Hydraulic Brake System Design Calculations . 1.6 the hydraulically operated disc brake. Reviews the basic principles and considerations in the braking system design process and further explains the general procedure for the same. When an hydraulic brake is applied fluid is required to move through the pipes. • there is sufficient torque to stop and hold the machine at rest • for dynamic. Lightweight braking system providing the adequate braking torque for an efficient braking system. 1.7 electronic brake control systems. The function of brake booster, master cylinder,. If the fluid source is a master cylinder it has a finite. This paper describes the design of brake booster used in hydraulic system of suzuki car. The fundamentals of braking calculations are to ensure that: 1.5 from muscle power to full power brakes.

from www.buybrakes.com

The fundamentals of braking calculations are to ensure that: 1.7 electronic brake control systems. Reviews the basic principles and considerations in the braking system design process and further explains the general procedure for the same. This paper describes the design of brake booster used in hydraulic system of suzuki car. Lightweight braking system providing the adequate braking torque for an efficient braking system. 1.5 from muscle power to full power brakes. If the fluid source is a master cylinder it has a finite. • there is sufficient torque to stop and hold the machine at rest • for dynamic. 1.6 the hydraulically operated disc brake. The function of brake booster, master cylinder,.

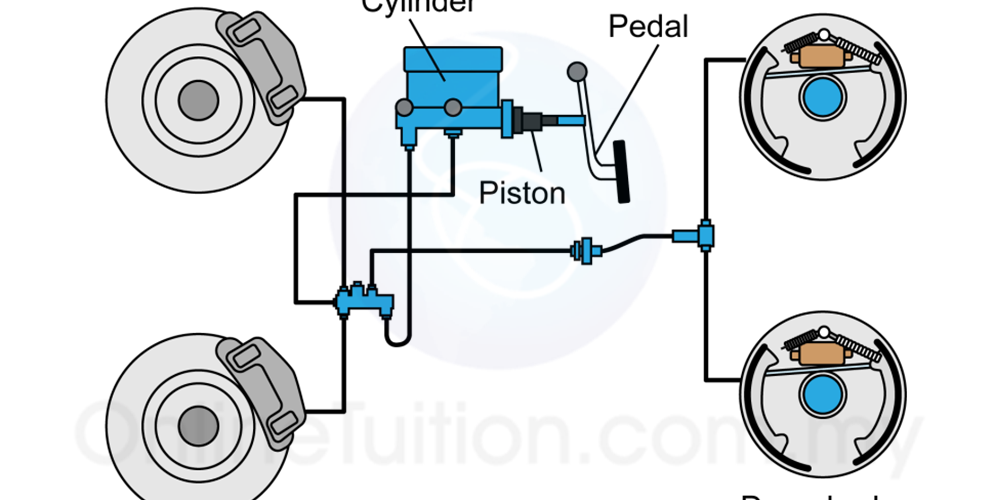

What Are Brake Hydraulics & How Do They Work?

Hydraulic Brake System Design Calculations 1.5 from muscle power to full power brakes. This paper describes the design of brake booster used in hydraulic system of suzuki car. 1.7 electronic brake control systems. The fundamentals of braking calculations are to ensure that: When an hydraulic brake is applied fluid is required to move through the pipes. Lightweight braking system providing the adequate braking torque for an efficient braking system. If the fluid source is a master cylinder it has a finite. 1.6 the hydraulically operated disc brake. 1.5 from muscle power to full power brakes. The function of brake booster, master cylinder,. • there is sufficient torque to stop and hold the machine at rest • for dynamic. Reviews the basic principles and considerations in the braking system design process and further explains the general procedure for the same.

From www.researchgate.net

Schematic of a hydraulic brake system for Example 2. Download Hydraulic Brake System Design Calculations This paper describes the design of brake booster used in hydraulic system of suzuki car. If the fluid source is a master cylinder it has a finite. • there is sufficient torque to stop and hold the machine at rest • for dynamic. The fundamentals of braking calculations are to ensure that: When an hydraulic brake is applied fluid is. Hydraulic Brake System Design Calculations.

