Rolling Tap Vs Cutting Tap . The key distinction between roll form and cut tap strength is that roll taps use the material itself to create a thread, whereas cutting taps physically remove material to achieve the same result. Roll tap advantages are inherent in the way they create the threads. But, the spiral angle on the front cutting edges helps eject the chips and the angled edge also gives superior cutting performance. Roll taps are often preferred over regular cutting taps for smaller or larger holes, challenging materials like stainless steel, or where chip issues could lead to tap breakage. This results in cut taps being the more precise option, but also leaving them more vulnerable to breakage under pressure. A cut tap and a roll tap both create a thread but in a different manner. Roll tapping is a specialised threading process that forms threads through material deformation rather than cutting. Both taps have advantages and disadvantages, and the right option for you may depend on the material being threaded. Form taps, or forming taps, are also called roll taps because they roll material into the thread form rather than cutting excess material away. This method compresses the material to create threads,. Do you know the difference between cut taps and roll (or form) taps? Roll taps, also known as form taps, hold distinct advantages over cut taps. When forming an internal thread, cut taps and roll taps are two of the most popular options.

from bluepointtool.com

Form taps, or forming taps, are also called roll taps because they roll material into the thread form rather than cutting excess material away. The key distinction between roll form and cut tap strength is that roll taps use the material itself to create a thread, whereas cutting taps physically remove material to achieve the same result. This results in cut taps being the more precise option, but also leaving them more vulnerable to breakage under pressure. When forming an internal thread, cut taps and roll taps are two of the most popular options. But, the spiral angle on the front cutting edges helps eject the chips and the angled edge also gives superior cutting performance. Roll taps, also known as form taps, hold distinct advantages over cut taps. A cut tap and a roll tap both create a thread but in a different manner. Do you know the difference between cut taps and roll (or form) taps? This method compresses the material to create threads,. Roll taps are often preferred over regular cutting taps for smaller or larger holes, challenging materials like stainless steel, or where chip issues could lead to tap breakage.

