Braze Bead Welding . To take your brazing skills to the next level, focus on small tips such. Start by cleaning and preparing the surfaces, then apply the filler metal using a. Weld diffrent types of material together. Braze welding is similar to brazing process, and the only difference is the way of brazing filler wire deposition. Braze weld steel involves heating the joint and adding filler metal to connect two pieces of metal. It is very similar to fusion welding except you. Uniform brazed joints were achieved at defocuses of +22, +25 and +30 mm. During braze welding, the welding rod. Reduces or elements the need for. The braze welding process is considered an excellent choice for the joining of coated (eg galvanized) thin sheet steels. Braze welding stainless steel requires advanced techniques such as pulse welding and machine brazing. Braze welding (also called bronze welding) is another procedure you can use to join two pieces of metal. Increased defocus distance resulted in a wider. The benefits of braze welding can be summarized like this:

from www.mdpi.com

Braze weld steel involves heating the joint and adding filler metal to connect two pieces of metal. The braze welding process is considered an excellent choice for the joining of coated (eg galvanized) thin sheet steels. Braze welding stainless steel requires advanced techniques such as pulse welding and machine brazing. During braze welding, the welding rod. Braze welding is similar to brazing process, and the only difference is the way of brazing filler wire deposition. Increased defocus distance resulted in a wider. The benefits of braze welding can be summarized like this: Braze welding (also called bronze welding) is another procedure you can use to join two pieces of metal. Start by cleaning and preparing the surfaces, then apply the filler metal using a. It is very similar to fusion welding except you.