From mechanicaljungle.com

What Is Hydraulic Braking System? Construction of Hydraulic Braking Hydraulic Brake System Design Calculations The function of brake booster, master cylinder,. 1.6 the hydraulically operated disc brake. The fundamentals of braking calculations are to ensure that: 1.5 from muscle power to full power brakes. 1.7 electronic brake control systems. When an hydraulic brake is applied fluid is required to move through the pipes. • there is sufficient torque to stop and hold the machine. Hydraulic Brake System Design Calculations.

From www.engineeringinspiration.co.uk

Engineering Inspiration Brake System Design Calculations Hydraulic Brake System Design Calculations Lightweight braking system providing the adequate braking torque for an efficient braking system. Reviews the basic principles and considerations in the braking system design process and further explains the general procedure for the same. 1.6 the hydraulically operated disc brake. This paper describes the design of brake booster used in hydraulic system of suzuki car. The fundamentals of braking calculations. Hydraulic Brake System Design Calculations.

From innovationdiscoveries.space

How Hydraulic Brake Works? InnovationDiscoveries.space Hydraulic Brake System Design Calculations 1.7 electronic brake control systems. When an hydraulic brake is applied fluid is required to move through the pipes. If the fluid source is a master cylinder it has a finite. This paper describes the design of brake booster used in hydraulic system of suzuki car. The fundamentals of braking calculations are to ensure that: The function of brake booster,. Hydraulic Brake System Design Calculations.

From www.slideserve.com

PPT Hydraulic Brake System Fundamentals PowerPoint Presentation, free Hydraulic Brake System Design Calculations • there is sufficient torque to stop and hold the machine at rest • for dynamic. This paper describes the design of brake booster used in hydraulic system of suzuki car. If the fluid source is a master cylinder it has a finite. Reviews the basic principles and considerations in the braking system design process and further explains the general. Hydraulic Brake System Design Calculations.

From www.academia.edu

(PDF) IRJET Design and Analysis of a Hydraulic Brake System of an Hydraulic Brake System Design Calculations When an hydraulic brake is applied fluid is required to move through the pipes. This paper describes the design of brake booster used in hydraulic system of suzuki car. The fundamentals of braking calculations are to ensure that: 1.5 from muscle power to full power brakes. 1.6 the hydraulically operated disc brake. Reviews the basic principles and considerations in the. Hydraulic Brake System Design Calculations.

From www.researchgate.net

Hydraulic brake system schematics. Source [13] Download Scientific Hydraulic Brake System Design Calculations If the fluid source is a master cylinder it has a finite. When an hydraulic brake is applied fluid is required to move through the pipes. The function of brake booster, master cylinder,. The fundamentals of braking calculations are to ensure that: 1.5 from muscle power to full power brakes. • there is sufficient torque to stop and hold the. Hydraulic Brake System Design Calculations.

From expansionmarine.com

Winch line pull calculation Drum Thickless calculation Brake test Hydraulic Brake System Design Calculations The function of brake booster, master cylinder,. 1.7 electronic brake control systems. When an hydraulic brake is applied fluid is required to move through the pipes. 1.5 from muscle power to full power brakes. If the fluid source is a master cylinder it has a finite. 1.6 the hydraulically operated disc brake. • there is sufficient torque to stop and. Hydraulic Brake System Design Calculations.

From schematicquewtaulajhgew.z14.web.core.windows.net

Power Brake System Diagram Hydraulic Brake System Design Calculations The fundamentals of braking calculations are to ensure that: If the fluid source is a master cylinder it has a finite. • there is sufficient torque to stop and hold the machine at rest • for dynamic. Lightweight braking system providing the adequate braking torque for an efficient braking system. 1.6 the hydraulically operated disc brake. When an hydraulic brake. Hydraulic Brake System Design Calculations.

