Grinding Wheel Measurements . Coarse grains are used for. Grinding wheels, regardless of their manufacturer, are made up of three main components: 10” x 1 ½” x ¼”, and should be located directly on the front or side of the wheel cartridge. There are three main types of grinding wheels, where various numbers differentiate between wheels with specific properties and uses —. Lower numbers (such as 10, 16 or 24) denote a wheel with coarse grain. It will look something like this: Grinding wheels are essential tools for wood and metal working. The general format for grinding wheel specifications will read as three numbers, with lowercase “x” symbols in between. The coarser the grain, the larger the size of the material removed. Today’s discussion revolves around grinding wheels, where we’ll dissect their materials, bonds, grain sizes, grades,. Understanding grinding wheel specifications is. Aluminum oxide, silicon carbide, zirconia, ceramic alumina, cbn,. They have a few fundamental requirements.

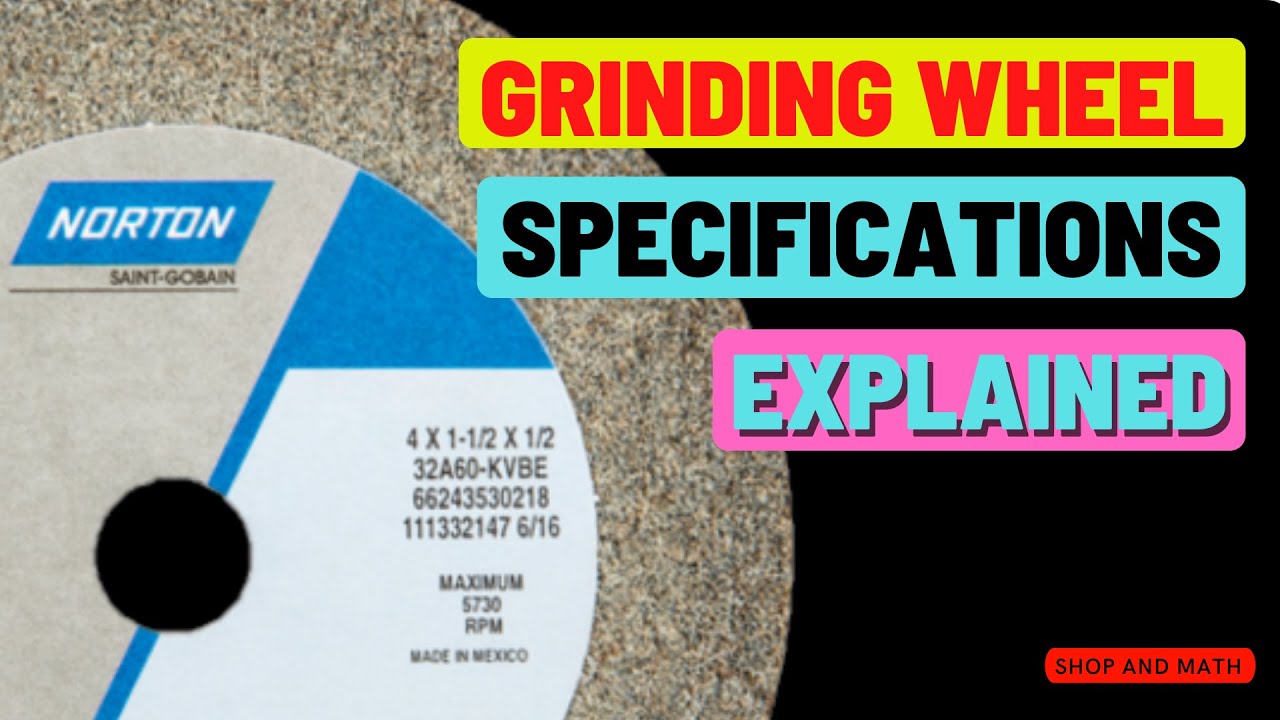

from www.youtube.com

The coarser the grain, the larger the size of the material removed. It will look something like this: Coarse grains are used for. Understanding grinding wheel specifications is. Today’s discussion revolves around grinding wheels, where we’ll dissect their materials, bonds, grain sizes, grades,. They have a few fundamental requirements. Aluminum oxide, silicon carbide, zirconia, ceramic alumina, cbn,. The general format for grinding wheel specifications will read as three numbers, with lowercase “x” symbols in between. Grinding wheels are essential tools for wood and metal working. 10” x 1 ½” x ¼”, and should be located directly on the front or side of the wheel cartridge.

