Glass Furnace Design . Glassmelting furnaces are of different types whose design and working operations are reviewed in this chapter. Furnace design (focus on continuous melting tanks) process steps. Design boundaries (melting rates, temperatures. In recent years key advances have taken place in the development of glass compositions, in float furnace design and operation and in the forming. When coupled with secondary models such as seeds removal, volatilization from melt surface (and also models for quality parameters such as silica dissolution, and homogeneity) furnace models have proven to be powerful tools for the design and operation of industrial glass furnaces. Horn® builds a wide variety of glass furnace types for its customers, ranging from the usual end fired furnace to the all electric melting.

from www.hornglass.com

Design boundaries (melting rates, temperatures. When coupled with secondary models such as seeds removal, volatilization from melt surface (and also models for quality parameters such as silica dissolution, and homogeneity) furnace models have proven to be powerful tools for the design and operation of industrial glass furnaces. In recent years key advances have taken place in the development of glass compositions, in float furnace design and operation and in the forming. Glassmelting furnaces are of different types whose design and working operations are reviewed in this chapter. Horn® builds a wide variety of glass furnace types for its customers, ranging from the usual end fired furnace to the all electric melting. Furnace design (focus on continuous melting tanks) process steps.

Melting Furnaces & Equipment

Glass Furnace Design Design boundaries (melting rates, temperatures. Glassmelting furnaces are of different types whose design and working operations are reviewed in this chapter. In recent years key advances have taken place in the development of glass compositions, in float furnace design and operation and in the forming. Furnace design (focus on continuous melting tanks) process steps. Design boundaries (melting rates, temperatures. When coupled with secondary models such as seeds removal, volatilization from melt surface (and also models for quality parameters such as silica dissolution, and homogeneity) furnace models have proven to be powerful tools for the design and operation of industrial glass furnaces. Horn® builds a wide variety of glass furnace types for its customers, ranging from the usual end fired furnace to the all electric melting.

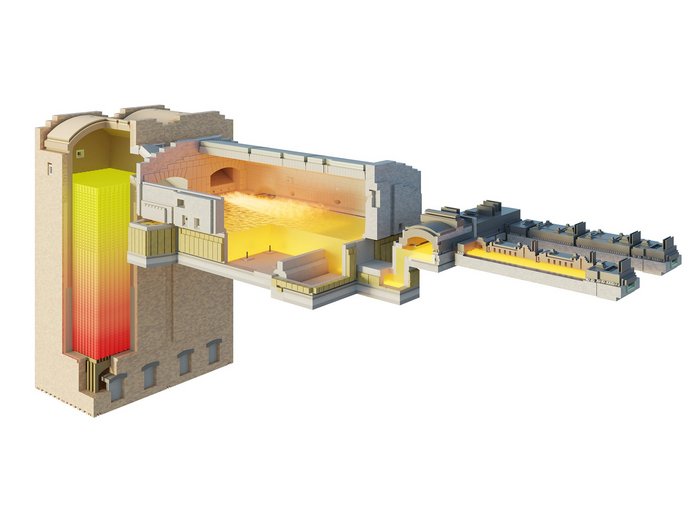

From www.agc-glass.eu

Hot furnace design AGC Glass Europe Glass Furnace Design Glassmelting furnaces are of different types whose design and working operations are reviewed in this chapter. When coupled with secondary models such as seeds removal, volatilization from melt surface (and also models for quality parameters such as silica dissolution, and homogeneity) furnace models have proven to be powerful tools for the design and operation of industrial glass furnaces. Design boundaries. Glass Furnace Design.

From www.glindco.com

Glass Melting Furnaces We design and supply world class glass melting Glass Furnace Design Glassmelting furnaces are of different types whose design and working operations are reviewed in this chapter. Furnace design (focus on continuous melting tanks) process steps. Design boundaries (melting rates, temperatures. When coupled with secondary models such as seeds removal, volatilization from melt surface (and also models for quality parameters such as silica dissolution, and homogeneity) furnace models have proven to. Glass Furnace Design.

From www.glassfurnaceengineering.com

Furnace Design Gas Combustion Industrial Glass Furnace Glass Production Glass Furnace Design Horn® builds a wide variety of glass furnace types for its customers, ranging from the usual end fired furnace to the all electric melting. When coupled with secondary models such as seeds removal, volatilization from melt surface (and also models for quality parameters such as silica dissolution, and homogeneity) furnace models have proven to be powerful tools for the design. Glass Furnace Design.

