Mould Casting Difference . the difference between casting and moulding is that moulding involves creating a negative space using a rigid mould to shape pliable. Casting involves pouring a liquid material, like metal or plastic, into a mold to achieve a certain shape. Molding generally involves creating a shape in a soft material that is then hardened, often with plastic or rubber. If the mold is made up of multiple pieces, it is put together securely and the casting material is applied. Manufacturers in a wide range of industries rely on components created by compression molding and injection molding. Casting creates an exact replica of the object that was molded, with only some slight sanding needing to be done. though the processes are similar, casting is more widely used to create metallic molds, whereas molding is the preferred method for making plastic molds. molding, often interchangeably used with ‘moulding’, is a manufacturing process of shaping materials into desired forms. the main difference between molding and casting is the use of the material in the process. The primary difference between molding and casting lies in the materials and processes used. casting is done once a mold of an object is available. Carbon fiber parts can be created using either method, depending on the specifications and tolerances associated with the project.

from mechanicstips.blogspot.com

though the processes are similar, casting is more widely used to create metallic molds, whereas molding is the preferred method for making plastic molds. the main difference between molding and casting is the use of the material in the process. Casting creates an exact replica of the object that was molded, with only some slight sanding needing to be done. Carbon fiber parts can be created using either method, depending on the specifications and tolerances associated with the project. casting is done once a mold of an object is available. If the mold is made up of multiple pieces, it is put together securely and the casting material is applied. molding, often interchangeably used with ‘moulding’, is a manufacturing process of shaping materials into desired forms. Manufacturers in a wide range of industries rely on components created by compression molding and injection molding. the difference between casting and moulding is that moulding involves creating a negative space using a rigid mould to shape pliable. Molding generally involves creating a shape in a soft material that is then hardened, often with plastic or rubber.

Casting process & it's Types MechanicsTips

Mould Casting Difference Molding generally involves creating a shape in a soft material that is then hardened, often with plastic or rubber. casting is done once a mold of an object is available. Casting creates an exact replica of the object that was molded, with only some slight sanding needing to be done. molding, often interchangeably used with ‘moulding’, is a manufacturing process of shaping materials into desired forms. Carbon fiber parts can be created using either method, depending on the specifications and tolerances associated with the project. Manufacturers in a wide range of industries rely on components created by compression molding and injection molding. the main difference between molding and casting is the use of the material in the process. The primary difference between molding and casting lies in the materials and processes used. Molding generally involves creating a shape in a soft material that is then hardened, often with plastic or rubber. Casting involves pouring a liquid material, like metal or plastic, into a mold to achieve a certain shape. If the mold is made up of multiple pieces, it is put together securely and the casting material is applied. the difference between casting and moulding is that moulding involves creating a negative space using a rigid mould to shape pliable. though the processes are similar, casting is more widely used to create metallic molds, whereas molding is the preferred method for making plastic molds.

From exyrjclhd.blob.core.windows.net

Permanent Mould Casting Vs Die Casting at Matthew Daniels blog Mould Casting Difference molding, often interchangeably used with ‘moulding’, is a manufacturing process of shaping materials into desired forms. Casting involves pouring a liquid material, like metal or plastic, into a mold to achieve a certain shape. Carbon fiber parts can be created using either method, depending on the specifications and tolerances associated with the project. though the processes are similar,. Mould Casting Difference.

From msvs-dei.vlabs.ac.in

Manufacturing ProcessesI Mould Casting Difference If the mold is made up of multiple pieces, it is put together securely and the casting material is applied. Manufacturers in a wide range of industries rely on components created by compression molding and injection molding. molding, often interchangeably used with ‘moulding’, is a manufacturing process of shaping materials into desired forms. Molding generally involves creating a shape. Mould Casting Difference.

From writingtips.org

'Mould' vs 'Mold' What's the Difference Between the Two? Mould Casting Difference though the processes are similar, casting is more widely used to create metallic molds, whereas molding is the preferred method for making plastic molds. Molding generally involves creating a shape in a soft material that is then hardened, often with plastic or rubber. Carbon fiber parts can be created using either method, depending on the specifications and tolerances associated. Mould Casting Difference.

