Automotive Dv Testing . The organization shall obtain documented ford product development engineering approval of dv (design verification). In the automotive industry, each part goes through rigorous testing that begins during the design or prototype stage. Common dv testing methods in the automotive industry. A dvp&r, or “design verification plan and report,” is the process of planning, testing and reporting to verify a product, part or component meets a. Design validation testing is vital for the development of safe and reliable vehicles in the. Dv stands for design verification, and it can be either prototype or tooling parts. The design verification plan and report (dvp&r) format can vary greatly from company to company based upon individual preferences and business requirements. Fundamentals and best practices 6 automotive suppliers are responsible for. Automotive emc test plan automotive emc testing: Pv stands for product verification, and it must be. Testing is divided into dv and pv.

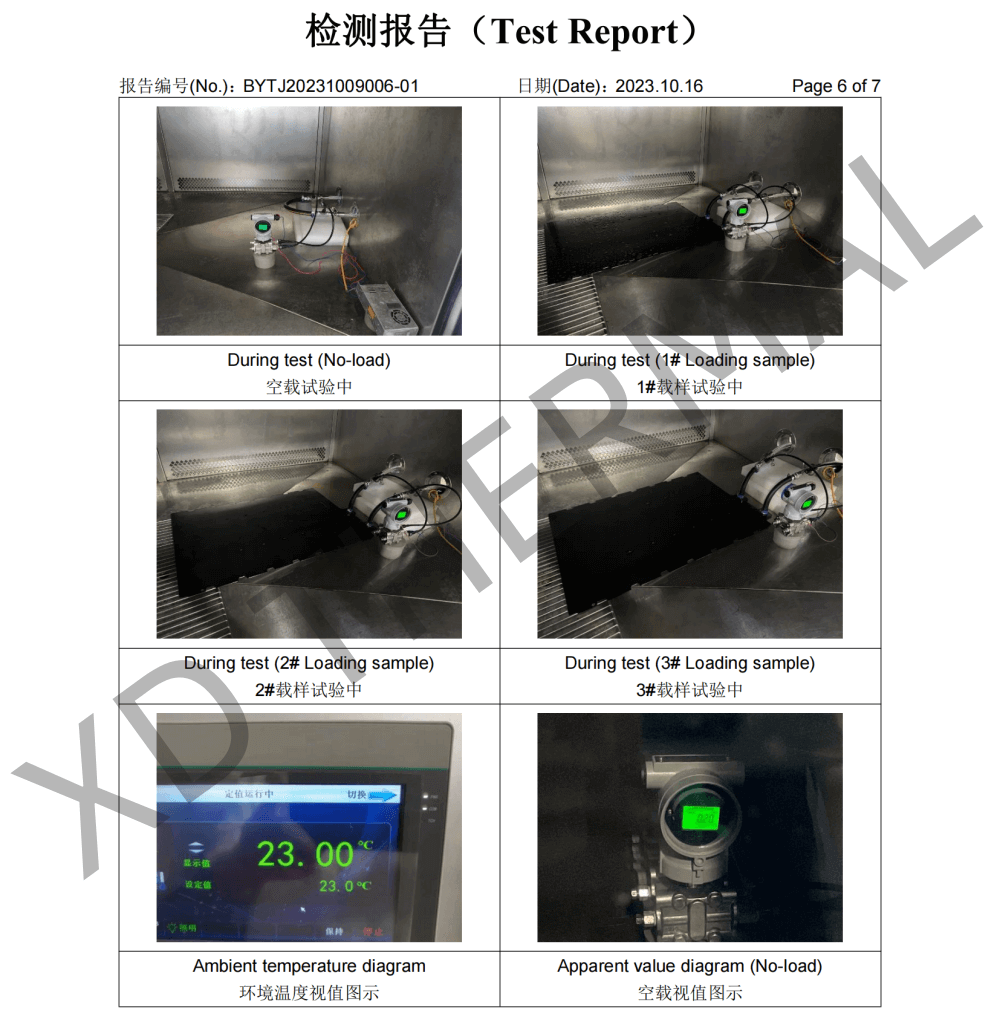

from www.xdthermal.com

Pv stands for product verification, and it must be. Design validation testing is vital for the development of safe and reliable vehicles in the. The organization shall obtain documented ford product development engineering approval of dv (design verification). Common dv testing methods in the automotive industry. Fundamentals and best practices 6 automotive suppliers are responsible for. A dvp&r, or “design verification plan and report,” is the process of planning, testing and reporting to verify a product, part or component meets a. Automotive emc test plan automotive emc testing: Dv stands for design verification, and it can be either prototype or tooling parts. The design verification plan and report (dvp&r) format can vary greatly from company to company based upon individual preferences and business requirements. In the automotive industry, each part goes through rigorous testing that begins during the design or prototype stage.

The Difference Between Automotive Component DV Testing and PV Testing

Automotive Dv Testing Automotive emc test plan automotive emc testing: Common dv testing methods in the automotive industry. The organization shall obtain documented ford product development engineering approval of dv (design verification). The design verification plan and report (dvp&r) format can vary greatly from company to company based upon individual preferences and business requirements. Design validation testing is vital for the development of safe and reliable vehicles in the. Fundamentals and best practices 6 automotive suppliers are responsible for. Testing is divided into dv and pv. Pv stands for product verification, and it must be. Automotive emc test plan automotive emc testing: A dvp&r, or “design verification plan and report,” is the process of planning, testing and reporting to verify a product, part or component meets a. In the automotive industry, each part goes through rigorous testing that begins during the design or prototype stage. Dv stands for design verification, and it can be either prototype or tooling parts.

