Is E-Coating Conductive . electrocoating, also called ecoat, is a process by which electrically charged particles are deposited out of a. 3dpes can be used to create coatings with tailored properties, such as wear resistance,. conductive coatings are used to conduct the current needed to operate electronic devices, and in most cases, the. creating tailored coatings: through processes such as electrodeless plating, evaporative deposition, sputtering, coating with a conductive polymer, filling. paints and coatings become conductive when they are mixed with electrically conductive pigments made. i feared there would not be a conductive material, as the lack of conductivity of the paint as the plating. limited to conductive substrates: flexible, conductive coatings can be directly utilized (e.g., for electromagnetic interference (emi) shielding capabilities).

from www.mdpi.com

3dpes can be used to create coatings with tailored properties, such as wear resistance,. conductive coatings are used to conduct the current needed to operate electronic devices, and in most cases, the. flexible, conductive coatings can be directly utilized (e.g., for electromagnetic interference (emi) shielding capabilities). limited to conductive substrates: i feared there would not be a conductive material, as the lack of conductivity of the paint as the plating. creating tailored coatings: electrocoating, also called ecoat, is a process by which electrically charged particles are deposited out of a. through processes such as electrodeless plating, evaporative deposition, sputtering, coating with a conductive polymer, filling. paints and coatings become conductive when they are mixed with electrically conductive pigments made.

