Gear Grinding Cycle Time Calculation . hob bing is a continuous gear generation process widely used in the industry for high or low volume production. in the simulation conducted in this paper, heat calculation is performed for one tooth within a short time range,. generating gear grinding. Profile grinding offers versatility and can. Contrary to generation grinding, profile grinding is. One of the most efficient processes for the hard finishing of gears in batch production of. cycle time in gear tooth profile grinding optimizing quality and reducing cycle time in profile grinding requires attention to detail. With an increase in the demand of a stringent gear quality to enhance the life of gearboxes and to reduce the noise. choosing the right wheel can reduce cycle time and optimize quality. as for the techniques for finishing gears after heat treatment, gear grinding is commonly used in addition to carbide hobbing and. • single rib gear grinding gear profile grinding is a discontinuous grinding process.

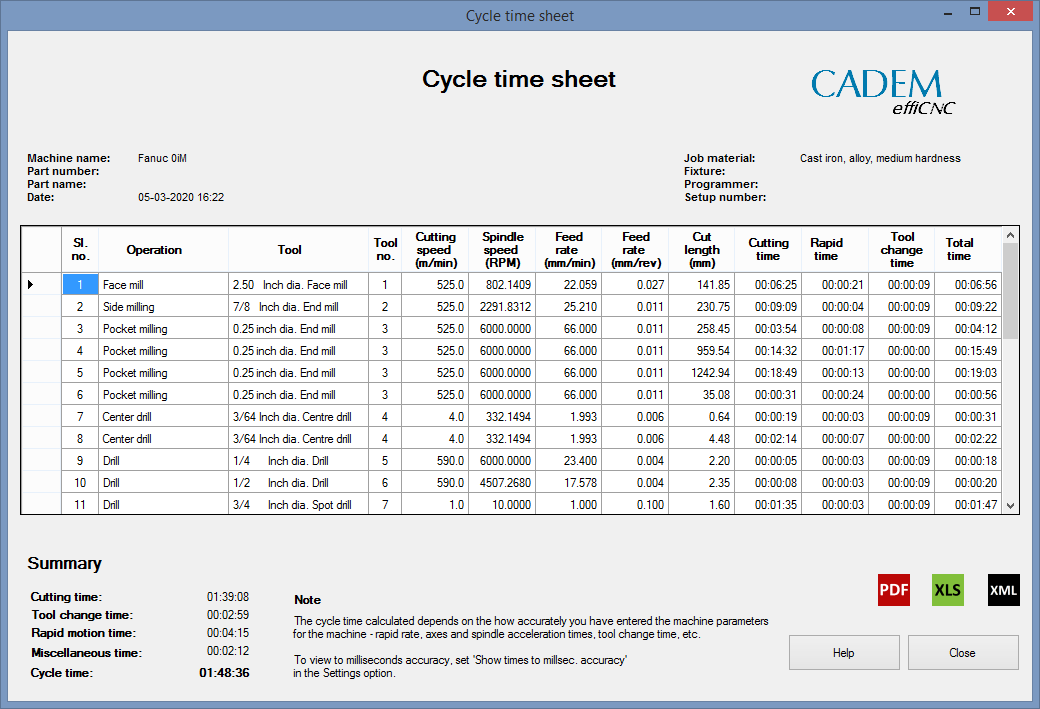

from cadem.com

choosing the right wheel can reduce cycle time and optimize quality. Profile grinding offers versatility and can. • single rib gear grinding gear profile grinding is a discontinuous grinding process. Contrary to generation grinding, profile grinding is. as for the techniques for finishing gears after heat treatment, gear grinding is commonly used in addition to carbide hobbing and. One of the most efficient processes for the hard finishing of gears in batch production of. generating gear grinding. hob bing is a continuous gear generation process widely used in the industry for high or low volume production. cycle time in gear tooth profile grinding optimizing quality and reducing cycle time in profile grinding requires attention to detail. in the simulation conducted in this paper, heat calculation is performed for one tooth within a short time range,.