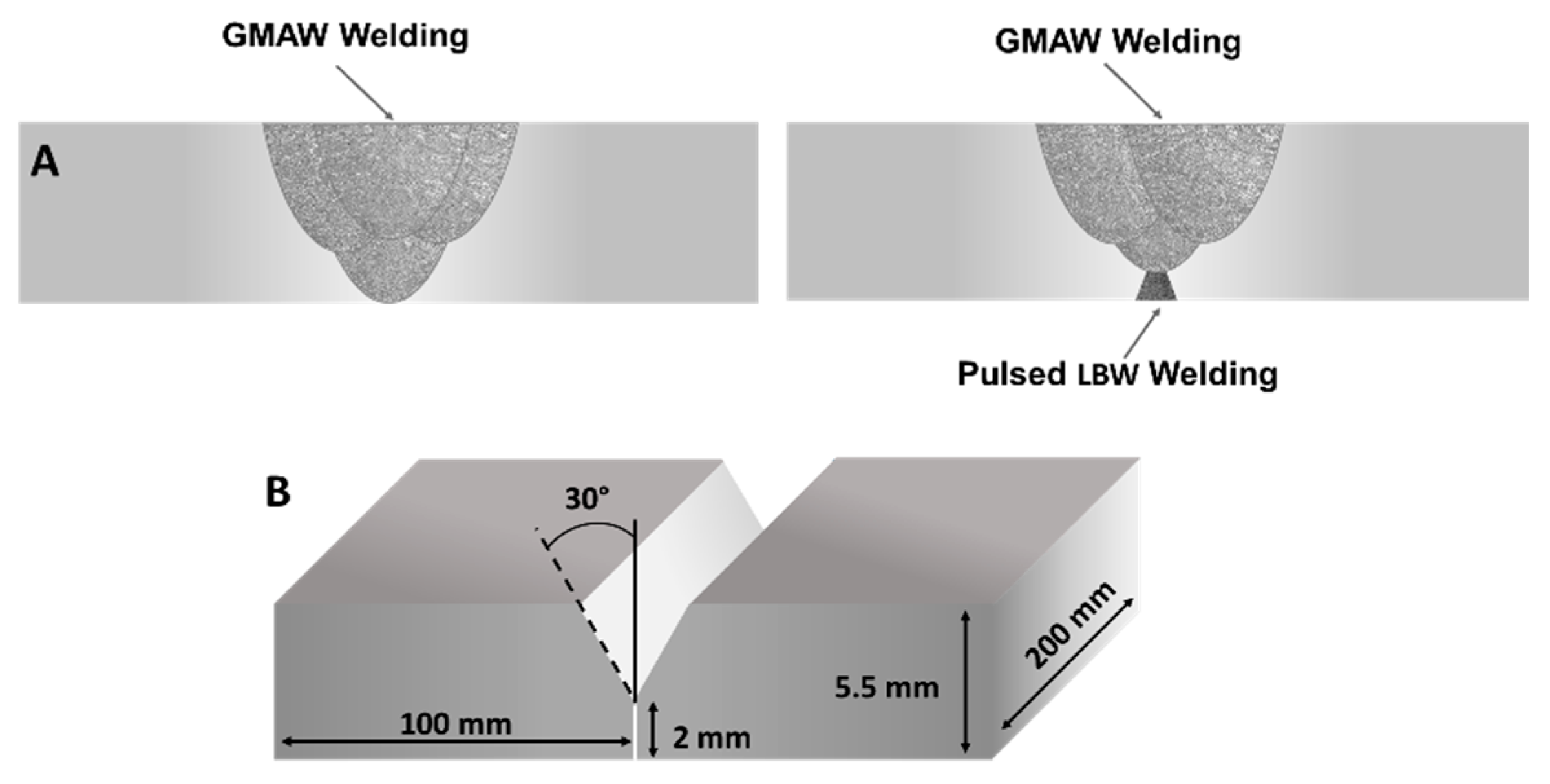

Materials Free FullText LowEnergy PulsedLaser Welding as a Root

Braze Bead Welding Braze welding is similar to brazing process, and the only difference is the way of brazing filler wire deposition. Start by cleaning and preparing the surfaces, then apply the filler metal using a. Braze welding stainless steel requires advanced techniques such as pulse welding and machine brazing. Reduces or elements the need for. Uniform brazed joints were achieved at defocuses of +22, +25 and +30 mm. The braze welding process is considered an excellent choice for the joining of coated (eg galvanized) thin sheet steels. Braze weld steel involves heating the joint and adding filler metal to connect two pieces of metal. It is very similar to fusion welding except you. Braze welding (also called bronze welding) is another procedure you can use to join two pieces of metal. The benefits of braze welding can be summarized like this: Braze welding is similar to brazing process, and the only difference is the way of brazing filler wire deposition. To take your brazing skills to the next level, focus on small tips such. During braze welding, the welding rod. Weld diffrent types of material together. Increased defocus distance resulted in a wider.

From www.youtube.com

Braze Welding YouTube Braze Bead Welding Braze weld steel involves heating the joint and adding filler metal to connect two pieces of metal. The benefits of braze welding can be summarized like this: It is very similar to fusion welding except you. Braze welding (also called bronze welding) is another procedure you can use to join two pieces of metal. To take your brazing skills to. Braze Bead Welding.

From computechmfg.com

Welding and Brazing Computech Braze Bead Welding The benefits of braze welding can be summarized like this: Weld diffrent types of material together. Increased defocus distance resulted in a wider. To take your brazing skills to the next level, focus on small tips such. Uniform brazed joints were achieved at defocuses of +22, +25 and +30 mm. Braze welding (also called bronze welding) is another procedure you. Braze Bead Welding.

From protigwelders.com

Can You Braze With a Tig Welder? (Differences) 2024 ProTigWelders Braze Bead Welding During braze welding, the welding rod. Braze weld steel involves heating the joint and adding filler metal to connect two pieces of metal. Uniform brazed joints were achieved at defocuses of +22, +25 and +30 mm. Start by cleaning and preparing the surfaces, then apply the filler metal using a. Reduces or elements the need for. Weld diffrent types of. Braze Bead Welding.

From weldguru.com

Welding Beads What Are They? & Different Types Braze Bead Welding Increased defocus distance resulted in a wider. It is very similar to fusion welding except you. The braze welding process is considered an excellent choice for the joining of coated (eg galvanized) thin sheet steels. To take your brazing skills to the next level, focus on small tips such. The benefits of braze welding can be summarized like this: Braze. Braze Bead Welding.

From www.weldingtipsandtricks.com

TIg Brazing vs Tig Welding Braze Bead Welding The benefits of braze welding can be summarized like this: Weld diffrent types of material together. During braze welding, the welding rod. Braze welding (also called bronze welding) is another procedure you can use to join two pieces of metal. Increased defocus distance resulted in a wider. Braze welding is similar to brazing process, and the only difference is the. Braze Bead Welding.