grinding wheel specifications explained (English) YouTube

Grinding Wheel Measurements Aluminum oxide, silicon carbide, zirconia, ceramic alumina, cbn,. Grinding wheels, regardless of their manufacturer, are made up of three main components: The coarser the grain, the larger the size of the material removed. It will look something like this: Aluminum oxide, silicon carbide, zirconia, ceramic alumina, cbn,. There are three main types of grinding wheels, where various numbers differentiate between wheels with specific properties and uses —. Grinding wheels are essential tools for wood and metal working. Lower numbers (such as 10, 16 or 24) denote a wheel with coarse grain. 10” x 1 ½” x ¼”, and should be located directly on the front or side of the wheel cartridge. The general format for grinding wheel specifications will read as three numbers, with lowercase “x” symbols in between. Coarse grains are used for. Understanding grinding wheel specifications is. Today’s discussion revolves around grinding wheels, where we’ll dissect their materials, bonds, grain sizes, grades,. They have a few fundamental requirements.

From victoryhardware.com.sg

Grinding Wheel Cylindrical Grinding Victory Hardware Co Grinding Wheel Measurements There are three main types of grinding wheels, where various numbers differentiate between wheels with specific properties and uses —. Grinding wheels, regardless of their manufacturer, are made up of three main components: Aluminum oxide, silicon carbide, zirconia, ceramic alumina, cbn,. Grinding wheels are essential tools for wood and metal working. 10” x 1 ½” x ¼”, and should be. Grinding Wheel Measurements.

From en.kuretoishi.com

Segments KURE GRINDING WHEEL offers a wide range of grinding wheels Grinding Wheel Measurements Lower numbers (such as 10, 16 or 24) denote a wheel with coarse grain. Aluminum oxide, silicon carbide, zirconia, ceramic alumina, cbn,. Grinding wheels, regardless of their manufacturer, are made up of three main components: The general format for grinding wheel specifications will read as three numbers, with lowercase “x” symbols in between. Coarse grains are used for. There are. Grinding Wheel Measurements.

From diamondwheelzz.com

Fepa 11V2 GRINDING WHEEL DIAMOND/CBN/ABRASIVES GRINDING WHEEL Grinding Wheel Measurements The coarser the grain, the larger the size of the material removed. Aluminum oxide, silicon carbide, zirconia, ceramic alumina, cbn,. Understanding grinding wheel specifications is. Coarse grains are used for. Today’s discussion revolves around grinding wheels, where we’ll dissect their materials, bonds, grain sizes, grades,. Grinding wheels are essential tools for wood and metal working. 10” x 1 ½” x. Grinding Wheel Measurements.

From www.indiamart.com

Metal Humac Grinding Wheel, Size/Dimension (100x6.0x16)mm, Thickness Grinding Wheel Measurements Grinding wheels are essential tools for wood and metal working. It will look something like this: Aluminum oxide, silicon carbide, zirconia, ceramic alumina, cbn,. There are three main types of grinding wheels, where various numbers differentiate between wheels with specific properties and uses —. 10” x 1 ½” x ¼”, and should be located directly on the front or side. Grinding Wheel Measurements.

From www.3betterdiamond.com

Diamond Grinding wheels for carbide Grinding Wheel Measurements Lower numbers (such as 10, 16 or 24) denote a wheel with coarse grain. Today’s discussion revolves around grinding wheels, where we’ll dissect their materials, bonds, grain sizes, grades,. The coarser the grain, the larger the size of the material removed. The general format for grinding wheel specifications will read as three numbers, with lowercase “x” symbols in between. 10”. Grinding Wheel Measurements.

From harveycooke.z13.web.core.windows.net

Norton Grinding Wheel Catalog Grinding Wheel Measurements Understanding grinding wheel specifications is. Coarse grains are used for. Today’s discussion revolves around grinding wheels, where we’ll dissect their materials, bonds, grain sizes, grades,. There are three main types of grinding wheels, where various numbers differentiate between wheels with specific properties and uses —. The general format for grinding wheel specifications will read as three numbers, with lowercase “x”. Grinding Wheel Measurements.

From www.extremeabrasives.com

Cutting and Grinding Wheels Application Guide Archives Extreme Grinding Wheel Measurements There are three main types of grinding wheels, where various numbers differentiate between wheels with specific properties and uses —. Lower numbers (such as 10, 16 or 24) denote a wheel with coarse grain. Understanding grinding wheel specifications is. 10” x 1 ½” x ¼”, and should be located directly on the front or side of the wheel cartridge. Grinding. Grinding Wheel Measurements.

