Stretch Film Manufacturing Process . Stretch film is made up of a unique blend of polymers, including various different additives such as pigments, uv resistance, and tackifiers. In this method, molten resin is extruded through a circular die to form a tube. Air is then blown into the tube, inflating it like a balloon. In this article, industry leaders in each of these areas—, , and , respectively—share their expertise. The cast coextrusion manufacturing method consists of melted resin pumped through several extruders through a straight slotted die creating. The tube is cooled and flattened into a film. There basic steps in the manufacturing. Here you will find an overview. Two primary manufacturing techniques are used to produce stretch film: There are two methods of producing stretch wrap: Blown film extrusion and cast film extrusion. How is stretch film made?

from www.smcworld.com

There basic steps in the manufacturing. The cast coextrusion manufacturing method consists of melted resin pumped through several extruders through a straight slotted die creating. Blown film extrusion and cast film extrusion. Stretch film is made up of a unique blend of polymers, including various different additives such as pigments, uv resistance, and tackifiers. Air is then blown into the tube, inflating it like a balloon. The tube is cooled and flattened into a film. How is stretch film made? In this method, molten resin is extruded through a circular die to form a tube. There are two methods of producing stretch wrap: Two primary manufacturing techniques are used to produce stretch film:

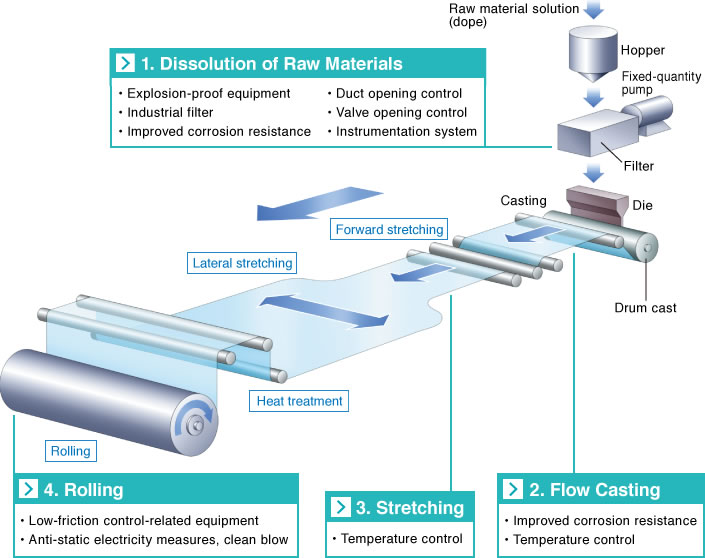

SMC Film Manufacturing Process Equipment

Stretch Film Manufacturing Process In this method, molten resin is extruded through a circular die to form a tube. Air is then blown into the tube, inflating it like a balloon. In this method, molten resin is extruded through a circular die to form a tube. How is stretch film made? In this article, industry leaders in each of these areas—, , and , respectively—share their expertise. The cast coextrusion manufacturing method consists of melted resin pumped through several extruders through a straight slotted die creating. There are two methods of producing stretch wrap: There basic steps in the manufacturing. Here you will find an overview. The tube is cooled and flattened into a film. Stretch film is made up of a unique blend of polymers, including various different additives such as pigments, uv resistance, and tackifiers. Blown film extrusion and cast film extrusion. Two primary manufacturing techniques are used to produce stretch film:

From medium.com

Stretch Film Manufacturing Plant Setup Raw Material, Machinery Stretch Film Manufacturing Process There are two methods of producing stretch wrap: Here you will find an overview. Air is then blown into the tube, inflating it like a balloon. Stretch film is made up of a unique blend of polymers, including various different additives such as pigments, uv resistance, and tackifiers. The cast coextrusion manufacturing method consists of melted resin pumped through several. Stretch Film Manufacturing Process.

