Disadvantages Of Rack And Pinion Mechanism . In reality, to achieve the desired travel length, multiple pieces of rack may be mounted. Advantages and disadvantages of using rack and pinion gear. Rack and pinion steering system. When the rack and pinion system fails, it can be difficult to steer, especially at lower speeds. However, you don’t want to overlook the possibility that something is wrong if the. The main disadvantages of gear transmission compared with belt transmission are: The mostly used steering system is rack and pinion and mostly 80 percent of commercial vehicles are using. Disadvantages of rack and pinion gear : Linear motion is indispensable to moving machines; Rack and pinion gear ratio and its significance. In this article, we are going to study what is rack and pinion steering system is and its subtopic like definition, history, construction or main parts, working, application,. Working principle of rack and pinion. Applications of rack and pinion gear. Rack and pinions can have excessive errors at the joint between two rack sections.

from mechanicaljungle.com

The mostly used steering system is rack and pinion and mostly 80 percent of commercial vehicles are using. Advantages and disadvantages of using rack and pinion gear. Working principle of rack and pinion. Linear motion is indispensable to moving machines; Rack and pinion steering system. In reality, to achieve the desired travel length, multiple pieces of rack may be mounted. However, you don’t want to overlook the possibility that something is wrong if the. Disadvantages of rack and pinion gear : Rack and pinions can have excessive errors at the joint between two rack sections. When the rack and pinion system fails, it can be difficult to steer, especially at lower speeds.

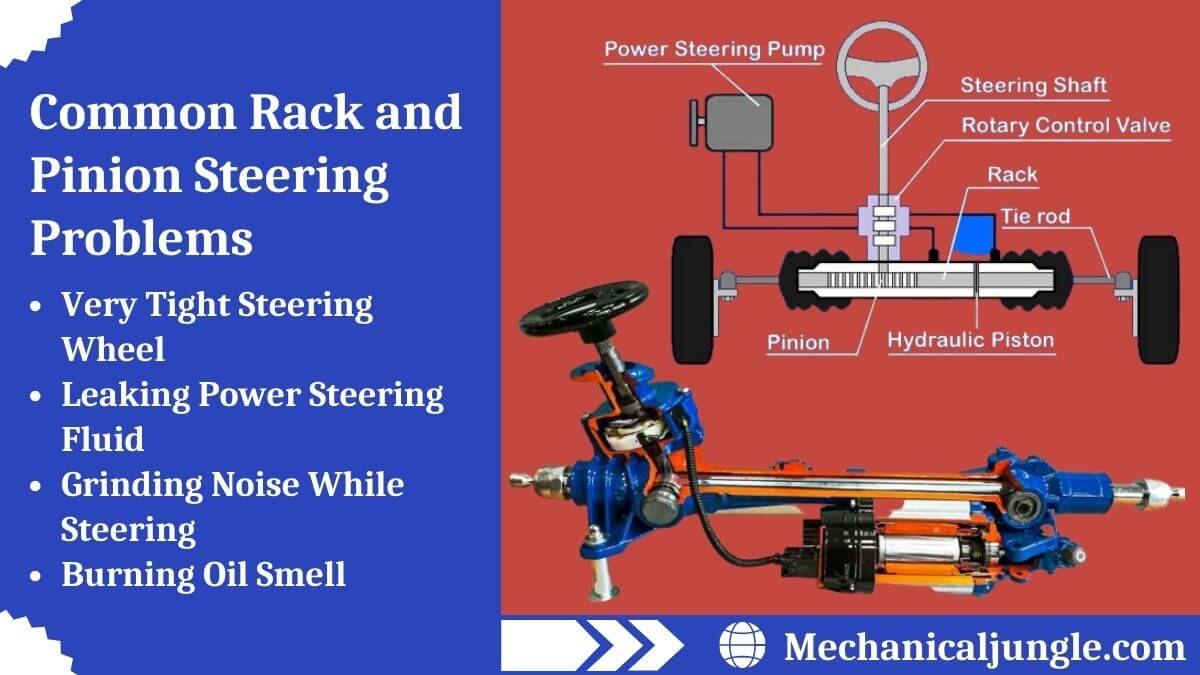

What Is a Rack and Pinion Steering? How Rack and Pinion Steering

Disadvantages Of Rack And Pinion Mechanism Linear motion is indispensable to moving machines; Rack and pinion gear ratio and its significance. In this article, we are going to study what is rack and pinion steering system is and its subtopic like definition, history, construction or main parts, working, application,. Advantages and disadvantages of using rack and pinion gear. Linear motion is indispensable to moving machines; When the rack and pinion system fails, it can be difficult to steer, especially at lower speeds. Working principle of rack and pinion. Rack and pinion steering system. The main disadvantages of gear transmission compared with belt transmission are: The mostly used steering system is rack and pinion and mostly 80 percent of commercial vehicles are using. In reality, to achieve the desired travel length, multiple pieces of rack may be mounted. Disadvantages of rack and pinion gear : However, you don’t want to overlook the possibility that something is wrong if the. Rack and pinions can have excessive errors at the joint between two rack sections. Applications of rack and pinion gear.