From www.bibielle.co.uk

Bibielle UK Grinding Wheels Grinding Wheel Measurements Lower numbers (such as 10, 16 or 24) denote a wheel with coarse grain. The coarser the grain, the larger the size of the material removed. Today’s discussion revolves around grinding wheels, where we’ll dissect their materials, bonds, grain sizes, grades,. The general format for grinding wheel specifications will read as three numbers, with lowercase “x” symbols in between. Grinding. Grinding Wheel Measurements.

From www.youtube.com

Grinding Wheel Shape And Size YouTube Grinding Wheel Measurements Coarse grains are used for. The coarser the grain, the larger the size of the material removed. Aluminum oxide, silicon carbide, zirconia, ceramic alumina, cbn,. They have a few fundamental requirements. Today’s discussion revolves around grinding wheels, where we’ll dissect their materials, bonds, grain sizes, grades,. 10” x 1 ½” x ¼”, and should be located directly on the front. Grinding Wheel Measurements.

From www.youtube.com

MOUNTING OF GRINDING WHEEL Changing New Grinding Wheel YouTube Grinding Wheel Measurements 10” x 1 ½” x ¼”, and should be located directly on the front or side of the wheel cartridge. Aluminum oxide, silicon carbide, zirconia, ceramic alumina, cbn,. Grinding wheels are essential tools for wood and metal working. Grinding wheels, regardless of their manufacturer, are made up of three main components: The coarser the grain, the larger the size of. Grinding Wheel Measurements.

From www.disco.co.jp

IF Grinding Wheels Product Information DISCO Corporation Grinding Wheel Measurements It will look something like this: Grinding wheels, regardless of their manufacturer, are made up of three main components: The coarser the grain, the larger the size of the material removed. Understanding grinding wheel specifications is. The general format for grinding wheel specifications will read as three numbers, with lowercase “x” symbols in between. They have a few fundamental requirements.. Grinding Wheel Measurements.

From www.researchgate.net

Grinding wheel specifications and surface parameters Download Grinding Wheel Measurements Lower numbers (such as 10, 16 or 24) denote a wheel with coarse grain. Grinding wheels are essential tools for wood and metal working. Aluminum oxide, silicon carbide, zirconia, ceramic alumina, cbn,. Today’s discussion revolves around grinding wheels, where we’ll dissect their materials, bonds, grain sizes, grades,. The general format for grinding wheel specifications will read as three numbers, with. Grinding Wheel Measurements.

From www.youtube.com

Standard Marking System of Grinding Wheel Designation of Grinding Grinding Wheel Measurements Lower numbers (such as 10, 16 or 24) denote a wheel with coarse grain. Aluminum oxide, silicon carbide, zirconia, ceramic alumina, cbn,. Coarse grains are used for. Understanding grinding wheel specifications is. They have a few fundamental requirements. Today’s discussion revolves around grinding wheels, where we’ll dissect their materials, bonds, grain sizes, grades,. The coarser the grain, the larger the. Grinding Wheel Measurements.

From www.forturetools.com

Grit chart of grinding wheels Forture Tools Grinding Wheel Measurements Grinding wheels are essential tools for wood and metal working. Aluminum oxide, silicon carbide, zirconia, ceramic alumina, cbn,. Lower numbers (such as 10, 16 or 24) denote a wheel with coarse grain. There are three main types of grinding wheels, where various numbers differentiate between wheels with specific properties and uses —. 10” x 1 ½” x ¼”, and should. Grinding Wheel Measurements.

From www.bayunion-tech.com

A15 Mounted Points and Mounted Wheels|Vitrified Grinding Wheels Grinding Wheel Measurements Lower numbers (such as 10, 16 or 24) denote a wheel with coarse grain. Today’s discussion revolves around grinding wheels, where we’ll dissect their materials, bonds, grain sizes, grades,. Aluminum oxide, silicon carbide, zirconia, ceramic alumina, cbn,. 10” x 1 ½” x ¼”, and should be located directly on the front or side of the wheel cartridge. The coarser the. Grinding Wheel Measurements.

From www.mscdirect.com

Wheel Types Grinding Wheel Measurements Aluminum oxide, silicon carbide, zirconia, ceramic alumina, cbn,. Today’s discussion revolves around grinding wheels, where we’ll dissect their materials, bonds, grain sizes, grades,. The coarser the grain, the larger the size of the material removed. 10” x 1 ½” x ¼”, and should be located directly on the front or side of the wheel cartridge. The general format for grinding. Grinding Wheel Measurements.