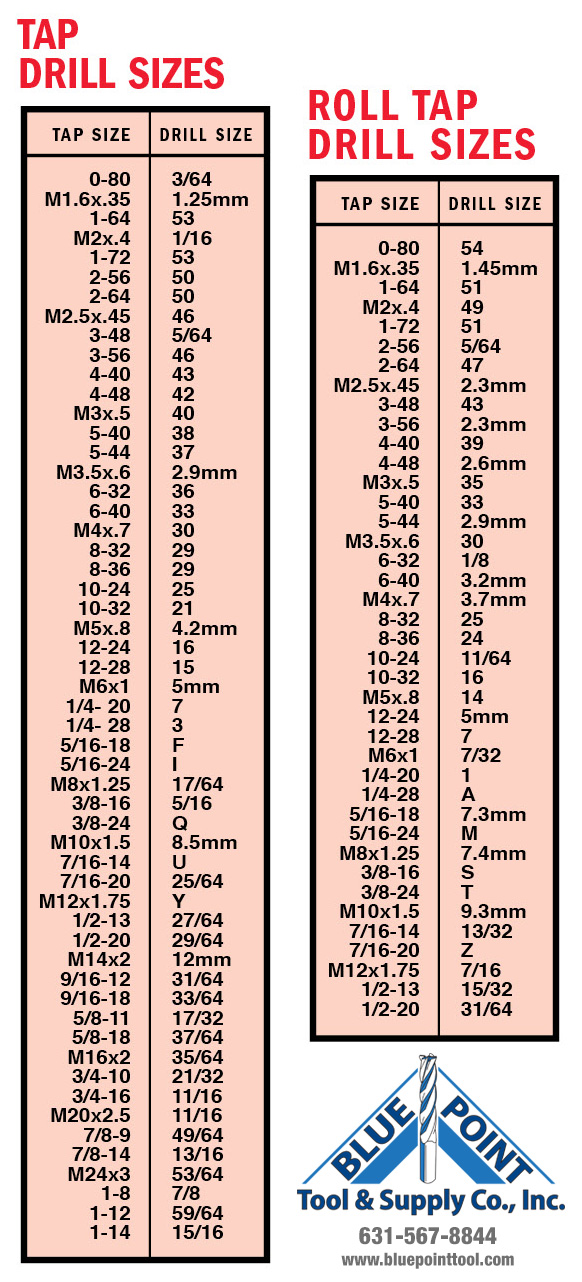

Tap Drill Sizes Blue Point Tool & Supply

Rolling Tap Vs Cutting Tap Roll taps are often preferred over regular cutting taps for smaller or larger holes, challenging materials like stainless steel, or where chip issues could lead to tap breakage. This results in cut taps being the more precise option, but also leaving them more vulnerable to breakage under pressure. The key distinction between roll form and cut tap strength is that roll taps use the material itself to create a thread, whereas cutting taps physically remove material to achieve the same result. Roll tap advantages are inherent in the way they create the threads. Both taps have advantages and disadvantages, and the right option for you may depend on the material being threaded. But, the spiral angle on the front cutting edges helps eject the chips and the angled edge also gives superior cutting performance. Roll tapping is a specialised threading process that forms threads through material deformation rather than cutting. Roll taps, also known as form taps, hold distinct advantages over cut taps. Form taps, or forming taps, are also called roll taps because they roll material into the thread form rather than cutting excess material away. Do you know the difference between cut taps and roll (or form) taps? A cut tap and a roll tap both create a thread but in a different manner. When forming an internal thread, cut taps and roll taps are two of the most popular options. Roll taps are often preferred over regular cutting taps for smaller or larger holes, challenging materials like stainless steel, or where chip issues could lead to tap breakage. This method compresses the material to create threads,.

From www.trigonenterprises.com

Taps Spiral fluted, Cut and Roll tap Forming Taps (Roll Tap) Distributor / Channel Partner Rolling Tap Vs Cutting Tap Roll taps, also known as form taps, hold distinct advantages over cut taps. A cut tap and a roll tap both create a thread but in a different manner. This method compresses the material to create threads,. The key distinction between roll form and cut tap strength is that roll taps use the material itself to create a thread, whereas. Rolling Tap Vs Cutting Tap.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Rolling Tap Vs Cutting Tap But, the spiral angle on the front cutting edges helps eject the chips and the angled edge also gives superior cutting performance. Roll taps, also known as form taps, hold distinct advantages over cut taps. Roll tapping is a specialised threading process that forms threads through material deformation rather than cutting. Form taps, or forming taps, are also called roll. Rolling Tap Vs Cutting Tap.

From threadingtoolsguide.com

3 threading taps in comparison machine tap, cutin tap or hand tap Rolling Tap Vs Cutting Tap Roll tap advantages are inherent in the way they create the threads. This method compresses the material to create threads,. When forming an internal thread, cut taps and roll taps are two of the most popular options. But, the spiral angle on the front cutting edges helps eject the chips and the angled edge also gives superior cutting performance. A. Rolling Tap Vs Cutting Tap.

From www.cutwel.co.uk

Roll Tapping vs Conventional (Cut) Tapping Cutwel Ltd Rolling Tap Vs Cutting Tap Roll tapping is a specialised threading process that forms threads through material deformation rather than cutting. This results in cut taps being the more precise option, but also leaving them more vulnerable to breakage under pressure. Roll taps are often preferred over regular cutting taps for smaller or larger holes, challenging materials like stainless steel, or where chip issues could. Rolling Tap Vs Cutting Tap.

From www.behance.net

Tesker Thread Rolling Process on Behance Rolling Tap Vs Cutting Tap Do you know the difference between cut taps and roll (or form) taps? But, the spiral angle on the front cutting edges helps eject the chips and the angled edge also gives superior cutting performance. Roll taps are often preferred over regular cutting taps for smaller or larger holes, challenging materials like stainless steel, or where chip issues could lead. Rolling Tap Vs Cutting Tap.

From www.ebay.co.uk

ú, HSS Spiral Flute, Point, Roll TAP M1.6 M2 M2.2 M2.3 M2.5 M2.6 M3 M3.5 M4 M4.5 eBay Rolling Tap Vs Cutting Tap Both taps have advantages and disadvantages, and the right option for you may depend on the material being threaded. Form taps, or forming taps, are also called roll taps because they roll material into the thread form rather than cutting excess material away. Do you know the difference between cut taps and roll (or form) taps? A cut tap and. Rolling Tap Vs Cutting Tap.