From www.statewidebearings.com.au

Rack And Pinion Statewide Bearings Disadvantages Of Rack And Pinion Mechanism In reality, to achieve the desired travel length, multiple pieces of rack may be mounted. The main disadvantages of gear transmission compared with belt transmission are: The mostly used steering system is rack and pinion and mostly 80 percent of commercial vehicles are using. Advantages and disadvantages of using rack and pinion gear. However, you don’t want to overlook the. Disadvantages Of Rack And Pinion Mechanism.

From schematicriddle.z21.web.core.windows.net

Design Of Rack And Pinion Mechanism Disadvantages Of Rack And Pinion Mechanism Rack and pinion steering system. Rack and pinion gear ratio and its significance. Advantages and disadvantages of using rack and pinion gear. When the rack and pinion system fails, it can be difficult to steer, especially at lower speeds. The mostly used steering system is rack and pinion and mostly 80 percent of commercial vehicles are using. In reality, to. Disadvantages Of Rack And Pinion Mechanism.

From www.researchgate.net

Sideways motion of the rack and pinion gear Download Scientific Diagram Disadvantages Of Rack And Pinion Mechanism Rack and pinion gear ratio and its significance. In this article, we are going to study what is rack and pinion steering system is and its subtopic like definition, history, construction or main parts, working, application,. Working principle of rack and pinion. In reality, to achieve the desired travel length, multiple pieces of rack may be mounted. The main disadvantages. Disadvantages Of Rack And Pinion Mechanism.

From hxepjrbod.blob.core.windows.net

Disadvantages For Rack And Pinion Mechanism at Tina Garica blog Disadvantages Of Rack And Pinion Mechanism Working principle of rack and pinion. Rack and pinions can have excessive errors at the joint between two rack sections. Disadvantages of rack and pinion gear : Rack and pinion gear ratio and its significance. Linear motion is indispensable to moving machines; In reality, to achieve the desired travel length, multiple pieces of rack may be mounted. Rack and pinion. Disadvantages Of Rack And Pinion Mechanism.

From www.linearmotiontips.com

Top 10 considerations when applying rack and pinion systems Disadvantages Of Rack And Pinion Mechanism In this article, we are going to study what is rack and pinion steering system is and its subtopic like definition, history, construction or main parts, working, application,. Applications of rack and pinion gear. Advantages and disadvantages of using rack and pinion gear. The mostly used steering system is rack and pinion and mostly 80 percent of commercial vehicles are. Disadvantages Of Rack And Pinion Mechanism.

From hxekmdcss.blob.core.windows.net

Disadvantages Of Rack And Pinion Steering at Madeline Thompson blog Disadvantages Of Rack And Pinion Mechanism In reality, to achieve the desired travel length, multiple pieces of rack may be mounted. Working principle of rack and pinion. When the rack and pinion system fails, it can be difficult to steer, especially at lower speeds. The main disadvantages of gear transmission compared with belt transmission are: Applications of rack and pinion gear. However, you don’t want to. Disadvantages Of Rack And Pinion Mechanism.

From www.linearmotiontips.com

Rack and pinion systems designs and applications Disadvantages Of Rack And Pinion Mechanism Rack and pinion gear ratio and its significance. Linear motion is indispensable to moving machines; Advantages and disadvantages of using rack and pinion gear. Rack and pinion steering system. Rack and pinions can have excessive errors at the joint between two rack sections. When the rack and pinion system fails, it can be difficult to steer, especially at lower speeds.. Disadvantages Of Rack And Pinion Mechanism.

From mechanicaljungle.com

What Is a Rack and Pinion Steering? How Rack and Pinion Steering Disadvantages Of Rack And Pinion Mechanism Applications of rack and pinion gear. Rack and pinion steering system. Disadvantages of rack and pinion gear : When the rack and pinion system fails, it can be difficult to steer, especially at lower speeds. In reality, to achieve the desired travel length, multiple pieces of rack may be mounted. Working principle of rack and pinion. Rack and pinions can. Disadvantages Of Rack And Pinion Mechanism.

