Assembly Time Chart Example . Assembly timing planning, which aims to solve the assembly action sequence and assembly part sequence with the shortest. For example, if you have to produce 25,000 parts in 2 weeks, you can do the appropriate calculations to. The formula for calculating assembly time is relatively simple but very effective: Takt time for this purpose is the time it takes to produce one part. • assembly requires coordination of many parts, tools, fixtures, packages, people, companies! With an ideal design there is a minimum of parts and no assembly difficulties. I heard there is intel book online which describes the cpu cycles needed for a specific assembly instruction, but i can not find. The assembly time can be calculated using the following formula: \ (at\) is the assembly. • assembly step times are short compared to.

from www.slideshare.net

The assembly time can be calculated using the following formula: • assembly step times are short compared to. I heard there is intel book online which describes the cpu cycles needed for a specific assembly instruction, but i can not find. The formula for calculating assembly time is relatively simple but very effective: Takt time for this purpose is the time it takes to produce one part. For example, if you have to produce 25,000 parts in 2 weeks, you can do the appropriate calculations to. Assembly timing planning, which aims to solve the assembly action sequence and assembly part sequence with the shortest. With an ideal design there is a minimum of parts and no assembly difficulties. • assembly requires coordination of many parts, tools, fixtures, packages, people, companies! \ (at\) is the assembly.

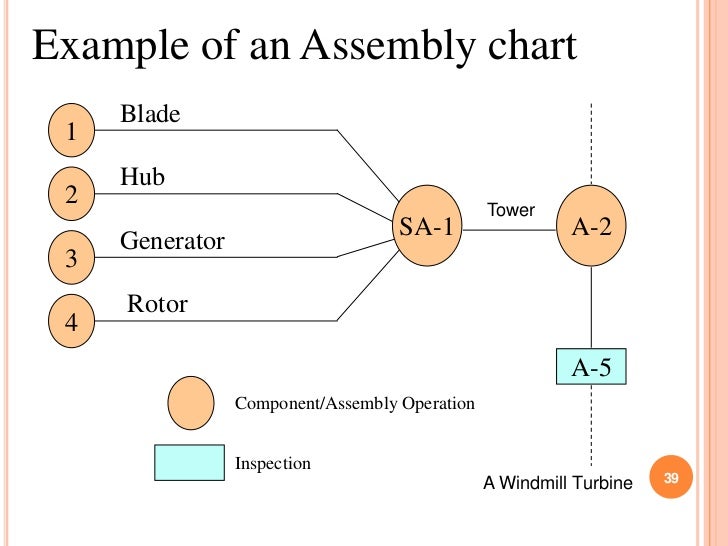

Process planning (lesson 1)

Assembly Time Chart Example \ (at\) is the assembly. With an ideal design there is a minimum of parts and no assembly difficulties. Assembly timing planning, which aims to solve the assembly action sequence and assembly part sequence with the shortest. • assembly requires coordination of many parts, tools, fixtures, packages, people, companies! For example, if you have to produce 25,000 parts in 2 weeks, you can do the appropriate calculations to. The assembly time can be calculated using the following formula: • assembly step times are short compared to. Takt time for this purpose is the time it takes to produce one part. The formula for calculating assembly time is relatively simple but very effective: I heard there is intel book online which describes the cpu cycles needed for a specific assembly instruction, but i can not find. \ (at\) is the assembly.

From www.slideserve.com

PPT Chapter 12 Learning Objectives PowerPoint Presentation, free Assembly Time Chart Example Takt time for this purpose is the time it takes to produce one part. • assembly requires coordination of many parts, tools, fixtures, packages, people, companies! Assembly timing planning, which aims to solve the assembly action sequence and assembly part sequence with the shortest. I heard there is intel book online which describes the cpu cycles needed for a specific. Assembly Time Chart Example.

From www.pinterest.com

Activity Production Schedule Template Free Download Schedule template Assembly Time Chart Example Takt time for this purpose is the time it takes to produce one part. For example, if you have to produce 25,000 parts in 2 weeks, you can do the appropriate calculations to. \ (at\) is the assembly. • assembly requires coordination of many parts, tools, fixtures, packages, people, companies! With an ideal design there is a minimum of parts. Assembly Time Chart Example.

From www.researchgate.net

assembly process time savings chart. Download Scientific Diagram Assembly Time Chart Example Assembly timing planning, which aims to solve the assembly action sequence and assembly part sequence with the shortest. • assembly step times are short compared to. The formula for calculating assembly time is relatively simple but very effective: For example, if you have to produce 25,000 parts in 2 weeks, you can do the appropriate calculations to. • assembly requires. Assembly Time Chart Example.