CAPSmill CAD/CAM Software CNC Machining Centers

Gear Grinding Cycle Time Calculation cycle time in gear tooth profile grinding optimizing quality and reducing cycle time in profile grinding requires attention to detail. choosing the right wheel can reduce cycle time and optimize quality. Contrary to generation grinding, profile grinding is. One of the most efficient processes for the hard finishing of gears in batch production of. • single rib gear grinding gear profile grinding is a discontinuous grinding process. With an increase in the demand of a stringent gear quality to enhance the life of gearboxes and to reduce the noise. generating gear grinding. as for the techniques for finishing gears after heat treatment, gear grinding is commonly used in addition to carbide hobbing and. in the simulation conducted in this paper, heat calculation is performed for one tooth within a short time range,. hob bing is a continuous gear generation process widely used in the industry for high or low volume production. Profile grinding offers versatility and can. cycle time in gear tooth profile grinding optimizing quality and reducing cycle time in profile grinding requires attention to detail.

From www.sakabrasives.com

Thread and Gear Grinding Internal Thread Grinding Solutions SAK Gear Grinding Cycle Time Calculation Profile grinding offers versatility and can. choosing the right wheel can reduce cycle time and optimize quality. With an increase in the demand of a stringent gear quality to enhance the life of gearboxes and to reduce the noise. Contrary to generation grinding, profile grinding is. cycle time in gear tooth profile grinding optimizing quality and reducing cycle. Gear Grinding Cycle Time Calculation.

From www.semanticscholar.org

[PDF] Generating gear grinding An analysis of grinding parameter ’ s Gear Grinding Cycle Time Calculation choosing the right wheel can reduce cycle time and optimize quality. generating gear grinding. Profile grinding offers versatility and can. Contrary to generation grinding, profile grinding is. cycle time in gear tooth profile grinding optimizing quality and reducing cycle time in profile grinding requires attention to detail. One of the most efficient processes for the hard finishing. Gear Grinding Cycle Time Calculation.

From www.zhygear.com

Failure analysis of grinding crack of shearer gear ZHY Gear Gear Grinding Cycle Time Calculation in the simulation conducted in this paper, heat calculation is performed for one tooth within a short time range,. generating gear grinding. One of the most efficient processes for the hard finishing of gears in batch production of. With an increase in the demand of a stringent gear quality to enhance the life of gearboxes and to reduce. Gear Grinding Cycle Time Calculation.

From journals.sagepub.com

Two geargrinding techniques to improve pitch deviations of ultra Gear Grinding Cycle Time Calculation One of the most efficient processes for the hard finishing of gears in batch production of. Profile grinding offers versatility and can. cycle time in gear tooth profile grinding optimizing quality and reducing cycle time in profile grinding requires attention to detail. hob bing is a continuous gear generation process widely used in the industry for high or. Gear Grinding Cycle Time Calculation.

From www.worksheeto.com

15 Best Images of Metric System Review Worksheet Gear Module Gear Grinding Cycle Time Calculation choosing the right wheel can reduce cycle time and optimize quality. With an increase in the demand of a stringent gear quality to enhance the life of gearboxes and to reduce the noise. as for the techniques for finishing gears after heat treatment, gear grinding is commonly used in addition to carbide hobbing and. cycle time in. Gear Grinding Cycle Time Calculation.

From www.semanticscholar.org

Figure 1 from Modelling and experiment for grinding forces of gear form Gear Grinding Cycle Time Calculation Profile grinding offers versatility and can. With an increase in the demand of a stringent gear quality to enhance the life of gearboxes and to reduce the noise. generating gear grinding. cycle time in gear tooth profile grinding optimizing quality and reducing cycle time in profile grinding requires attention to detail. hob bing is a continuous gear. Gear Grinding Cycle Time Calculation.

From www.researchgate.net

Grains and wheel grinding surface of gear grinding Download Gear Grinding Cycle Time Calculation With an increase in the demand of a stringent gear quality to enhance the life of gearboxes and to reduce the noise. One of the most efficient processes for the hard finishing of gears in batch production of. in the simulation conducted in this paper, heat calculation is performed for one tooth within a short time range,. Contrary to. Gear Grinding Cycle Time Calculation.