From www.glassfurnaceengineering.com

Furnace Design Gas Combustion Glass Melter Glass Production Glass Furnace Design Horn® builds a wide variety of glass furnace types for its customers, ranging from the usual end fired furnace to the all electric melting. Glassmelting furnaces are of different types whose design and working operations are reviewed in this chapter. Furnace design (focus on continuous melting tanks) process steps. Design boundaries (melting rates, temperatures. In recent years key advances have. Glass Furnace Design.

From www.gsl.cz

Optical & Technical Glass Furnaces Glass Service Glass Furnace Design Design boundaries (melting rates, temperatures. Furnace design (focus on continuous melting tanks) process steps. When coupled with secondary models such as seeds removal, volatilization from melt surface (and also models for quality parameters such as silica dissolution, and homogeneity) furnace models have proven to be powerful tools for the design and operation of industrial glass furnaces. Glassmelting furnaces are of. Glass Furnace Design.

From www.mdpi.com

Applied Sciences Free FullText Transient Numerical Simulation of Glass Furnace Design When coupled with secondary models such as seeds removal, volatilization from melt surface (and also models for quality parameters such as silica dissolution, and homogeneity) furnace models have proven to be powerful tools for the design and operation of industrial glass furnaces. Glassmelting furnaces are of different types whose design and working operations are reviewed in this chapter. In recent. Glass Furnace Design.

From www.youtube.com

Furnace for the Future A Huge Milestone Towards ClimateNeutral Glass Glass Furnace Design Furnace design (focus on continuous melting tanks) process steps. Design boundaries (melting rates, temperatures. In recent years key advances have taken place in the development of glass compositions, in float furnace design and operation and in the forming. Horn® builds a wide variety of glass furnace types for its customers, ranging from the usual end fired furnace to the all. Glass Furnace Design.

From www.agrmrefractory.com

China Glass Furnace Design Engineering Manufacturers, Suppliers and Glass Furnace Design When coupled with secondary models such as seeds removal, volatilization from melt surface (and also models for quality parameters such as silica dissolution, and homogeneity) furnace models have proven to be powerful tools for the design and operation of industrial glass furnaces. Glassmelting furnaces are of different types whose design and working operations are reviewed in this chapter. Horn® builds. Glass Furnace Design.

From www.hornglass.com

HORN® GLASS INDUSTRIES Glass Furnace Design When coupled with secondary models such as seeds removal, volatilization from melt surface (and also models for quality parameters such as silica dissolution, and homogeneity) furnace models have proven to be powerful tools for the design and operation of industrial glass furnaces. Furnace design (focus on continuous melting tanks) process steps. In recent years key advances have taken place in. Glass Furnace Design.

From jordonglass.com

GXP Standard Flat Glass Tempering Furnace Jordon Glass Machinery Glass Furnace Design When coupled with secondary models such as seeds removal, volatilization from melt surface (and also models for quality parameters such as silica dissolution, and homogeneity) furnace models have proven to be powerful tools for the design and operation of industrial glass furnaces. Design boundaries (melting rates, temperatures. Horn® builds a wide variety of glass furnace types for its customers, ranging. Glass Furnace Design.

From niesenglass.ch

NG40 Mobile Glass Furnace Niesenglass Switzerland GmbH Glass Furnace Design Horn® builds a wide variety of glass furnace types for its customers, ranging from the usual end fired furnace to the all electric melting. Furnace design (focus on continuous melting tanks) process steps. Glassmelting furnaces are of different types whose design and working operations are reviewed in this chapter. In recent years key advances have taken place in the development. Glass Furnace Design.

From www.hornglass.com

All Electric Furnaces Glass Furnace Design Design boundaries (melting rates, temperatures. Horn® builds a wide variety of glass furnace types for its customers, ranging from the usual end fired furnace to the all electric melting. Furnace design (focus on continuous melting tanks) process steps. When coupled with secondary models such as seeds removal, volatilization from melt surface (and also models for quality parameters such as silica. Glass Furnace Design.

From www.hornglass.com

Melting Furnaces & Equipment Glass Furnace Design In recent years key advances have taken place in the development of glass compositions, in float furnace design and operation and in the forming. Glassmelting furnaces are of different types whose design and working operations are reviewed in this chapter. Furnace design (focus on continuous melting tanks) process steps. When coupled with secondary models such as seeds removal, volatilization from. Glass Furnace Design.

From www.nitrex.com

GLASS FURNACE Nitrex Glass Furnace Design Glassmelting furnaces are of different types whose design and working operations are reviewed in this chapter. Furnace design (focus on continuous melting tanks) process steps. Design boundaries (melting rates, temperatures. When coupled with secondary models such as seeds removal, volatilization from melt surface (and also models for quality parameters such as silica dissolution, and homogeneity) furnace models have proven to. Glass Furnace Design.