From slideplayer.com

COMPLEX MECHANICAL FUNCTIONS ppt download Disadvantages Of Rack And Pinion Mechanism In reality, to achieve the desired travel length, multiple pieces of rack may be mounted. Disadvantages of rack and pinion gear : The mostly used steering system is rack and pinion and mostly 80 percent of commercial vehicles are using. However, you don’t want to overlook the possibility that something is wrong if the. In this article, we are going. Disadvantages Of Rack And Pinion Mechanism.

From vn.misumi-ec.com

No.000153 Lifting Mechanism Using Rack and Pinions inCAD Library Disadvantages Of Rack And Pinion Mechanism The mostly used steering system is rack and pinion and mostly 80 percent of commercial vehicles are using. Linear motion is indispensable to moving machines; Disadvantages of rack and pinion gear : Rack and pinion gear ratio and its significance. Advantages and disadvantages of using rack and pinion gear. In this article, we are going to study what is rack. Disadvantages Of Rack And Pinion Mechanism.

From studypolygon.com

Rack & Pinion Mechanism in SolidWorks Motion Study in SolidWorks Disadvantages Of Rack And Pinion Mechanism Rack and pinions can have excessive errors at the joint between two rack sections. Working principle of rack and pinion. When the rack and pinion system fails, it can be difficult to steer, especially at lower speeds. In reality, to achieve the desired travel length, multiple pieces of rack may be mounted. The mostly used steering system is rack and. Disadvantages Of Rack And Pinion Mechanism.

From mechanicwadloper2l5.z21.web.core.windows.net

Disadvantages Of Rack And Pinion Disadvantages Of Rack And Pinion Mechanism The mostly used steering system is rack and pinion and mostly 80 percent of commercial vehicles are using. The main disadvantages of gear transmission compared with belt transmission are: In reality, to achieve the desired travel length, multiple pieces of rack may be mounted. Linear motion is indispensable to moving machines; Rack and pinion gear ratio and its significance. Applications. Disadvantages Of Rack And Pinion Mechanism.

From www.engineeringchoice.com

Rack and Pinion Steering Definition & Overview Engineering Choice Disadvantages Of Rack And Pinion Mechanism However, you don’t want to overlook the possibility that something is wrong if the. Advantages and disadvantages of using rack and pinion gear. When the rack and pinion system fails, it can be difficult to steer, especially at lower speeds. Rack and pinions can have excessive errors at the joint between two rack sections. Rack and pinion gear ratio and. Disadvantages Of Rack And Pinion Mechanism.

From www.researchgate.net

display working principle of rack and pinion mechanism and internal Disadvantages Of Rack And Pinion Mechanism In this article, we are going to study what is rack and pinion steering system is and its subtopic like definition, history, construction or main parts, working, application,. Disadvantages of rack and pinion gear : Rack and pinions can have excessive errors at the joint between two rack sections. The main disadvantages of gear transmission compared with belt transmission are:. Disadvantages Of Rack And Pinion Mechanism.

From hxepjrbod.blob.core.windows.net

Disadvantages For Rack And Pinion Mechanism at Tina Garica blog Disadvantages Of Rack And Pinion Mechanism Applications of rack and pinion gear. Advantages and disadvantages of using rack and pinion gear. However, you don’t want to overlook the possibility that something is wrong if the. The mostly used steering system is rack and pinion and mostly 80 percent of commercial vehicles are using. When the rack and pinion system fails, it can be difficult to steer,. Disadvantages Of Rack And Pinion Mechanism.

From www.linkedin.com

The advantages and disadvantages of the rack and pinion device and the Disadvantages Of Rack And Pinion Mechanism In reality, to achieve the desired travel length, multiple pieces of rack may be mounted. The mostly used steering system is rack and pinion and mostly 80 percent of commercial vehicles are using. Working principle of rack and pinion. Rack and pinion gear ratio and its significance. The main disadvantages of gear transmission compared with belt transmission are: In this. Disadvantages Of Rack And Pinion Mechanism.

From www.alamy.com

Diagram of a rack and pinion Stock Photo Alamy Disadvantages Of Rack And Pinion Mechanism Rack and pinion gear ratio and its significance. Applications of rack and pinion gear. However, you don’t want to overlook the possibility that something is wrong if the. Linear motion is indispensable to moving machines; In reality, to achieve the desired travel length, multiple pieces of rack may be mounted. Disadvantages of rack and pinion gear : Rack and pinions. Disadvantages Of Rack And Pinion Mechanism.

