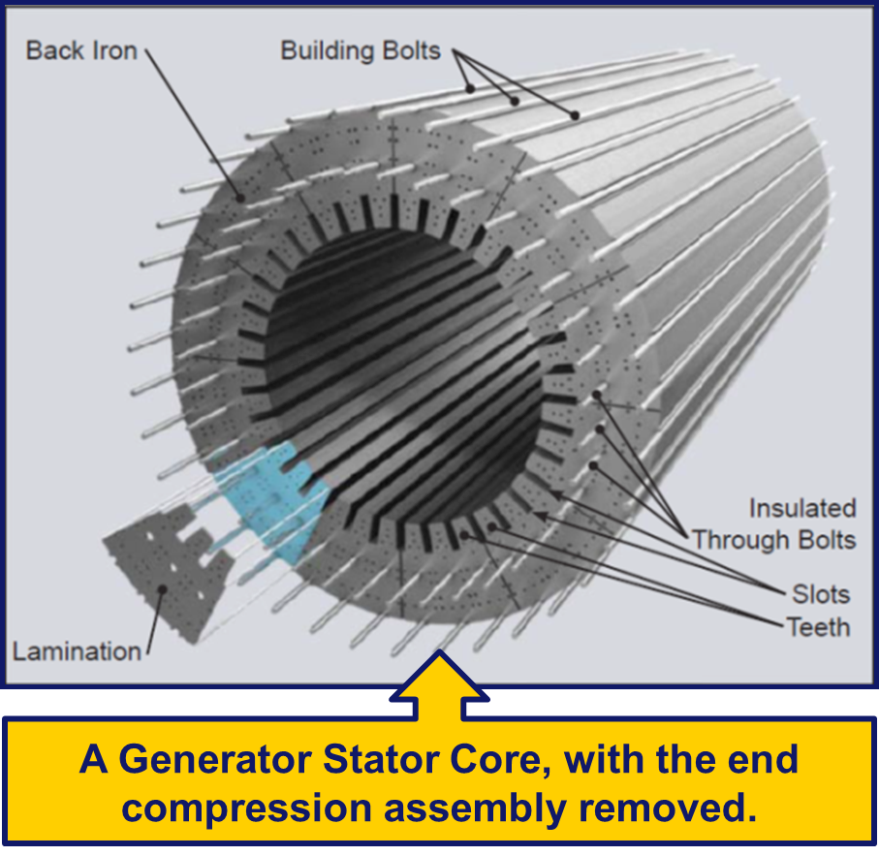

How Does Stator Core Work . Explore the fundamentals, advancements, and applications of stators in modern engineering. The main function of this core is to hold the irregular magnetic field which generates losses like eddy current & hysteresis. In motors, the stator creates a rotating magnetic field that interacts with the rotor, inducting current and generating electromagnetic forces that drive rotation. The stator produces the magnetic field that interacts with the rotor to produce movement, while the rotor rotates in response to this magnetic field. The stator of an electric motor is the core component consisting of a laminated iron core and windings. The stator core is pressed with the upper pressure ring installed to give the sheet pressure specified. The hollow portion of the iron core is used to house the stator windings. A stator is the stationary part of an electric motor or generator, consisting of coils or windings mounted on an iron core, designed to create a magnetic field when electric current flows through it. Stator mainly works based on a spinning electromotive device configuration like the field magnet or the armature. The field magnet is used to communicate with the armature to produce motion whereas the armature gets its influence from moving field coils on the rotor. The pressure ring is then locked. The stator iron core is typically made of silicon steel sheets to reduce magnetic and iron losses. Understanding how these components work together is crucial for understanding how electric motors function and how they can be controlled.

from www.powerservicesgroup.com

The stator of an electric motor is the core component consisting of a laminated iron core and windings. The hollow portion of the iron core is used to house the stator windings. The pressure ring is then locked. The field magnet is used to communicate with the armature to produce motion whereas the armature gets its influence from moving field coils on the rotor. Stator mainly works based on a spinning electromotive device configuration like the field magnet or the armature. A stator is the stationary part of an electric motor or generator, consisting of coils or windings mounted on an iron core, designed to create a magnetic field when electric current flows through it. The stator iron core is typically made of silicon steel sheets to reduce magnetic and iron losses. In motors, the stator creates a rotating magnetic field that interacts with the rotor, inducting current and generating electromagnetic forces that drive rotation. The stator produces the magnetic field that interacts with the rotor to produce movement, while the rotor rotates in response to this magnetic field. The main function of this core is to hold the irregular magnetic field which generates losses like eddy current & hysteresis.