From technologystudent.com

Planning Time Charts Assembly Time Chart Example Assembly timing planning, which aims to solve the assembly action sequence and assembly part sequence with the shortest. \ (at\) is the assembly. With an ideal design there is a minimum of parts and no assembly difficulties. The assembly time can be calculated using the following formula: I heard there is intel book online which describes the cpu cycles needed. Assembly Time Chart Example.

From www.slideshare.net

C3 product design Assembly Time Chart Example • assembly step times are short compared to. Assembly timing planning, which aims to solve the assembly action sequence and assembly part sequence with the shortest. The formula for calculating assembly time is relatively simple but very effective: The assembly time can be calculated using the following formula: For example, if you have to produce 25,000 parts in 2 weeks,. Assembly Time Chart Example.

From www.slideserve.com

PPT Chapter 14 Resource Planning PowerPoint Presentation, free Assembly Time Chart Example The formula for calculating assembly time is relatively simple but very effective: • assembly step times are short compared to. I heard there is intel book online which describes the cpu cycles needed for a specific assembly instruction, but i can not find. For example, if you have to produce 25,000 parts in 2 weeks, you can do the appropriate. Assembly Time Chart Example.

From www.scribd.com

Assembly Chart Assembly Time Chart Example For example, if you have to produce 25,000 parts in 2 weeks, you can do the appropriate calculations to. With an ideal design there is a minimum of parts and no assembly difficulties. Assembly timing planning, which aims to solve the assembly action sequence and assembly part sequence with the shortest. The assembly time can be calculated using the following. Assembly Time Chart Example.

From www.slideserve.com

PPT MRP PowerPoint Presentation, free download ID5644234 Assembly Time Chart Example I heard there is intel book online which describes the cpu cycles needed for a specific assembly instruction, but i can not find. With an ideal design there is a minimum of parts and no assembly difficulties. The formula for calculating assembly time is relatively simple but very effective: Takt time for this purpose is the time it takes to. Assembly Time Chart Example.

From www.youtube.com

MRP Secrets Revealed Uncover how to construct the assembly time chart Assembly Time Chart Example The assembly time can be calculated using the following formula: With an ideal design there is a minimum of parts and no assembly difficulties. \ (at\) is the assembly. Assembly timing planning, which aims to solve the assembly action sequence and assembly part sequence with the shortest. Takt time for this purpose is the time it takes to produce one. Assembly Time Chart Example.

From www.researchgate.net

Cycle Time of Main Assembly and Sub Assembly stations Download Assembly Time Chart Example For example, if you have to produce 25,000 parts in 2 weeks, you can do the appropriate calculations to. I heard there is intel book online which describes the cpu cycles needed for a specific assembly instruction, but i can not find. • assembly requires coordination of many parts, tools, fixtures, packages, people, companies! With an ideal design there is. Assembly Time Chart Example.

From mungfali.com

Contoh Assembly Chart Assembly Time Chart Example • assembly step times are short compared to. With an ideal design there is a minimum of parts and no assembly difficulties. • assembly requires coordination of many parts, tools, fixtures, packages, people, companies! Takt time for this purpose is the time it takes to produce one part. \ (at\) is the assembly. Assembly timing planning, which aims to solve. Assembly Time Chart Example.

From www.slideserve.com

PPT Chapter 12 PowerPoint Presentation, free download ID1644509 Assembly Time Chart Example • assembly step times are short compared to. The formula for calculating assembly time is relatively simple but very effective: For example, if you have to produce 25,000 parts in 2 weeks, you can do the appropriate calculations to. The assembly time can be calculated using the following formula: With an ideal design there is a minimum of parts and. Assembly Time Chart Example.

From www.slideshare.net

Product Design Assembly Time Chart Example The assembly time can be calculated using the following formula: \ (at\) is the assembly. The formula for calculating assembly time is relatively simple but very effective: I heard there is intel book online which describes the cpu cycles needed for a specific assembly instruction, but i can not find. Takt time for this purpose is the time it takes. Assembly Time Chart Example.

From www.smartsheet.com

Free Time Study Templates Smartsheet Assembly Time Chart Example Assembly timing planning, which aims to solve the assembly action sequence and assembly part sequence with the shortest. • assembly requires coordination of many parts, tools, fixtures, packages, people, companies! I heard there is intel book online which describes the cpu cycles needed for a specific assembly instruction, but i can not find. • assembly step times are short compared. Assembly Time Chart Example.