From www.diydoctor.org.uk

How to Braze Metal in 6 Easy Steps DIY Doctor Braze Bead Welding Reduces or elements the need for. Uniform brazed joints were achieved at defocuses of +22, +25 and +30 mm. During braze welding, the welding rod. Braze weld steel involves heating the joint and adding filler metal to connect two pieces of metal. The benefits of braze welding can be summarized like this: Braze welding stainless steel requires advanced techniques such. Braze Bead Welding.

From xkldase.edu.vn

Aggregate more than 133 backing ring in welding best xkldase.edu.vn Braze Bead Welding Reduces or elements the need for. The braze welding process is considered an excellent choice for the joining of coated (eg galvanized) thin sheet steels. Increased defocus distance resulted in a wider. Start by cleaning and preparing the surfaces, then apply the filler metal using a. Braze welding is similar to brazing process, and the only difference is the way. Braze Bead Welding.

From www.youtube.com

🔥 Gas Brazing Technique YouTube Braze Bead Welding The benefits of braze welding can be summarized like this: Start by cleaning and preparing the surfaces, then apply the filler metal using a. Braze welding is similar to brazing process, and the only difference is the way of brazing filler wire deposition. Weld diffrent types of material together. Braze weld steel involves heating the joint and adding filler metal. Braze Bead Welding.

From www.youtube.com

Difference between brazing and braze welding II Brazing & Braze Welding Braze Bead Welding During braze welding, the welding rod. Braze welding stainless steel requires advanced techniques such as pulse welding and machine brazing. Weld diffrent types of material together. Start by cleaning and preparing the surfaces, then apply the filler metal using a. It is very similar to fusion welding except you. Braze welding is similar to brazing process, and the only difference. Braze Bead Welding.

From www.mig-welding.co.uk

MIG Welding Cast Iron Braze Bead Welding During braze welding, the welding rod. Braze weld steel involves heating the joint and adding filler metal to connect two pieces of metal. Start by cleaning and preparing the surfaces, then apply the filler metal using a. To take your brazing skills to the next level, focus on small tips such. Braze welding is similar to brazing process, and the. Braze Bead Welding.

From smooth-robotics.com

Weaving in welding A comprehensive guide to weave patterns Braze Bead Welding Weld diffrent types of material together. Braze welding (also called bronze welding) is another procedure you can use to join two pieces of metal. Uniform brazed joints were achieved at defocuses of +22, +25 and +30 mm. It is very similar to fusion welding except you. Reduces or elements the need for. Braze welding is similar to brazing process, and. Braze Bead Welding.

From localrevive.com

What is Braze Welding? How Does It Work? A Complete Guide Braze Bead Welding It is very similar to fusion welding except you. Braze welding (also called bronze welding) is another procedure you can use to join two pieces of metal. Increased defocus distance resulted in a wider. Reduces or elements the need for. The braze welding process is considered an excellent choice for the joining of coated (eg galvanized) thin sheet steels. Start. Braze Bead Welding.

From blog.thepipingmart.com

Exothermic Welding vs Brazing What's the Difference Braze Bead Welding The braze welding process is considered an excellent choice for the joining of coated (eg galvanized) thin sheet steels. To take your brazing skills to the next level, focus on small tips such. Increased defocus distance resulted in a wider. Uniform brazed joints were achieved at defocuses of +22, +25 and +30 mm. It is very similar to fusion welding. Braze Bead Welding.

From www.reddit.com

How to make/ Welding perfectly sharp corner? r/Welding Braze Bead Welding Braze welding stainless steel requires advanced techniques such as pulse welding and machine brazing. Braze welding (also called bronze welding) is another procedure you can use to join two pieces of metal. During braze welding, the welding rod. To take your brazing skills to the next level, focus on small tips such. Weld diffrent types of material together. Uniform brazed. Braze Bead Welding.

From weldingpros.net

Types Of Welding Beads, Patterns, & Techniques Braze Bead Welding To take your brazing skills to the next level, focus on small tips such. Reduces or elements the need for. Weld diffrent types of material together. During braze welding, the welding rod. Braze welding stainless steel requires advanced techniques such as pulse welding and machine brazing. Braze welding (also called bronze welding) is another procedure you can use to join. Braze Bead Welding.