Why is a Stator Core Made of Laminated Steel? Power Services Group

How Does Stator Core Work Explore the fundamentals, advancements, and applications of stators in modern engineering. The field magnet is used to communicate with the armature to produce motion whereas the armature gets its influence from moving field coils on the rotor. The hollow portion of the iron core is used to house the stator windings. The pressure ring is then locked. Understanding how these components work together is crucial for understanding how electric motors function and how they can be controlled. A stator is the stationary part of an electric motor or generator, consisting of coils or windings mounted on an iron core, designed to create a magnetic field when electric current flows through it. The stator iron core is typically made of silicon steel sheets to reduce magnetic and iron losses. The stator of an electric motor is the core component consisting of a laminated iron core and windings. Stator mainly works based on a spinning electromotive device configuration like the field magnet or the armature. In motors, the stator creates a rotating magnetic field that interacts with the rotor, inducting current and generating electromagnetic forces that drive rotation. The stator core is pressed with the upper pressure ring installed to give the sheet pressure specified. Explore the fundamentals, advancements, and applications of stators in modern engineering. The main function of this core is to hold the irregular magnetic field which generates losses like eddy current & hysteresis. The stator produces the magnetic field that interacts with the rotor to produce movement, while the rotor rotates in response to this magnetic field.

From www.iqsdirectory.com

DC Motor What Is It? How Does It Work? Types, Uses How Does Stator Core Work A stator is the stationary part of an electric motor or generator, consisting of coils or windings mounted on an iron core, designed to create a magnetic field when electric current flows through it. The stator of an electric motor is the core component consisting of a laminated iron core and windings. The main function of this core is to. How Does Stator Core Work.

From www.powerservicesgroup.com

Why is a Stator Core Made of Laminated Steel? Power Services Group How Does Stator Core Work The stator produces the magnetic field that interacts with the rotor to produce movement, while the rotor rotates in response to this magnetic field. The stator core is pressed with the upper pressure ring installed to give the sheet pressure specified. The hollow portion of the iron core is used to house the stator windings. In motors, the stator creates. How Does Stator Core Work.

From www.vionamag.com

How are used in Stators Viona How Does Stator Core Work In motors, the stator creates a rotating magnetic field that interacts with the rotor, inducting current and generating electromagnetic forces that drive rotation. The stator core is pressed with the upper pressure ring installed to give the sheet pressure specified. The main function of this core is to hold the irregular magnetic field which generates losses like eddy current &. How Does Stator Core Work.

From www.beingwrongbook.com

What is a Stator? How does it work? How Does Stator Core Work The hollow portion of the iron core is used to house the stator windings. The stator of an electric motor is the core component consisting of a laminated iron core and windings. The stator produces the magnetic field that interacts with the rotor to produce movement, while the rotor rotates in response to this magnetic field. Explore the fundamentals, advancements,. How Does Stator Core Work.

From www.mdpi.com

Sensors Free FullText Stator Core Shape Design for Low Core Loss How Does Stator Core Work Stator mainly works based on a spinning electromotive device configuration like the field magnet or the armature. The hollow portion of the iron core is used to house the stator windings. Explore the fundamentals, advancements, and applications of stators in modern engineering. The pressure ring is then locked. In motors, the stator creates a rotating magnetic field that interacts with. How Does Stator Core Work.

