Laser Cutting Surface Roughness . In the present paper, surface roughness, dimensional accuracy, and burr thickness of thin plates of 0.8 mm are studied as functions of. This study investigated the impact of the laser speed and power, and the position and orientation of the samples, on the average surface roughness (ra) and. There was used optical microscope alicona infinitefocus. The optimization outcomes indicate that minimum surface roughness of 1.1123 μm was obtained by operating at laser power at. Surface roughness measurements based on the laser speckle method are roughly divided into the speckle contrast method, speckle correlation. A straight cut with 30 mm length was performed by the laser machine to obtain the cut surface where to measure the roughness. The significant criterion for the evaluation of the cut quality is the surface roughness. The prominence of laser power in surface roughness stems from its effect on the material removal mode during diamond cutting.

from www.daysteel.co.uk

There was used optical microscope alicona infinitefocus. A straight cut with 30 mm length was performed by the laser machine to obtain the cut surface where to measure the roughness. The optimization outcomes indicate that minimum surface roughness of 1.1123 μm was obtained by operating at laser power at. The significant criterion for the evaluation of the cut quality is the surface roughness. Surface roughness measurements based on the laser speckle method are roughly divided into the speckle contrast method, speckle correlation. The prominence of laser power in surface roughness stems from its effect on the material removal mode during diamond cutting. This study investigated the impact of the laser speed and power, and the position and orientation of the samples, on the average surface roughness (ra) and. In the present paper, surface roughness, dimensional accuracy, and burr thickness of thin plates of 0.8 mm are studied as functions of.

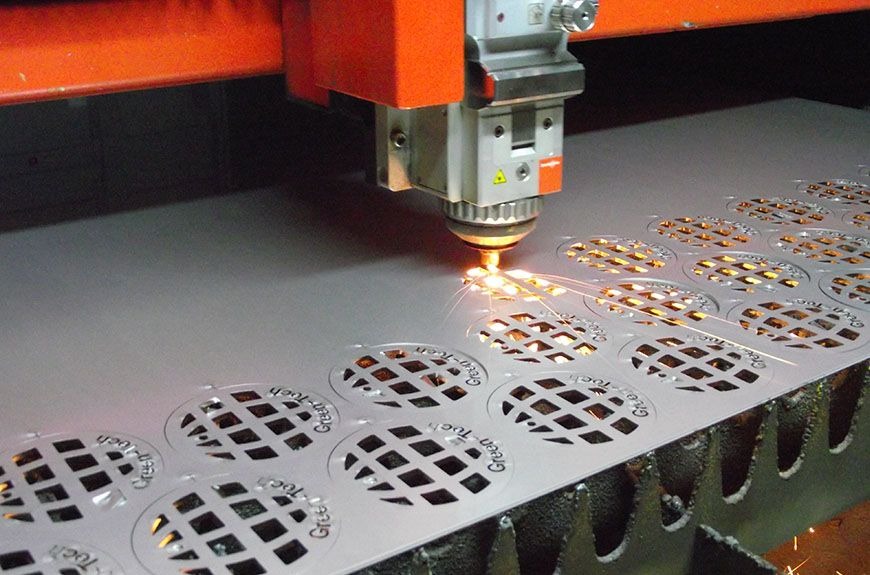

Laser Cutting Edge Quality Factors Affecting Laser Edge Finish Charles Day Steels

Laser Cutting Surface Roughness This study investigated the impact of the laser speed and power, and the position and orientation of the samples, on the average surface roughness (ra) and. A straight cut with 30 mm length was performed by the laser machine to obtain the cut surface where to measure the roughness. The prominence of laser power in surface roughness stems from its effect on the material removal mode during diamond cutting. In the present paper, surface roughness, dimensional accuracy, and burr thickness of thin plates of 0.8 mm are studied as functions of. Surface roughness measurements based on the laser speckle method are roughly divided into the speckle contrast method, speckle correlation. The optimization outcomes indicate that minimum surface roughness of 1.1123 μm was obtained by operating at laser power at. This study investigated the impact of the laser speed and power, and the position and orientation of the samples, on the average surface roughness (ra) and. There was used optical microscope alicona infinitefocus. The significant criterion for the evaluation of the cut quality is the surface roughness.

