Types Of Nozzle In Injection Moulding . Injection moulding shrinkage is an unavoidable side effect of plastic contracting when it cools inside the mould cavity, similar to the metal casting process. Nozzle tip design and size will impact mold. The three common nozzle tip designs found in the injection molding industry are general purpose, reverse taper, and free flow. 3.2.4 nozzle and nozzle tip the material path in the nozzle and nozzle tip should be smooth without pockets or rough transitions where. Modern injection molding machines have nozzles that can do different things, like separate the melt flow, mix it, or stop it. Types of an injection molding nozzle: Let’s look more closely at some of the most popular types of nozzles used in molding:

from themechanicalengineering.com

Let’s look more closely at some of the most popular types of nozzles used in molding: Injection moulding shrinkage is an unavoidable side effect of plastic contracting when it cools inside the mould cavity, similar to the metal casting process. The three common nozzle tip designs found in the injection molding industry are general purpose, reverse taper, and free flow. 3.2.4 nozzle and nozzle tip the material path in the nozzle and nozzle tip should be smooth without pockets or rough transitions where. Types of an injection molding nozzle: Modern injection molding machines have nozzles that can do different things, like separate the melt flow, mix it, or stop it. Nozzle tip design and size will impact mold.

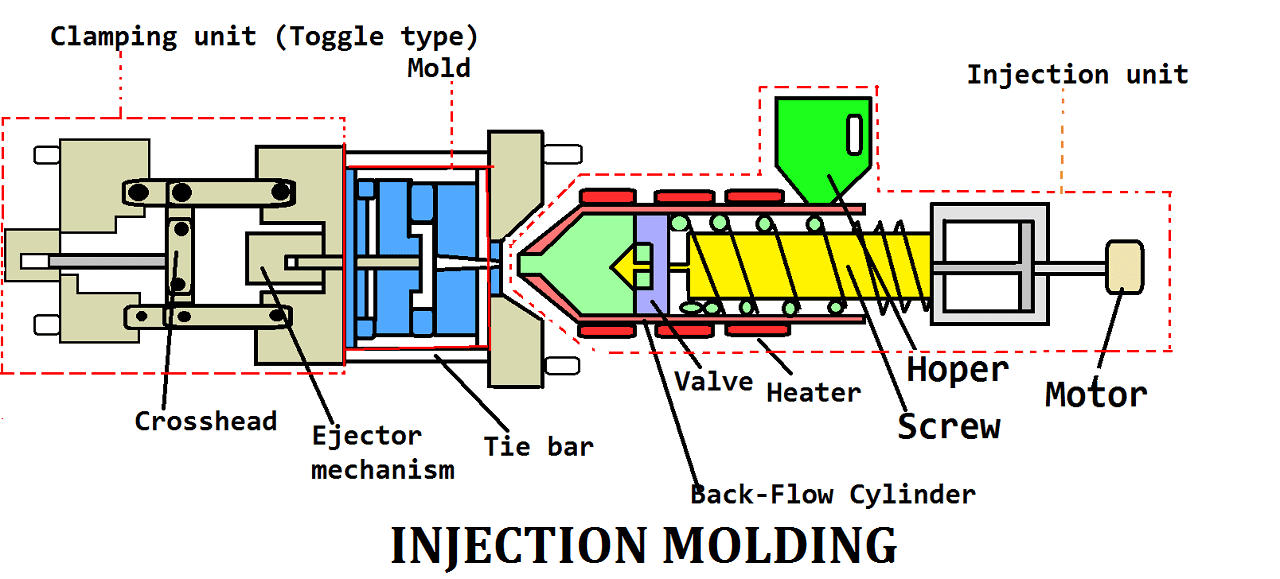

Injection Molding Definition, Construction, Working Process

Types Of Nozzle In Injection Moulding Let’s look more closely at some of the most popular types of nozzles used in molding: 3.2.4 nozzle and nozzle tip the material path in the nozzle and nozzle tip should be smooth without pockets or rough transitions where. Let’s look more closely at some of the most popular types of nozzles used in molding: Nozzle tip design and size will impact mold. Types of an injection molding nozzle: Modern injection molding machines have nozzles that can do different things, like separate the melt flow, mix it, or stop it. Injection moulding shrinkage is an unavoidable side effect of plastic contracting when it cools inside the mould cavity, similar to the metal casting process. The three common nozzle tip designs found in the injection molding industry are general purpose, reverse taper, and free flow.