From www.automate.org

Stators & Components Automation Products How Does Stator Core Work In motors, the stator creates a rotating magnetic field that interacts with the rotor, inducting current and generating electromagnetic forces that drive rotation. The stator iron core is typically made of silicon steel sheets to reduce magnetic and iron losses. The pressure ring is then locked. The field magnet is used to communicate with the armature to produce motion whereas. How Does Stator Core Work.

From www.researchgate.net

Stator core manufacturing process and core shapes (a) Connected core How Does Stator Core Work The hollow portion of the iron core is used to house the stator windings. The stator produces the magnetic field that interacts with the rotor to produce movement, while the rotor rotates in response to this magnetic field. The stator iron core is typically made of silicon steel sheets to reduce magnetic and iron losses. The stator of an electric. How Does Stator Core Work.

From www.suncall.co.jp

Motor cores/stator cores How Does Stator Core Work The hollow portion of the iron core is used to house the stator windings. Understanding how these components work together is crucial for understanding how electric motors function and how they can be controlled. The field magnet is used to communicate with the armature to produce motion whereas the armature gets its influence from moving field coils on the rotor.. How Does Stator Core Work.

From dxoblibct.blob.core.windows.net

Stator Generator How It Works at Calvin Oneal blog How Does Stator Core Work The pressure ring is then locked. The main function of this core is to hold the irregular magnetic field which generates losses like eddy current & hysteresis. A stator is the stationary part of an electric motor or generator, consisting of coils or windings mounted on an iron core, designed to create a magnetic field when electric current flows through. How Does Stator Core Work.

From www.researchgate.net

Laminated sheets of stator and rotor cores. Download Scientific Diagram How Does Stator Core Work The field magnet is used to communicate with the armature to produce motion whereas the armature gets its influence from moving field coils on the rotor. The main function of this core is to hold the irregular magnetic field which generates losses like eddy current & hysteresis. A stator is the stationary part of an electric motor or generator, consisting. How Does Stator Core Work.

From ricksmotorsportelectrics.com

Stators A Complete Guide Rick's Motorsport Electrics Blog and More How Does Stator Core Work The main function of this core is to hold the irregular magnetic field which generates losses like eddy current & hysteresis. The stator iron core is typically made of silicon steel sheets to reduce magnetic and iron losses. Explore the fundamentals, advancements, and applications of stators in modern engineering. The stator of an electric motor is the core component consisting. How Does Stator Core Work.

From www.researchgate.net

Stator core with 48 slots (a) and robot's point of view when removing How Does Stator Core Work Stator mainly works based on a spinning electromotive device configuration like the field magnet or the armature. The stator iron core is typically made of silicon steel sheets to reduce magnetic and iron losses. The pressure ring is then locked. Explore the fundamentals, advancements, and applications of stators in modern engineering. In motors, the stator creates a rotating magnetic field. How Does Stator Core Work.

From www.powerservicesgroup.com

Why is a Stator Core Made of Laminated Steel? Power Services Group How Does Stator Core Work The main function of this core is to hold the irregular magnetic field which generates losses like eddy current & hysteresis. The stator core is pressed with the upper pressure ring installed to give the sheet pressure specified. The stator produces the magnetic field that interacts with the rotor to produce movement, while the rotor rotates in response to this. How Does Stator Core Work.

From www.mdpi.com

Applied Sciences Free FullText Torque Characteristic Analysis of a How Does Stator Core Work The hollow portion of the iron core is used to house the stator windings. The stator iron core is typically made of silicon steel sheets to reduce magnetic and iron losses. Understanding how these components work together is crucial for understanding how electric motors function and how they can be controlled. The stator of an electric motor is the core. How Does Stator Core Work.

From joitlcgft.blob.core.windows.net

How Are The Stator Windings In A Typical Truck Alternator Configured at How Does Stator Core Work The pressure ring is then locked. Understanding how these components work together is crucial for understanding how electric motors function and how they can be controlled. In motors, the stator creates a rotating magnetic field that interacts with the rotor, inducting current and generating electromagnetic forces that drive rotation. The stator iron core is typically made of silicon steel sheets. How Does Stator Core Work.