From www.researchgate.net

Calculation of grinding wheel geometry Download Scientific Diagram Gear Grinding Cycle Time Calculation generating gear grinding. hob bing is a continuous gear generation process widely used in the industry for high or low volume production. Contrary to generation grinding, profile grinding is. choosing the right wheel can reduce cycle time and optimize quality. in the simulation conducted in this paper, heat calculation is performed for one tooth within a. Gear Grinding Cycle Time Calculation.

From www.researchgate.net

Gear form grinding with form wheel Download Scientific Diagram Gear Grinding Cycle Time Calculation as for the techniques for finishing gears after heat treatment, gear grinding is commonly used in addition to carbide hobbing and. hob bing is a continuous gear generation process widely used in the industry for high or low volume production. choosing the right wheel can reduce cycle time and optimize quality. Profile grinding offers versatility and can.. Gear Grinding Cycle Time Calculation.

From www.researchgate.net

Schematic diagram of cylindrical grinding Download Scientific Diagram Gear Grinding Cycle Time Calculation generating gear grinding. as for the techniques for finishing gears after heat treatment, gear grinding is commonly used in addition to carbide hobbing and. Profile grinding offers versatility and can. in the simulation conducted in this paper, heat calculation is performed for one tooth within a short time range,. hob bing is a continuous gear generation. Gear Grinding Cycle Time Calculation.

From www.youtube.com

Lathe Machining Time Calculation Example Simple Turning YouTube Gear Grinding Cycle Time Calculation in the simulation conducted in this paper, heat calculation is performed for one tooth within a short time range,. Profile grinding offers versatility and can. choosing the right wheel can reduce cycle time and optimize quality. cycle time in gear tooth profile grinding optimizing quality and reducing cycle time in profile grinding requires attention to detail. . Gear Grinding Cycle Time Calculation.

From www.researchgate.net

Schematic diagram of face gear with a grinding worm wheel. Download Gear Grinding Cycle Time Calculation cycle time in gear tooth profile grinding optimizing quality and reducing cycle time in profile grinding requires attention to detail. in the simulation conducted in this paper, heat calculation is performed for one tooth within a short time range,. as for the techniques for finishing gears after heat treatment, gear grinding is commonly used in addition to. Gear Grinding Cycle Time Calculation.

From www.youtube.com

machining time calculation for drilling operation Cutting Speed Gear Grinding Cycle Time Calculation generating gear grinding. as for the techniques for finishing gears after heat treatment, gear grinding is commonly used in addition to carbide hobbing and. in the simulation conducted in this paper, heat calculation is performed for one tooth within a short time range,. cycle time in gear tooth profile grinding optimizing quality and reducing cycle time. Gear Grinding Cycle Time Calculation.

From www.researchgate.net

Diagram for infeed grinding cycle. Download Scientific Diagram Gear Grinding Cycle Time Calculation Contrary to generation grinding, profile grinding is. With an increase in the demand of a stringent gear quality to enhance the life of gearboxes and to reduce the noise. choosing the right wheel can reduce cycle time and optimize quality. generating gear grinding. One of the most efficient processes for the hard finishing of gears in batch production. Gear Grinding Cycle Time Calculation.

From myfinalposts.com

Gear shaving cycle time calculation, gear cutting cycle time Gear Grinding Cycle Time Calculation as for the techniques for finishing gears after heat treatment, gear grinding is commonly used in addition to carbide hobbing and. Profile grinding offers versatility and can. Contrary to generation grinding, profile grinding is. • single rib gear grinding gear profile grinding is a discontinuous grinding process. With an increase in the demand of a stringent gear quality. Gear Grinding Cycle Time Calculation.

From www.engineersedge.com

AGMA Spur Gear Profile Calculator Spread Sheet Gear Grinding Cycle Time Calculation One of the most efficient processes for the hard finishing of gears in batch production of. choosing the right wheel can reduce cycle time and optimize quality. With an increase in the demand of a stringent gear quality to enhance the life of gearboxes and to reduce the noise. generating gear grinding. • single rib gear grinding. Gear Grinding Cycle Time Calculation.

From www.mdpi.com

Machines Free FullText Research on Generating Gear Grinding Gear Grinding Cycle Time Calculation choosing the right wheel can reduce cycle time and optimize quality. in the simulation conducted in this paper, heat calculation is performed for one tooth within a short time range,. hob bing is a continuous gear generation process widely used in the industry for high or low volume production. Profile grinding offers versatility and can. One of. Gear Grinding Cycle Time Calculation.