From studylib.net

SMN Injection Moulding Mixing Nozzle Types Of Nozzle In Injection Moulding Modern injection molding machines have nozzles that can do different things, like separate the melt flow, mix it, or stop it. The three common nozzle tip designs found in the injection molding industry are general purpose, reverse taper, and free flow. Let’s look more closely at some of the most popular types of nozzles used in molding: 3.2.4 nozzle and. Types Of Nozzle In Injection Moulding.

From toolingmagazine.com

Injection Molding Basics TOOLING MAGAZINE Types Of Nozzle In Injection Moulding 3.2.4 nozzle and nozzle tip the material path in the nozzle and nozzle tip should be smooth without pockets or rough transitions where. Modern injection molding machines have nozzles that can do different things, like separate the melt flow, mix it, or stop it. Let’s look more closely at some of the most popular types of nozzles used in molding:. Types Of Nozzle In Injection Moulding.

From pazard.com

5 kinds of Injection molding nozzle tip types you must know Pazard Types Of Nozzle In Injection Moulding Let’s look more closely at some of the most popular types of nozzles used in molding: Nozzle tip design and size will impact mold. The three common nozzle tip designs found in the injection molding industry are general purpose, reverse taper, and free flow. Types of an injection molding nozzle: Injection moulding shrinkage is an unavoidable side effect of plastic. Types Of Nozzle In Injection Moulding.

From www.magneticplaten.com

Injection Molding Basics What Is It and How Does It Work HVR MAG Types Of Nozzle In Injection Moulding Injection moulding shrinkage is an unavoidable side effect of plastic contracting when it cools inside the mould cavity, similar to the metal casting process. Nozzle tip design and size will impact mold. Let’s look more closely at some of the most popular types of nozzles used in molding: Modern injection molding machines have nozzles that can do different things, like. Types Of Nozzle In Injection Moulding.

From prototool.com

Injection Molding Nozzle How to Troubleshoot Nozzle Leaks Types Of Nozzle In Injection Moulding Nozzle tip design and size will impact mold. Types of an injection molding nozzle: Modern injection molding machines have nozzles that can do different things, like separate the melt flow, mix it, or stop it. Injection moulding shrinkage is an unavoidable side effect of plastic contracting when it cools inside the mould cavity, similar to the metal casting process. The. Types Of Nozzle In Injection Moulding.

From www.grommetseal.com

Liquid Silicone Injection Molding Design GuideLSR Mould & LIM Types Of Nozzle In Injection Moulding Let’s look more closely at some of the most popular types of nozzles used in molding: Nozzle tip design and size will impact mold. 3.2.4 nozzle and nozzle tip the material path in the nozzle and nozzle tip should be smooth without pockets or rough transitions where. Types of an injection molding nozzle: Injection moulding shrinkage is an unavoidable side. Types Of Nozzle In Injection Moulding.

From exoiisphe.blob.core.windows.net

How Many Types Of Nozzle In Injection Moulding Machine at Larry Wicker blog Types Of Nozzle In Injection Moulding Let’s look more closely at some of the most popular types of nozzles used in molding: Modern injection molding machines have nozzles that can do different things, like separate the melt flow, mix it, or stop it. The three common nozzle tip designs found in the injection molding industry are general purpose, reverse taper, and free flow. Injection moulding shrinkage. Types Of Nozzle In Injection Moulding.

From www.moldex3d.com

Unignorable Simulation of Barrels and Nozzles Blog Moldex3D Types Of Nozzle In Injection Moulding 3.2.4 nozzle and nozzle tip the material path in the nozzle and nozzle tip should be smooth without pockets or rough transitions where. Injection moulding shrinkage is an unavoidable side effect of plastic contracting when it cools inside the mould cavity, similar to the metal casting process. The three common nozzle tip designs found in the injection molding industry are. Types Of Nozzle In Injection Moulding.

From exoiisphe.blob.core.windows.net

How Many Types Of Nozzle In Injection Moulding Machine at Larry Wicker blog Types Of Nozzle In Injection Moulding Modern injection molding machines have nozzles that can do different things, like separate the melt flow, mix it, or stop it. Let’s look more closely at some of the most popular types of nozzles used in molding: Nozzle tip design and size will impact mold. Injection moulding shrinkage is an unavoidable side effect of plastic contracting when it cools inside. Types Of Nozzle In Injection Moulding.

From exoiisphe.blob.core.windows.net

How Many Types Of Nozzle In Injection Moulding Machine at Larry Wicker blog Types Of Nozzle In Injection Moulding Nozzle tip design and size will impact mold. Injection moulding shrinkage is an unavoidable side effect of plastic contracting when it cools inside the mould cavity, similar to the metal casting process. The three common nozzle tip designs found in the injection molding industry are general purpose, reverse taper, and free flow. Let’s look more closely at some of the. Types Of Nozzle In Injection Moulding.