From www.ferretti-construction.com

Glass Furnace Foundation Ferretti Construction Glass Furnace Design Horn® builds a wide variety of glass furnace types for its customers, ranging from the usual end fired furnace to the all electric melting. In recent years key advances have taken place in the development of glass compositions, in float furnace design and operation and in the forming. Furnace design (focus on continuous melting tanks) process steps. When coupled with. Glass Furnace Design.

From www.fusedazs.com

15 Factors To Consider When Selecting Refractories For The Glass Glass Furnace Design In recent years key advances have taken place in the development of glass compositions, in float furnace design and operation and in the forming. Design boundaries (melting rates, temperatures. Furnace design (focus on continuous melting tanks) process steps. Horn® builds a wide variety of glass furnace types for its customers, ranging from the usual end fired furnace to the all. Glass Furnace Design.

From ar.inspiredpencil.com

How Furnace Works Diagram Glass Furnace Design In recent years key advances have taken place in the development of glass compositions, in float furnace design and operation and in the forming. Design boundaries (melting rates, temperatures. When coupled with secondary models such as seeds removal, volatilization from melt surface (and also models for quality parameters such as silica dissolution, and homogeneity) furnace models have proven to be. Glass Furnace Design.

From www.crefin.it

Furnace Melting Glass Furnaces Crefin Glass Furnace Design Glassmelting furnaces are of different types whose design and working operations are reviewed in this chapter. Furnace design (focus on continuous melting tanks) process steps. Design boundaries (melting rates, temperatures. Horn® builds a wide variety of glass furnace types for its customers, ranging from the usual end fired furnace to the all electric melting. When coupled with secondary models such. Glass Furnace Design.

From www.hertwich.com

Melting furnaces Glass Furnace Design Horn® builds a wide variety of glass furnace types for its customers, ranging from the usual end fired furnace to the all electric melting. When coupled with secondary models such as seeds removal, volatilization from melt surface (and also models for quality parameters such as silica dissolution, and homogeneity) furnace models have proven to be powerful tools for the design. Glass Furnace Design.

From onlinelibrary.wiley.com

A Review of Mathematical Process Models for the Electric Arc Furnace Glass Furnace Design Design boundaries (melting rates, temperatures. In recent years key advances have taken place in the development of glass compositions, in float furnace design and operation and in the forming. When coupled with secondary models such as seeds removal, volatilization from melt surface (and also models for quality parameters such as silica dissolution, and homogeneity) furnace models have proven to be. Glass Furnace Design.

From wdg-us.com

WetDog Glass Furnace Design Horn® builds a wide variety of glass furnace types for its customers, ranging from the usual end fired furnace to the all electric melting. Furnace design (focus on continuous melting tanks) process steps. When coupled with secondary models such as seeds removal, volatilization from melt surface (and also models for quality parameters such as silica dissolution, and homogeneity) furnace models. Glass Furnace Design.

From www.agc-glass.eu

Hot furnace design AGC Glass Europe Glass Furnace Design Design boundaries (melting rates, temperatures. In recent years key advances have taken place in the development of glass compositions, in float furnace design and operation and in the forming. Glassmelting furnaces are of different types whose design and working operations are reviewed in this chapter. Horn® builds a wide variety of glass furnace types for its customers, ranging from the. Glass Furnace Design.

From www.hornglass.com

Melting Furnaces & Equipment Glass Furnace Design Horn® builds a wide variety of glass furnace types for its customers, ranging from the usual end fired furnace to the all electric melting. When coupled with secondary models such as seeds removal, volatilization from melt surface (and also models for quality parameters such as silica dissolution, and homogeneity) furnace models have proven to be powerful tools for the design. Glass Furnace Design.

From niesenglass.ch

Glass Furnaces Niesenglass Switzerland GmbH Glass Furnace Design Design boundaries (melting rates, temperatures. In recent years key advances have taken place in the development of glass compositions, in float furnace design and operation and in the forming. Furnace design (focus on continuous melting tanks) process steps. Horn® builds a wide variety of glass furnace types for its customers, ranging from the usual end fired furnace to the all. Glass Furnace Design.