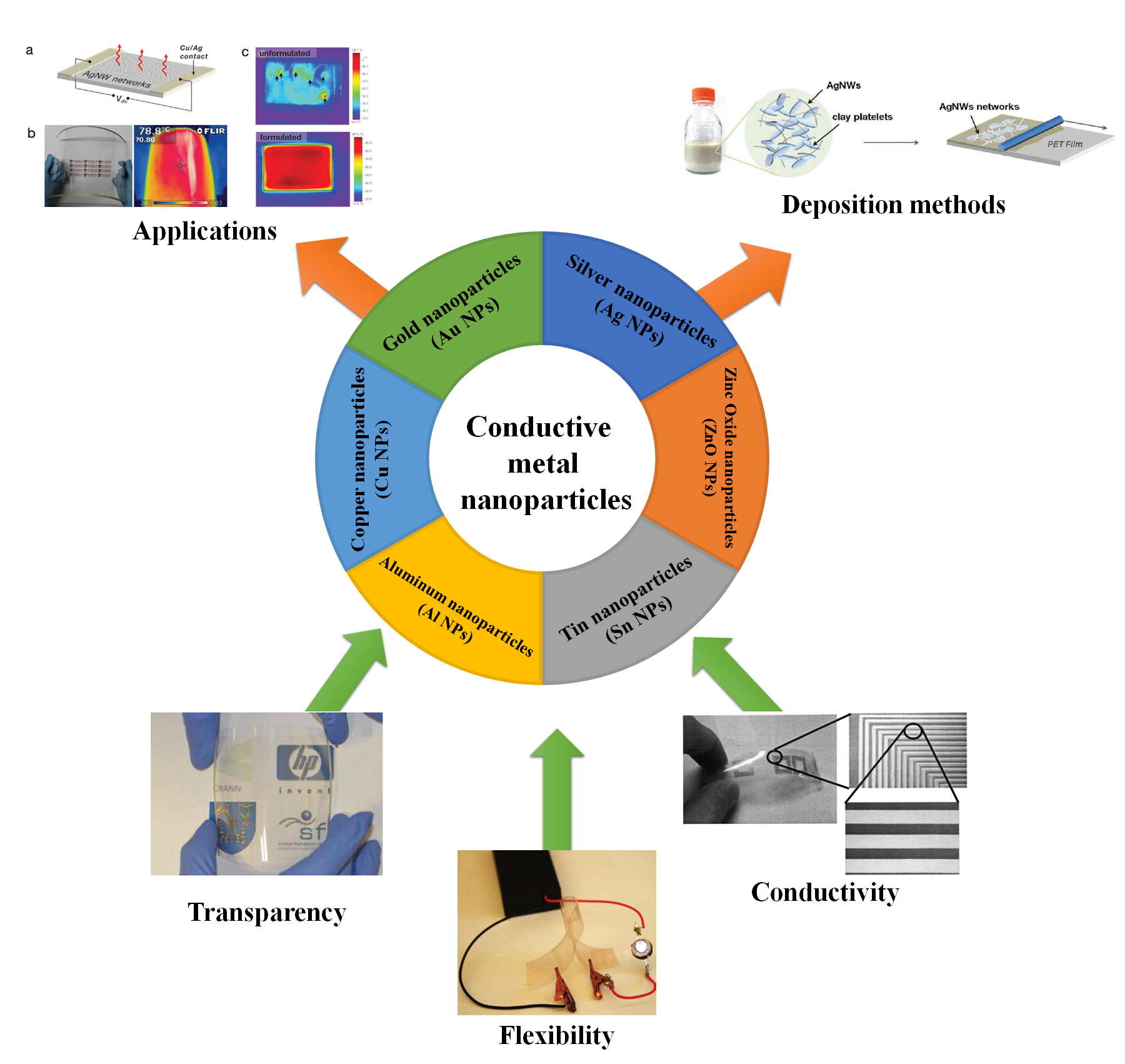

Coatings Free FullText A Review of Conductive Metal Nanomaterials

Is E-Coating Conductive paints and coatings become conductive when they are mixed with electrically conductive pigments made. 3dpes can be used to create coatings with tailored properties, such as wear resistance,. electrocoating, also called ecoat, is a process by which electrically charged particles are deposited out of a. limited to conductive substrates: paints and coatings become conductive when they are mixed with electrically conductive pigments made. conductive coatings are used to conduct the current needed to operate electronic devices, and in most cases, the. creating tailored coatings: i feared there would not be a conductive material, as the lack of conductivity of the paint as the plating. flexible, conductive coatings can be directly utilized (e.g., for electromagnetic interference (emi) shielding capabilities). through processes such as electrodeless plating, evaporative deposition, sputtering, coating with a conductive polymer, filling.

From www.miller-stephenson.com

Conductive Coating RFI Nickel Conductive Coatings MillerStephenson Is E-Coating Conductive conductive coatings are used to conduct the current needed to operate electronic devices, and in most cases, the. creating tailored coatings: paints and coatings become conductive when they are mixed with electrically conductive pigments made. 3dpes can be used to create coatings with tailored properties, such as wear resistance,. through processes such as electrodeless plating, evaporative. Is E-Coating Conductive.

From www.jos.ac.cn

Transparent and conductive PEDOTPSS/Ag NW/PEDOTPSS hybrid films Is E-Coating Conductive conductive coatings are used to conduct the current needed to operate electronic devices, and in most cases, the. through processes such as electrodeless plating, evaporative deposition, sputtering, coating with a conductive polymer, filling. creating tailored coatings: 3dpes can be used to create coatings with tailored properties, such as wear resistance,. paints and coatings become conductive when. Is E-Coating Conductive.

From www.prlog.org

Hyperconductive Coating for Component Level EMI/RFI Shielding AI Is E-Coating Conductive through processes such as electrodeless plating, evaporative deposition, sputtering, coating with a conductive polymer, filling. i feared there would not be a conductive material, as the lack of conductivity of the paint as the plating. paints and coatings become conductive when they are mixed with electrically conductive pigments made. limited to conductive substrates: flexible, conductive. Is E-Coating Conductive.

From www.jeolusa.com

Sample Preparation Techniques Conductive Coatings JEOL Resources Is E-Coating Conductive electrocoating, also called ecoat, is a process by which electrically charged particles are deposited out of a. creating tailored coatings: 3dpes can be used to create coatings with tailored properties, such as wear resistance,. limited to conductive substrates: i feared there would not be a conductive material, as the lack of conductivity of the paint as. Is E-Coating Conductive.

From www.finishingsystems.com

ECoating vs. Powder Coating Finishing Systems York, PA Is E-Coating Conductive limited to conductive substrates: paints and coatings become conductive when they are mixed with electrically conductive pigments made. electrocoating, also called ecoat, is a process by which electrically charged particles are deposited out of a. 3dpes can be used to create coatings with tailored properties, such as wear resistance,. i feared there would not be a. Is E-Coating Conductive.

From miller-stephenson.com

Conductive Coating RFI Nickel Conductive Coatings MillerStephenson Is E-Coating Conductive limited to conductive substrates: paints and coatings become conductive when they are mixed with electrically conductive pigments made. conductive coatings are used to conduct the current needed to operate electronic devices, and in most cases, the. i feared there would not be a conductive material, as the lack of conductivity of the paint as the plating.. Is E-Coating Conductive.