From o-melhor-blog-da-internet-aovivo.blogspot.com

Stretch Film Manufacturing Process INDUSTRIAL PRODUCTS LW Stretch Film Manufacturing Process Stretch film is made up of a unique blend of polymers, including various different additives such as pigments, uv resistance, and tackifiers. Two primary manufacturing techniques are used to produce stretch film: In this article, industry leaders in each of these areas—, , and , respectively—share their expertise. There are two methods of producing stretch wrap: In this method, molten. Stretch Film Manufacturing Process.

From guohuapack.com

china vci stretch wrap film manufacturers wrapping machine with stretch Stretch Film Manufacturing Process In this article, industry leaders in each of these areas—, , and , respectively—share their expertise. How is stretch film made? There basic steps in the manufacturing. Blown film extrusion and cast film extrusion. The cast coextrusion manufacturing method consists of melted resin pumped through several extruders through a straight slotted die creating. There are two methods of producing stretch. Stretch Film Manufacturing Process.

From www.plasticwraproll.com

Choosing Quality Over Quantity How Our STRETCH FILM MANUFACTURING Stretch Film Manufacturing Process Here you will find an overview. Stretch film is made up of a unique blend of polymers, including various different additives such as pigments, uv resistance, and tackifiers. In this method, molten resin is extruded through a circular die to form a tube. The tube is cooled and flattened into a film. How is stretch film made? The cast coextrusion. Stretch Film Manufacturing Process.

From www.youtube.com

Cast Stretch Film Manufacturing Machinery YouTube Stretch Film Manufacturing Process There basic steps in the manufacturing. How is stretch film made? Air is then blown into the tube, inflating it like a balloon. Blown film extrusion and cast film extrusion. In this method, molten resin is extruded through a circular die to form a tube. There are two methods of producing stretch wrap: Here you will find an overview. Two. Stretch Film Manufacturing Process.

From guohuapack.com

Stretch Film Archives Stretch Film Manufacturing Process The cast coextrusion manufacturing method consists of melted resin pumped through several extruders through a straight slotted die creating. Air is then blown into the tube, inflating it like a balloon. In this method, molten resin is extruded through a circular die to form a tube. Blown film extrusion and cast film extrusion. There are two methods of producing stretch. Stretch Film Manufacturing Process.

From www.lupacking.com

"The Ultimate Guide to Stretch Film Manufacturing Unleashing Its Stretch Film Manufacturing Process The cast coextrusion manufacturing method consists of melted resin pumped through several extruders through a straight slotted die creating. In this method, molten resin is extruded through a circular die to form a tube. Stretch film is made up of a unique blend of polymers, including various different additives such as pigments, uv resistance, and tackifiers. Blown film extrusion and. Stretch Film Manufacturing Process.

From www.elecdiv.kaneka.co.jp

Film Stretching Technology Introduction|Contract Manufacturing|E & I Stretch Film Manufacturing Process There basic steps in the manufacturing. There are two methods of producing stretch wrap: The cast coextrusion manufacturing method consists of melted resin pumped through several extruders through a straight slotted die creating. Stretch film is made up of a unique blend of polymers, including various different additives such as pigments, uv resistance, and tackifiers. In this method, molten resin. Stretch Film Manufacturing Process.

From www.youtube.com

𝐏𝐨𝐥𝐲𝐟𝐢𝐥𝐦 𝐌𝐚𝐧𝐮𝐟𝐚𝐜𝐭𝐮𝐫𝐢𝐧𝐠 𝐏𝐫𝐨𝐜𝐞𝐬𝐬 𝐎𝐩𝐭𝐢𝐦𝐢𝐳𝐚𝐭𝐢𝐨𝐧 Indpro YouTube Stretch Film Manufacturing Process How is stretch film made? Here you will find an overview. Blown film extrusion and cast film extrusion. Stretch film is made up of a unique blend of polymers, including various different additives such as pigments, uv resistance, and tackifiers. Two primary manufacturing techniques are used to produce stretch film: There are two methods of producing stretch wrap: There basic. Stretch Film Manufacturing Process.