From www.fivesgroup.com

Float glass furnace technology to reduce energy use Fives Group Glass Furnace Design Furnace design (focus on continuous melting tanks) process steps. When coupled with secondary models such as seeds removal, volatilization from melt surface (and also models for quality parameters such as silica dissolution, and homogeneity) furnace models have proven to be powerful tools for the design and operation of industrial glass furnaces. Design boundaries (melting rates, temperatures. Glassmelting furnaces are of. Glass Furnace Design.

From www.glassfurnaceengineering.com

Design Engineering Available 80tpd Industrial Glass Furnace Glass Glass Furnace Design In recent years key advances have taken place in the development of glass compositions, in float furnace design and operation and in the forming. Horn® builds a wide variety of glass furnace types for its customers, ranging from the usual end fired furnace to the all electric melting. Glassmelting furnaces are of different types whose design and working operations are. Glass Furnace Design.

From www.furnace.com.au

Furnace Engineering // Heat Processing Furnaces // Custom Heat Glass Furnace Design Design boundaries (melting rates, temperatures. Glassmelting furnaces are of different types whose design and working operations are reviewed in this chapter. When coupled with secondary models such as seeds removal, volatilization from melt surface (and also models for quality parameters such as silica dissolution, and homogeneity) furnace models have proven to be powerful tools for the design and operation of. Glass Furnace Design.

From www.mdpi.com

Energies Free FullText The Use of CFD for the Design and Glass Furnace Design When coupled with secondary models such as seeds removal, volatilization from melt surface (and also models for quality parameters such as silica dissolution, and homogeneity) furnace models have proven to be powerful tools for the design and operation of industrial glass furnaces. In recent years key advances have taken place in the development of glass compositions, in float furnace design. Glass Furnace Design.

From www.tegs.ru

Glass melting furnace TEGS Glass Furnace Design Furnace design (focus on continuous melting tanks) process steps. When coupled with secondary models such as seeds removal, volatilization from melt surface (and also models for quality parameters such as silica dissolution, and homogeneity) furnace models have proven to be powerful tools for the design and operation of industrial glass furnaces. In recent years key advances have taken place in. Glass Furnace Design.

From www.ceramicforum.co.jp

Glass Furnace Simulation Service Ceramic Forum, Glass Manufacturing Glass Furnace Design When coupled with secondary models such as seeds removal, volatilization from melt surface (and also models for quality parameters such as silica dissolution, and homogeneity) furnace models have proven to be powerful tools for the design and operation of industrial glass furnaces. Horn® builds a wide variety of glass furnace types for its customers, ranging from the usual end fired. Glass Furnace Design.

From www.yumpu.com

Float Glass Furnaces Brochure Toledo Engineering Co., Inc. Glass Furnace Design Horn® builds a wide variety of glass furnace types for its customers, ranging from the usual end fired furnace to the all electric melting. Design boundaries (melting rates, temperatures. Furnace design (focus on continuous melting tanks) process steps. When coupled with secondary models such as seeds removal, volatilization from melt surface (and also models for quality parameters such as silica. Glass Furnace Design.

From www.glassfurnaceengineering.com

Melting ISO45001 Borosilicate Electric Glass Furnace Glass Furnace Design Furnace design (focus on continuous melting tanks) process steps. Glassmelting furnaces are of different types whose design and working operations are reviewed in this chapter. Design boundaries (melting rates, temperatures. When coupled with secondary models such as seeds removal, volatilization from melt surface (and also models for quality parameters such as silica dissolution, and homogeneity) furnace models have proven to. Glass Furnace Design.

From www.hornglass.com

Melting Furnaces & Equipment Glass Furnace Design Horn® builds a wide variety of glass furnace types for its customers, ranging from the usual end fired furnace to the all electric melting. Furnace design (focus on continuous melting tanks) process steps. Glassmelting furnaces are of different types whose design and working operations are reviewed in this chapter. Design boundaries (melting rates, temperatures. When coupled with secondary models such. Glass Furnace Design.

From www.enerex.in

Furnace Design Energy Experts Glass Furnace Design In recent years key advances have taken place in the development of glass compositions, in float furnace design and operation and in the forming. Horn® builds a wide variety of glass furnace types for its customers, ranging from the usual end fired furnace to the all electric melting. Glassmelting furnaces are of different types whose design and working operations are. Glass Furnace Design.

From glassopenbook.com

Furnaces & Batch Plants Sp. z o.o. Glass Furnace Design Horn® builds a wide variety of glass furnace types for its customers, ranging from the usual end fired furnace to the all electric melting. Furnace design (focus on continuous melting tanks) process steps. Glassmelting furnaces are of different types whose design and working operations are reviewed in this chapter. When coupled with secondary models such as seeds removal, volatilization from. Glass Furnace Design.