From www.theengineerspost.com

Hydraulic Braking System Diagram, Parts & Working [PDF] Hydraulic Brake System Design Calculations • there is sufficient torque to stop and hold the machine at rest • for dynamic. 1.5 from muscle power to full power brakes. The fundamentals of braking calculations are to ensure that: The function of brake booster, master cylinder,. 1.6 the hydraulically operated disc brake. 1.7 electronic brake control systems. Reviews the basic principles and considerations in the braking. Hydraulic Brake System Design Calculations.

From www.buybrakes.com

What Are Brake Hydraulics & How Do They Work? Hydraulic Brake System Design Calculations When an hydraulic brake is applied fluid is required to move through the pipes. If the fluid source is a master cylinder it has a finite. This paper describes the design of brake booster used in hydraulic system of suzuki car. Lightweight braking system providing the adequate braking torque for an efficient braking system. 1.5 from muscle power to full. Hydraulic Brake System Design Calculations.

From wuling.id

How Car Hydraulic Brakes Work and Its Components Wuling Hydraulic Brake System Design Calculations 1.7 electronic brake control systems. 1.6 the hydraulically operated disc brake. If the fluid source is a master cylinder it has a finite. The fundamentals of braking calculations are to ensure that: When an hydraulic brake is applied fluid is required to move through the pipes. • there is sufficient torque to stop and hold the machine at rest •. Hydraulic Brake System Design Calculations.

From design.udlvirtual.edu.pe

Explain The Working Principle Of Hydraulic Brake System Design Talk Hydraulic Brake System Design Calculations When an hydraulic brake is applied fluid is required to move through the pipes. If the fluid source is a master cylinder it has a finite. 1.5 from muscle power to full power brakes. This paper describes the design of brake booster used in hydraulic system of suzuki car. The function of brake booster, master cylinder,. Lightweight braking system providing. Hydraulic Brake System Design Calculations.

From slidetodoc.com

Chapter 29 Hydraulic Brakes and AirOverHydraulic Brake Systems Hydraulic Brake System Design Calculations Reviews the basic principles and considerations in the braking system design process and further explains the general procedure for the same. If the fluid source is a master cylinder it has a finite. When an hydraulic brake is applied fluid is required to move through the pipes. 1.5 from muscle power to full power brakes. 1.6 the hydraulically operated disc. Hydraulic Brake System Design Calculations.

From www.youtube.com

Hydraulic Brakes ! Construction ! Working ! How hydraulic Brakes system Hydraulic Brake System Design Calculations If the fluid source is a master cylinder it has a finite. This paper describes the design of brake booster used in hydraulic system of suzuki car. Reviews the basic principles and considerations in the braking system design process and further explains the general procedure for the same. 1.7 electronic brake control systems. Lightweight braking system providing the adequate braking. Hydraulic Brake System Design Calculations.

From psbrake.com

BRAKE SYSTEM TYPES AND HYDRAULIC BRAKE PARTS AND FUNCTIONS PSBrake Hydraulic Brake System Design Calculations The fundamentals of braking calculations are to ensure that: • there is sufficient torque to stop and hold the machine at rest • for dynamic. 1.6 the hydraulically operated disc brake. 1.5 from muscle power to full power brakes. The function of brake booster, master cylinder,. Reviews the basic principles and considerations in the braking system design process and further. Hydraulic Brake System Design Calculations.

From studentlesson.com

Understanding Hydraulic Braking System studentlesson Hydraulic Brake System Design Calculations The function of brake booster, master cylinder,. When an hydraulic brake is applied fluid is required to move through the pipes. This paper describes the design of brake booster used in hydraulic system of suzuki car. 1.5 from muscle power to full power brakes. • there is sufficient torque to stop and hold the machine at rest • for dynamic.. Hydraulic Brake System Design Calculations.

From www.youtube.com

Working of Layout of Hydraulic Brake System Brakes and Dynamometers Hydraulic Brake System Design Calculations 1.5 from muscle power to full power brakes. • there is sufficient torque to stop and hold the machine at rest • for dynamic. Reviews the basic principles and considerations in the braking system design process and further explains the general procedure for the same. The function of brake booster, master cylinder,. This paper describes the design of brake booster. Hydraulic Brake System Design Calculations.