From www.youtube.com

Rack And Pinion Mechanism Mechanical Engineering YouTube Disadvantages Of Rack And Pinion Mechanism When the rack and pinion system fails, it can be difficult to steer, especially at lower speeds. Disadvantages of rack and pinion gear : Working principle of rack and pinion. Rack and pinions can have excessive errors at the joint between two rack sections. Linear motion is indispensable to moving machines; However, you don’t want to overlook the possibility that. Disadvantages Of Rack And Pinion Mechanism.

From api.projectchrono.org

Project Chrono Steering mechanism models Disadvantages Of Rack And Pinion Mechanism The mostly used steering system is rack and pinion and mostly 80 percent of commercial vehicles are using. Applications of rack and pinion gear. Rack and pinions can have excessive errors at the joint between two rack sections. In this article, we are going to study what is rack and pinion steering system is and its subtopic like definition, history,. Disadvantages Of Rack And Pinion Mechanism.

From gm0.org

A marketing image for the tetrix rack and pinion Disadvantages Of Rack And Pinion Mechanism In this article, we are going to study what is rack and pinion steering system is and its subtopic like definition, history, construction or main parts, working, application,. Working principle of rack and pinion. However, you don’t want to overlook the possibility that something is wrong if the. In reality, to achieve the desired travel length, multiple pieces of rack. Disadvantages Of Rack And Pinion Mechanism.

From www.slideserve.com

PPT Mechanisms PowerPoint Presentation ID6865470 Disadvantages Of Rack And Pinion Mechanism Disadvantages of rack and pinion gear : Working principle of rack and pinion. Rack and pinions can have excessive errors at the joint between two rack sections. The main disadvantages of gear transmission compared with belt transmission are: The mostly used steering system is rack and pinion and mostly 80 percent of commercial vehicles are using. When the rack and. Disadvantages Of Rack And Pinion Mechanism.

From www.engineeringchoice.com

What is Rack and Pinion? Definition and Application Disadvantages Of Rack And Pinion Mechanism The mostly used steering system is rack and pinion and mostly 80 percent of commercial vehicles are using. Disadvantages of rack and pinion gear : Rack and pinions can have excessive errors at the joint between two rack sections. Advantages and disadvantages of using rack and pinion gear. When the rack and pinion system fails, it can be difficult to. Disadvantages Of Rack And Pinion Mechanism.

From dizz.com

Rack and Pinion Working, Application, Pros & Cons [PDF] Design Disadvantages Of Rack And Pinion Mechanism The main disadvantages of gear transmission compared with belt transmission are: When the rack and pinion system fails, it can be difficult to steer, especially at lower speeds. Linear motion is indispensable to moving machines; Advantages and disadvantages of using rack and pinion gear. In reality, to achieve the desired travel length, multiple pieces of rack may be mounted. Disadvantages. Disadvantages Of Rack And Pinion Mechanism.

From www.dubizzle.com

Ackerman's Principle of Steering Working, Pros & More Disadvantages Of Rack And Pinion Mechanism Rack and pinion steering system. Rack and pinion gear ratio and its significance. The mostly used steering system is rack and pinion and mostly 80 percent of commercial vehicles are using. Working principle of rack and pinion. The main disadvantages of gear transmission compared with belt transmission are: Advantages and disadvantages of using rack and pinion gear. Applications of rack. Disadvantages Of Rack And Pinion Mechanism.

From hxepjrbod.blob.core.windows.net

Disadvantages For Rack And Pinion Mechanism at Tina Garica blog Disadvantages Of Rack And Pinion Mechanism In reality, to achieve the desired travel length, multiple pieces of rack may be mounted. Working principle of rack and pinion. Disadvantages of rack and pinion gear : Applications of rack and pinion gear. However, you don’t want to overlook the possibility that something is wrong if the. Linear motion is indispensable to moving machines; Rack and pinion steering system.. Disadvantages Of Rack And Pinion Mechanism.

From www.bridgemanimages.com

Image of Diagram of a rackandpinion mechanism. Disadvantages Of Rack And Pinion Mechanism Rack and pinion steering system. Rack and pinion gear ratio and its significance. Rack and pinions can have excessive errors at the joint between two rack sections. In reality, to achieve the desired travel length, multiple pieces of rack may be mounted. However, you don’t want to overlook the possibility that something is wrong if the. The main disadvantages of. Disadvantages Of Rack And Pinion Mechanism.