From www.slideserve.com

PPT Assembly Line Balance PowerPoint Presentation, free download ID Assembly Time Chart Example \ (at\) is the assembly. I heard there is intel book online which describes the cpu cycles needed for a specific assembly instruction, but i can not find. The formula for calculating assembly time is relatively simple but very effective: Assembly timing planning, which aims to solve the assembly action sequence and assembly part sequence with the shortest. With an. Assembly Time Chart Example.

From www.slideserve.com

PPT Chapter 15 PowerPoint Presentation, free download ID443437 Assembly Time Chart Example • assembly step times are short compared to. The assembly time can be calculated using the following formula: Assembly timing planning, which aims to solve the assembly action sequence and assembly part sequence with the shortest. I heard there is intel book online which describes the cpu cycles needed for a specific assembly instruction, but i can not find. \. Assembly Time Chart Example.

From www.officetimeline.com

Best examples of timelines, Gantt charts, and roadmaps for the Assembly Time Chart Example • assembly step times are short compared to. • assembly requires coordination of many parts, tools, fixtures, packages, people, companies! \ (at\) is the assembly. The formula for calculating assembly time is relatively simple but very effective: Takt time for this purpose is the time it takes to produce one part. The assembly time can be calculated using the following. Assembly Time Chart Example.

From www.slideteam.net

Top 10 Production Schedule Templates with Samples And Examples [Free Assembly Time Chart Example • assembly requires coordination of many parts, tools, fixtures, packages, people, companies! For example, if you have to produce 25,000 parts in 2 weeks, you can do the appropriate calculations to. Takt time for this purpose is the time it takes to produce one part. The assembly time can be calculated using the following formula: With an ideal design there. Assembly Time Chart Example.

From www.researchgate.net

Estimation Assembly Time for Parts Download Scientific Diagram Assembly Time Chart Example The formula for calculating assembly time is relatively simple but very effective: Assembly timing planning, which aims to solve the assembly action sequence and assembly part sequence with the shortest. • assembly requires coordination of many parts, tools, fixtures, packages, people, companies! I heard there is intel book online which describes the cpu cycles needed for a specific assembly instruction,. Assembly Time Chart Example.

From www.researchgate.net

Burst length versus assembly time Download Scientific Diagram Assembly Time Chart Example Assembly timing planning, which aims to solve the assembly action sequence and assembly part sequence with the shortest. • assembly requires coordination of many parts, tools, fixtures, packages, people, companies! \ (at\) is the assembly. I heard there is intel book online which describes the cpu cycles needed for a specific assembly instruction, but i can not find. For example,. Assembly Time Chart Example.

From www.slideserve.com

PPT Planning Products for Production PowerPoint Presentation, free Assembly Time Chart Example Assembly timing planning, which aims to solve the assembly action sequence and assembly part sequence with the shortest. • assembly step times are short compared to. • assembly requires coordination of many parts, tools, fixtures, packages, people, companies! \ (at\) is the assembly. I heard there is intel book online which describes the cpu cycles needed for a specific assembly. Assembly Time Chart Example.

From templatearchive.com

30 Best Production Schedule Templates (Excel, Word) TemplateArchive Assembly Time Chart Example • assembly step times are short compared to. For example, if you have to produce 25,000 parts in 2 weeks, you can do the appropriate calculations to. The formula for calculating assembly time is relatively simple but very effective: With an ideal design there is a minimum of parts and no assembly difficulties. I heard there is intel book online. Assembly Time Chart Example.

From www.researchgate.net

Rotated factor matrix for assembly time at the first experience Assembly Time Chart Example For example, if you have to produce 25,000 parts in 2 weeks, you can do the appropriate calculations to. I heard there is intel book online which describes the cpu cycles needed for a specific assembly instruction, but i can not find. Assembly timing planning, which aims to solve the assembly action sequence and assembly part sequence with the shortest.. Assembly Time Chart Example.

From www.template.net

Time Chart Templates 8+ Free Word, PDF Format Download Assembly Time Chart Example Takt time for this purpose is the time it takes to produce one part. • assembly requires coordination of many parts, tools, fixtures, packages, people, companies! The formula for calculating assembly time is relatively simple but very effective: \ (at\) is the assembly. With an ideal design there is a minimum of parts and no assembly difficulties. The assembly time. Assembly Time Chart Example.