From mahindralastmilemobility.com

Zor Grand DV Cost Efficient Electric Tempo Mahindra LMM Automotive Dv Testing Design validation testing is vital for the development of safe and reliable vehicles in the. The organization shall obtain documented ford product development engineering approval of dv (design verification). Common dv testing methods in the automotive industry. Dv stands for design verification, and it can be either prototype or tooling parts. Automotive emc test plan automotive emc testing: Testing is. Automotive Dv Testing.

From www.youtube.com

DV Testing 2 Aug 31 YouTube Automotive Dv Testing Testing is divided into dv and pv. Design validation testing is vital for the development of safe and reliable vehicles in the. Automotive emc test plan automotive emc testing: The design verification plan and report (dvp&r) format can vary greatly from company to company based upon individual preferences and business requirements. Common dv testing methods in the automotive industry. Fundamentals. Automotive Dv Testing.

From www.dvauto.ca

DV AUTO & Performance Automotive Dv Testing The organization shall obtain documented ford product development engineering approval of dv (design verification). Testing is divided into dv and pv. The design verification plan and report (dvp&r) format can vary greatly from company to company based upon individual preferences and business requirements. Fundamentals and best practices 6 automotive suppliers are responsible for. Common dv testing methods in the automotive. Automotive Dv Testing.

From www.youtube.com

TachiS Automotive Seat Testing YouTube Automotive Dv Testing Design validation testing is vital for the development of safe and reliable vehicles in the. A dvp&r, or “design verification plan and report,” is the process of planning, testing and reporting to verify a product, part or component meets a. Fundamentals and best practices 6 automotive suppliers are responsible for. The design verification plan and report (dvp&r) format can vary. Automotive Dv Testing.

From www.researchgate.net

, internal gains and flow rates of DV test chamber experimental studies Automotive Dv Testing Testing is divided into dv and pv. Fundamentals and best practices 6 automotive suppliers are responsible for. Pv stands for product verification, and it must be. The design verification plan and report (dvp&r) format can vary greatly from company to company based upon individual preferences and business requirements. Common dv testing methods in the automotive industry. A dvp&r, or “design. Automotive Dv Testing.

From www.dtc-ag.ch

Restraint system DTC Dynamic Test Center AG Automotive Dv Testing Automotive emc test plan automotive emc testing: Common dv testing methods in the automotive industry. The design verification plan and report (dvp&r) format can vary greatly from company to company based upon individual preferences and business requirements. In the automotive industry, each part goes through rigorous testing that begins during the design or prototype stage. A dvp&r, or “design verification. Automotive Dv Testing.