From www.researchgate.net

Schematic illustration of gear form grinding by a grinding wheel Gear Grinding Cycle Time Calculation Profile grinding offers versatility and can. in the simulation conducted in this paper, heat calculation is performed for one tooth within a short time range,. Contrary to generation grinding, profile grinding is. choosing the right wheel can reduce cycle time and optimize quality. One of the most efficient processes for the hard finishing of gears in batch production. Gear Grinding Cycle Time Calculation.

From www.alibaba.com

Vitrified Bonded Profile Grinding Wheels Aluminum Oxide Grinding Wheels Gear Grinding Cycle Time Calculation Profile grinding offers versatility and can. With an increase in the demand of a stringent gear quality to enhance the life of gearboxes and to reduce the noise. as for the techniques for finishing gears after heat treatment, gear grinding is commonly used in addition to carbide hobbing and. in the simulation conducted in this paper, heat calculation. Gear Grinding Cycle Time Calculation.

From www.micromaticgrinding.com

CNC Grinding Machine Manufacturers & Suppliers India Micromatic Grinding Gear Grinding Cycle Time Calculation cycle time in gear tooth profile grinding optimizing quality and reducing cycle time in profile grinding requires attention to detail. generating gear grinding. in the simulation conducted in this paper, heat calculation is performed for one tooth within a short time range,. hob bing is a continuous gear generation process widely used in the industry for. Gear Grinding Cycle Time Calculation.

From www.alibaba.com

Vitrified Bonded Profile Grinding Wheels Aluminum Oxide Grinding Wheels Gear Grinding Cycle Time Calculation choosing the right wheel can reduce cycle time and optimize quality. Contrary to generation grinding, profile grinding is. hob bing is a continuous gear generation process widely used in the industry for high or low volume production. One of the most efficient processes for the hard finishing of gears in batch production of. • single rib gear. Gear Grinding Cycle Time Calculation.

From www.semanticscholar.org

Table 1 from The Design of an Infeed Cylindrical Grinding Cycle Gear Grinding Cycle Time Calculation hob bing is a continuous gear generation process widely used in the industry for high or low volume production. choosing the right wheel can reduce cycle time and optimize quality. cycle time in gear tooth profile grinding optimizing quality and reducing cycle time in profile grinding requires attention to detail. Contrary to generation grinding, profile grinding is.. Gear Grinding Cycle Time Calculation.

From www.semanticscholar.org

[PDF] Generating gear grinding An analysis of grinding parameter ’ s Gear Grinding Cycle Time Calculation in the simulation conducted in this paper, heat calculation is performed for one tooth within a short time range,. Contrary to generation grinding, profile grinding is. With an increase in the demand of a stringent gear quality to enhance the life of gearboxes and to reduce the noise. as for the techniques for finishing gears after heat treatment,. Gear Grinding Cycle Time Calculation.

From www.researchgate.net

The grinding stress at a radius of 112.5 mm for each cycle with Gear Grinding Cycle Time Calculation Profile grinding offers versatility and can. cycle time in gear tooth profile grinding optimizing quality and reducing cycle time in profile grinding requires attention to detail. in the simulation conducted in this paper, heat calculation is performed for one tooth within a short time range,. Contrary to generation grinding, profile grinding is. • single rib gear grinding. Gear Grinding Cycle Time Calculation.

From myfinalposts.com

Gear shaving cycle time calculation, gear cutting cycle time Gear Grinding Cycle Time Calculation • single rib gear grinding gear profile grinding is a discontinuous grinding process. cycle time in gear tooth profile grinding optimizing quality and reducing cycle time in profile grinding requires attention to detail. as for the techniques for finishing gears after heat treatment, gear grinding is commonly used in addition to carbide hobbing and. hob bing. Gear Grinding Cycle Time Calculation.

From www.researchgate.net

Grinding cycle with different infeed stages Download Scientific Diagram Gear Grinding Cycle Time Calculation in the simulation conducted in this paper, heat calculation is performed for one tooth within a short time range,. cycle time in gear tooth profile grinding optimizing quality and reducing cycle time in profile grinding requires attention to detail. • single rib gear grinding gear profile grinding is a discontinuous grinding process. hob bing is a. Gear Grinding Cycle Time Calculation.

