Carbide End Mill Speed Feed Calculator . For deep slots reduce the ft./min. enjoy this simple to use feed and speed calculator for end milling processes. the proper speed and feed help improve tool life and remove material at the optimal rate. Choose a type of operation (drilling, reaming, boring, counterboring, face milling, slab. Find sfm, ipm, rpm, and more here. determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut length. 35 rows enter cutter diameter and surface speed to calculate the r.p.m. Calculate the sfm, then use the rpm. how to use this calculator: free cnc speed and feed calculator allows cnc machinists and cad/cam programmers to calculate milling and drilling speeds. getting good speeds and feeds is quick and easy:

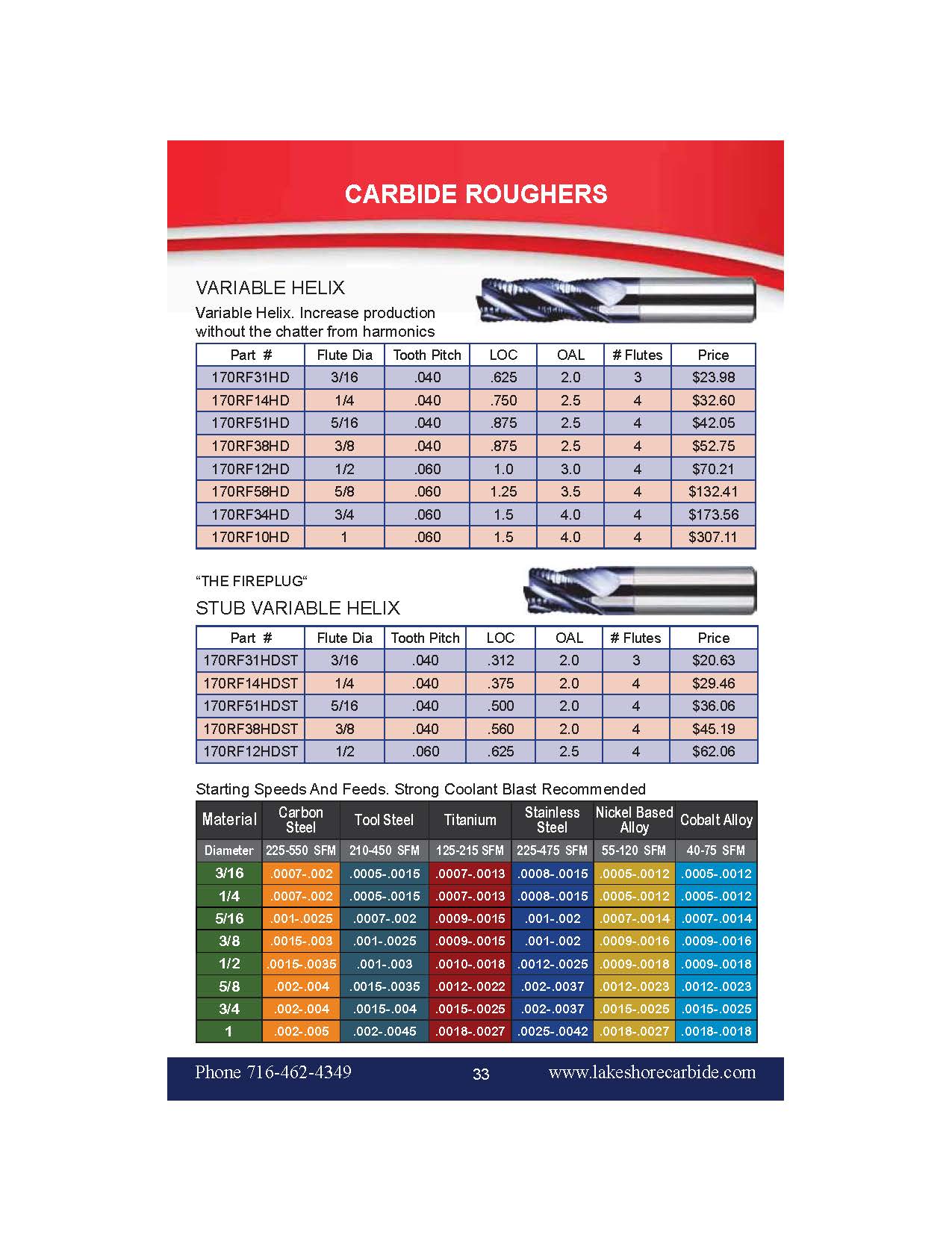

from www.lakeshorecarbide.com

free cnc speed and feed calculator allows cnc machinists and cad/cam programmers to calculate milling and drilling speeds. how to use this calculator: Choose a type of operation (drilling, reaming, boring, counterboring, face milling, slab. the proper speed and feed help improve tool life and remove material at the optimal rate. Find sfm, ipm, rpm, and more here. enjoy this simple to use feed and speed calculator for end milling processes. Calculate the sfm, then use the rpm. 35 rows enter cutter diameter and surface speed to calculate the r.p.m. determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut length. For deep slots reduce the ft./min.

Variable Rougher Speeds & Feeds Lakeshore Carbide Inc.

Carbide End Mill Speed Feed Calculator For deep slots reduce the ft./min. free cnc speed and feed calculator allows cnc machinists and cad/cam programmers to calculate milling and drilling speeds. enjoy this simple to use feed and speed calculator for end milling processes. 35 rows enter cutter diameter and surface speed to calculate the r.p.m. Find sfm, ipm, rpm, and more here. Calculate the sfm, then use the rpm. determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut length. Choose a type of operation (drilling, reaming, boring, counterboring, face milling, slab. the proper speed and feed help improve tool life and remove material at the optimal rate. how to use this calculator: getting good speeds and feeds is quick and easy: For deep slots reduce the ft./min.

From fmcarbide.com

Carbide End Mill Feeds and Speeds Explained FM Carbide Carbide End Mill Speed Feed Calculator determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut length. how to use this calculator: 35 rows enter cutter diameter and surface speed to calculate the r.p.m. For deep slots reduce the ft./min. enjoy this simple to use feed and speed calculator. Carbide End Mill Speed Feed Calculator.

From dat.perueduca.edu.pe

