Roughing Turning Inserts . Burr formation is often a problem at the end of the cut (when leaving the workpiece). Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Plus, all the related charts and theory! Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your turning operations. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Cnmg (rhomboid 80 degree), dnmg (diamond 55 degree) and wnmg (trigon 80 degree) are the most popular roughing inserts. Roughing with high depths of cut. Choose the chip breaker (geometry) based on the selected machining operation: Leaving a chamfer or a radius (rolling over a corner) could. Whatever your component or requirements for surface finish, find productive insert grades.

from www.carbidetoolinserts.com

Leaving a chamfer or a radius (rolling over a corner) could. Whatever your component or requirements for surface finish, find productive insert grades. Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your turning operations. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Plus, all the related charts and theory! Cnmg (rhomboid 80 degree), dnmg (diamond 55 degree) and wnmg (trigon 80 degree) are the most popular roughing inserts. Burr formation is often a problem at the end of the cut (when leaving the workpiece). Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Roughing with high depths of cut. Choose the chip breaker (geometry) based on the selected machining operation:

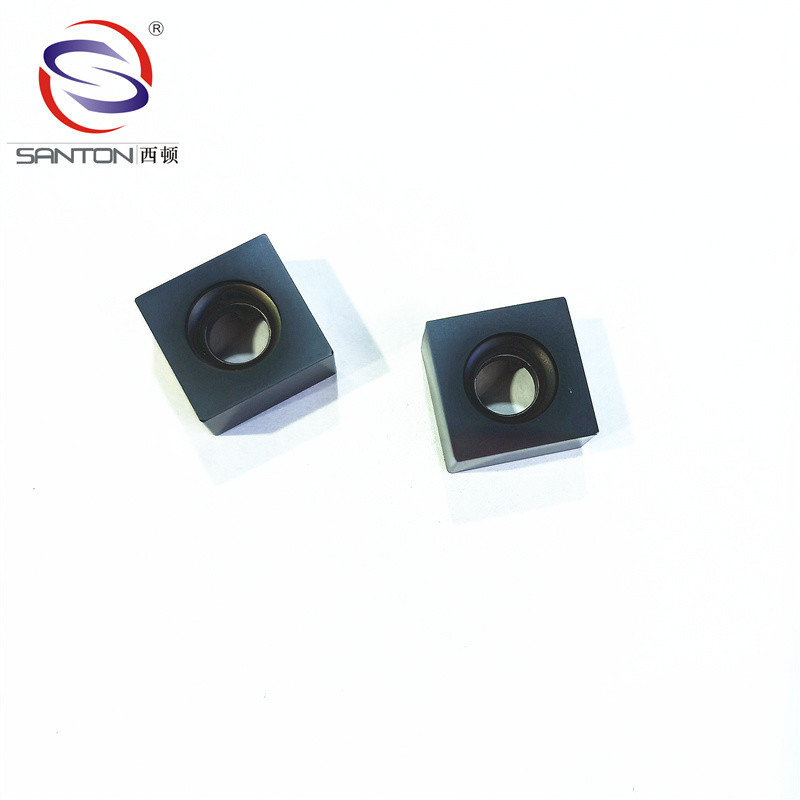

11.5 G/Cm3 Indexable Milling Inserts P15 CVD Shallow Roughing Lathe Turning Inserts

Roughing Turning Inserts Burr formation is often a problem at the end of the cut (when leaving the workpiece). Leaving a chamfer or a radius (rolling over a corner) could. Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your turning operations. Burr formation is often a problem at the end of the cut (when leaving the workpiece). Whatever your component or requirements for surface finish, find productive insert grades. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Cnmg (rhomboid 80 degree), dnmg (diamond 55 degree) and wnmg (trigon 80 degree) are the most popular roughing inserts. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Choose the chip breaker (geometry) based on the selected machining operation: Plus, all the related charts and theory! Roughing with high depths of cut.

From www.ebay.co.uk

Insert Inserts Turning APKT1003PDR Inserts Roughing Semifinishing Steel eBay Roughing Turning Inserts Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Choose the chip breaker (geometry) based on the selected machining operation: Roughing with high depths of cut. Plus, all the related charts and theory! Leaving a chamfer or a radius (rolling over a corner) could. Select workpiece material,. Roughing Turning Inserts.

From www.aliexpress.com

ZCCCT DNMG150608 DNMG 150608 Finishing Medium Roughing Turning Carbide Inserts Cutting Tool CNC Roughing Turning Inserts Choose the chip breaker (geometry) based on the selected machining operation: Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Whatever your component or requirements for surface finish, find productive insert grades. Plus, all the related charts and theory! Roughing with high depths of cut. Leaving a chamfer or a radius (rolling over. Roughing Turning Inserts.