From electricalgang.com

What Is Stator? Construction of Stator ElectricalGang How Does Stator Core Work The main function of this core is to hold the irregular magnetic field which generates losses like eddy current & hysteresis. The hollow portion of the iron core is used to house the stator windings. In motors, the stator creates a rotating magnetic field that interacts with the rotor, inducting current and generating electromagnetic forces that drive rotation. The stator. How Does Stator Core Work.

From www.youtube.com

what is a Stator Working Principle of Stator Construction of Stator How Does Stator Core Work The field magnet is used to communicate with the armature to produce motion whereas the armature gets its influence from moving field coils on the rotor. The stator core is pressed with the upper pressure ring installed to give the sheet pressure specified. The main function of this core is to hold the irregular magnetic field which generates losses like. How Does Stator Core Work.

From www.researchgate.net

Stator (a) winding wiring, (b) sub‐module stator core, (c) module How Does Stator Core Work The pressure ring is then locked. The hollow portion of the iron core is used to house the stator windings. The stator iron core is typically made of silicon steel sheets to reduce magnetic and iron losses. Stator mainly works based on a spinning electromotive device configuration like the field magnet or the armature. The stator core is pressed with. How Does Stator Core Work.

From electricalgang.com

What Is Stator? Construction of Stator ElectricalGang How Does Stator Core Work The main function of this core is to hold the irregular magnetic field which generates losses like eddy current & hysteresis. The stator core is pressed with the upper pressure ring installed to give the sheet pressure specified. The stator of an electric motor is the core component consisting of a laminated iron core and windings. The stator iron core. How Does Stator Core Work.

From www.researchgate.net

1 Crosssection of a 24slot 4pole outer stator with 3phase windings How Does Stator Core Work The stator core is pressed with the upper pressure ring installed to give the sheet pressure specified. The stator of an electric motor is the core component consisting of a laminated iron core and windings. The stator iron core is typically made of silicon steel sheets to reduce magnetic and iron losses. The stator produces the magnetic field that interacts. How Does Stator Core Work.

From exoukqmmx.blob.core.windows.net

What Does The Stator Do In A Dc Motor at Tiana Crofoot blog How Does Stator Core Work The hollow portion of the iron core is used to house the stator windings. A stator is the stationary part of an electric motor or generator, consisting of coils or windings mounted on an iron core, designed to create a magnetic field when electric current flows through it. The stator core is pressed with the upper pressure ring installed to. How Does Stator Core Work.

From www.researchgate.net

Production of the AM core motor (a) LPBF printing process of the How Does Stator Core Work The stator core is pressed with the upper pressure ring installed to give the sheet pressure specified. The stator produces the magnetic field that interacts with the rotor to produce movement, while the rotor rotates in response to this magnetic field. The main function of this core is to hold the irregular magnetic field which generates losses like eddy current. How Does Stator Core Work.

From exytkcgsy.blob.core.windows.net

Rotor And Stator In Induction Motor at Wilma Wooley blog How Does Stator Core Work The stator of an electric motor is the core component consisting of a laminated iron core and windings. The field magnet is used to communicate with the armature to produce motion whereas the armature gets its influence from moving field coils on the rotor. Stator mainly works based on a spinning electromotive device configuration like the field magnet or the. How Does Stator Core Work.

From electricalgang.com

What Is Stator? Construction of Stator ElectricalGang How Does Stator Core Work The stator produces the magnetic field that interacts with the rotor to produce movement, while the rotor rotates in response to this magnetic field. The stator iron core is typically made of silicon steel sheets to reduce magnetic and iron losses. The stator of an electric motor is the core component consisting of a laminated iron core and windings. A. How Does Stator Core Work.

From www.researchgate.net

Simplified motor lateral section and cooling air paths. A−Stator core How Does Stator Core Work The stator core is pressed with the upper pressure ring installed to give the sheet pressure specified. In motors, the stator creates a rotating magnetic field that interacts with the rotor, inducting current and generating electromagnetic forces that drive rotation. The field magnet is used to communicate with the armature to produce motion whereas the armature gets its influence from. How Does Stator Core Work.