From mubashirghori.blogspot.com

Muhammad Mubashir Ghori Understand the Brazing & Braze Welding Braze Bead Welding It is very similar to fusion welding except you. To take your brazing skills to the next level, focus on small tips such. Start by cleaning and preparing the surfaces, then apply the filler metal using a. Braze welding is similar to brazing process, and the only difference is the way of brazing filler wire deposition. Braze welding (also called. Braze Bead Welding.

From weldingtroop.com

Aluminum Brazing Complete Guide Advantages Over Welding Braze Bead Welding Braze welding stainless steel requires advanced techniques such as pulse welding and machine brazing. Braze welding is similar to brazing process, and the only difference is the way of brazing filler wire deposition. Weld diffrent types of material together. Increased defocus distance resulted in a wider. Braze welding (also called bronze welding) is another procedure you can use to join. Braze Bead Welding.

From animalia-life.club

Mig Welding Bead Braze Bead Welding During braze welding, the welding rod. To take your brazing skills to the next level, focus on small tips such. Braze welding (also called bronze welding) is another procedure you can use to join two pieces of metal. Braze welding stainless steel requires advanced techniques such as pulse welding and machine brazing. The benefits of braze welding can be summarized. Braze Bead Welding.

From weldersmanual.com

Welding Beads Types Of Beads Welders Manual Braze Bead Welding Increased defocus distance resulted in a wider. To take your brazing skills to the next level, focus on small tips such. The braze welding process is considered an excellent choice for the joining of coated (eg galvanized) thin sheet steels. Braze welding stainless steel requires advanced techniques such as pulse welding and machine brazing. During braze welding, the welding rod.. Braze Bead Welding.

From blog.thepipingmart.com

Brazing vs TIG Welding What's the Difference Braze Bead Welding Start by cleaning and preparing the surfaces, then apply the filler metal using a. Increased defocus distance resulted in a wider. The benefits of braze welding can be summarized like this: Braze welding (also called bronze welding) is another procedure you can use to join two pieces of metal. Braze welding stainless steel requires advanced techniques such as pulse welding. Braze Bead Welding.

From www.weldpundit.com

Is It Better to Braze or Weld Cast Iron? Pros and Cons Braze Bead Welding Braze weld steel involves heating the joint and adding filler metal to connect two pieces of metal. Braze welding (also called bronze welding) is another procedure you can use to join two pieces of metal. It is very similar to fusion welding except you. Uniform brazed joints were achieved at defocuses of +22, +25 and +30 mm. The benefits of. Braze Bead Welding.

From www.pinterest.se

Пин на доске сварка Braze Bead Welding Braze weld steel involves heating the joint and adding filler metal to connect two pieces of metal. Start by cleaning and preparing the surfaces, then apply the filler metal using a. The benefits of braze welding can be summarized like this: Increased defocus distance resulted in a wider. Uniform brazed joints were achieved at defocuses of +22, +25 and +30. Braze Bead Welding.

From thegraduateengineer.com

What is Porosity in Welds The Graduate Engineer Braze Bead Welding Start by cleaning and preparing the surfaces, then apply the filler metal using a. Reduces or elements the need for. The braze welding process is considered an excellent choice for the joining of coated (eg galvanized) thin sheet steels. Uniform brazed joints were achieved at defocuses of +22, +25 and +30 mm. Braze weld steel involves heating the joint and. Braze Bead Welding.

From welderplanet.com

What Is A Bead In Welding Welder Braze Bead Welding The benefits of braze welding can be summarized like this: Reduces or elements the need for. The braze welding process is considered an excellent choice for the joining of coated (eg galvanized) thin sheet steels. Increased defocus distance resulted in a wider. To take your brazing skills to the next level, focus on small tips such. Start by cleaning and. Braze Bead Welding.

From weldinginsider.com

Understanding the Basic Welding Symbols Braze Bead Welding During braze welding, the welding rod. Braze welding is similar to brazing process, and the only difference is the way of brazing filler wire deposition. Increased defocus distance resulted in a wider. Weld diffrent types of material together. Braze welding (also called bronze welding) is another procedure you can use to join two pieces of metal. The benefits of braze. Braze Bead Welding.