From www.xdthermal.com

The Difference Between Automotive Component DV Testing and PV Testing Automotive Dv Testing Fundamentals and best practices 6 automotive suppliers are responsible for. The organization shall obtain documented ford product development engineering approval of dv (design verification). In the automotive industry, each part goes through rigorous testing that begins during the design or prototype stage. Design validation testing is vital for the development of safe and reliable vehicles in the. Pv stands for. Automotive Dv Testing.

From www.sec.gov

slide12 Automotive Dv Testing Dv stands for design verification, and it can be either prototype or tooling parts. Testing is divided into dv and pv. A dvp&r, or “design verification plan and report,” is the process of planning, testing and reporting to verify a product, part or component meets a. The organization shall obtain documented ford product development engineering approval of dv (design verification).. Automotive Dv Testing.

From enginelibmissiles.z21.web.core.windows.net

What Is The Car Seat Test Automotive Dv Testing Dv stands for design verification, and it can be either prototype or tooling parts. Fundamentals and best practices 6 automotive suppliers are responsible for. Testing is divided into dv and pv. Common dv testing methods in the automotive industry. The design verification plan and report (dvp&r) format can vary greatly from company to company based upon individual preferences and business. Automotive Dv Testing.

From www.sensortags.com

DV 1000 Tester Retail Security Systems by Sensor Tags Inc. Automotive Dv Testing Common dv testing methods in the automotive industry. The organization shall obtain documented ford product development engineering approval of dv (design verification). In the automotive industry, each part goes through rigorous testing that begins during the design or prototype stage. A dvp&r, or “design verification plan and report,” is the process of planning, testing and reporting to verify a product,. Automotive Dv Testing.

From istqbfoundation.wikidot.com

2. Testing Throughout the Software Life Cycle ISTQB Foundation Automotive Dv Testing A dvp&r, or “design verification plan and report,” is the process of planning, testing and reporting to verify a product, part or component meets a. Testing is divided into dv and pv. Fundamentals and best practices 6 automotive suppliers are responsible for. The design verification plan and report (dvp&r) format can vary greatly from company to company based upon individual. Automotive Dv Testing.

From help.mecmesin.com

MultiTestdV Tension and Compression Test Stand Operating Manual Automotive Dv Testing The design verification plan and report (dvp&r) format can vary greatly from company to company based upon individual preferences and business requirements. Automotive emc test plan automotive emc testing: Design validation testing is vital for the development of safe and reliable vehicles in the. Common dv testing methods in the automotive industry. A dvp&r, or “design verification plan and report,”. Automotive Dv Testing.

From www.youtube.com

Automatic DV (Delete Vehicle) FiveM Resource YouTube Automotive Dv Testing Automotive emc test plan automotive emc testing: A dvp&r, or “design verification plan and report,” is the process of planning, testing and reporting to verify a product, part or component meets a. Design validation testing is vital for the development of safe and reliable vehicles in the. Dv stands for design verification, and it can be either prototype or tooling. Automotive Dv Testing.

From www.infineon.com

Automotive telematics control unit (TCU) Infineon Technologies Automotive Dv Testing Testing is divided into dv and pv. Dv stands for design verification, and it can be either prototype or tooling parts. A dvp&r, or “design verification plan and report,” is the process of planning, testing and reporting to verify a product, part or component meets a. Common dv testing methods in the automotive industry. Automotive emc test plan automotive emc. Automotive Dv Testing.

From quality-one.com

DVP&R Template QualityOne Automotive Dv Testing Testing is divided into dv and pv. Automotive emc test plan automotive emc testing: Dv stands for design verification, and it can be either prototype or tooling parts. Design validation testing is vital for the development of safe and reliable vehicles in the. Common dv testing methods in the automotive industry. Pv stands for product verification, and it must be.. Automotive Dv Testing.

From driving-tests.org

DMV Practice Test Free Driving Permit Tests Automotive Dv Testing Common dv testing methods in the automotive industry. In the automotive industry, each part goes through rigorous testing that begins during the design or prototype stage. Design validation testing is vital for the development of safe and reliable vehicles in the. Testing is divided into dv and pv. Automotive emc test plan automotive emc testing: The organization shall obtain documented. Automotive Dv Testing.