From rapidabrasives.ca

Learning about Grinding Wheels Rapid Abrasives & Accessories Grinding Wheel Measurements Lower numbers (such as 10, 16 or 24) denote a wheel with coarse grain. They have a few fundamental requirements. The general format for grinding wheel specifications will read as three numbers, with lowercase “x” symbols in between. Coarse grains are used for. 10” x 1 ½” x ¼”, and should be located directly on the front or side of. Grinding Wheel Measurements.

From www.eaglesuperabrasives.com

Grinding Wheel Mesh FEPA Grit Sizes Grinding Wheel Measurements Aluminum oxide, silicon carbide, zirconia, ceramic alumina, cbn,. Understanding grinding wheel specifications is. Lower numbers (such as 10, 16 or 24) denote a wheel with coarse grain. Today’s discussion revolves around grinding wheels, where we’ll dissect their materials, bonds, grain sizes, grades,. Coarse grains are used for. Grinding wheels, regardless of their manufacturer, are made up of three main components:. Grinding Wheel Measurements.

From www.indiamart.com

Ag4 Grinding Wheel, Size/Dimension 100 X 5.0 X 16 mm ( L X W X H Grinding Wheel Measurements Grinding wheels are essential tools for wood and metal working. There are three main types of grinding wheels, where various numbers differentiate between wheels with specific properties and uses —. Grinding wheels, regardless of their manufacturer, are made up of three main components: Understanding grinding wheel specifications is. 10” x 1 ½” x ¼”, and should be located directly on. Grinding Wheel Measurements.

From www.indiamart.com

Bosh Professional Abrasive Grinding Wheel, Size/Dimension 100x6.0x16 Grinding Wheel Measurements Grinding wheels are essential tools for wood and metal working. The coarser the grain, the larger the size of the material removed. They have a few fundamental requirements. 10” x 1 ½” x ¼”, and should be located directly on the front or side of the wheel cartridge. Lower numbers (such as 10, 16 or 24) denote a wheel with. Grinding Wheel Measurements.

From elizabethhowell.z21.web.core.windows.net

Norton Grinding Wheel Identification Chart Grinding Wheel Measurements There are three main types of grinding wheels, where various numbers differentiate between wheels with specific properties and uses —. Coarse grains are used for. The coarser the grain, the larger the size of the material removed. Grinding wheels are essential tools for wood and metal working. They have a few fundamental requirements. The general format for grinding wheel specifications. Grinding Wheel Measurements.

From www.forturetools.com

Abrasives grit size Forture Tools Grinding Wheel Measurements The coarser the grain, the larger the size of the material removed. It will look something like this: There are three main types of grinding wheels, where various numbers differentiate between wheels with specific properties and uses —. They have a few fundamental requirements. Grinding wheels, regardless of their manufacturer, are made up of three main components: Lower numbers (such. Grinding Wheel Measurements.

From www.highspeedtraining.co.uk

Classification of Grinding Wheels Which Do I Need? Grinding Wheel Measurements 10” x 1 ½” x ¼”, and should be located directly on the front or side of the wheel cartridge. Today’s discussion revolves around grinding wheels, where we’ll dissect their materials, bonds, grain sizes, grades,. Understanding grinding wheel specifications is. There are three main types of grinding wheels, where various numbers differentiate between wheels with specific properties and uses —.. Grinding Wheel Measurements.

From www.youtube.com

grinding wheel Standard Marking System grinding wheel types Grinding Wheel Measurements Grinding wheels are essential tools for wood and metal working. Lower numbers (such as 10, 16 or 24) denote a wheel with coarse grain. Today’s discussion revolves around grinding wheels, where we’ll dissect their materials, bonds, grain sizes, grades,. It will look something like this: The coarser the grain, the larger the size of the material removed. Grinding wheels, regardless. Grinding Wheel Measurements.

From www.youtube.com

Grinding Wheel Specification YouTube Grinding Wheel Measurements They have a few fundamental requirements. Today’s discussion revolves around grinding wheels, where we’ll dissect their materials, bonds, grain sizes, grades,. 10” x 1 ½” x ¼”, and should be located directly on the front or side of the wheel cartridge. Grinding wheels are essential tools for wood and metal working. It will look something like this: The general format. Grinding Wheel Measurements.

From www.pinterest.com

1V1 Shape grinding wheels Drill bit sizes, Reamers, Metric bolt sizes Grinding Wheel Measurements There are three main types of grinding wheels, where various numbers differentiate between wheels with specific properties and uses —. The general format for grinding wheel specifications will read as three numbers, with lowercase “x” symbols in between. Grinding wheels, regardless of their manufacturer, are made up of three main components: Coarse grains are used for. Grinding wheels are essential. Grinding Wheel Measurements.