End Mill Cutting Speed Chart Printable Templates Free Carbide End Mill Speed Feed Calculator Find sfm, ipm, rpm, and more here. how to use this calculator: determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut length. enjoy this simple to use feed and speed calculator for end milling processes. 35 rows enter cutter diameter and surface. Carbide End Mill Speed Feed Calculator.

From community.carbide3d.com

Speeds, Feeds, Power, and Force (SFPF) Calculator History Carbide 3D Carbide End Mill Speed Feed Calculator getting good speeds and feeds is quick and easy: Calculate the sfm, then use the rpm. free cnc speed and feed calculator allows cnc machinists and cad/cam programmers to calculate milling and drilling speeds. the proper speed and feed help improve tool life and remove material at the optimal rate. 35 rows enter cutter diameter and. Carbide End Mill Speed Feed Calculator.

From community.carbide3d.com

Tutorial on feeds and speeds Tutorials Carbide 3D Community Site Carbide End Mill Speed Feed Calculator For deep slots reduce the ft./min. the proper speed and feed help improve tool life and remove material at the optimal rate. Calculate the sfm, then use the rpm. getting good speeds and feeds is quick and easy: 35 rows enter cutter diameter and surface speed to calculate the r.p.m. determine the spindle speed (rpm) and. Carbide End Mill Speed Feed Calculator.

From ar.inspiredpencil.com

End Mill Speed Chart Carbide End Mill Speed Feed Calculator getting good speeds and feeds is quick and easy: free cnc speed and feed calculator allows cnc machinists and cad/cam programmers to calculate milling and drilling speeds. Find sfm, ipm, rpm, and more here. Calculate the sfm, then use the rpm. Choose a type of operation (drilling, reaming, boring, counterboring, face milling, slab. determine the spindle speed. Carbide End Mill Speed Feed Calculator.

From www.cnccookbook.com

GWizard Calculator Feeds and Speeds Examples for Experienced CNC'ers Carbide End Mill Speed Feed Calculator the proper speed and feed help improve tool life and remove material at the optimal rate. For deep slots reduce the ft./min. 35 rows enter cutter diameter and surface speed to calculate the r.p.m. Find sfm, ipm, rpm, and more here. how to use this calculator: enjoy this simple to use feed and speed calculator for. Carbide End Mill Speed Feed Calculator.

From mecsoft.com

The Milling Feeds & Speeds Calculator MecSoft Corporation Carbide End Mill Speed Feed Calculator free cnc speed and feed calculator allows cnc machinists and cad/cam programmers to calculate milling and drilling speeds. 35 rows enter cutter diameter and surface speed to calculate the r.p.m. Find sfm, ipm, rpm, and more here. Calculate the sfm, then use the rpm. determine the spindle speed (rpm) and feed rate (ipm) for a milling operation,. Carbide End Mill Speed Feed Calculator.