From mechanicstips.blogspot.com

Casting process & it's Types MechanicsTips Mould Casting Difference molding, often interchangeably used with ‘moulding’, is a manufacturing process of shaping materials into desired forms. though the processes are similar, casting is more widely used to create metallic molds, whereas molding is the preferred method for making plastic molds. the main difference between molding and casting is the use of the material in the process. Casting. Mould Casting Difference.

From fyondolen.blob.core.windows.net

What Is The Difference Between Casting And Moulding at Kathy Barnes blog Mould Casting Difference casting is done once a mold of an object is available. molding, often interchangeably used with ‘moulding’, is a manufacturing process of shaping materials into desired forms. The primary difference between molding and casting lies in the materials and processes used. Manufacturers in a wide range of industries rely on components created by compression molding and injection molding.. Mould Casting Difference.

From www.youtube.com

Permanent Mould Casting Process Animation YouTube Mould Casting Difference Casting involves pouring a liquid material, like metal or plastic, into a mold to achieve a certain shape. the difference between casting and moulding is that moulding involves creating a negative space using a rigid mould to shape pliable. molding, often interchangeably used with ‘moulding’, is a manufacturing process of shaping materials into desired forms. Carbon fiber parts. Mould Casting Difference.

From www.researchgate.net

Types of Mould for Casting. Download Table Mould Casting Difference Casting creates an exact replica of the object that was molded, with only some slight sanding needing to be done. the main difference between molding and casting is the use of the material in the process. Carbon fiber parts can be created using either method, depending on the specifications and tolerances associated with the project. molding, often interchangeably. Mould Casting Difference.

From www.thelibraryofmanufacturing.com

Basic Permanent Mold Casting Mould Casting Difference molding, often interchangeably used with ‘moulding’, is a manufacturing process of shaping materials into desired forms. Molding generally involves creating a shape in a soft material that is then hardened, often with plastic or rubber. Casting creates an exact replica of the object that was molded, with only some slight sanding needing to be done. though the processes. Mould Casting Difference.

From thenextfind.com

20+ Differences Between Cast And Mold (Explained) Mould Casting Difference Manufacturers in a wide range of industries rely on components created by compression molding and injection molding. Carbon fiber parts can be created using either method, depending on the specifications and tolerances associated with the project. Molding generally involves creating a shape in a soft material that is then hardened, often with plastic or rubber. casting is done once. Mould Casting Difference.

From blog.thepipingmart.com

2 Applications of TIG Welding for Industrial and Commercial Mould Casting Difference If the mold is made up of multiple pieces, it is put together securely and the casting material is applied. Molding generally involves creating a shape in a soft material that is then hardened, often with plastic or rubber. the difference between casting and moulding is that moulding involves creating a negative space using a rigid mould to shape. Mould Casting Difference.

From www.smooth-on.com

What is the difference between molding and casting? Mould Casting Difference Casting creates an exact replica of the object that was molded, with only some slight sanding needing to be done. Manufacturers in a wide range of industries rely on components created by compression molding and injection molding. The primary difference between molding and casting lies in the materials and processes used. Casting involves pouring a liquid material, like metal or. Mould Casting Difference.

From www.mech4study.com

Types of Casting in Manufacturing mech4study Mould Casting Difference the difference between casting and moulding is that moulding involves creating a negative space using a rigid mould to shape pliable. Casting creates an exact replica of the object that was molded, with only some slight sanding needing to be done. Manufacturers in a wide range of industries rely on components created by compression molding and injection molding. Molding. Mould Casting Difference.

From hxeguyrvy.blob.core.windows.net

Moulding And Casting Process Pdf at Tara Chun blog Mould Casting Difference Casting involves pouring a liquid material, like metal or plastic, into a mold to achieve a certain shape. Manufacturers in a wide range of industries rely on components created by compression molding and injection molding. the main difference between molding and casting is the use of the material in the process. Molding generally involves creating a shape in a. Mould Casting Difference.