From www.prohandtools.com

Best 23 Grinding Wheel Sizes for 2020 Grinding Wheel Measurements The coarser the grain, the larger the size of the material removed. Aluminum oxide, silicon carbide, zirconia, ceramic alumina, cbn,. Coarse grains are used for. Grinding wheels are essential tools for wood and metal working. There are three main types of grinding wheels, where various numbers differentiate between wheels with specific properties and uses —. 10” x 1 ½” x. Grinding Wheel Measurements.

From www.ctemag.com

Wear mechanics of cylindrical grinding wheels Cutting Tool Engineering Grinding Wheel Measurements It will look something like this: They have a few fundamental requirements. Grinding wheels, regardless of their manufacturer, are made up of three main components: The general format for grinding wheel specifications will read as three numbers, with lowercase “x” symbols in between. There are three main types of grinding wheels, where various numbers differentiate between wheels with specific properties. Grinding Wheel Measurements.

From www.indiamart.com

GRINDING WHEEL, Size/Dimension 100*4*16 MM at Rs 25/piece in Surat Grinding Wheel Measurements Aluminum oxide, silicon carbide, zirconia, ceramic alumina, cbn,. They have a few fundamental requirements. Coarse grains are used for. Understanding grinding wheel specifications is. Grinding wheels are essential tools for wood and metal working. There are three main types of grinding wheels, where various numbers differentiate between wheels with specific properties and uses —. Today’s discussion revolves around grinding wheels,. Grinding Wheel Measurements.

From victoryhardware.com.sg

How to select your Grinding Wheels Victory Hardware Co Grinding Wheel Measurements They have a few fundamental requirements. 10” x 1 ½” x ¼”, and should be located directly on the front or side of the wheel cartridge. It will look something like this: Grinding wheels, regardless of their manufacturer, are made up of three main components: Understanding grinding wheel specifications is. Coarse grains are used for. The coarser the grain, the. Grinding Wheel Measurements.

From finemetalworking.com

Surface Grinding Wheels Types and Specification Grinding Wheel Measurements Coarse grains are used for. 10” x 1 ½” x ¼”, and should be located directly on the front or side of the wheel cartridge. Aluminum oxide, silicon carbide, zirconia, ceramic alumina, cbn,. They have a few fundamental requirements. Understanding grinding wheel specifications is. Lower numbers (such as 10, 16 or 24) denote a wheel with coarse grain. Grinding wheels,. Grinding Wheel Measurements.

From www.practicalmachinist.com

Grinding wheel grit size Grinding Wheel Measurements There are three main types of grinding wheels, where various numbers differentiate between wheels with specific properties and uses —. They have a few fundamental requirements. The coarser the grain, the larger the size of the material removed. Understanding grinding wheel specifications is. Lower numbers (such as 10, 16 or 24) denote a wheel with coarse grain. Grinding wheels are. Grinding Wheel Measurements.

From agrindtool.com

Grinding Wheel Speed Chart Grinding Wheel Measurements Aluminum oxide, silicon carbide, zirconia, ceramic alumina, cbn,. Understanding grinding wheel specifications is. There are three main types of grinding wheels, where various numbers differentiate between wheels with specific properties and uses —. Lower numbers (such as 10, 16 or 24) denote a wheel with coarse grain. Grinding wheels, regardless of their manufacturer, are made up of three main components:. Grinding Wheel Measurements.

From www.youtube.com

grinding wheel specifications explained (English) YouTube Grinding Wheel Measurements Lower numbers (such as 10, 16 or 24) denote a wheel with coarse grain. It will look something like this: Grinding wheels are essential tools for wood and metal working. They have a few fundamental requirements. The general format for grinding wheel specifications will read as three numbers, with lowercase “x” symbols in between. Coarse grains are used for. 10”. Grinding Wheel Measurements.

From www.forturetools.com

How to read a grinding wheel's specification Forture Tools Grinding Wheel Measurements There are three main types of grinding wheels, where various numbers differentiate between wheels with specific properties and uses —. Aluminum oxide, silicon carbide, zirconia, ceramic alumina, cbn,. Grinding wheels, regardless of their manufacturer, are made up of three main components: Coarse grains are used for. Understanding grinding wheel specifications is. They have a few fundamental requirements. The general format. Grinding Wheel Measurements.