From localrevive.com

What Is It? How Does It Work? Process, Types (2022) Rolling Tap Vs Cutting Tap But, the spiral angle on the front cutting edges helps eject the chips and the angled edge also gives superior cutting performance. Form taps, or forming taps, are also called roll taps because they roll material into the thread form rather than cutting excess material away. Roll tap advantages are inherent in the way they create the threads. A cut. Rolling Tap Vs Cutting Tap.

From www.cutwel.co.uk

Roll Tapping vs Conventional (Cut) Tapping Cutwel Ltd Rolling Tap Vs Cutting Tap Both taps have advantages and disadvantages, and the right option for you may depend on the material being threaded. Roll taps are often preferred over regular cutting taps for smaller or larger holes, challenging materials like stainless steel, or where chip issues could lead to tap breakage. But, the spiral angle on the front cutting edges helps eject the chips. Rolling Tap Vs Cutting Tap.

From www.cutwel.co.uk

Roll Tapping vs Conventional (Cut) Tapping Cutwel Ltd Rolling Tap Vs Cutting Tap Do you know the difference between cut taps and roll (or form) taps? Roll taps are often preferred over regular cutting taps for smaller or larger holes, challenging materials like stainless steel, or where chip issues could lead to tap breakage. The key distinction between roll form and cut tap strength is that roll taps use the material itself to. Rolling Tap Vs Cutting Tap.

From www.jarviscuttingtools.com

Forming Tap Drill Sizes Jarvis Cutting Tools Rolling Tap Vs Cutting Tap This results in cut taps being the more precise option, but also leaving them more vulnerable to breakage under pressure. Form taps, or forming taps, are also called roll taps because they roll material into the thread form rather than cutting excess material away. But, the spiral angle on the front cutting edges helps eject the chips and the angled. Rolling Tap Vs Cutting Tap.

From www.directindustry.com

Stainless steel roll form tap Formtap Formdrill throughhole / HSSE Rolling Tap Vs Cutting Tap But, the spiral angle on the front cutting edges helps eject the chips and the angled edge also gives superior cutting performance. Roll tapping is a specialised threading process that forms threads through material deformation rather than cutting. This results in cut taps being the more precise option, but also leaving them more vulnerable to breakage under pressure. The key. Rolling Tap Vs Cutting Tap.

From www.promaxxtool.com

Different Types of Taps and When to Use Them ProMAXX Tool Rolling Tap Vs Cutting Tap Form taps, or forming taps, are also called roll taps because they roll material into the thread form rather than cutting excess material away. When forming an internal thread, cut taps and roll taps are two of the most popular options. But, the spiral angle on the front cutting edges helps eject the chips and the angled edge also gives. Rolling Tap Vs Cutting Tap.

From www.rolledthreads.com

How Does the Thread Rolling Process Work? Rolling Tap Vs Cutting Tap This results in cut taps being the more precise option, but also leaving them more vulnerable to breakage under pressure. Roll taps are often preferred over regular cutting taps for smaller or larger holes, challenging materials like stainless steel, or where chip issues could lead to tap breakage. Form taps, or forming taps, are also called roll taps because they. Rolling Tap Vs Cutting Tap.

From www.jarviscuttingtools.com

Cutting Taps vs. Forming Taps Difference Jarvis Rolling Tap Vs Cutting Tap Roll tapping is a specialised threading process that forms threads through material deformation rather than cutting. But, the spiral angle on the front cutting edges helps eject the chips and the angled edge also gives superior cutting performance. Roll taps are often preferred over regular cutting taps for smaller or larger holes, challenging materials like stainless steel, or where chip. Rolling Tap Vs Cutting Tap.

From www.anchorboltexpress.com

Roll Thread vs. Cut Thread Anchor Bolt Express Rolling Tap Vs Cutting Tap Roll taps are often preferred over regular cutting taps for smaller or larger holes, challenging materials like stainless steel, or where chip issues could lead to tap breakage. But, the spiral angle on the front cutting edges helps eject the chips and the angled edge also gives superior cutting performance. When forming an internal thread, cut taps and roll taps. Rolling Tap Vs Cutting Tap.

From sctoolsonline.medium.com

5 Types of Thread Cutting Tools & Their Usage by SC Tools Medium Rolling Tap Vs Cutting Tap Roll tapping is a specialised threading process that forms threads through material deformation rather than cutting. When forming an internal thread, cut taps and roll taps are two of the most popular options. Roll tap advantages are inherent in the way they create the threads. Roll taps, also known as form taps, hold distinct advantages over cut taps. Do you. Rolling Tap Vs Cutting Tap.