From www.shop-apt.co.uk

CNMG 120412 RM M250 Carbide Inserts for Turning PVD Coated for Roughing Stainless Associated Roughing Turning Inserts Plus, all the related charts and theory! Burr formation is often a problem at the end of the cut (when leaving the workpiece). Roughing with high depths of cut. Choose the chip breaker (geometry) based on the selected machining operation: Whatever your component or requirements for surface finish, find productive insert grades. Understanding the material properties and machining conditions is. Roughing Turning Inserts.

From www.shop-apt.co.uk

CNMG 190612 GS US15 Carbide Turning Inserts PVD Coated for Medium to Roughing Hitemp Alloys Roughing Turning Inserts Roughing with high depths of cut. Burr formation is often a problem at the end of the cut (when leaving the workpiece). Cnmg (rhomboid 80 degree), dnmg (diamond 55 degree) and wnmg (trigon 80 degree) are the most popular roughing inserts. Whatever your component or requirements for surface finish, find productive insert grades. Plus, all the related charts and theory!. Roughing Turning Inserts.

From www.cutwel.co.uk

CNMGGR Roughing Turning Inserts Cutwel Lathe Tool Specialist Roughing Turning Inserts Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Plus, all the related charts and theory! Roughing with high depths of cut. Cnmg (rhomboid 80 degree), dnmg (diamond 55 degree) and wnmg (trigon 80 degree) are the most popular roughing inserts. Selecting the right turning inserts involves considering multiple factors, including insert shape,. Roughing Turning Inserts.

From www.kennametal.com

ISO/ANSI Turning Inserts ISO Turning Carbide Insert • Roughing Negative Geometry Roughing Turning Inserts Burr formation is often a problem at the end of the cut (when leaving the workpiece). Choose the chip breaker (geometry) based on the selected machining operation: Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Cnmg (rhomboid 80 degree), dnmg (diamond 55 degree) and wnmg (trigon. Roughing Turning Inserts.

From www.carbidetoolinserts.com

Roughing K30 Carbide Turning Inserts Vibration Resistance 92.5 HRA Tube Scarfing Inserts Roughing Turning Inserts Burr formation is often a problem at the end of the cut (when leaving the workpiece). Whatever your component or requirements for surface finish, find productive insert grades. Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your turning operations. Cnmg (rhomboid 80 degree), dnmg (diamond 55 degree) and wnmg (trigon 80 degree) are. Roughing Turning Inserts.

From www.cutwel.co.uk

CNMMGH Heavy Roughing Turning Inserts Cutwel Lathe Tool Specialist Roughing Turning Inserts Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your turning operations. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Cnmg (rhomboid 80 degree), dnmg (diamond 55 degree) and wnmg (trigon 80 degree) are the most popular roughing inserts. Selecting the right turning inserts involves considering. Roughing Turning Inserts.

From www.kennametal.com

ISO/ANSI Turning Inserts ISO Turning Carbide Insert • Roughing Negative Geometry Roughing Turning Inserts Whatever your component or requirements for surface finish, find productive insert grades. Roughing with high depths of cut. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Plus, all the related charts and theory! Leaving a chamfer or a radius (rolling over a corner) could. Select workpiece material, workpiece condition, and roughing/finishing to. Roughing Turning Inserts.

From www.kennametal.com

ISO/ANSI Turning Inserts ISO Turning Carbide Insert • Roughing Positive Geometry Roughing Turning Inserts Whatever your component or requirements for surface finish, find productive insert grades. Cnmg (rhomboid 80 degree), dnmg (diamond 55 degree) and wnmg (trigon 80 degree) are the most popular roughing inserts. Burr formation is often a problem at the end of the cut (when leaving the workpiece). Plus, all the related charts and theory! Roughing with high depths of cut.. Roughing Turning Inserts.

From xmkktool.en.made-in-china.com

High Quality Roughing and Finishing Indexable Milling Inserts Milling Tools CNC/PCD/CBN Turning Roughing Turning Inserts Cnmg (rhomboid 80 degree), dnmg (diamond 55 degree) and wnmg (trigon 80 degree) are the most popular roughing inserts. Roughing with high depths of cut. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Plus, all the related charts and theory! Choose the chip breaker (geometry) based. Roughing Turning Inserts.

From xmkktool.en.made-in-china.com

High Quality Roughing and Finishing Indexable Milling Inserts Milling Tools CNC/PCD/CBN Turning Roughing Turning Inserts Burr formation is often a problem at the end of the cut (when leaving the workpiece). Leaving a chamfer or a radius (rolling over a corner) could. Plus, all the related charts and theory! Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Whatever your component or. Roughing Turning Inserts.