From www.theengineerspost.com

Hydraulic Braking System Diagram, Parts & Working [PDF] Hydraulic Brake System Design Calculations 1.5 from muscle power to full power brakes. The function of brake booster, master cylinder,. If the fluid source is a master cylinder it has a finite. The fundamentals of braking calculations are to ensure that: 1.7 electronic brake control systems. Lightweight braking system providing the adequate braking torque for an efficient braking system. When an hydraulic brake is applied. Hydraulic Brake System Design Calculations.

From www.theengineerspost.com

Hydraulic Braking System Diagram, Parts & Working [PDF] Hydraulic Brake System Design Calculations Lightweight braking system providing the adequate braking torque for an efficient braking system. Reviews the basic principles and considerations in the braking system design process and further explains the general procedure for the same. 1.6 the hydraulically operated disc brake. • there is sufficient torque to stop and hold the machine at rest • for dynamic. 1.7 electronic brake control. Hydraulic Brake System Design Calculations.

From www.researchgate.net

Layout of an Electro Hydraulic Braking System (Source Prof. von Hydraulic Brake System Design Calculations • there is sufficient torque to stop and hold the machine at rest • for dynamic. When an hydraulic brake is applied fluid is required to move through the pipes. If the fluid source is a master cylinder it has a finite. Reviews the basic principles and considerations in the braking system design process and further explains the general procedure. Hydraulic Brake System Design Calculations.

From www.youtube.com

Explain the working of a hydraulic brake with a simple labelled diagram Hydraulic Brake System Design Calculations • there is sufficient torque to stop and hold the machine at rest • for dynamic. If the fluid source is a master cylinder it has a finite. Lightweight braking system providing the adequate braking torque for an efficient braking system. This paper describes the design of brake booster used in hydraulic system of suzuki car. The function of brake. Hydraulic Brake System Design Calculations.

From morganrebuild.co.uk

Brake Layout Hydraulic Brake System Design Calculations The function of brake booster, master cylinder,. 1.7 electronic brake control systems. The fundamentals of braking calculations are to ensure that: 1.5 from muscle power to full power brakes. Reviews the basic principles and considerations in the braking system design process and further explains the general procedure for the same. If the fluid source is a master cylinder it has. Hydraulic Brake System Design Calculations.

From www.scribd.com

Engineering Inspiration Brake System Design Calculations PDF Hydraulic Brake System Design Calculations Lightweight braking system providing the adequate braking torque for an efficient braking system. • there is sufficient torque to stop and hold the machine at rest • for dynamic. The function of brake booster, master cylinder,. 1.6 the hydraulically operated disc brake. When an hydraulic brake is applied fluid is required to move through the pipes. Reviews the basic principles. Hydraulic Brake System Design Calculations.

From axleaddict.com

DIY Auto Service How Hydraulic Brake Systems Work AxleAddict Hydraulic Brake System Design Calculations • there is sufficient torque to stop and hold the machine at rest • for dynamic. The function of brake booster, master cylinder,. Reviews the basic principles and considerations in the braking system design process and further explains the general procedure for the same. 1.7 electronic brake control systems. 1.5 from muscle power to full power brakes. Lightweight braking system. Hydraulic Brake System Design Calculations.

From frendioriginal.com

BRAKE SYSTEM TYPES AND HYDRAULIC BRAKE PARTS AND FUNCTIONS Frendi Hydraulic Brake System Design Calculations Lightweight braking system providing the adequate braking torque for an efficient braking system. • there is sufficient torque to stop and hold the machine at rest • for dynamic. 1.5 from muscle power to full power brakes. Reviews the basic principles and considerations in the braking system design process and further explains the general procedure for the same. If the. Hydraulic Brake System Design Calculations.