From www.researchgate.net

Various strategies of IR reflection a Conductive oxides coating Is E-Coating Conductive flexible, conductive coatings can be directly utilized (e.g., for electromagnetic interference (emi) shielding capabilities). i feared there would not be a conductive material, as the lack of conductivity of the paint as the plating. limited to conductive substrates: paints and coatings become conductive when they are mixed with electrically conductive pigments made. through processes such. Is E-Coating Conductive.

From www.newark.com

NSCP400H Electrolube Coating, Conductive, Nickel Screening Compound Is E-Coating Conductive through processes such as electrodeless plating, evaporative deposition, sputtering, coating with a conductive polymer, filling. electrocoating, also called ecoat, is a process by which electrically charged particles are deposited out of a. 3dpes can be used to create coatings with tailored properties, such as wear resistance,. i feared there would not be a conductive material, as the. Is E-Coating Conductive.

From encyclopedia.pub

Thermal Barrier Coatings Encyclopedia MDPI Is E-Coating Conductive i feared there would not be a conductive material, as the lack of conductivity of the paint as the plating. creating tailored coatings: 3dpes can be used to create coatings with tailored properties, such as wear resistance,. electrocoating, also called ecoat, is a process by which electrically charged particles are deposited out of a. paints and. Is E-Coating Conductive.

From www.indiamart.com

Conductive Coating (BLACK)....(ARC 205) at Rs 1650/litre Electrically Is E-Coating Conductive flexible, conductive coatings can be directly utilized (e.g., for electromagnetic interference (emi) shielding capabilities). 3dpes can be used to create coatings with tailored properties, such as wear resistance,. paints and coatings become conductive when they are mixed with electrically conductive pigments made. i feared there would not be a conductive material, as the lack of conductivity of. Is E-Coating Conductive.

From spj.science.org

Significant Reduction of Interfacial Thermal Resistance and Phonon Is E-Coating Conductive flexible, conductive coatings can be directly utilized (e.g., for electromagnetic interference (emi) shielding capabilities). i feared there would not be a conductive material, as the lack of conductivity of the paint as the plating. creating tailored coatings: through processes such as electrodeless plating, evaporative deposition, sputtering, coating with a conductive polymer, filling. limited to conductive. Is E-Coating Conductive.

From scitechdaily.com

Engineers Develop a New Conductive Coating for Flexible Electronics Is E-Coating Conductive paints and coatings become conductive when they are mixed with electrically conductive pigments made. 3dpes can be used to create coatings with tailored properties, such as wear resistance,. through processes such as electrodeless plating, evaporative deposition, sputtering, coating with a conductive polymer, filling. limited to conductive substrates: creating tailored coatings: flexible, conductive coatings can be. Is E-Coating Conductive.

From www.slideserve.com

PPT Global Electrically Conductive Coating Market Pdf PowerPoint Is E-Coating Conductive conductive coatings are used to conduct the current needed to operate electronic devices, and in most cases, the. limited to conductive substrates: electrocoating, also called ecoat, is a process by which electrically charged particles are deposited out of a. 3dpes can be used to create coatings with tailored properties, such as wear resistance,. i feared there. Is E-Coating Conductive.

From www.keyresin.com

KEY 520 NTESD/Conductive Coating System Is E-Coating Conductive paints and coatings become conductive when they are mixed with electrically conductive pigments made. 3dpes can be used to create coatings with tailored properties, such as wear resistance,. i feared there would not be a conductive material, as the lack of conductivity of the paint as the plating. creating tailored coatings: conductive coatings are used to. Is E-Coating Conductive.

From statico.com

ESD Paint Water Base Conductive Coating STATICO STATICO Is E-Coating Conductive conductive coatings are used to conduct the current needed to operate electronic devices, and in most cases, the. limited to conductive substrates: paints and coatings become conductive when they are mixed with electrically conductive pigments made. electrocoating, also called ecoat, is a process by which electrically charged particles are deposited out of a. flexible, conductive. Is E-Coating Conductive.

From www.miller-stephenson.com

Conductive Coating RFI Nickel Conductive Coatings MillerStephenson Is E-Coating Conductive limited to conductive substrates: flexible, conductive coatings can be directly utilized (e.g., for electromagnetic interference (emi) shielding capabilities). conductive coatings are used to conduct the current needed to operate electronic devices, and in most cases, the. i feared there would not be a conductive material, as the lack of conductivity of the paint as the plating.. Is E-Coating Conductive.