From www.kennametal.com

ISO/ANSI Turning Inserts ISO Turning Carbide Insert • Roughing Positive Geometry Roughing Turning Inserts Roughing with high depths of cut. Cnmg (rhomboid 80 degree), dnmg (diamond 55 degree) and wnmg (trigon 80 degree) are the most popular roughing inserts. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Burr formation is often a problem at the end of the cut (when. Roughing Turning Inserts.

From xmkktool.en.made-in-china.com

High Quality Roughing and Finishing Indexable Milling Inserts Milling Tools CNC/PCD/CBN Turning Roughing Turning Inserts Roughing with high depths of cut. Leaving a chamfer or a radius (rolling over a corner) could. Whatever your component or requirements for surface finish, find productive insert grades. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Choose the chip breaker (geometry) based on the selected. Roughing Turning Inserts.

From www.carbidetoolinserts.com

11.5 G/Cm3 Indexable Milling Inserts P15 CVD Shallow Roughing Lathe Turning Inserts Roughing Turning Inserts Choose the chip breaker (geometry) based on the selected machining operation: Leaving a chamfer or a radius (rolling over a corner) could. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Cnmg (rhomboid 80 degree), dnmg (diamond 55 degree) and wnmg (trigon 80 degree) are the most popular roughing inserts. Whatever your component. Roughing Turning Inserts.

From www.carbidetoolinserts.com

Roughing K30 Carbide Turning Inserts Vibration Resistance 92.5 HRA Tube Scarfing Inserts Roughing Turning Inserts Whatever your component or requirements for surface finish, find productive insert grades. Choose the chip breaker (geometry) based on the selected machining operation: Plus, all the related charts and theory! Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker. Roughing Turning Inserts.

From en.zzklt.com

Roughing turning inserts for steel【价格 批发 公司】Zhuzhou Kerno Advanced Materials Co.,LTD Roughing Turning Inserts Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Leaving a chamfer or a radius (rolling over a corner) could. Roughing with high depths of cut. Whatever your component or requirements for surface finish, find productive insert grades. Burr formation is often a problem at the end. Roughing Turning Inserts.

From www.big-tools.com

Triangle Turning Insert TNMG160408R Carbide Cutting Tool Plate for Roughing of Steel Bigtools Roughing Turning Inserts Roughing with high depths of cut. Leaving a chamfer or a radius (rolling over a corner) could. Whatever your component or requirements for surface finish, find productive insert grades. Cnmg (rhomboid 80 degree), dnmg (diamond 55 degree) and wnmg (trigon 80 degree) are the most popular roughing inserts. Plus, all the related charts and theory! Select workpiece material, workpiece condition,. Roughing Turning Inserts.

From xmkktool.en.made-in-china.com

High Quality Roughing and Finishing Indexable Milling Inserts Milling Tools CNC/PCD/CBN Turning Roughing Turning Inserts Choose the chip breaker (geometry) based on the selected machining operation: Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your turning operations. Burr formation is often a problem at the end of the cut (when leaving the workpiece). Plus, all the related charts and theory! Understanding the material properties and machining conditions is. Roughing Turning Inserts.

From www.shop-apt.co.uk

WNMG 080412 RP PC25 Carbide Inserts for Turning CVD Coated for Roughing Steel Associated Roughing Turning Inserts Roughing with high depths of cut. Cnmg (rhomboid 80 degree), dnmg (diamond 55 degree) and wnmg (trigon 80 degree) are the most popular roughing inserts. Leaving a chamfer or a radius (rolling over a corner) could. Whatever your component or requirements for surface finish, find productive insert grades. Understanding the material properties and machining conditions is crucial for optimizing performance. Roughing Turning Inserts.

From lonestarcarbide.com

Roughing, Turning & Boring Inserts Lone Star Carbide & Tooling Roughing Turning Inserts Plus, all the related charts and theory! Leaving a chamfer or a radius (rolling over a corner) could. Cnmg (rhomboid 80 degree), dnmg (diamond 55 degree) and wnmg (trigon 80 degree) are the most popular roughing inserts. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Select workpiece material, workpiece condition, and roughing/finishing. Roughing Turning Inserts.

From mtimagazine.com

Walter completes range of roughturning inserts MTI Magazine Roughing Turning Inserts Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Roughing with high depths of cut. Leaving a chamfer or a radius (rolling over a corner) could. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Select workpiece material, workpiece condition,. Roughing Turning Inserts.