From smooth-robotics.com

Weaving in welding A comprehensive guide to weave patterns Braze Bead Welding It is very similar to fusion welding except you. Weld diffrent types of material together. Braze weld steel involves heating the joint and adding filler metal to connect two pieces of metal. Uniform brazed joints were achieved at defocuses of +22, +25 and +30 mm. Reduces or elements the need for. The braze welding process is considered an excellent choice. Braze Bead Welding.

From www.pinterest.com

Tig weave Metaalkunst Braze Bead Welding Reduces or elements the need for. Increased defocus distance resulted in a wider. Uniform brazed joints were achieved at defocuses of +22, +25 and +30 mm. Braze welding (also called bronze welding) is another procedure you can use to join two pieces of metal. The braze welding process is considered an excellent choice for the joining of coated (eg galvanized). Braze Bead Welding.

From www.mdpi.com

Materials Free FullText LowEnergy PulsedLaser Welding as a Root Braze Bead Welding Uniform brazed joints were achieved at defocuses of +22, +25 and +30 mm. Braze welding is similar to brazing process, and the only difference is the way of brazing filler wire deposition. Weld diffrent types of material together. The braze welding process is considered an excellent choice for the joining of coated (eg galvanized) thin sheet steels. Braze welding (also. Braze Bead Welding.

From theweldings.com

Braze welding process Weld World Braze Bead Welding Braze welding (also called bronze welding) is another procedure you can use to join two pieces of metal. Braze weld steel involves heating the joint and adding filler metal to connect two pieces of metal. It is very similar to fusion welding except you. Reduces or elements the need for. The benefits of braze welding can be summarized like this:. Braze Bead Welding.

From animalia-life.club

Mig Welding Bead Braze Bead Welding Uniform brazed joints were achieved at defocuses of +22, +25 and +30 mm. Braze welding (also called bronze welding) is another procedure you can use to join two pieces of metal. Braze weld steel involves heating the joint and adding filler metal to connect two pieces of metal. The braze welding process is considered an excellent choice for the joining. Braze Bead Welding.

From welderstream.com

Welding Beads & Types of Welding Beads TIG/MIG/STICK Braze Bead Welding The braze welding process is considered an excellent choice for the joining of coated (eg galvanized) thin sheet steels. Braze welding is similar to brazing process, and the only difference is the way of brazing filler wire deposition. Uniform brazed joints were achieved at defocuses of +22, +25 and +30 mm. It is very similar to fusion welding except you.. Braze Bead Welding.

From www.researchgate.net

MIG/MAG braze welding [4] Download Scientific Diagram Braze Bead Welding To take your brazing skills to the next level, focus on small tips such. Braze welding stainless steel requires advanced techniques such as pulse welding and machine brazing. Braze welding is similar to brazing process, and the only difference is the way of brazing filler wire deposition. Start by cleaning and preparing the surfaces, then apply the filler metal using. Braze Bead Welding.

From www.youtube.com

Stick Welding Basics How to Run Straight Consistent Beads YouTube Braze Bead Welding The benefits of braze welding can be summarized like this: The braze welding process is considered an excellent choice for the joining of coated (eg galvanized) thin sheet steels. It is very similar to fusion welding except you. Weld diffrent types of material together. Increased defocus distance resulted in a wider. To take your brazing skills to the next level,. Braze Bead Welding.

From www.slideserve.com

PPT Chapter 33 Other Welding Processes, Brazing and Soldering Braze Bead Welding The braze welding process is considered an excellent choice for the joining of coated (eg galvanized) thin sheet steels. Increased defocus distance resulted in a wider. Uniform brazed joints were achieved at defocuses of +22, +25 and +30 mm. Braze welding is similar to brazing process, and the only difference is the way of brazing filler wire deposition. The benefits. Braze Bead Welding.

From www.youtube.com

Braze welding YouTube Braze Bead Welding Weld diffrent types of material together. Braze welding (also called bronze welding) is another procedure you can use to join two pieces of metal. Braze welding stainless steel requires advanced techniques such as pulse welding and machine brazing. It is very similar to fusion welding except you. During braze welding, the welding rod. Increased defocus distance resulted in a wider.. Braze Bead Welding.