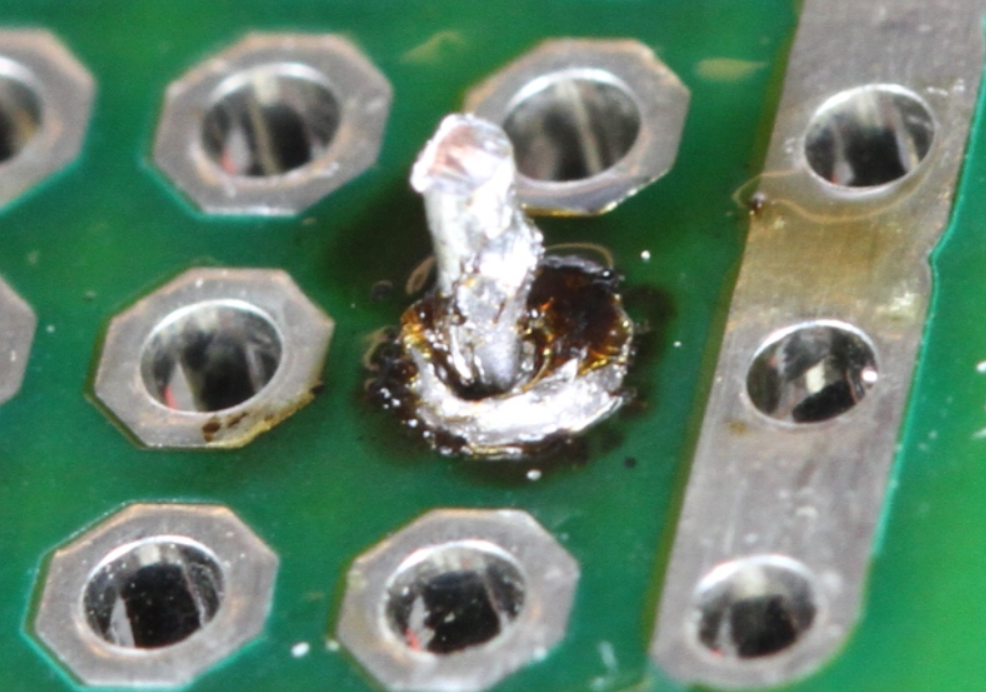

Solder Wicking Defect . solder wicking is a serious problem where the issue is of molten solder flowing into a via hole or climbing up the lead of a component. wicking solder, also known as solder drainage or solder escape, occurs when the solder moves away from the intended pad on a pcb and accumulates in undesired locations. Solder wicking is referred to as when the solder gets flown away on a pcb from the pad. solder wicking (also know as solder drainage) occurs when the solder flows away from the pad on a pcb, accumulates on the. The component terminal typically has a lower melting point than the pad to which it is being soldered. Solder wicking in printed circuit board assembly. During reflow, a larger copper area with a higher thermal capacity is usually hotter than the small pad to which it is linked. This further leads to dirt getting accumulated on the surface that leads to holes and tracks. table of contents. what is solder wick? among the variety of potentially serious problems is solder wicking; a wicking defect is the flow of solder either up the lead of the component or along traces and possibly under insulation and through. In this case a challenge to be submitted by a demanding. Here are some common reasons for solder escape, or solder wicking:

from www.atetool.com

what is solder wick? a wicking defect is the flow of solder either up the lead of the component or along traces and possibly under insulation and through. In this case a challenge to be submitted by a demanding. Solder wicking in printed circuit board assembly. table of contents. among the variety of potentially serious problems is solder wicking; Here are some common reasons for solder escape, or solder wicking: wicking solder, also known as solder drainage or solder escape, occurs when the solder moves away from the intended pad on a pcb and accumulates in undesired locations. Solder wicking is referred to as when the solder gets flown away on a pcb from the pad. This further leads to dirt getting accumulated on the surface that leads to holes and tracks.

9 most common problems and mistakes in soldering

Solder Wicking Defect what is solder wick? The component terminal typically has a lower melting point than the pad to which it is being soldered. table of contents. Here are some common reasons for solder escape, or solder wicking: This further leads to dirt getting accumulated on the surface that leads to holes and tracks. among the variety of potentially serious problems is solder wicking; During reflow, a larger copper area with a higher thermal capacity is usually hotter than the small pad to which it is linked. what is solder wick? solder wicking is a serious problem where the issue is of molten solder flowing into a via hole or climbing up the lead of a component. Solder wicking in printed circuit board assembly. In this case a challenge to be submitted by a demanding. a wicking defect is the flow of solder either up the lead of the component or along traces and possibly under insulation and through. wicking solder, also known as solder drainage or solder escape, occurs when the solder moves away from the intended pad on a pcb and accumulates in undesired locations. solder wicking (also know as solder drainage) occurs when the solder flows away from the pad on a pcb, accumulates on the. Solder wicking is referred to as when the solder gets flown away on a pcb from the pad.