From www.researchgate.net

Types of Mould for Casting. Download Table Mould Casting Difference Manufacturers in a wide range of industries rely on components created by compression molding and injection molding. Molding generally involves creating a shape in a soft material that is then hardened, often with plastic or rubber. If the mold is made up of multiple pieces, it is put together securely and the casting material is applied. The primary difference between. Mould Casting Difference.

From www.iqsdirectory.com

Iron Castings Types, Applications, Process, and Benefits Mould Casting Difference Casting involves pouring a liquid material, like metal or plastic, into a mold to achieve a certain shape. casting is done once a mold of an object is available. though the processes are similar, casting is more widely used to create metallic molds, whereas molding is the preferred method for making plastic molds. Manufacturers in a wide range. Mould Casting Difference.

From www.iqsdirectory.com

Permanent Mold Castings What Is It? How Does It Work? Advantages Mould Casting Difference Casting creates an exact replica of the object that was molded, with only some slight sanding needing to be done. the main difference between molding and casting is the use of the material in the process. molding, often interchangeably used with ‘moulding’, is a manufacturing process of shaping materials into desired forms. If the mold is made up. Mould Casting Difference.

From www.diecasting-mould.com

Permanent Mold Casting vs Die Casting vs Sand Casting What is Mould Casting Difference Casting creates an exact replica of the object that was molded, with only some slight sanding needing to be done. Manufacturers in a wide range of industries rely on components created by compression molding and injection molding. casting is done once a mold of an object is available. The primary difference between molding and casting lies in the materials. Mould Casting Difference.

From www.open.edu

Ceramic mould casting OpenLearn Open University Mould Casting Difference the difference between casting and moulding is that moulding involves creating a negative space using a rigid mould to shape pliable. the main difference between molding and casting is the use of the material in the process. The primary difference between molding and casting lies in the materials and processes used. casting is done once a mold. Mould Casting Difference.

From formechanicalengineering.blogspot.com

for mechanical engineering expendable mold casting Mould Casting Difference Casting involves pouring a liquid material, like metal or plastic, into a mold to achieve a certain shape. Casting creates an exact replica of the object that was molded, with only some slight sanding needing to be done. Carbon fiber parts can be created using either method, depending on the specifications and tolerances associated with the project. molding, often. Mould Casting Difference.

From www.youtube.com

Pattern Types and Mold Cavity Animation in Casting Process by Shubham Mould Casting Difference Manufacturers in a wide range of industries rely on components created by compression molding and injection molding. If the mold is made up of multiple pieces, it is put together securely and the casting material is applied. The primary difference between molding and casting lies in the materials and processes used. Casting involves pouring a liquid material, like metal or. Mould Casting Difference.