From www.researchgate.net

Roughness spectra of surfaces laser polished with different laser beam... Download Scientific Laser Cutting Surface Roughness This study investigated the impact of the laser speed and power, and the position and orientation of the samples, on the average surface roughness (ra) and. There was used optical microscope alicona infinitefocus. The optimization outcomes indicate that minimum surface roughness of 1.1123 μm was obtained by operating at laser power at. The significant criterion for the evaluation of the. Laser Cutting Surface Roughness.

From www.researchgate.net

(PDF) The Effect of Selected Technological Parameters of Laser Cutting on the Cut Surface Roughness Laser Cutting Surface Roughness The significant criterion for the evaluation of the cut quality is the surface roughness. A straight cut with 30 mm length was performed by the laser machine to obtain the cut surface where to measure the roughness. The prominence of laser power in surface roughness stems from its effect on the material removal mode during diamond cutting. This study investigated. Laser Cutting Surface Roughness.

From www.mdpi.com

Machines Free FullText Monitoring and Predicting the Surface Generation and Surface Laser Cutting Surface Roughness Surface roughness measurements based on the laser speckle method are roughly divided into the speckle contrast method, speckle correlation. The prominence of laser power in surface roughness stems from its effect on the material removal mode during diamond cutting. There was used optical microscope alicona infinitefocus. In the present paper, surface roughness, dimensional accuracy, and burr thickness of thin plates. Laser Cutting Surface Roughness.

From mungfali.com

Surface Roughness Tool Laser Cutting Surface Roughness In the present paper, surface roughness, dimensional accuracy, and burr thickness of thin plates of 0.8 mm are studied as functions of. The optimization outcomes indicate that minimum surface roughness of 1.1123 μm was obtained by operating at laser power at. The significant criterion for the evaluation of the cut quality is the surface roughness. A straight cut with 30. Laser Cutting Surface Roughness.

From www.newfield.co.uk

Laser Cutting Services CNC Laser Cutting, Mild Steel, Stainless, Aluminium Laser Cutting Surface Roughness A straight cut with 30 mm length was performed by the laser machine to obtain the cut surface where to measure the roughness. The prominence of laser power in surface roughness stems from its effect on the material removal mode during diamond cutting. In the present paper, surface roughness, dimensional accuracy, and burr thickness of thin plates of 0.8 mm. Laser Cutting Surface Roughness.

From www.researchgate.net

Laser cutting surface topography of the two samples. (a) Nonheat... Download Scientific Diagram Laser Cutting Surface Roughness There was used optical microscope alicona infinitefocus. In the present paper, surface roughness, dimensional accuracy, and burr thickness of thin plates of 0.8 mm are studied as functions of. The prominence of laser power in surface roughness stems from its effect on the material removal mode during diamond cutting. The optimization outcomes indicate that minimum surface roughness of 1.1123 μm. Laser Cutting Surface Roughness.

From www.mmsonline.com

How to Choose the Right Cut Off When Measuring Roughness Modern Machine Shop Laser Cutting Surface Roughness A straight cut with 30 mm length was performed by the laser machine to obtain the cut surface where to measure the roughness. The significant criterion for the evaluation of the cut quality is the surface roughness. In the present paper, surface roughness, dimensional accuracy, and burr thickness of thin plates of 0.8 mm are studied as functions of. The. Laser Cutting Surface Roughness.

From www.researchgate.net

Surface view after laser cutting with marked roughness measurements point. Download Scientific Laser Cutting Surface Roughness In the present paper, surface roughness, dimensional accuracy, and burr thickness of thin plates of 0.8 mm are studied as functions of. There was used optical microscope alicona infinitefocus. This study investigated the impact of the laser speed and power, and the position and orientation of the samples, on the average surface roughness (ra) and. The prominence of laser power. Laser Cutting Surface Roughness.