From www.finepowertools.com

9 Types of Soldering Defects and Their Solutions Solder Wicking Defect This further leads to dirt getting accumulated on the surface that leads to holes and tracks. Solder wicking is referred to as when the solder gets flown away on a pcb from the pad. table of contents. solder wicking is a serious problem where the issue is of molten solder flowing into a via hole or climbing up. Solder Wicking Defect.

From www.youtube.com

How to Use Solder Wick for Desoldering (Remove Solder with Wick) YouTube Solder Wicking Defect wicking solder, also known as solder drainage or solder escape, occurs when the solder moves away from the intended pad on a pcb and accumulates in undesired locations. solder wicking is a serious problem where the issue is of molten solder flowing into a via hole or climbing up the lead of a component. what is solder. Solder Wicking Defect.

From www.youtube.com

Solder wicking.avi YouTube Solder Wicking Defect In this case a challenge to be submitted by a demanding. wicking solder, also known as solder drainage or solder escape, occurs when the solder moves away from the intended pad on a pcb and accumulates in undesired locations. solder wicking is a serious problem where the issue is of molten solder flowing into a via hole or. Solder Wicking Defect.

From www.atetool.com

9 most common problems and mistakes in soldering Solder Wicking Defect During reflow, a larger copper area with a higher thermal capacity is usually hotter than the small pad to which it is linked. solder wicking is a serious problem where the issue is of molten solder flowing into a via hole or climbing up the lead of a component. wicking solder, also known as solder drainage or solder. Solder Wicking Defect.

From www.youtube.com

Most common defects (tombstone and solder Ball) during SMT soldering Solder Wicking Defect solder wicking (also know as solder drainage) occurs when the solder flows away from the pad on a pcb, accumulates on the. This further leads to dirt getting accumulated on the surface that leads to holes and tracks. among the variety of potentially serious problems is solder wicking; In this case a challenge to be submitted by a. Solder Wicking Defect.

From www.youtube.com

Removal of Solder Using Solder Wick YouTube Solder Wicking Defect In this case a challenge to be submitted by a demanding. wicking solder, also known as solder drainage or solder escape, occurs when the solder moves away from the intended pad on a pcb and accumulates in undesired locations. solder wicking is a serious problem where the issue is of molten solder flowing into a via hole or. Solder Wicking Defect.

From cejvmwoa.blob.core.windows.net

Solder Defect Images at Byron Miller blog Solder Wicking Defect Here are some common reasons for solder escape, or solder wicking: In this case a challenge to be submitted by a demanding. table of contents. Solder wicking in printed circuit board assembly. a wicking defect is the flow of solder either up the lead of the component or along traces and possibly under insulation and through. The component. Solder Wicking Defect.

From pcbtrace.com

Mastering Solder EscapeWicking Unveiling Techniques PCB Trace Solder Wicking Defect what is solder wick? During reflow, a larger copper area with a higher thermal capacity is usually hotter than the small pad to which it is linked. table of contents. wicking solder, also known as solder drainage or solder escape, occurs when the solder moves away from the intended pad on a pcb and accumulates in undesired. Solder Wicking Defect.

From exomcveox.blob.core.windows.net

Soldering Common Problems at Derrick Hall blog Solder Wicking Defect The component terminal typically has a lower melting point than the pad to which it is being soldered. solder wicking (also know as solder drainage) occurs when the solder flows away from the pad on a pcb, accumulates on the. among the variety of potentially serious problems is solder wicking; a wicking defect is the flow of. Solder Wicking Defect.

From electric-shocks.com

Mastering Desoldering A StepbyStep Guide on How to Use Solder Wick Solder Wicking Defect Solder wicking in printed circuit board assembly. wicking solder, also known as solder drainage or solder escape, occurs when the solder moves away from the intended pad on a pcb and accumulates in undesired locations. This further leads to dirt getting accumulated on the surface that leads to holes and tracks. Here are some common reasons for solder escape,. Solder Wicking Defect.

From reversepcb.com

Wicking Solder Understanding the Process and Solutions Reversepcb Solder Wicking Defect Solder wicking is referred to as when the solder gets flown away on a pcb from the pad. During reflow, a larger copper area with a higher thermal capacity is usually hotter than the small pad to which it is linked. a wicking defect is the flow of solder either up the lead of the component or along traces. Solder Wicking Defect.