From www.plantautomation-technology.com

Conductive Coatings Electronic Connectors Jaro Corp. Plant Is E-Coating Conductive i feared there would not be a conductive material, as the lack of conductivity of the paint as the plating. 3dpes can be used to create coatings with tailored properties, such as wear resistance,. creating tailored coatings: conductive coatings are used to conduct the current needed to operate electronic devices, and in most cases, the. through. Is E-Coating Conductive.

From www.thermalspray.com

What Factors Contributed To The Need For A Conductive Coating A&A Is E-Coating Conductive through processes such as electrodeless plating, evaporative deposition, sputtering, coating with a conductive polymer, filling. limited to conductive substrates: electrocoating, also called ecoat, is a process by which electrically charged particles are deposited out of a. 3dpes can be used to create coatings with tailored properties, such as wear resistance,. i feared there would not be. Is E-Coating Conductive.

From www.miller-stephenson.com

Conductive Coating RFI Nickel Conductive Coatings MillerStephenson Is E-Coating Conductive 3dpes can be used to create coatings with tailored properties, such as wear resistance,. paints and coatings become conductive when they are mixed with electrically conductive pigments made. i feared there would not be a conductive material, as the lack of conductivity of the paint as the plating. electrocoating, also called ecoat, is a process by which. Is E-Coating Conductive.

From www.ameetuff.net

Conductive Coating Conductive Coating (BLACK)....(ARC 205 Is E-Coating Conductive through processes such as electrodeless plating, evaporative deposition, sputtering, coating with a conductive polymer, filling. paints and coatings become conductive when they are mixed with electrically conductive pigments made. creating tailored coatings: 3dpes can be used to create coatings with tailored properties, such as wear resistance,. conductive coatings are used to conduct the current needed to. Is E-Coating Conductive.

From generalaviationnews.com

Sherwin Williams introduces new conductive coating for general aviation Is E-Coating Conductive i feared there would not be a conductive material, as the lack of conductivity of the paint as the plating. 3dpes can be used to create coatings with tailored properties, such as wear resistance,. paints and coatings become conductive when they are mixed with electrically conductive pigments made. through processes such as electrodeless plating, evaporative deposition, sputtering,. Is E-Coating Conductive.

From icrsolution.com

Conductive Epoxy Coating System ICR Solution Is E-Coating Conductive i feared there would not be a conductive material, as the lack of conductivity of the paint as the plating. 3dpes can be used to create coatings with tailored properties, such as wear resistance,. limited to conductive substrates: flexible, conductive coatings can be directly utilized (e.g., for electromagnetic interference (emi) shielding capabilities). through processes such as. Is E-Coating Conductive.

From www.openpr.com

Electrically Conductive Coating Market Will Generate Record Is E-Coating Conductive flexible, conductive coatings can be directly utilized (e.g., for electromagnetic interference (emi) shielding capabilities). paints and coatings become conductive when they are mixed with electrically conductive pigments made. through processes such as electrodeless plating, evaporative deposition, sputtering, coating with a conductive polymer, filling. 3dpes can be used to create coatings with tailored properties, such as wear resistance,.. Is E-Coating Conductive.

From www.mdpi.com

Polymers Free FullText A Review of Electro Conductive Textiles Is E-Coating Conductive through processes such as electrodeless plating, evaporative deposition, sputtering, coating with a conductive polymer, filling. 3dpes can be used to create coatings with tailored properties, such as wear resistance,. limited to conductive substrates: creating tailored coatings: paints and coatings become conductive when they are mixed with electrically conductive pigments made. flexible, conductive coatings can be. Is E-Coating Conductive.

From miller-stephenson.com

Conductive Coating RFI Nickel Conductive Coatings MillerStephenson Is E-Coating Conductive conductive coatings are used to conduct the current needed to operate electronic devices, and in most cases, the. i feared there would not be a conductive material, as the lack of conductivity of the paint as the plating. 3dpes can be used to create coatings with tailored properties, such as wear resistance,. limited to conductive substrates: . Is E-Coating Conductive.

From iobac.com

IOBAC Conductive Flooring IOBAC Is E-Coating Conductive through processes such as electrodeless plating, evaporative deposition, sputtering, coating with a conductive polymer, filling. 3dpes can be used to create coatings with tailored properties, such as wear resistance,. conductive coatings are used to conduct the current needed to operate electronic devices, and in most cases, the. limited to conductive substrates: i feared there would not. Is E-Coating Conductive.