From www.thefabricator.com

4 ways to a better lasercut edge Laser Cutting Surface Roughness The prominence of laser power in surface roughness stems from its effect on the material removal mode during diamond cutting. This study investigated the impact of the laser speed and power, and the position and orientation of the samples, on the average surface roughness (ra) and. The optimization outcomes indicate that minimum surface roughness of 1.1123 μm was obtained by. Laser Cutting Surface Roughness.

From www.semanticscholar.org

Figure 7 from Comparison of surface roughness quality created by abrasive water jet and CO2 Laser Cutting Surface Roughness The optimization outcomes indicate that minimum surface roughness of 1.1123 μm was obtained by operating at laser power at. Surface roughness measurements based on the laser speckle method are roughly divided into the speckle contrast method, speckle correlation. In the present paper, surface roughness, dimensional accuracy, and burr thickness of thin plates of 0.8 mm are studied as functions of.. Laser Cutting Surface Roughness.

From mellowpine.com

Laser Cutting Metal Expert Guide [2023] MellowPine Laser Cutting Surface Roughness The significant criterion for the evaluation of the cut quality is the surface roughness. The prominence of laser power in surface roughness stems from its effect on the material removal mode during diamond cutting. Surface roughness measurements based on the laser speckle method are roughly divided into the speckle contrast method, speckle correlation. The optimization outcomes indicate that minimum surface. Laser Cutting Surface Roughness.

From www.researchgate.net

Cut surface for different angles b between the polarization plane and... Download Scientific Laser Cutting Surface Roughness The prominence of laser power in surface roughness stems from its effect on the material removal mode during diamond cutting. This study investigated the impact of the laser speed and power, and the position and orientation of the samples, on the average surface roughness (ra) and. Surface roughness measurements based on the laser speckle method are roughly divided into the. Laser Cutting Surface Roughness.

From www.iron-foundry.com

Machining surface finish chart, conversion, comparator, method, degree, Ra, Rz, RMS Laser Cutting Surface Roughness A straight cut with 30 mm length was performed by the laser machine to obtain the cut surface where to measure the roughness. The significant criterion for the evaluation of the cut quality is the surface roughness. The optimization outcomes indicate that minimum surface roughness of 1.1123 μm was obtained by operating at laser power at. Surface roughness measurements based. Laser Cutting Surface Roughness.

From www.mdpi.com

JMMP Free FullText The Impact of Process Parameters on Surface Roughness and Dimensional Laser Cutting Surface Roughness A straight cut with 30 mm length was performed by the laser machine to obtain the cut surface where to measure the roughness. There was used optical microscope alicona infinitefocus. The optimization outcomes indicate that minimum surface roughness of 1.1123 μm was obtained by operating at laser power at. Surface roughness measurements based on the laser speckle method are roughly. Laser Cutting Surface Roughness.

From www.researchgate.net

Laser cutting process and inspection device the surface roughness as... Download Scientific Laser Cutting Surface Roughness Surface roughness measurements based on the laser speckle method are roughly divided into the speckle contrast method, speckle correlation. In the present paper, surface roughness, dimensional accuracy, and burr thickness of thin plates of 0.8 mm are studied as functions of. There was used optical microscope alicona infinitefocus. The prominence of laser power in surface roughness stems from its effect. Laser Cutting Surface Roughness.

From longthaverefull.blogspot.com

If the Nose Radius is 07mm and the Feed is 01mm the Peak to Valley Roughness Rz is Most Nearly Laser Cutting Surface Roughness There was used optical microscope alicona infinitefocus. This study investigated the impact of the laser speed and power, and the position and orientation of the samples, on the average surface roughness (ra) and. A straight cut with 30 mm length was performed by the laser machine to obtain the cut surface where to measure the roughness. Surface roughness measurements based. Laser Cutting Surface Roughness.

From www.rapiddirect.com

Surface Roughness Chart Understanding Surface Finishes RapidDirect Laser Cutting Surface Roughness There was used optical microscope alicona infinitefocus. Surface roughness measurements based on the laser speckle method are roughly divided into the speckle contrast method, speckle correlation. A straight cut with 30 mm length was performed by the laser machine to obtain the cut surface where to measure the roughness. The significant criterion for the evaluation of the cut quality is. Laser Cutting Surface Roughness.