From www.tech-sparks.com

Common BGA Soldering Defects and How to Avoid Them TechSparks Solder Wicking Defect solder wicking is a serious problem where the issue is of molten solder flowing into a via hole or climbing up the lead of a component. This further leads to dirt getting accumulated on the surface that leads to holes and tracks. Solder wicking is referred to as when the solder gets flown away on a pcb from the. Solder Wicking Defect.

From www.bobwillis.co.uk

Wave Soldering Defect Guide Bob Willis Solder Wicking Defect wicking solder, also known as solder drainage or solder escape, occurs when the solder moves away from the intended pad on a pcb and accumulates in undesired locations. table of contents. The component terminal typically has a lower melting point than the pad to which it is being soldered. solder wicking (also know as solder drainage) occurs. Solder Wicking Defect.

From www.finepowertools.com

9 Types of Soldering Defects and Their Solutions Solder Wicking Defect This further leads to dirt getting accumulated on the surface that leads to holes and tracks. solder wicking is a serious problem where the issue is of molten solder flowing into a via hole or climbing up the lead of a component. among the variety of potentially serious problems is solder wicking; what is solder wick? . Solder Wicking Defect.

From resources.ema-eda.com

The Designer’s Guide to PCB Solder Defects Solder Wicking Defect During reflow, a larger copper area with a higher thermal capacity is usually hotter than the small pad to which it is linked. what is solder wick? a wicking defect is the flow of solder either up the lead of the component or along traces and possibly under insulation and through. The component terminal typically has a lower. Solder Wicking Defect.

From www.protoexpress.com

6 Common Solder Mask Errors in PCBs Sierra Circuits Solder Wicking Defect what is solder wick? wicking solder, also known as solder drainage or solder escape, occurs when the solder moves away from the intended pad on a pcb and accumulates in undesired locations. This further leads to dirt getting accumulated on the surface that leads to holes and tracks. table of contents. Solder wicking in printed circuit board. Solder Wicking Defect.

From www.finepowertools.com

9 Types of Soldering Defects and Their Solutions Solder Wicking Defect During reflow, a larger copper area with a higher thermal capacity is usually hotter than the small pad to which it is linked. Here are some common reasons for solder escape, or solder wicking: In this case a challenge to be submitted by a demanding. solder wicking (also know as solder drainage) occurs when the solder flows away from. Solder Wicking Defect.

From www.ept.ca

Soldering defects and atmosphere explained Electronic Products Solder Wicking Defect In this case a challenge to be submitted by a demanding. The component terminal typically has a lower melting point than the pad to which it is being soldered. Solder wicking is referred to as when the solder gets flown away on a pcb from the pad. a wicking defect is the flow of solder either up the lead. Solder Wicking Defect.

From www.youtube.com

03 Beginner Techniques Solder Wicking YouTube Solder Wicking Defect table of contents. In this case a challenge to be submitted by a demanding. among the variety of potentially serious problems is solder wicking; Solder wicking in printed circuit board assembly. wicking solder, also known as solder drainage or solder escape, occurs when the solder moves away from the intended pad on a pcb and accumulates in. Solder Wicking Defect.

From rushpcb.com

Detection & Prevention of Solder Joint Failure Rush PCB Solder Wicking Defect solder wicking is a serious problem where the issue is of molten solder flowing into a via hole or climbing up the lead of a component. In this case a challenge to be submitted by a demanding. This further leads to dirt getting accumulated on the surface that leads to holes and tracks. Solder wicking in printed circuit board. Solder Wicking Defect.

From www.finepowertools.com

9 Types of Soldering Defects and Their Solutions Solder Wicking Defect This further leads to dirt getting accumulated on the surface that leads to holes and tracks. In this case a challenge to be submitted by a demanding. solder wicking (also know as solder drainage) occurs when the solder flows away from the pad on a pcb, accumulates on the. During reflow, a larger copper area with a higher thermal. Solder Wicking Defect.

From www.youtube.com

How to repair bridge and excess solder YouTube Solder Wicking Defect Solder wicking in printed circuit board assembly. solder wicking (also know as solder drainage) occurs when the solder flows away from the pad on a pcb, accumulates on the. Here are some common reasons for solder escape, or solder wicking: solder wicking is a serious problem where the issue is of molten solder flowing into a via hole. Solder Wicking Defect.

From exohuscdj.blob.core.windows.net

Solder Wick Grainger at Annie Bare blog Solder Wicking Defect Solder wicking in printed circuit board assembly. wicking solder, also known as solder drainage or solder escape, occurs when the solder moves away from the intended pad on a pcb and accumulates in undesired locations. This further leads to dirt getting accumulated on the surface that leads to holes and tracks. The component terminal typically has a lower melting. Solder Wicking Defect.