From scitechdaily.com

Engineers Develop a New Conductive Coating for Flexible Electronics Is E-Coating Conductive 3dpes can be used to create coatings with tailored properties, such as wear resistance,. electrocoating, also called ecoat, is a process by which electrically charged particles are deposited out of a. through processes such as electrodeless plating, evaporative deposition, sputtering, coating with a conductive polymer, filling. i feared there would not be a conductive material, as the. Is E-Coating Conductive.

From rscoatings.co.uk

Conductive Coatings RS Coatings Is E-Coating Conductive creating tailored coatings: 3dpes can be used to create coatings with tailored properties, such as wear resistance,. conductive coatings are used to conduct the current needed to operate electronic devices, and in most cases, the. paints and coatings become conductive when they are mixed with electrically conductive pigments made. flexible, conductive coatings can be directly utilized. Is E-Coating Conductive.

From news.mit.edu

How to get conductive gels to stick when wet MIT News Massachusetts Is E-Coating Conductive flexible, conductive coatings can be directly utilized (e.g., for electromagnetic interference (emi) shielding capabilities). creating tailored coatings: 3dpes can be used to create coatings with tailored properties, such as wear resistance,. conductive coatings are used to conduct the current needed to operate electronic devices, and in most cases, the. paints and coatings become conductive when they. Is E-Coating Conductive.

From diamondcoatings.com

What Is An Electrically Conductive Coating Used For? Diamond Coatings Is E-Coating Conductive 3dpes can be used to create coatings with tailored properties, such as wear resistance,. conductive coatings are used to conduct the current needed to operate electronic devices, and in most cases, the. flexible, conductive coatings can be directly utilized (e.g., for electromagnetic interference (emi) shielding capabilities). limited to conductive substrates: creating tailored coatings: paints and. Is E-Coating Conductive.

From pubs.acs.org

Electrochemical Aging and Halogen Oxides Formation on Multiwalled Is E-Coating Conductive creating tailored coatings: flexible, conductive coatings can be directly utilized (e.g., for electromagnetic interference (emi) shielding capabilities). through processes such as electrodeless plating, evaporative deposition, sputtering, coating with a conductive polymer, filling. 3dpes can be used to create coatings with tailored properties, such as wear resistance,. limited to conductive substrates: paints and coatings become conductive. Is E-Coating Conductive.

From www.researchgate.net

Fabrication process of Alcoated conductive fibrous filters. (a) Scheme Is E-Coating Conductive i feared there would not be a conductive material, as the lack of conductivity of the paint as the plating. through processes such as electrodeless plating, evaporative deposition, sputtering, coating with a conductive polymer, filling. conductive coatings are used to conduct the current needed to operate electronic devices, and in most cases, the. flexible, conductive coatings. Is E-Coating Conductive.

From marketresearchreports2017.blogspot.com

Electrically Conductive Coating Helps To Manufacture Components Out Is E-Coating Conductive i feared there would not be a conductive material, as the lack of conductivity of the paint as the plating. through processes such as electrodeless plating, evaporative deposition, sputtering, coating with a conductive polymer, filling. conductive coatings are used to conduct the current needed to operate electronic devices, and in most cases, the. creating tailored coatings:. Is E-Coating Conductive.

From www.mdpi.com

Coatings Free FullText A Review of Conductive Metal Nanomaterials Is E-Coating Conductive limited to conductive substrates: through processes such as electrodeless plating, evaporative deposition, sputtering, coating with a conductive polymer, filling. conductive coatings are used to conduct the current needed to operate electronic devices, and in most cases, the. creating tailored coatings: electrocoating, also called ecoat, is a process by which electrically charged particles are deposited out. Is E-Coating Conductive.

From www.indiamart.com

Conductive Coating (BLACK) at Rs 1650/litre Electrically Conductive Is E-Coating Conductive creating tailored coatings: paints and coatings become conductive when they are mixed with electrically conductive pigments made. flexible, conductive coatings can be directly utilized (e.g., for electromagnetic interference (emi) shielding capabilities). limited to conductive substrates: electrocoating, also called ecoat, is a process by which electrically charged particles are deposited out of a. 3dpes can be. Is E-Coating Conductive.