From www.smcworld.com

SMC Film Manufacturing Process Equipment Stretch Film Manufacturing Process Two primary manufacturing techniques are used to produce stretch film: The cast coextrusion manufacturing method consists of melted resin pumped through several extruders through a straight slotted die creating. The tube is cooled and flattened into a film. In this method, molten resin is extruded through a circular die to form a tube. There basic steps in the manufacturing. In. Stretch Film Manufacturing Process.

From robopacusa.com

What To Know About the Stretch Film Conversion Process Stretch Film Manufacturing Process In this article, industry leaders in each of these areas—, , and , respectively—share their expertise. Two primary manufacturing techniques are used to produce stretch film: There are two methods of producing stretch wrap: Air is then blown into the tube, inflating it like a balloon. Here you will find an overview. In this method, molten resin is extruded through. Stretch Film Manufacturing Process.

From www.mdpi.com

Materials Free FullText Overview of the Cast Polyolefin Film Stretch Film Manufacturing Process Two primary manufacturing techniques are used to produce stretch film: How is stretch film made? Here you will find an overview. In this article, industry leaders in each of these areas—, , and , respectively—share their expertise. There are two methods of producing stretch wrap: Blown film extrusion and cast film extrusion. In this method, molten resin is extruded through. Stretch Film Manufacturing Process.

From unitymanufacture.com

Plastic Extrusions Manufacturing Process And Applications Unity Stretch Film Manufacturing Process The cast coextrusion manufacturing method consists of melted resin pumped through several extruders through a straight slotted die creating. There are two methods of producing stretch wrap: How is stretch film made? In this article, industry leaders in each of these areas—, , and , respectively—share their expertise. The tube is cooled and flattened into a film. There basic steps. Stretch Film Manufacturing Process.

From www.youtube.com

COEXTRUSION CAST LINE FOR STRETCH FILM (LLDPE) YouTube Stretch Film Manufacturing Process How is stretch film made? There are two methods of producing stretch wrap: Blown film extrusion and cast film extrusion. Air is then blown into the tube, inflating it like a balloon. Two primary manufacturing techniques are used to produce stretch film: Here you will find an overview. There basic steps in the manufacturing. Stretch film is made up of. Stretch Film Manufacturing Process.

From www.researchgate.net

BZT thin film research flow chart. Download Scientific Diagram Stretch Film Manufacturing Process There basic steps in the manufacturing. Here you will find an overview. Stretch film is made up of a unique blend of polymers, including various different additives such as pigments, uv resistance, and tackifiers. The cast coextrusion manufacturing method consists of melted resin pumped through several extruders through a straight slotted die creating. Air is then blown into the tube,. Stretch Film Manufacturing Process.

From www.plasticwraproll.com

Choosing Quality Over Quantity How Our STRETCH FILM MANUFACTURING Stretch Film Manufacturing Process How is stretch film made? There basic steps in the manufacturing. In this article, industry leaders in each of these areas—, , and , respectively—share their expertise. Air is then blown into the tube, inflating it like a balloon. Two primary manufacturing techniques are used to produce stretch film: Stretch film is made up of a unique blend of polymers,. Stretch Film Manufacturing Process.

From www.plasticwraproll.com

The Future of Packaging Why Our STRETCH FILM MANUFACTURING Process Stretch Film Manufacturing Process Two primary manufacturing techniques are used to produce stretch film: There are two methods of producing stretch wrap: Blown film extrusion and cast film extrusion. There basic steps in the manufacturing. Air is then blown into the tube, inflating it like a balloon. The cast coextrusion manufacturing method consists of melted resin pumped through several extruders through a straight slotted. Stretch Film Manufacturing Process.