From www.cutwel.co.uk

How to select the correct tap for your job Cutwel Ltd Rolling Tap Vs Cutting Tap This results in cut taps being the more precise option, but also leaving them more vulnerable to breakage under pressure. Roll tap advantages are inherent in the way they create the threads. Roll taps, also known as form taps, hold distinct advantages over cut taps. This method compresses the material to create threads,. The key distinction between roll form and. Rolling Tap Vs Cutting Tap.

From www.harveyperformance.com

8 Unique Facts About Thread Forming Taps In The Loupe Rolling Tap Vs Cutting Tap The key distinction between roll form and cut tap strength is that roll taps use the material itself to create a thread, whereas cutting taps physically remove material to achieve the same result. This method compresses the material to create threads,. A cut tap and a roll tap both create a thread but in a different manner. But, the spiral. Rolling Tap Vs Cutting Tap.

From www.stgmachine.com

What is the Difference Between a Cut Tap and a Roll Tap? STG Machine Rolling Tap Vs Cutting Tap The key distinction between roll form and cut tap strength is that roll taps use the material itself to create a thread, whereas cutting taps physically remove material to achieve the same result. Roll tap advantages are inherent in the way they create the threads. Form taps, or forming taps, are also called roll taps because they roll material into. Rolling Tap Vs Cutting Tap.

From www.youtube.com

TAP DIFFERENCE BETWEEN CUT & ROLL TAP in hindi YouTube Rolling Tap Vs Cutting Tap The key distinction between roll form and cut tap strength is that roll taps use the material itself to create a thread, whereas cutting taps physically remove material to achieve the same result. Roll tap advantages are inherent in the way they create the threads. Form taps, or forming taps, are also called roll taps because they roll material into. Rolling Tap Vs Cutting Tap.

From www.jarviscuttingtools.com

Forming Taps Jarvis Cutting Tools Rolling Tap Vs Cutting Tap Roll tapping is a specialised threading process that forms threads through material deformation rather than cutting. The key distinction between roll form and cut tap strength is that roll taps use the material itself to create a thread, whereas cutting taps physically remove material to achieve the same result. Do you know the difference between cut taps and roll (or. Rolling Tap Vs Cutting Tap.

From bluepointtool.com

Tap Drill Sizes Blue Point Tool & Supply Rolling Tap Vs Cutting Tap When forming an internal thread, cut taps and roll taps are two of the most popular options. This results in cut taps being the more precise option, but also leaving them more vulnerable to breakage under pressure. Roll tapping is a specialised threading process that forms threads through material deformation rather than cutting. The key distinction between roll form and. Rolling Tap Vs Cutting Tap.

From bluepointtool.com

STI Roll Tap Drill Sizes, STI Tap Drill Sizes, and Pipe Tap Drill Sizes Blue Point Tool & Supply Rolling Tap Vs Cutting Tap But, the spiral angle on the front cutting edges helps eject the chips and the angled edge also gives superior cutting performance. This results in cut taps being the more precise option, but also leaving them more vulnerable to breakage under pressure. Both taps have advantages and disadvantages, and the right option for you may depend on the material being. Rolling Tap Vs Cutting Tap.

From martinsupply.com

Cut Taps vs. Roll Taps What is the difference? Martin Supply Rolling Tap Vs Cutting Tap Form taps, or forming taps, are also called roll taps because they roll material into the thread form rather than cutting excess material away. This method compresses the material to create threads,. The key distinction between roll form and cut tap strength is that roll taps use the material itself to create a thread, whereas cutting taps physically remove material. Rolling Tap Vs Cutting Tap.

From threadingtoolsguide.com

3 threading taps in comparison machine tap, cutin tap or hand tap Rolling Tap Vs Cutting Tap Roll taps, also known as form taps, hold distinct advantages over cut taps. Form taps, or forming taps, are also called roll taps because they roll material into the thread form rather than cutting excess material away. The key distinction between roll form and cut tap strength is that roll taps use the material itself to create a thread, whereas. Rolling Tap Vs Cutting Tap.