From www.youtube.com

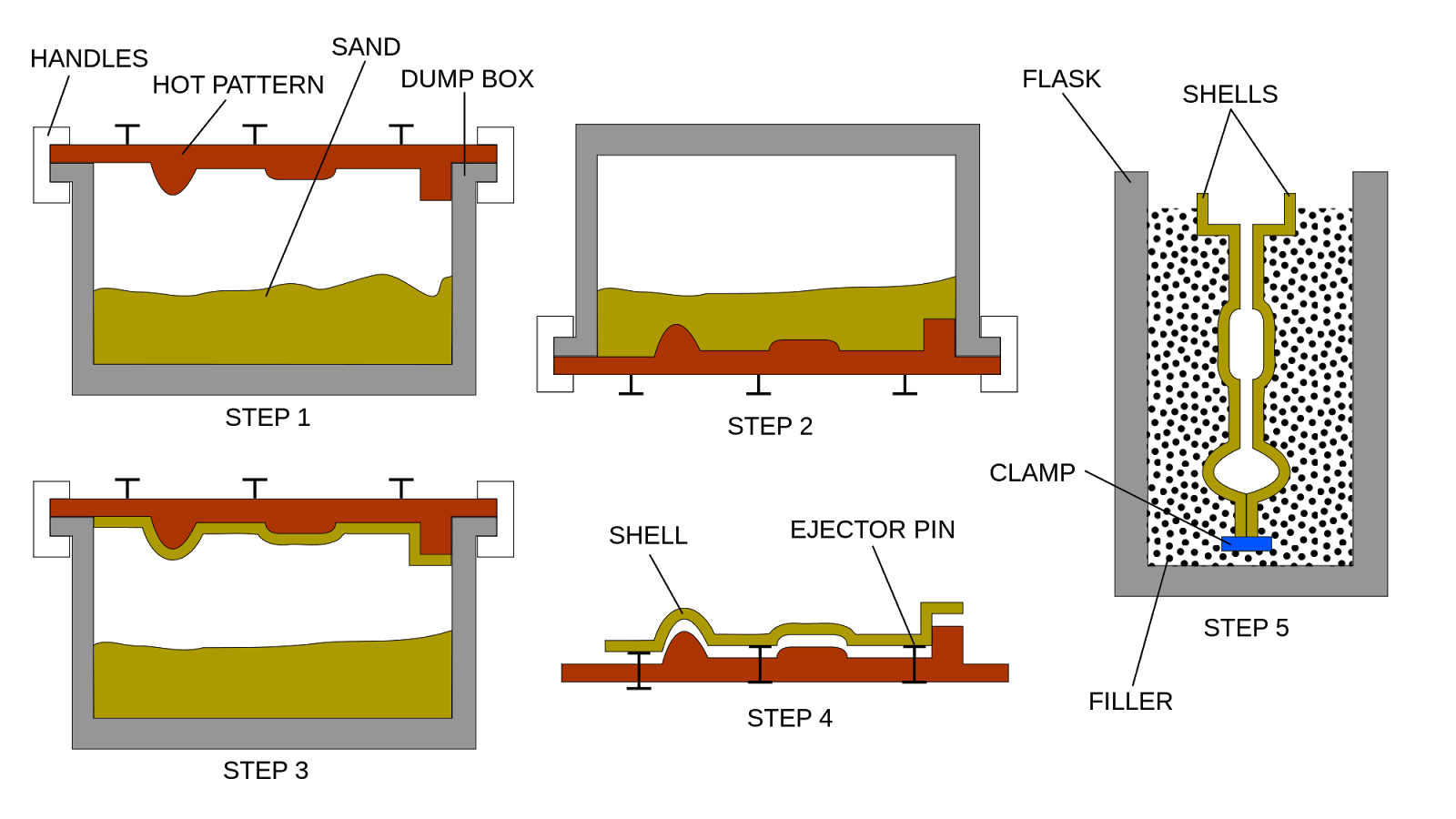

Shell Moulding Process Working Animation Manufacturing Processes Mould Casting Difference The primary difference between molding and casting lies in the materials and processes used. Casting creates an exact replica of the object that was molded, with only some slight sanding needing to be done. the difference between casting and moulding is that moulding involves creating a negative space using a rigid mould to shape pliable. molding, often interchangeably. Mould Casting Difference.

From startup-buzz.com

The Beginner’s Guide to Permanent Mold Casting Startup Buzz Mould Casting Difference though the processes are similar, casting is more widely used to create metallic molds, whereas molding is the preferred method for making plastic molds. Molding generally involves creating a shape in a soft material that is then hardened, often with plastic or rubber. Casting creates an exact replica of the object that was molded, with only some slight sanding. Mould Casting Difference.

From exyeqcfef.blob.core.windows.net

Casting And Moulding Process Difference at Cynthia Perez blog Mould Casting Difference molding, often interchangeably used with ‘moulding’, is a manufacturing process of shaping materials into desired forms. If the mold is made up of multiple pieces, it is put together securely and the casting material is applied. Molding generally involves creating a shape in a soft material that is then hardened, often with plastic or rubber. Casting involves pouring a. Mould Casting Difference.

From www.gabrian.com

Die Casting vs. Sand Casting What is the Difference? Mould Casting Difference casting is done once a mold of an object is available. The primary difference between molding and casting lies in the materials and processes used. Carbon fiber parts can be created using either method, depending on the specifications and tolerances associated with the project. Casting involves pouring a liquid material, like metal or plastic, into a mold to achieve. Mould Casting Difference.