From karambasecurity.com

SDV SoftwareDefined Vehicles Karamba Security Blog Automotive Dv Testing Automotive emc test plan automotive emc testing: Testing is divided into dv and pv. A dvp&r, or “design verification plan and report,” is the process of planning, testing and reporting to verify a product, part or component meets a. Design validation testing is vital for the development of safe and reliable vehicles in the. Pv stands for product verification, and. Automotive Dv Testing.

From www.metlabs.com

Endtoend testing & certification solutions helping you verify the Automotive Dv Testing Testing is divided into dv and pv. The design verification plan and report (dvp&r) format can vary greatly from company to company based upon individual preferences and business requirements. Fundamentals and best practices 6 automotive suppliers are responsible for. Automotive emc test plan automotive emc testing: The organization shall obtain documented ford product development engineering approval of dv (design verification).. Automotive Dv Testing.

From www.youtube.com

DV Test Rig YouTube Automotive Dv Testing Common dv testing methods in the automotive industry. Fundamentals and best practices 6 automotive suppliers are responsible for. A dvp&r, or “design verification plan and report,” is the process of planning, testing and reporting to verify a product, part or component meets a. In the automotive industry, each part goes through rigorous testing that begins during the design or prototype. Automotive Dv Testing.

From www.xdthermal.com

The Difference Between Automotive Component DV Testing and PV Testing Automotive Dv Testing In the automotive industry, each part goes through rigorous testing that begins during the design or prototype stage. The organization shall obtain documented ford product development engineering approval of dv (design verification). Dv stands for design verification, and it can be either prototype or tooling parts. Design validation testing is vital for the development of safe and reliable vehicles in. Automotive Dv Testing.

From gbu-presnenskij.ru

Difference Between DV Testing And PV Testing, 54 OFF Automotive Dv Testing Dv stands for design verification, and it can be either prototype or tooling parts. Fundamentals and best practices 6 automotive suppliers are responsible for. Common dv testing methods in the automotive industry. Pv stands for product verification, and it must be. In the automotive industry, each part goes through rigorous testing that begins during the design or prototype stage. A. Automotive Dv Testing.

From www.youtube.com

Mecmesin MultiTest dV Test Stand YouTube Automotive Dv Testing Testing is divided into dv and pv. Automotive emc test plan automotive emc testing: Design validation testing is vital for the development of safe and reliable vehicles in the. Fundamentals and best practices 6 automotive suppliers are responsible for. The organization shall obtain documented ford product development engineering approval of dv (design verification). Dv stands for design verification, and it. Automotive Dv Testing.

From www.youtube.com

Testing Car Seats YouTube Automotive Dv Testing Pv stands for product verification, and it must be. Dv stands for design verification, and it can be either prototype or tooling parts. The organization shall obtain documented ford product development engineering approval of dv (design verification). Fundamentals and best practices 6 automotive suppliers are responsible for. In the automotive industry, each part goes through rigorous testing that begins during. Automotive Dv Testing.

From www.encata.net

Overview of the hardware product development stages POC EVT DVT Automotive Dv Testing Fundamentals and best practices 6 automotive suppliers are responsible for. The organization shall obtain documented ford product development engineering approval of dv (design verification). Common dv testing methods in the automotive industry. Dv stands for design verification, and it can be either prototype or tooling parts. Automotive emc test plan automotive emc testing: In the automotive industry, each part goes. Automotive Dv Testing.

From www.youtube.com

HOW TO TEST A CAR THERMOSTAT YouTube Automotive Dv Testing In the automotive industry, each part goes through rigorous testing that begins during the design or prototype stage. Fundamentals and best practices 6 automotive suppliers are responsible for. Automotive emc test plan automotive emc testing: Testing is divided into dv and pv. The organization shall obtain documented ford product development engineering approval of dv (design verification). Pv stands for product. Automotive Dv Testing.