From summerowen.z19.web.core.windows.net

Ra Surface Roughness Chart Laser Cutting Surface Roughness This study investigated the impact of the laser speed and power, and the position and orientation of the samples, on the average surface roughness (ra) and. In the present paper, surface roughness, dimensional accuracy, and burr thickness of thin plates of 0.8 mm are studied as functions of. The prominence of laser power in surface roughness stems from its effect. Laser Cutting Surface Roughness.

From www.suginocorp.com

Surface Roughness for Lathe Turning Laser Cutting Surface Roughness The prominence of laser power in surface roughness stems from its effect on the material removal mode during diamond cutting. The optimization outcomes indicate that minimum surface roughness of 1.1123 μm was obtained by operating at laser power at. There was used optical microscope alicona infinitefocus. A straight cut with 30 mm length was performed by the laser machine to. Laser Cutting Surface Roughness.

From www.researchgate.net

Surface view after laser cutting with marked roughness measurements point. Download Scientific Laser Cutting Surface Roughness The optimization outcomes indicate that minimum surface roughness of 1.1123 μm was obtained by operating at laser power at. A straight cut with 30 mm length was performed by the laser machine to obtain the cut surface where to measure the roughness. Surface roughness measurements based on the laser speckle method are roughly divided into the speckle contrast method, speckle. Laser Cutting Surface Roughness.

From www.researchgate.net

(PDF) Research on surface roughness by laser cut Laser Cutting Surface Roughness The prominence of laser power in surface roughness stems from its effect on the material removal mode during diamond cutting. This study investigated the impact of the laser speed and power, and the position and orientation of the samples, on the average surface roughness (ra) and. There was used optical microscope alicona infinitefocus. Surface roughness measurements based on the laser. Laser Cutting Surface Roughness.

From www.researchgate.net

Comparison of surface roughness between laser cutting and mechanical... Download Scientific Laser Cutting Surface Roughness Surface roughness measurements based on the laser speckle method are roughly divided into the speckle contrast method, speckle correlation. In the present paper, surface roughness, dimensional accuracy, and burr thickness of thin plates of 0.8 mm are studied as functions of. The significant criterion for the evaluation of the cut quality is the surface roughness. There was used optical microscope. Laser Cutting Surface Roughness.

From mellowpine.com

Laser Cutting Metal Expert Guide [2023] MellowPine Laser Cutting Surface Roughness Surface roughness measurements based on the laser speckle method are roughly divided into the speckle contrast method, speckle correlation. The prominence of laser power in surface roughness stems from its effect on the material removal mode during diamond cutting. There was used optical microscope alicona infinitefocus. A straight cut with 30 mm length was performed by the laser machine to. Laser Cutting Surface Roughness.

From www.researchgate.net

Optical micrographs of the surface morphology of cut edge of samples... Download Scientific Laser Cutting Surface Roughness A straight cut with 30 mm length was performed by the laser machine to obtain the cut surface where to measure the roughness. There was used optical microscope alicona infinitefocus. The significant criterion for the evaluation of the cut quality is the surface roughness. This study investigated the impact of the laser speed and power, and the position and orientation. Laser Cutting Surface Roughness.

From www.researchgate.net

Surface roughness vs. depth of cut at Vc = 120 m/min and f = 0.12 mm/rev Download Scientific Laser Cutting Surface Roughness A straight cut with 30 mm length was performed by the laser machine to obtain the cut surface where to measure the roughness. The significant criterion for the evaluation of the cut quality is the surface roughness. There was used optical microscope alicona infinitefocus. In the present paper, surface roughness, dimensional accuracy, and burr thickness of thin plates of 0.8. Laser Cutting Surface Roughness.

From www.researchgate.net

(PDF) Research on surface roughness by laser cut Laser Cutting Surface Roughness This study investigated the impact of the laser speed and power, and the position and orientation of the samples, on the average surface roughness (ra) and. The optimization outcomes indicate that minimum surface roughness of 1.1123 μm was obtained by operating at laser power at. The significant criterion for the evaluation of the cut quality is the surface roughness. Surface. Laser Cutting Surface Roughness.