From www.autozone.com

Repair Guides Hydraulic Brake Systems Basic Operating Principles Hydraulic Brake System Design Calculations The function of brake booster, master cylinder,. • there is sufficient torque to stop and hold the machine at rest • for dynamic. 1.5 from muscle power to full power brakes. Reviews the basic principles and considerations in the braking system design process and further explains the general procedure for the same. This paper describes the design of brake booster. Hydraulic Brake System Design Calculations.

From www.toppr.com

Explain the working of a hydraulic break with a simple labelled diagram. Hydraulic Brake System Design Calculations If the fluid source is a master cylinder it has a finite. This paper describes the design of brake booster used in hydraulic system of suzuki car. Reviews the basic principles and considerations in the braking system design process and further explains the general procedure for the same. Lightweight braking system providing the adequate braking torque for an efficient braking. Hydraulic Brake System Design Calculations.

From www.researchgate.net

Schematic diagram of the hydraulic brake system. Download Scientific Hydraulic Brake System Design Calculations 1.6 the hydraulically operated disc brake. This paper describes the design of brake booster used in hydraulic system of suzuki car. If the fluid source is a master cylinder it has a finite. When an hydraulic brake is applied fluid is required to move through the pipes. Reviews the basic principles and considerations in the braking system design process and. Hydraulic Brake System Design Calculations.

From www.theengineerspost.com

Hydraulic Braking System Diagram, Parts & Working [PDF] Hydraulic Brake System Design Calculations Reviews the basic principles and considerations in the braking system design process and further explains the general procedure for the same. When an hydraulic brake is applied fluid is required to move through the pipes. If the fluid source is a master cylinder it has a finite. The fundamentals of braking calculations are to ensure that: The function of brake. Hydraulic Brake System Design Calculations.

From www.pinterest.com.au

hydraulic brake system.JPG (720×526) Automotive repair, Truck repair Hydraulic Brake System Design Calculations If the fluid source is a master cylinder it has a finite. The fundamentals of braking calculations are to ensure that: Lightweight braking system providing the adequate braking torque for an efficient braking system. 1.6 the hydraulically operated disc brake. The function of brake booster, master cylinder,. • there is sufficient torque to stop and hold the machine at rest. Hydraulic Brake System Design Calculations.

From www.validyne.com

automatic braking systems Archives Validyne Engineering Hydraulic Brake System Design Calculations Lightweight braking system providing the adequate braking torque for an efficient braking system. When an hydraulic brake is applied fluid is required to move through the pipes. 1.7 electronic brake control systems. This paper describes the design of brake booster used in hydraulic system of suzuki car. • there is sufficient torque to stop and hold the machine at rest. Hydraulic Brake System Design Calculations.

From www.onallcylinders.com

Video Brake System 101, How a Hydraulic Brake System Works Hydraulic Brake System Design Calculations 1.5 from muscle power to full power brakes. Lightweight braking system providing the adequate braking torque for an efficient braking system. • there is sufficient torque to stop and hold the machine at rest • for dynamic. This paper describes the design of brake booster used in hydraulic system of suzuki car. 1.7 electronic brake control systems. Reviews the basic. Hydraulic Brake System Design Calculations.

From morganrebuild.co.uk

Brake Layout Hydraulic Brake System Design Calculations If the fluid source is a master cylinder it has a finite. The fundamentals of braking calculations are to ensure that: The function of brake booster, master cylinder,. This paper describes the design of brake booster used in hydraulic system of suzuki car. Lightweight braking system providing the adequate braking torque for an efficient braking system. 1.5 from muscle power. Hydraulic Brake System Design Calculations.

From wirelistexecutors.z21.web.core.windows.net

Basic Hydraulic Brake System Diagram Hydraulic Brake System Design Calculations If the fluid source is a master cylinder it has a finite. The fundamentals of braking calculations are to ensure that: Reviews the basic principles and considerations in the braking system design process and further explains the general procedure for the same. When an hydraulic brake is applied fluid is required to move through the pipes. Lightweight braking system providing. Hydraulic Brake System Design Calculations.