From www.usitools.com

Insert CNMG VQ rough & semifinishing turning Roughing Turning Inserts Cnmg (rhomboid 80 degree), dnmg (diamond 55 degree) and wnmg (trigon 80 degree) are the most popular roughing inserts. Plus, all the related charts and theory! Whatever your component or requirements for surface finish, find productive insert grades. Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your turning operations. Roughing with high depths. Roughing Turning Inserts.

From www.walmart.com

High Strength High Performance Insert Blade, Turning Inserts, Cast Iron Roughing Steel Semi Roughing Turning Inserts Roughing with high depths of cut. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your. Roughing Turning Inserts.

From www.alibaba.com

Cnc Lathe Indexable Solid Carbide Turning Insert Blade For Turning Tool Holder Wnmg 431/433/432 Roughing Turning Inserts Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Plus, all the related charts and theory! Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your turning operations. Burr formation is often a problem at the end of the cut (when. Roughing Turning Inserts.

From www.cutwel.co.uk

CNMGGR Roughing Turning Inserts Cutwel Lathe Tool Specialist Roughing Turning Inserts Leaving a chamfer or a radius (rolling over a corner) could. Roughing with high depths of cut. Whatever your component or requirements for surface finish, find productive insert grades. Burr formation is often a problem at the end of the cut (when leaving the workpiece). Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for. Roughing Turning Inserts.

From www.cutwel.co.uk

SNMGGR Roughing Turning Inserts Cutwel Lathe Tool Specialist Roughing Turning Inserts Cnmg (rhomboid 80 degree), dnmg (diamond 55 degree) and wnmg (trigon 80 degree) are the most popular roughing inserts. Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your turning operations. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Whatever your component or requirements for surface. Roughing Turning Inserts.

From www.kennametal.com

ISO/ANSI Turning Inserts ISO Turning Carbide Insert • Roughing Positive Geometry Roughing Turning Inserts Choose the chip breaker (geometry) based on the selected machining operation: Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Roughing with high depths of cut. Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your turning operations. Cnmg (rhomboid 80 degree), dnmg (diamond 55 degree) and. Roughing Turning Inserts.

From carbidecomponents.com

CNGG 120408 Carbide inserts Turning inserts for Roughing Work Roughing Turning Inserts Choose the chip breaker (geometry) based on the selected machining operation: Burr formation is often a problem at the end of the cut (when leaving the workpiece). Whatever your component or requirements for surface finish, find productive insert grades. Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your turning operations. Roughing with high. Roughing Turning Inserts.

From www.usitools.com

Turning insert roughing et semifinishing pour tools AD Roughing Turning Inserts Choose the chip breaker (geometry) based on the selected machining operation: Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your turning operations. Cnmg (rhomboid 80 degree), dnmg (diamond 55 degree) and wnmg (trigon 80 degree) are the most popular roughing inserts. Plus, all the related charts and theory! Selecting the right turning inserts. Roughing Turning Inserts.

From www.shop-apt.co.uk

WNMG 080408 GS US15 Carbide Turning Inserts PVD Coated for Medium to Roughing Hitemp Alloys Roughing Turning Inserts Roughing with high depths of cut. Plus, all the related charts and theory! Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your turning operations. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Burr formation is often a problem at. Roughing Turning Inserts.

From carbidecomponents.com

CNGG 120408 Carbide inserts Turning inserts for Roughing Work Roughing Turning Inserts Roughing with high depths of cut. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Choose the chip breaker (geometry) based on the selected machining operation: Select workpiece material, workpiece condition,. Roughing Turning Inserts.

From www.alibaba.com

Dcmt11t308 Positive Universal Roughing Geometry Tungsten Carbide Turning Inserts Buy Cutting Roughing Turning Inserts Choose the chip breaker (geometry) based on the selected machining operation: Whatever your component or requirements for surface finish, find productive insert grades. Burr formation is often a problem at the end of the cut (when leaving the workpiece). Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your turning operations. Plus, all the. Roughing Turning Inserts.

From www.kennametal.com

ISO/ANSI Turning Inserts ISO Turning Carbide Insert • Roughing Positive Geometry Roughing Turning Inserts Burr formation is often a problem at the end of the cut (when leaving the workpiece). Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Whatever your component or requirements for surface finish, find productive insert grades. Roughing with high depths of cut. Select workpiece material, workpiece condition, and roughing/finishing to find the. Roughing Turning Inserts.

From senotools.en.made-in-china.com

Original Zcc Tungsten Carbide Knife Turning Tools Tnmg160408rS Ybc251 Roughing Turning Inserts Roughing Turning Inserts Plus, all the related charts and theory! Roughing with high depths of cut. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Cnmg (rhomboid 80 degree), dnmg (diamond 55 degree) and wnmg (trigon 80 degree) are the most popular roughing inserts. Burr formation is often a problem at the end of the cut. Roughing Turning Inserts.