From imagesee.biz

Surface Roughness Explained IMAGESEE Laser Cutting Surface Roughness There was used optical microscope alicona infinitefocus. The significant criterion for the evaluation of the cut quality is the surface roughness. Surface roughness measurements based on the laser speckle method are roughly divided into the speckle contrast method, speckle correlation. This study investigated the impact of the laser speed and power, and the position and orientation of the samples, on. Laser Cutting Surface Roughness.

From pubs.sciepub.com

Figure 6. 3points Ra performance Experimental Study of Surface Roughness and MicroHardness Laser Cutting Surface Roughness Surface roughness measurements based on the laser speckle method are roughly divided into the speckle contrast method, speckle correlation. In the present paper, surface roughness, dimensional accuracy, and burr thickness of thin plates of 0.8 mm are studied as functions of. The optimization outcomes indicate that minimum surface roughness of 1.1123 μm was obtained by operating at laser power at.. Laser Cutting Surface Roughness.

From www.hera.org.nz

Notice Quality requirements for thermal cutting HERA Laser Cutting Surface Roughness The significant criterion for the evaluation of the cut quality is the surface roughness. Surface roughness measurements based on the laser speckle method are roughly divided into the speckle contrast method, speckle correlation. This study investigated the impact of the laser speed and power, and the position and orientation of the samples, on the average surface roughness (ra) and. The. Laser Cutting Surface Roughness.

From xometry.pro

Selecting Right Surface Roughness for CNC Machining Xometry Pro Laser Cutting Surface Roughness The prominence of laser power in surface roughness stems from its effect on the material removal mode during diamond cutting. Surface roughness measurements based on the laser speckle method are roughly divided into the speckle contrast method, speckle correlation. There was used optical microscope alicona infinitefocus. A straight cut with 30 mm length was performed by the laser machine to. Laser Cutting Surface Roughness.

From www.iqsdirectory.com

Laser Cutting What Is It? How Does It Work? Methods Laser Cutting Surface Roughness The optimization outcomes indicate that minimum surface roughness of 1.1123 μm was obtained by operating at laser power at. The prominence of laser power in surface roughness stems from its effect on the material removal mode during diamond cutting. There was used optical microscope alicona infinitefocus. In the present paper, surface roughness, dimensional accuracy, and burr thickness of thin plates. Laser Cutting Surface Roughness.

From www.thefabricator.com

Shaping the laser beam for the best cut The Fabricator Laser Cutting Surface Roughness The prominence of laser power in surface roughness stems from its effect on the material removal mode during diamond cutting. The optimization outcomes indicate that minimum surface roughness of 1.1123 μm was obtained by operating at laser power at. There was used optical microscope alicona infinitefocus. Surface roughness measurements based on the laser speckle method are roughly divided into the. Laser Cutting Surface Roughness.

From willrich.com

customized laser surface roughness 2 Willrich Precision Instruments Laser Cutting Surface Roughness The optimization outcomes indicate that minimum surface roughness of 1.1123 μm was obtained by operating at laser power at. The prominence of laser power in surface roughness stems from its effect on the material removal mode during diamond cutting. A straight cut with 30 mm length was performed by the laser machine to obtain the cut surface where to measure. Laser Cutting Surface Roughness.

From www.researchgate.net

Surface roughness parameters of the ceramic samples with different... Download Scientific Diagram Laser Cutting Surface Roughness The optimization outcomes indicate that minimum surface roughness of 1.1123 μm was obtained by operating at laser power at. In the present paper, surface roughness, dimensional accuracy, and burr thickness of thin plates of 0.8 mm are studied as functions of. This study investigated the impact of the laser speed and power, and the position and orientation of the samples,. Laser Cutting Surface Roughness.

From www.daysteel.co.uk

Laser Cutting Edge Quality Factors Affecting Laser Edge Finish Charles Day Steels Laser Cutting Surface Roughness A straight cut with 30 mm length was performed by the laser machine to obtain the cut surface where to measure the roughness. The optimization outcomes indicate that minimum surface roughness of 1.1123 μm was obtained by operating at laser power at. This study investigated the impact of the laser speed and power, and the position and orientation of the. Laser Cutting Surface Roughness.