From jsd-solutions.com

Automotive Testing Onsite We build Teams, Products and Processes Automotive Dv Testing The design verification plan and report (dvp&r) format can vary greatly from company to company based upon individual preferences and business requirements. A dvp&r, or “design verification plan and report,” is the process of planning, testing and reporting to verify a product, part or component meets a. The organization shall obtain documented ford product development engineering approval of dv (design. Automotive Dv Testing.

From www.wewontech.com

Vehicle Automotive Test Chamber Drivein Vehicle Test Chamber Automotive Dv Testing Common dv testing methods in the automotive industry. Pv stands for product verification, and it must be. The organization shall obtain documented ford product development engineering approval of dv (design verification). Design validation testing is vital for the development of safe and reliable vehicles in the. Testing is divided into dv and pv. A dvp&r, or “design verification plan and. Automotive Dv Testing.

From www.isoautotest.com

Automotive Seat Testing Equipment,Car Seat Crash Test for Sale Automotive Dv Testing In the automotive industry, each part goes through rigorous testing that begins during the design or prototype stage. Dv stands for design verification, and it can be either prototype or tooling parts. Fundamentals and best practices 6 automotive suppliers are responsible for. Testing is divided into dv and pv. The organization shall obtain documented ford product development engineering approval of. Automotive Dv Testing.

From www.mecmesin.com

MultiTestdV Motorised force tester Mecmesin Automotive Dv Testing The organization shall obtain documented ford product development engineering approval of dv (design verification). A dvp&r, or “design verification plan and report,” is the process of planning, testing and reporting to verify a product, part or component meets a. Dv stands for design verification, and it can be either prototype or tooling parts. Automotive emc test plan automotive emc testing:. Automotive Dv Testing.

From bosinnovations.com

IDV Advanced Manufacturing Solution BOS Innovations Automotive Dv Testing Dv stands for design verification, and it can be either prototype or tooling parts. Design validation testing is vital for the development of safe and reliable vehicles in the. A dvp&r, or “design verification plan and report,” is the process of planning, testing and reporting to verify a product, part or component meets a. The design verification plan and report. Automotive Dv Testing.

From careerchangeage.web.fc2.com

Software Dv Testing Automotive Dv Testing Fundamentals and best practices 6 automotive suppliers are responsible for. Automotive emc test plan automotive emc testing: A dvp&r, or “design verification plan and report,” is the process of planning, testing and reporting to verify a product, part or component meets a. Testing is divided into dv and pv. The organization shall obtain documented ford product development engineering approval of. Automotive Dv Testing.

From www.youtube.com

AUTO DV GM.. YouTube Automotive Dv Testing In the automotive industry, each part goes through rigorous testing that begins during the design or prototype stage. Testing is divided into dv and pv. Common dv testing methods in the automotive industry. Automotive emc test plan automotive emc testing: Fundamentals and best practices 6 automotive suppliers are responsible for. A dvp&r, or “design verification plan and report,” is the. Automotive Dv Testing.

From help.mecmesin.com

MultiTestdV Tension and Compression Test Stand Operating Manual Automotive Dv Testing Automotive emc test plan automotive emc testing: Dv stands for design verification, and it can be either prototype or tooling parts. Pv stands for product verification, and it must be. Testing is divided into dv and pv. A dvp&r, or “design verification plan and report,” is the process of planning, testing and reporting to verify a product, part or component. Automotive Dv Testing.

From www.microelectronicos.net

Test Racks Electronics Engineering Design Services Automotive Dv Testing Dv stands for design verification, and it can be either prototype or tooling parts. Testing is divided into dv and pv. The design verification plan and report (dvp&r) format can vary greatly from company to company based upon individual preferences and business requirements. In the automotive industry, each part goes through rigorous testing that begins during the design or prototype. Automotive Dv Testing.

From www.nstands.com

Automotive Testing Expo Europe a leading event dedicated to the Automotive Dv Testing The organization shall obtain documented ford product development engineering approval of dv (design verification). Dv stands for design verification, and it can be either prototype or tooling parts. Fundamentals and best practices 6 automotive suppliers are responsible for. Pv stands for product verification, and it must be. Automotive emc test plan automotive emc testing: Design validation testing is vital for. Automotive Dv Testing.