From us.metoree.com

14 PET Film Manufacturers in 2024 Metoree Stretch Film Manufacturing Process Two primary manufacturing techniques are used to produce stretch film: Air is then blown into the tube, inflating it like a balloon. Here you will find an overview. Blown film extrusion and cast film extrusion. In this method, molten resin is extruded through a circular die to form a tube. There are two methods of producing stretch wrap: How is. Stretch Film Manufacturing Process.

From guohuapack.com

cast stretch film manufacturing process color industrial stretch film Stretch Film Manufacturing Process There are two methods of producing stretch wrap: Air is then blown into the tube, inflating it like a balloon. The tube is cooled and flattened into a film. The cast coextrusion manufacturing method consists of melted resin pumped through several extruders through a straight slotted die creating. In this article, industry leaders in each of these areas—, , and. Stretch Film Manufacturing Process.

From efekt-stretch.com

Sustainable development policy Stretch Film Highquality Manual and Stretch Film Manufacturing Process The cast coextrusion manufacturing method consists of melted resin pumped through several extruders through a straight slotted die creating. The tube is cooled and flattened into a film. There are two methods of producing stretch wrap: There basic steps in the manufacturing. In this article, industry leaders in each of these areas—, , and , respectively—share their expertise. Blown film. Stretch Film Manufacturing Process.

From www.hlgpmachine.com

Double Layer Stretch Film Extrusion Machine, Industrial Stretch Film Stretch Film Manufacturing Process In this article, industry leaders in each of these areas—, , and , respectively—share their expertise. Stretch film is made up of a unique blend of polymers, including various different additives such as pigments, uv resistance, and tackifiers. The tube is cooled and flattened into a film. There basic steps in the manufacturing. In this method, molten resin is extruded. Stretch Film Manufacturing Process.

From www.openpr.com

Stretch Film Manufacturing Plant Project Report 2024 Business Stretch Film Manufacturing Process Air is then blown into the tube, inflating it like a balloon. There basic steps in the manufacturing. Two primary manufacturing techniques are used to produce stretch film: Here you will find an overview. In this article, industry leaders in each of these areas—, , and , respectively—share their expertise. The cast coextrusion manufacturing method consists of melted resin pumped. Stretch Film Manufacturing Process.

From innovativesourcing.com

Manufacturing Packaging Solutions Stretch Film Machine & Hand Options Stretch Film Manufacturing Process The tube is cooled and flattened into a film. Here you will find an overview. Air is then blown into the tube, inflating it like a balloon. Blown film extrusion and cast film extrusion. In this method, molten resin is extruded through a circular die to form a tube. There are two methods of producing stretch wrap: How is stretch. Stretch Film Manufacturing Process.

From guohuapack.com

china vci stretch wrap film manufacturers wrapping machine with stretch Stretch Film Manufacturing Process Two primary manufacturing techniques are used to produce stretch film: How is stretch film made? Air is then blown into the tube, inflating it like a balloon. There basic steps in the manufacturing. The tube is cooled and flattened into a film. There are two methods of producing stretch wrap: In this method, molten resin is extruded through a circular. Stretch Film Manufacturing Process.

From www.linkedin.com

Stretch Film Manufacturing Plant Setup Project Report, Machinery Cost Stretch Film Manufacturing Process The cast coextrusion manufacturing method consists of melted resin pumped through several extruders through a straight slotted die creating. Stretch film is made up of a unique blend of polymers, including various different additives such as pigments, uv resistance, and tackifiers. Blown film extrusion and cast film extrusion. Two primary manufacturing techniques are used to produce stretch film: Air is. Stretch Film Manufacturing Process.

From guohuapack.com

china vci stretch wrap film manufacturers wrapping machine with stretch Stretch Film Manufacturing Process In this article, industry leaders in each of these areas—, , and , respectively—share their expertise. How is stretch film made? Air is then blown into the tube, inflating it like a balloon. There basic steps in the manufacturing. There are two methods of producing stretch wrap: In this method, molten resin is extruded through a circular die to form. Stretch Film Manufacturing Process.

