. Veneers thus developed are often. In today’s blog, our lumber experts discuss plain sawn vs. Among the more common cut types you’ll see are. Quarter Cut Vs Plain Sliced.

From www.pinterest.com

A helpful illustration of the difference between/ how to identify Quarter Cut Vs Plain Sliced Quarter cut is most commonly used with oak because of the flake effect. Veneers thus developed are often. This creates a straight, tight grain with a flaked or rayed pattern depending on the species. In today’s blog, our lumber experts discuss plain sawn vs. This method bisects annual growth. The short answer for here is: The resulting veneer is called. Quarter Cut Vs Plain Sliced.

From www.facebook.com

The Keeping It Real Show Tonight, we are on location at the Congress Quarter Cut Vs Plain Sliced The resulting veneer is called quarter sliced if heavy flake is visible and rift cut when the flake is minimal. The short answer for here is: Plain slicing (also known as plain sawn or flat cut) a log produces thin veneers that are no wider than the log and have a pronounced repeating grain pattern. Flat cut or plain sliced. Quarter Cut Vs Plain Sliced.

From www.familyhandyman.com

How to Buy RoughSawn Lumber — The Family Handyman Quarter Cut Vs Plain Sliced Veneers thus developed are often. Quarter cut is most commonly used with oak because of the flake effect. Also known as flat sawn wood, plain sawn wood is produced by making a cut on a tangent to. This method bisects annual growth. The short answer for here is: This creates a straight, tight grain with a flaked or rayed pattern. Quarter Cut Vs Plain Sliced.