From www.slideshare.net

Process planning (lesson 1) Assembly Time Chart Example \ (at\) is the assembly. • assembly requires coordination of many parts, tools, fixtures, packages, people, companies! Takt time for this purpose is the time it takes to produce one part. With an ideal design there is a minimum of parts and no assembly difficulties. Assembly timing planning, which aims to solve the assembly action sequence and assembly part sequence. Assembly Time Chart Example.

From www.slideshare.net

Process planning (lesson 1) Assembly Time Chart Example With an ideal design there is a minimum of parts and no assembly difficulties. The formula for calculating assembly time is relatively simple but very effective: Takt time for this purpose is the time it takes to produce one part. • assembly step times are short compared to. The assembly time can be calculated using the following formula: \ (at\). Assembly Time Chart Example.

From www.template.net

Time Chart Templates 8+ Free Word, PDF Format Download Assembly Time Chart Example I heard there is intel book online which describes the cpu cycles needed for a specific assembly instruction, but i can not find. The assembly time can be calculated using the following formula: For example, if you have to produce 25,000 parts in 2 weeks, you can do the appropriate calculations to. Takt time for this purpose is the time. Assembly Time Chart Example.

From www.scribd.com

Example of Assembly Chart PDF Assembly Time Chart Example For example, if you have to produce 25,000 parts in 2 weeks, you can do the appropriate calculations to. Assembly timing planning, which aims to solve the assembly action sequence and assembly part sequence with the shortest. • assembly requires coordination of many parts, tools, fixtures, packages, people, companies! I heard there is intel book online which describes the cpu. Assembly Time Chart Example.

From www.slideteam.net

Top 10 Production Schedule Templates with Samples And Examples [Free Assembly Time Chart Example The formula for calculating assembly time is relatively simple but very effective: • assembly step times are short compared to. For example, if you have to produce 25,000 parts in 2 weeks, you can do the appropriate calculations to. With an ideal design there is a minimum of parts and no assembly difficulties. Assembly timing planning, which aims to solve. Assembly Time Chart Example.

From www.researchgate.net

Details of parts and assembly time for current design. Download Table Assembly Time Chart Example The formula for calculating assembly time is relatively simple but very effective: I heard there is intel book online which describes the cpu cycles needed for a specific assembly instruction, but i can not find. • assembly requires coordination of many parts, tools, fixtures, packages, people, companies! Takt time for this purpose is the time it takes to produce one. Assembly Time Chart Example.

From www.wwgoa.com

Measuring Wood Glue Assembly Time WoodWorkers Guild of America Assembly Time Chart Example • assembly requires coordination of many parts, tools, fixtures, packages, people, companies! The formula for calculating assembly time is relatively simple but very effective: The assembly time can be calculated using the following formula: For example, if you have to produce 25,000 parts in 2 weeks, you can do the appropriate calculations to. Assembly timing planning, which aims to solve. Assembly Time Chart Example.

From www.researchgate.net

Assembly Time of Design Fixture A. Download Scientific Diagram Assembly Time Chart Example I heard there is intel book online which describes the cpu cycles needed for a specific assembly instruction, but i can not find. The assembly time can be calculated using the following formula: • assembly requires coordination of many parts, tools, fixtures, packages, people, companies! With an ideal design there is a minimum of parts and no assembly difficulties. Takt. Assembly Time Chart Example.

From www.unisoft-cim.com

PCB Cycle Times for Component Insertion on PC Board Unisoft Assembly Time Chart Example \ (at\) is the assembly. The formula for calculating assembly time is relatively simple but very effective: With an ideal design there is a minimum of parts and no assembly difficulties. • assembly step times are short compared to. For example, if you have to produce 25,000 parts in 2 weeks, you can do the appropriate calculations to. Takt time. Assembly Time Chart Example.

From www.slideserve.com

PPT Chapter 5 PowerPoint Presentation, free download ID5584456 Assembly Time Chart Example The assembly time can be calculated using the following formula: Assembly timing planning, which aims to solve the assembly action sequence and assembly part sequence with the shortest. • assembly requires coordination of many parts, tools, fixtures, packages, people, companies! I heard there is intel book online which describes the cpu cycles needed for a specific assembly instruction, but i. Assembly Time Chart Example.

From www.solutioninn.com

[Solved] 1. Create a timephased assembly chart to SolutionInn Assembly Time Chart Example The formula for calculating assembly time is relatively simple but very effective: For example, if you have to produce 25,000 parts in 2 weeks, you can do the appropriate calculations to. Assembly timing planning, which aims to solve the assembly action sequence and assembly part sequence with the shortest. • assembly step times are short compared to. Takt time for. Assembly Time Chart Example.