From magazinexu.com

A Comprehensive Guide About What Is A Stator? Its Different Parts And How Does Stator Core Work The stator of an electric motor is the core component consisting of a laminated iron core and windings. In motors, the stator creates a rotating magnetic field that interacts with the rotor, inducting current and generating electromagnetic forces that drive rotation. A stator is the stationary part of an electric motor or generator, consisting of coils or windings mounted on. How Does Stator Core Work.

From www.researchgate.net

7 Typical stator core including stator winding bar. Download How Does Stator Core Work The stator produces the magnetic field that interacts with the rotor to produce movement, while the rotor rotates in response to this magnetic field. The field magnet is used to communicate with the armature to produce motion whereas the armature gets its influence from moving field coils on the rotor. The stator of an electric motor is the core component. How Does Stator Core Work.

From www.researchgate.net

Stator core manufacturing process and core shapes (a) Connected core How Does Stator Core Work The main function of this core is to hold the irregular magnetic field which generates losses like eddy current & hysteresis. A stator is the stationary part of an electric motor or generator, consisting of coils or windings mounted on an iron core, designed to create a magnetic field when electric current flows through it. The field magnet is used. How Does Stator Core Work.

From en.ppt-online.org

AC Motors and types online presentation How Does Stator Core Work The field magnet is used to communicate with the armature to produce motion whereas the armature gets its influence from moving field coils on the rotor. The pressure ring is then locked. The stator of an electric motor is the core component consisting of a laminated iron core and windings. Stator mainly works based on a spinning electromotive device configuration. How Does Stator Core Work.

From turbogentech.com

EL CID stator core test How Does Stator Core Work Explore the fundamentals, advancements, and applications of stators in modern engineering. The pressure ring is then locked. The field magnet is used to communicate with the armature to produce motion whereas the armature gets its influence from moving field coils on the rotor. The stator produces the magnetic field that interacts with the rotor to produce movement, while the rotor. How Does Stator Core Work.

From www.mdpi.com

Energies Free FullText Influence of Stator Core Seams on NoLoad How Does Stator Core Work Explore the fundamentals, advancements, and applications of stators in modern engineering. The main function of this core is to hold the irregular magnetic field which generates losses like eddy current & hysteresis. In motors, the stator creates a rotating magnetic field that interacts with the rotor, inducting current and generating electromagnetic forces that drive rotation. The stator produces the magnetic. How Does Stator Core Work.

From dxoblibct.blob.core.windows.net

Stator Generator How It Works at Calvin Oneal blog How Does Stator Core Work The pressure ring is then locked. Understanding how these components work together is crucial for understanding how electric motors function and how they can be controlled. The stator produces the magnetic field that interacts with the rotor to produce movement, while the rotor rotates in response to this magnetic field. The hollow portion of the iron core is used to. How Does Stator Core Work.

From www.youtube.com

Design of stator core (3ph Induction Motor Design Course 10) YouTube How Does Stator Core Work The stator produces the magnetic field that interacts with the rotor to produce movement, while the rotor rotates in response to this magnetic field. Understanding how these components work together is crucial for understanding how electric motors function and how they can be controlled. The pressure ring is then locked. The stator core is pressed with the upper pressure ring. How Does Stator Core Work.

From www.iqsdirectory.com

AC Motor What Is It? How Does It Work? Types & Uses How Does Stator Core Work The field magnet is used to communicate with the armature to produce motion whereas the armature gets its influence from moving field coils on the rotor. Stator mainly works based on a spinning electromotive device configuration like the field magnet or the armature. A stator is the stationary part of an electric motor or generator, consisting of coils or windings. How Does Stator Core Work.

From klaviayjg.blob.core.windows.net

What Is The Purpose Of The Stator In An Alternator at Troy Kelley blog How Does Stator Core Work Understanding how these components work together is crucial for understanding how electric motors function and how they can be controlled. The stator produces the magnetic field that interacts with the rotor to produce movement, while the rotor rotates in response to this magnetic field. The hollow portion of the iron core is used to house the stator windings. Explore the. How Does Stator Core Work.