From informacionpublica2021.svet.gob.gt

Speeds, Feeds, Power, And Force (SFPF) Calculator Carbide, 52 OFF Carbide End Mill Speed Feed Calculator the proper speed and feed help improve tool life and remove material at the optimal rate. For deep slots reduce the ft./min. Calculate the sfm, then use the rpm. Find sfm, ipm, rpm, and more here. free cnc speed and feed calculator allows cnc machinists and cad/cam programmers to calculate milling and drilling speeds. getting good speeds. Carbide End Mill Speed Feed Calculator.

From samhotool.com

Mastering Carbide End Mill Feeds and Speeds A Comprehensive Guide SAMHO Carbide End Mill Speed Feed Calculator how to use this calculator: 35 rows enter cutter diameter and surface speed to calculate the r.p.m. determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut length. enjoy this simple to use feed and speed calculator for end milling processes. getting. Carbide End Mill Speed Feed Calculator.

From www.carbideanddiamondtooling.com

Carbide End Mills Speed and Feeds Carbide End Mill Speed Feed Calculator 35 rows enter cutter diameter and surface speed to calculate the r.p.m. Calculate the sfm, then use the rpm. Choose a type of operation (drilling, reaming, boring, counterboring, face milling, slab. enjoy this simple to use feed and speed calculator for end milling processes. free cnc speed and feed calculator allows cnc machinists and cad/cam programmers to. Carbide End Mill Speed Feed Calculator.

From dxoefokuc.blob.core.windows.net

Osg Carbide End Mills Speeds And Feeds at Damion Hoffman blog Carbide End Mill Speed Feed Calculator determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut length. Calculate the sfm, then use the rpm. enjoy this simple to use feed and speed calculator for end milling processes. getting good speeds and feeds is quick and easy: how to use. Carbide End Mill Speed Feed Calculator.

From samhotool.com

Mastering Carbide End Mill Feeds and Speeds A Comprehensive Guide SAMHO Carbide End Mill Speed Feed Calculator determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut length. For deep slots reduce the ft./min. Choose a type of operation (drilling, reaming, boring, counterboring, face milling, slab. Calculate the sfm, then use the rpm. 35 rows enter cutter diameter and surface speed to. Carbide End Mill Speed Feed Calculator.

From exonqggtm.blob.core.windows.net

Machining Speeds And Feeds App at Alice Jackson blog Carbide End Mill Speed Feed Calculator Find sfm, ipm, rpm, and more here. enjoy this simple to use feed and speed calculator for end milling processes. how to use this calculator: 35 rows enter cutter diameter and surface speed to calculate the r.p.m. determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time. Carbide End Mill Speed Feed Calculator.

From ar.inspiredpencil.com

End Mill Speed Chart Carbide End Mill Speed Feed Calculator how to use this calculator: 35 rows enter cutter diameter and surface speed to calculate the r.p.m. For deep slots reduce the ft./min. Find sfm, ipm, rpm, and more here. Calculate the sfm, then use the rpm. determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for. Carbide End Mill Speed Feed Calculator.

From bamil.lewisburgdistrictumc.org

carbide end mill speed and feed chart Bamil Carbide End Mill Speed Feed Calculator getting good speeds and feeds is quick and easy: how to use this calculator: For deep slots reduce the ft./min. Calculate the sfm, then use the rpm. enjoy this simple to use feed and speed calculator for end milling processes. Choose a type of operation (drilling, reaming, boring, counterboring, face milling, slab. Find sfm, ipm, rpm, and. Carbide End Mill Speed Feed Calculator.

From cncphilosophy.com

Learn Cnc Speeds & Feeds with rpm & feedrate calculator Carbide End Mill Speed Feed Calculator For deep slots reduce the ft./min. enjoy this simple to use feed and speed calculator for end milling processes. 35 rows enter cutter diameter and surface speed to calculate the r.p.m. the proper speed and feed help improve tool life and remove material at the optimal rate. how to use this calculator: Choose a type of. Carbide End Mill Speed Feed Calculator.