From www.diecasting-mould.com

What is a Sprue in Die Casting Difference Between Sprue and Runner Mould Casting Difference The primary difference between molding and casting lies in the materials and processes used. Casting creates an exact replica of the object that was molded, with only some slight sanding needing to be done. Molding generally involves creating a shape in a soft material that is then hardened, often with plastic or rubber. though the processes are similar, casting. Mould Casting Difference.

From hxepjpxhc.blob.core.windows.net

Moulding Methods In Casting at Antonio Davis blog Mould Casting Difference Carbon fiber parts can be created using either method, depending on the specifications and tolerances associated with the project. Casting creates an exact replica of the object that was molded, with only some slight sanding needing to be done. The primary difference between molding and casting lies in the materials and processes used. If the mold is made up of. Mould Casting Difference.

From engineeringstuff.co.in

Sand mold casting Explained Engineeringstuff Mould Casting Difference The primary difference between molding and casting lies in the materials and processes used. casting is done once a mold of an object is available. Casting involves pouring a liquid material, like metal or plastic, into a mold to achieve a certain shape. Manufacturers in a wide range of industries rely on components created by compression molding and injection. Mould Casting Difference.

From gioxjyotv.blob.core.windows.net

Casting Molding Difference at Lorenzo Hildreth blog Mould Casting Difference Carbon fiber parts can be created using either method, depending on the specifications and tolerances associated with the project. The primary difference between molding and casting lies in the materials and processes used. If the mold is made up of multiple pieces, it is put together securely and the casting material is applied. the difference between casting and moulding. Mould Casting Difference.

From www.ace-mold.com

Die Casting Vs Permanent Mold Casting ACE Group Mould Casting Difference Casting creates an exact replica of the object that was molded, with only some slight sanding needing to be done. casting is done once a mold of an object is available. molding, often interchangeably used with ‘moulding’, is a manufacturing process of shaping materials into desired forms. though the processes are similar, casting is more widely used. Mould Casting Difference.

From davidneat.wordpress.com

‘Beginner’s Basics’ mouldmaking and casting explained davidneat Mould Casting Difference Casting creates an exact replica of the object that was molded, with only some slight sanding needing to be done. Carbon fiber parts can be created using either method, depending on the specifications and tolerances associated with the project. the main difference between molding and casting is the use of the material in the process. Casting involves pouring a. Mould Casting Difference.

From www.thelibraryofmanufacturing.com

Basic Permanent Mold Casting Mould Casting Difference molding, often interchangeably used with ‘moulding’, is a manufacturing process of shaping materials into desired forms. The primary difference between molding and casting lies in the materials and processes used. If the mold is made up of multiple pieces, it is put together securely and the casting material is applied. Casting involves pouring a liquid material, like metal or. Mould Casting Difference.

From www.kimuragrp.co.jp

Full Mold Casting KIMURA Mould Casting Difference though the processes are similar, casting is more widely used to create metallic molds, whereas molding is the preferred method for making plastic molds. Manufacturers in a wide range of industries rely on components created by compression molding and injection molding. Casting involves pouring a liquid material, like metal or plastic, into a mold to achieve a certain shape.. Mould Casting Difference.

From blog.thepipingmart.com

Advantages and Disadvantages of Shell Mold Casting Mould Casting Difference the main difference between molding and casting is the use of the material in the process. the difference between casting and moulding is that moulding involves creating a negative space using a rigid mould to shape pliable. If the mold is made up of multiple pieces, it is put together securely and the casting material is applied. Casting. Mould Casting Difference.

From fyondolen.blob.core.windows.net

What Is The Difference Between Casting And Moulding at Kathy Barnes blog Mould Casting Difference Casting involves pouring a liquid material, like metal or plastic, into a mold to achieve a certain shape. Carbon fiber parts can be created using either method, depending on the specifications and tolerances associated with the project. though the processes are similar, casting is more widely used to create metallic molds, whereas molding is the preferred method for making. Mould Casting Difference.

From engineeringlearn.com

16 Types of Moulding [Explained with Complete Details] Engineering Learn Mould Casting Difference Casting creates an exact replica of the object that was molded, with only some slight sanding needing to be done. casting is done once a mold of an object is available. the main difference between molding and casting is the use of the material in the process. though the processes are similar, casting is more widely used. Mould Casting Difference.