From www.youtube.com

Steering Rack and pinion Mechanism in Solidworks YouTube Disadvantages Of Rack And Pinion Mechanism Advantages and disadvantages of using rack and pinion gear. Working principle of rack and pinion. The main disadvantages of gear transmission compared with belt transmission are: Rack and pinion steering system. In this article, we are going to study what is rack and pinion steering system is and its subtopic like definition, history, construction or main parts, working, application,. In. Disadvantages Of Rack And Pinion Mechanism.

From hxevxpwtn.blob.core.windows.net

Drill Press Rack And Pinion Mechanism at Curtis Danko blog Disadvantages Of Rack And Pinion Mechanism Rack and pinion gear ratio and its significance. Rack and pinions can have excessive errors at the joint between two rack sections. Working principle of rack and pinion. Applications of rack and pinion gear. In this article, we are going to study what is rack and pinion steering system is and its subtopic like definition, history, construction or main parts,. Disadvantages Of Rack And Pinion Mechanism.

From classicautoadvisors.com

Steering System Basics Rack & Pinion vs Recirculating Ball Disadvantages Of Rack And Pinion Mechanism In reality, to achieve the desired travel length, multiple pieces of rack may be mounted. Working principle of rack and pinion. Rack and pinions can have excessive errors at the joint between two rack sections. Rack and pinion gear ratio and its significance. Applications of rack and pinion gear. Advantages and disadvantages of using rack and pinion gear. The mostly. Disadvantages Of Rack And Pinion Mechanism.

From www.youtube.com

Determining a linear drive with racks and pinions YouTube Disadvantages Of Rack And Pinion Mechanism Applications of rack and pinion gear. Linear motion is indispensable to moving machines; The main disadvantages of gear transmission compared with belt transmission are: However, you don’t want to overlook the possibility that something is wrong if the. When the rack and pinion system fails, it can be difficult to steer, especially at lower speeds. Working principle of rack and. Disadvantages Of Rack And Pinion Mechanism.

From www.youtube.com

Mechanism 17 Rack and Pinion SolidWorks Tutorial YouTube Disadvantages Of Rack And Pinion Mechanism Rack and pinions can have excessive errors at the joint between two rack sections. The main disadvantages of gear transmission compared with belt transmission are: Advantages and disadvantages of using rack and pinion gear. Applications of rack and pinion gear. Rack and pinion gear ratio and its significance. In reality, to achieve the desired travel length, multiple pieces of rack. Disadvantages Of Rack And Pinion Mechanism.

From www.researchgate.net

Rack and pinion mechanism (a) 3D internal mechanism of SBPG (b Disadvantages Of Rack And Pinion Mechanism Rack and pinions can have excessive errors at the joint between two rack sections. Rack and pinion steering system. In reality, to achieve the desired travel length, multiple pieces of rack may be mounted. However, you don’t want to overlook the possibility that something is wrong if the. Working principle of rack and pinion. Linear motion is indispensable to moving. Disadvantages Of Rack And Pinion Mechanism.

From www.youtube.com

Mechanism 19 2 racks & pinion gear SolidWorks Tutorial YouTube Disadvantages Of Rack And Pinion Mechanism In reality, to achieve the desired travel length, multiple pieces of rack may be mounted. However, you don’t want to overlook the possibility that something is wrong if the. Rack and pinion gear ratio and its significance. Rack and pinions can have excessive errors at the joint between two rack sections. When the rack and pinion system fails, it can. Disadvantages Of Rack And Pinion Mechanism.

From hxekmdcss.blob.core.windows.net

Disadvantages Of Rack And Pinion Steering at Madeline Thompson blog Disadvantages Of Rack And Pinion Mechanism The main disadvantages of gear transmission compared with belt transmission are: The mostly used steering system is rack and pinion and mostly 80 percent of commercial vehicles are using. In this article, we are going to study what is rack and pinion steering system is and its subtopic like definition, history, construction or main parts, working, application,. Rack and pinion. Disadvantages Of Rack And Pinion Mechanism.

From www.youtube.com

Rack and Pinion Steering Gearbox Mechanism Working Explained with Disadvantages Of Rack And Pinion Mechanism In reality, to achieve the desired travel length, multiple pieces of rack may be mounted. Applications of rack and pinion gear. Disadvantages of rack and pinion gear : In this article, we are going to study what is rack and pinion steering system is and its subtopic like definition, history, construction or main parts, working, application,. Rack and pinion gear. Disadvantages Of Rack And Pinion Mechanism.