From www.2linc.com

Speeds And Feeds Calculator For End Mills Easy To Use 2L Inc. Carbide End Mill Speed Feed Calculator getting good speeds and feeds is quick and easy: 35 rows enter cutter diameter and surface speed to calculate the r.p.m. enjoy this simple to use feed and speed calculator for end milling processes. the proper speed and feed help improve tool life and remove material at the optimal rate. Calculate the sfm, then use the. Carbide End Mill Speed Feed Calculator.

From exoztxrrv.blob.core.windows.net

Carbide Countersink Speeds And Feeds at Ryan Blasko blog Carbide End Mill Speed Feed Calculator Choose a type of operation (drilling, reaming, boring, counterboring, face milling, slab. Calculate the sfm, then use the rpm. free cnc speed and feed calculator allows cnc machinists and cad/cam programmers to calculate milling and drilling speeds. enjoy this simple to use feed and speed calculator for end milling processes. 35 rows enter cutter diameter and surface. Carbide End Mill Speed Feed Calculator.

From ar.inspiredpencil.com

End Mill Speed Chart Carbide End Mill Speed Feed Calculator Choose a type of operation (drilling, reaming, boring, counterboring, face milling, slab. determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut length. Calculate the sfm, then use the rpm. 35 rows enter cutter diameter and surface speed to calculate the r.p.m. how to. Carbide End Mill Speed Feed Calculator.

From www.scribd.com

Speed and Feed Carbide End Mills and Drills Carbide End Mill Speed Feed Calculator free cnc speed and feed calculator allows cnc machinists and cad/cam programmers to calculate milling and drilling speeds. enjoy this simple to use feed and speed calculator for end milling processes. Find sfm, ipm, rpm, and more here. For deep slots reduce the ft./min. 35 rows enter cutter diameter and surface speed to calculate the r.p.m. Calculate. Carbide End Mill Speed Feed Calculator.

From mungfali.com

End Mill Speed And Feed Chart Carbide End Mill Speed Feed Calculator the proper speed and feed help improve tool life and remove material at the optimal rate. Find sfm, ipm, rpm, and more here. For deep slots reduce the ft./min. getting good speeds and feeds is quick and easy: 35 rows enter cutter diameter and surface speed to calculate the r.p.m. free cnc speed and feed calculator. Carbide End Mill Speed Feed Calculator.

From www.2linc.com

Speeds And Feeds End Mills, Engraving, Spring Loaded Tools 2L Inc. Carbide End Mill Speed Feed Calculator how to use this calculator: enjoy this simple to use feed and speed calculator for end milling processes. the proper speed and feed help improve tool life and remove material at the optimal rate. Choose a type of operation (drilling, reaming, boring, counterboring, face milling, slab. free cnc speed and feed calculator allows cnc machinists and. Carbide End Mill Speed Feed Calculator.

From dxoefokuc.blob.core.windows.net

Osg Carbide End Mills Speeds And Feeds at Damion Hoffman blog Carbide End Mill Speed Feed Calculator Calculate the sfm, then use the rpm. Find sfm, ipm, rpm, and more here. free cnc speed and feed calculator allows cnc machinists and cad/cam programmers to calculate milling and drilling speeds. the proper speed and feed help improve tool life and remove material at the optimal rate. For deep slots reduce the ft./min. enjoy this simple. Carbide End Mill Speed Feed Calculator.

From www.carbidedepot.com

Kennametal Solid Carbide End Mill Roughing Application Guide Carbide End Mill Speed Feed Calculator Choose a type of operation (drilling, reaming, boring, counterboring, face milling, slab. enjoy this simple to use feed and speed calculator for end milling processes. determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut length. Calculate the sfm, then use the rpm. Find sfm,. Carbide End Mill Speed Feed Calculator.

From samhotool.com

Mastering Carbide End Mill Feeds and Speeds A Comprehensive Guide SAMHO Carbide End Mill Speed Feed Calculator For deep slots reduce the ft./min. determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut length. enjoy this simple to use feed and speed calculator for end milling processes. Calculate the sfm, then use the rpm. how to use this calculator: free. Carbide End Mill Speed Feed Calculator.

From dxoefokuc.blob.core.windows.net

Osg Carbide End Mills Speeds And Feeds at Damion Hoffman blog Carbide End Mill Speed Feed Calculator how to use this calculator: 35 rows enter cutter diameter and surface speed to calculate the r.p.m. For deep slots reduce the ft./min. the proper speed and feed help improve tool life and remove material at the optimal rate. Choose a type of operation (drilling, reaming, boring, counterboring, face milling, slab. enjoy this simple to use. Carbide End Mill Speed Feed Calculator.