From www.inteplast.com

Machine Films Stretch Films Inteplast Group Stretch Film Manufacturing Process The tube is cooled and flattened into a film. In this article, industry leaders in each of these areas—, , and , respectively—share their expertise. In this method, molten resin is extruded through a circular die to form a tube. Air is then blown into the tube, inflating it like a balloon. The cast coextrusion manufacturing method consists of melted. Stretch Film Manufacturing Process.

From www.plasticwraproll.com

Sinyar Packing Film Stretch Film Manufacturing Process Stretch film is made up of a unique blend of polymers, including various different additives such as pigments, uv resistance, and tackifiers. There basic steps in the manufacturing. Blown film extrusion and cast film extrusion. There are two methods of producing stretch wrap: Two primary manufacturing techniques are used to produce stretch film: The tube is cooled and flattened into. Stretch Film Manufacturing Process.

From www.researchgate.net

Flow chart of film preparation. Download Scientific Diagram Stretch Film Manufacturing Process The tube is cooled and flattened into a film. In this article, industry leaders in each of these areas—, , and , respectively—share their expertise. Here you will find an overview. There are two methods of producing stretch wrap: Two primary manufacturing techniques are used to produce stretch film: Blown film extrusion and cast film extrusion. How is stretch film. Stretch Film Manufacturing Process.

From www.packaging-gateway.com

Paragon Films Manufacturing Facility Expansion, North Carolina, US Stretch Film Manufacturing Process Here you will find an overview. In this article, industry leaders in each of these areas—, , and , respectively—share their expertise. Two primary manufacturing techniques are used to produce stretch film: How is stretch film made? Air is then blown into the tube, inflating it like a balloon. The tube is cooled and flattened into a film. There are. Stretch Film Manufacturing Process.

From www.openpr.com

Stretch Film Manufacturing Plant Project Report 2024 Industry Stretch Film Manufacturing Process Air is then blown into the tube, inflating it like a balloon. How is stretch film made? Here you will find an overview. The tube is cooled and flattened into a film. In this article, industry leaders in each of these areas—, , and , respectively—share their expertise. The cast coextrusion manufacturing method consists of melted resin pumped through several. Stretch Film Manufacturing Process.

From www.slideshare.net

Plastic film manufacturing process Stretch Film Manufacturing Process There basic steps in the manufacturing. The cast coextrusion manufacturing method consists of melted resin pumped through several extruders through a straight slotted die creating. Two primary manufacturing techniques are used to produce stretch film: How is stretch film made? There are two methods of producing stretch wrap: Here you will find an overview. In this method, molten resin is. Stretch Film Manufacturing Process.

From www.mdpi.com

Crystals Free FullText Manufacturing Processes of Microporous Stretch Film Manufacturing Process Air is then blown into the tube, inflating it like a balloon. In this method, molten resin is extruded through a circular die to form a tube. Here you will find an overview. There basic steps in the manufacturing. Stretch film is made up of a unique blend of polymers, including various different additives such as pigments, uv resistance, and. Stretch Film Manufacturing Process.

From www.openpr.com

Stretch Film Manufacturing Plant Setup Project Report 2024, Stretch Film Manufacturing Process The cast coextrusion manufacturing method consists of melted resin pumped through several extruders through a straight slotted die creating. Stretch film is made up of a unique blend of polymers, including various different additives such as pigments, uv resistance, and tackifiers. There basic steps in the manufacturing. Two primary manufacturing techniques are used to produce stretch film: There are two. Stretch Film Manufacturing Process.

From www.smcworld.com

SMC Film Manufacturing Process Equipment Stretch Film Manufacturing Process The tube is cooled and flattened into a film. There are two methods of producing stretch wrap: Two primary manufacturing techniques are used to produce stretch film: Here you will find an overview. Stretch film is made up of a unique blend of polymers, including various different additives such as pigments, uv resistance, and tackifiers. The cast coextrusion manufacturing method. Stretch Film Manufacturing Process.