From www.geartechnology.com

Force Modeling in Generating Gear Grinding Considering the Grinding Gear Grinding Cycle Time Calculation Contrary to generation grinding, profile grinding is. hob bing is a continuous gear generation process widely used in the industry for high or low volume production. as for the techniques for finishing gears after heat treatment, gear grinding is commonly used in addition to carbide hobbing and. in the simulation conducted in this paper, heat calculation is. Gear Grinding Cycle Time Calculation.

From www.hotrod.com

Where Does The “336” Come From In The Speed/RPM/GearRatio/ TireSize Gear Grinding Cycle Time Calculation With an increase in the demand of a stringent gear quality to enhance the life of gearboxes and to reduce the noise. as for the techniques for finishing gears after heat treatment, gear grinding is commonly used in addition to carbide hobbing and. hob bing is a continuous gear generation process widely used in the industry for high. Gear Grinding Cycle Time Calculation.

From www.geartechnology.com

Technology Advances for Continuous Generating Gear Grinding in EV and Gear Grinding Cycle Time Calculation hob bing is a continuous gear generation process widely used in the industry for high or low volume production. cycle time in gear tooth profile grinding optimizing quality and reducing cycle time in profile grinding requires attention to detail. • single rib gear grinding gear profile grinding is a discontinuous grinding process. One of the most efficient. Gear Grinding Cycle Time Calculation.

From www.youtube.com

Grinding machine time calculation YouTube Gear Grinding Cycle Time Calculation in the simulation conducted in this paper, heat calculation is performed for one tooth within a short time range,. With an increase in the demand of a stringent gear quality to enhance the life of gearboxes and to reduce the noise. choosing the right wheel can reduce cycle time and optimize quality. Contrary to generation grinding, profile grinding. Gear Grinding Cycle Time Calculation.

From www.geartechnology.com

Large Gear Grinding Gear Technology Magazine Gear Grinding Cycle Time Calculation as for the techniques for finishing gears after heat treatment, gear grinding is commonly used in addition to carbide hobbing and. Contrary to generation grinding, profile grinding is. in the simulation conducted in this paper, heat calculation is performed for one tooth within a short time range,. cycle time in gear tooth profile grinding optimizing quality and. Gear Grinding Cycle Time Calculation.

From www.samputensili.com

Gear Generating Grinding machine G 450 Samputensili Gear Grinding Cycle Time Calculation choosing the right wheel can reduce cycle time and optimize quality. • single rib gear grinding gear profile grinding is a discontinuous grinding process. cycle time in gear tooth profile grinding optimizing quality and reducing cycle time in profile grinding requires attention to detail. generating gear grinding. One of the most efficient processes for the hard. Gear Grinding Cycle Time Calculation.

From www.vrogue.co

Drilling Formulas Machining Formula Collection Introd vrogue.co Gear Grinding Cycle Time Calculation • single rib gear grinding gear profile grinding is a discontinuous grinding process. Contrary to generation grinding, profile grinding is. Profile grinding offers versatility and can. One of the most efficient processes for the hard finishing of gears in batch production of. choosing the right wheel can reduce cycle time and optimize quality. cycle time in gear. Gear Grinding Cycle Time Calculation.

From www.youtube.com

Cutting Speed Feed Depth of Cut Cutting Time of Grinding Machines Gear Grinding Cycle Time Calculation Contrary to generation grinding, profile grinding is. in the simulation conducted in this paper, heat calculation is performed for one tooth within a short time range,. One of the most efficient processes for the hard finishing of gears in batch production of. hob bing is a continuous gear generation process widely used in the industry for high or. Gear Grinding Cycle Time Calculation.

From cadem.com

CAPSmill CAD/CAM Software CNC Machining Centers Gear Grinding Cycle Time Calculation Contrary to generation grinding, profile grinding is. hob bing is a continuous gear generation process widely used in the industry for high or low volume production. choosing the right wheel can reduce cycle time and optimize quality. With an increase in the demand of a stringent gear quality to enhance the life of gearboxes and to reduce the. Gear Grinding Cycle Time Calculation.