From drillbitsunlimited.com

Feed and Speed Values for Carbide Routers and End Mills Drill Bits Carbide End Mill Speed Feed Calculator getting good speeds and feeds is quick and easy: 35 rows enter cutter diameter and surface speed to calculate the r.p.m. For deep slots reduce the ft./min. Choose a type of operation (drilling, reaming, boring, counterboring, face milling, slab. free cnc speed and feed calculator allows cnc machinists and cad/cam programmers to calculate milling and drilling speeds.. Carbide End Mill Speed Feed Calculator.

From dxoplbffv.blob.core.windows.net

Carbide End Mill Rpm at Diana French blog Carbide End Mill Speed Feed Calculator Find sfm, ipm, rpm, and more here. For deep slots reduce the ft./min. the proper speed and feed help improve tool life and remove material at the optimal rate. free cnc speed and feed calculator allows cnc machinists and cad/cam programmers to calculate milling and drilling speeds. Calculate the sfm, then use the rpm. getting good speeds. Carbide End Mill Speed Feed Calculator.

From atlascuttingtools.com

Speeds and Feeds for Carbide Drilling Carbide End Mill Speed Feed Calculator the proper speed and feed help improve tool life and remove material at the optimal rate. For deep slots reduce the ft./min. Calculate the sfm, then use the rpm. 35 rows enter cutter diameter and surface speed to calculate the r.p.m. how to use this calculator: getting good speeds and feeds is quick and easy: . Carbide End Mill Speed Feed Calculator.

From mellowpine.com

Speeds and Feeds Beginner Guide with Table MellowPine Carbide End Mill Speed Feed Calculator determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut length. how to use this calculator: enjoy this simple to use feed and speed calculator for end milling processes. Find sfm, ipm, rpm, and more here. 35 rows enter cutter diameter and surface. Carbide End Mill Speed Feed Calculator.

From www.scribd.com

Carbide End Mill Feeds and Speeds TuffCut XR 177 Metric Cast Iron Steel Carbide End Mill Speed Feed Calculator Choose a type of operation (drilling, reaming, boring, counterboring, face milling, slab. Calculate the sfm, then use the rpm. determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut length. getting good speeds and feeds is quick and easy: Find sfm, ipm, rpm, and more. Carbide End Mill Speed Feed Calculator.

From www.lakeshorecarbide.com

Variable Rougher Speeds & Feeds Lakeshore Carbide Inc. Carbide End Mill Speed Feed Calculator 35 rows enter cutter diameter and surface speed to calculate the r.p.m. determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut length. how to use this calculator: the proper speed and feed help improve tool life and remove material at the optimal. Carbide End Mill Speed Feed Calculator.

From simmonslosonfere.blogspot.com

Ball Nose End Mill Speeds and Feeds Simmons Losonfere Carbide End Mill Speed Feed Calculator enjoy this simple to use feed and speed calculator for end milling processes. Calculate the sfm, then use the rpm. For deep slots reduce the ft./min. Find sfm, ipm, rpm, and more here. Choose a type of operation (drilling, reaming, boring, counterboring, face milling, slab. the proper speed and feed help improve tool life and remove material at. Carbide End Mill Speed Feed Calculator.

From dxoefokuc.blob.core.windows.net

Osg Carbide End Mills Speeds And Feeds at Damion Hoffman blog Carbide End Mill Speed Feed Calculator Choose a type of operation (drilling, reaming, boring, counterboring, face milling, slab. free cnc speed and feed calculator allows cnc machinists and cad/cam programmers to calculate milling and drilling speeds. For deep slots reduce the ft./min. 35 rows enter cutter diameter and surface speed to calculate the r.p.m. determine the spindle speed (rpm) and feed rate (ipm). Carbide End Mill Speed Feed Calculator.

From exoztxrrv.blob.core.windows.net

Carbide Countersink Speeds And Feeds at Ryan Blasko blog Carbide End Mill Speed Feed Calculator free cnc speed and feed calculator allows cnc machinists and cad/cam programmers to calculate milling and drilling speeds. enjoy this simple to use feed and speed calculator for end milling processes. how to use this calculator: Calculate the sfm, then use the rpm. 35 rows enter cutter diameter and surface speed to calculate the r.p.m. . Carbide End Mill Speed Feed Calculator.