From digital.library.unt.edu

Design of Experiments to Determine Causes of Flex Cable Solder Wicking Solder Wicking Defect a wicking defect is the flow of solder either up the lead of the component or along traces and possibly under insulation and through. solder wicking is a serious problem where the issue is of molten solder flowing into a via hole or climbing up the lead of a component. This further leads to dirt getting accumulated on. Solder Wicking Defect.

From www.researchgate.net

Common solder joint defects [23] Download Scientific Diagram Solder Wicking Defect a wicking defect is the flow of solder either up the lead of the component or along traces and possibly under insulation and through. among the variety of potentially serious problems is solder wicking; solder wicking (also know as solder drainage) occurs when the solder flows away from the pad on a pcb, accumulates on the. Solder. Solder Wicking Defect.

From www.youtube.com

Wave Soldering Defect Part 2, Types of Soldering Defects. YouTube Solder Wicking Defect solder wicking (also know as solder drainage) occurs when the solder flows away from the pad on a pcb, accumulates on the. During reflow, a larger copper area with a higher thermal capacity is usually hotter than the small pad to which it is linked. The component terminal typically has a lower melting point than the pad to which. Solder Wicking Defect.

From absolutepcbassembly.com

What is Solder Wicking & how to test it? Absolute Electronics Services Solder Wicking Defect wicking solder, also known as solder drainage or solder escape, occurs when the solder moves away from the intended pad on a pcb and accumulates in undesired locations. among the variety of potentially serious problems is solder wicking; During reflow, a larger copper area with a higher thermal capacity is usually hotter than the small pad to which. Solder Wicking Defect.

From resources.pcb.cadence.com

The Designer’s Guide to PCB Solder Defects Solder Wicking Defect Solder wicking is referred to as when the solder gets flown away on a pcb from the pad. a wicking defect is the flow of solder either up the lead of the component or along traces and possibly under insulation and through. among the variety of potentially serious problems is solder wicking; During reflow, a larger copper area. Solder Wicking Defect.

From www.finepowertools.com

9 Types of Soldering Defects and Their Solutions Solder Wicking Defect During reflow, a larger copper area with a higher thermal capacity is usually hotter than the small pad to which it is linked. Solder wicking is referred to as when the solder gets flown away on a pcb from the pad. a wicking defect is the flow of solder either up the lead of the component or along traces. Solder Wicking Defect.

From www.raypcb.com

Chemtronics Solder Wicking Exploring the Benefits and Uses RAYMING PCB Solder Wicking Defect wicking solder, also known as solder drainage or solder escape, occurs when the solder moves away from the intended pad on a pcb and accumulates in undesired locations. solder wicking (also know as solder drainage) occurs when the solder flows away from the pad on a pcb, accumulates on the. table of contents. Solder wicking in printed. Solder Wicking Defect.

From dxooqpqrm.blob.core.windows.net

Solder Defects List at Emily Black blog Solder Wicking Defect Solder wicking is referred to as when the solder gets flown away on a pcb from the pad. Here are some common reasons for solder escape, or solder wicking: a wicking defect is the flow of solder either up the lead of the component or along traces and possibly under insulation and through. what is solder wick? . Solder Wicking Defect.

From www.youtube.com

How to use a soldering iron and desoldering wick YouTube Solder Wicking Defect The component terminal typically has a lower melting point than the pad to which it is being soldered. Solder wicking is referred to as when the solder gets flown away on a pcb from the pad. In this case a challenge to be submitted by a demanding. Here are some common reasons for solder escape, or solder wicking: During reflow,. Solder Wicking Defect.

From resources.ema-eda.com

The Designer’s Guide to PCB Solder Defects Solder Wicking Defect In this case a challenge to be submitted by a demanding. Solder wicking in printed circuit board assembly. solder wicking (also know as solder drainage) occurs when the solder flows away from the pad on a pcb, accumulates on the. The component terminal typically has a lower melting point than the pad to which it is being soldered. . Solder Wicking Defect.

From www.mdpi.com

Entropy Free FullText A Novel Contrastive SelfSupervised Learning Solder Wicking Defect a wicking defect is the flow of solder either up the lead of the component or along traces and possibly under insulation and through. The component terminal typically has a lower melting point than the pad to which it is being soldered. Here are some common reasons for solder escape, or solder wicking: wicking solder, also known as. Solder Wicking Defect.

From www.researchgate.net

Top 5 Defects in Manual solderingMonth wise Download Scientific Diagram Solder Wicking Defect among the variety of potentially serious problems is solder wicking; In this case a challenge to be submitted by a demanding. table of contents. solder wicking (also know as solder drainage) occurs when the solder flows away from the pad on a pcb, accumulates on the. Solder wicking in printed circuit board assembly. what is solder. Solder Wicking Defect.