From martinsupply.com

Cut Taps vs. Roll Taps What is the difference? Martin Supply Rolling Tap Vs Cutting Tap Do you know the difference between cut taps and roll (or form) taps? Form taps, or forming taps, are also called roll taps because they roll material into the thread form rather than cutting excess material away. Both taps have advantages and disadvantages, and the right option for you may depend on the material being threaded. Roll taps, also known. Rolling Tap Vs Cutting Tap.

From klopsend.weebly.com

klopsend Blog Rolling Tap Vs Cutting Tap When forming an internal thread, cut taps and roll taps are two of the most popular options. Roll taps, also known as form taps, hold distinct advantages over cut taps. Both taps have advantages and disadvantages, and the right option for you may depend on the material being threaded. This method compresses the material to create threads,. Form taps, or. Rolling Tap Vs Cutting Tap.

From radarglop.weebly.com

What is the difference between cutting tap and forming tap radarglop Rolling Tap Vs Cutting Tap This results in cut taps being the more precise option, but also leaving them more vulnerable to breakage under pressure. The key distinction between roll form and cut tap strength is that roll taps use the material itself to create a thread, whereas cutting taps physically remove material to achieve the same result. Both taps have advantages and disadvantages, and. Rolling Tap Vs Cutting Tap.

From www.cutwel.co.uk

Expert Guide on Threading Taps Cutwel Ltd Rolling Tap Vs Cutting Tap Roll tap advantages are inherent in the way they create the threads. A cut tap and a roll tap both create a thread but in a different manner. Form taps, or forming taps, are also called roll taps because they roll material into the thread form rather than cutting excess material away. This results in cut taps being the more. Rolling Tap Vs Cutting Tap.

From www.cutwel.co.uk

Roll Tapping vs Conventional (Cut) Tapping Cutwel Ltd Rolling Tap Vs Cutting Tap Roll taps are often preferred over regular cutting taps for smaller or larger holes, challenging materials like stainless steel, or where chip issues could lead to tap breakage. The key distinction between roll form and cut tap strength is that roll taps use the material itself to create a thread, whereas cutting taps physically remove material to achieve the same. Rolling Tap Vs Cutting Tap.

From www.evdesignandmanufacturing.com

Forming taps vs. cutting taps Which one should you choose? EV Design & Manufacturing Rolling Tap Vs Cutting Tap Roll tapping is a specialised threading process that forms threads through material deformation rather than cutting. This results in cut taps being the more precise option, but also leaving them more vulnerable to breakage under pressure. Roll tap advantages are inherent in the way they create the threads. Both taps have advantages and disadvantages, and the right option for you. Rolling Tap Vs Cutting Tap.

From taptite.com

ThreadRolling Screws or ThreadForming… REMINC & CONTI Fasteners Rolling Tap Vs Cutting Tap Roll taps, also known as form taps, hold distinct advantages over cut taps. Roll tapping is a specialised threading process that forms threads through material deformation rather than cutting. Do you know the difference between cut taps and roll (or form) taps? This results in cut taps being the more precise option, but also leaving them more vulnerable to breakage. Rolling Tap Vs Cutting Tap.

From cmsbos.weebly.com

What is the difference between cutting tap and forming tap cmsBos Rolling Tap Vs Cutting Tap Roll tapping is a specialised threading process that forms threads through material deformation rather than cutting. This results in cut taps being the more precise option, but also leaving them more vulnerable to breakage under pressure. This method compresses the material to create threads,. Form taps, or forming taps, are also called roll taps because they roll material into the. Rolling Tap Vs Cutting Tap.

From www.trigonenterprises.com

Taps Spiral fluted, Cut and Roll tap Smooth OSG Taps Distributor / Channel Partner from Pune Rolling Tap Vs Cutting Tap Roll taps, also known as form taps, hold distinct advantages over cut taps. This method compresses the material to create threads,. Do you know the difference between cut taps and roll (or form) taps? Roll tapping is a specialised threading process that forms threads through material deformation rather than cutting. The key distinction between roll form and cut tap strength. Rolling Tap Vs Cutting Tap.

From localrevive.com

What Is It? How Does It Work? Process, Types (2022) Rolling Tap Vs Cutting Tap The key distinction between roll form and cut tap strength is that roll taps use the material itself to create a thread, whereas cutting taps physically remove material to achieve the same result. Form taps, or forming taps, are also called roll taps because they roll material into the thread form rather than cutting excess material away. Roll tap advantages. Rolling Tap Vs Cutting Tap.