From www.dgmfmoldclamps.com

Injection Molding Machine Nozzle Tips Supplier Mould Clamps Manufacturer Types Of Nozzle In Injection Moulding Injection moulding shrinkage is an unavoidable side effect of plastic contracting when it cools inside the mould cavity, similar to the metal casting process. The three common nozzle tip designs found in the injection molding industry are general purpose, reverse taper, and free flow. 3.2.4 nozzle and nozzle tip the material path in the nozzle and nozzle tip should be. Types Of Nozzle In Injection Moulding.

From www.pinterest.com

Injection moulding machine overview Injection Moulding Process, Plastic Types Of Nozzle In Injection Moulding Types of an injection molding nozzle: Modern injection molding machines have nozzles that can do different things, like separate the melt flow, mix it, or stop it. Nozzle tip design and size will impact mold. Injection moulding shrinkage is an unavoidable side effect of plastic contracting when it cools inside the mould cavity, similar to the metal casting process. The. Types Of Nozzle In Injection Moulding.

From www.youtube.com

Types of Nozzle, Injection Moulding Nozzle, Shut off Nozzle Types Of Nozzle In Injection Moulding Types of an injection molding nozzle: The three common nozzle tip designs found in the injection molding industry are general purpose, reverse taper, and free flow. Let’s look more closely at some of the most popular types of nozzles used in molding: Modern injection molding machines have nozzles that can do different things, like separate the melt flow, mix it,. Types Of Nozzle In Injection Moulding.

From www.echosupply.com

Injection Molding Basics Hot Runner Systems Echo Supply Types Of Nozzle In Injection Moulding The three common nozzle tip designs found in the injection molding industry are general purpose, reverse taper, and free flow. Modern injection molding machines have nozzles that can do different things, like separate the melt flow, mix it, or stop it. 3.2.4 nozzle and nozzle tip the material path in the nozzle and nozzle tip should be smooth without pockets. Types Of Nozzle In Injection Moulding.

From www.tradeindia.com

Nozzel Polished Round Stainless Steel Nozzle For Injection Molding Types Of Nozzle In Injection Moulding The three common nozzle tip designs found in the injection molding industry are general purpose, reverse taper, and free flow. Nozzle tip design and size will impact mold. 3.2.4 nozzle and nozzle tip the material path in the nozzle and nozzle tip should be smooth without pockets or rough transitions where. Modern injection molding machines have nozzles that can do. Types Of Nozzle In Injection Moulding.

From www.slideserve.com

PPT Injection Moulding Technology Part 3 PowerPoint Presentation Types Of Nozzle In Injection Moulding Nozzle tip design and size will impact mold. Modern injection molding machines have nozzles that can do different things, like separate the melt flow, mix it, or stop it. Injection moulding shrinkage is an unavoidable side effect of plastic contracting when it cools inside the mould cavity, similar to the metal casting process. The three common nozzle tip designs found. Types Of Nozzle In Injection Moulding.

From themechanicalengineering.com

Injection Molding Definition, Construction, Working Process Types Of Nozzle In Injection Moulding Modern injection molding machines have nozzles that can do different things, like separate the melt flow, mix it, or stop it. Injection moulding shrinkage is an unavoidable side effect of plastic contracting when it cools inside the mould cavity, similar to the metal casting process. 3.2.4 nozzle and nozzle tip the material path in the nozzle and nozzle tip should. Types Of Nozzle In Injection Moulding.

From www.vrogue.co

Mixing Nozzle For Injection Molding Machines Fluid Pr vrogue.co Types Of Nozzle In Injection Moulding Let’s look more closely at some of the most popular types of nozzles used in molding: Nozzle tip design and size will impact mold. Injection moulding shrinkage is an unavoidable side effect of plastic contracting when it cools inside the mould cavity, similar to the metal casting process. Types of an injection molding nozzle: 3.2.4 nozzle and nozzle tip the. Types Of Nozzle In Injection Moulding.

From www.dgmfmoldclamps.com

Injection Molding Machine Nozzle Tips Supplier Mould Clamps Manufacturer Types Of Nozzle In Injection Moulding 3.2.4 nozzle and nozzle tip the material path in the nozzle and nozzle tip should be smooth without pockets or rough transitions where. Let’s look more closely at some of the most popular types of nozzles used in molding: The three common nozzle tip designs found in the injection molding industry are general purpose, reverse taper, and free flow. Types. Types Of Nozzle In Injection Moulding.

From www.youtube.com

Nozzle Tip selection in Plastic injection moulding from NRH to save Types Of Nozzle In Injection Moulding Injection moulding shrinkage is an unavoidable side effect of plastic contracting when it cools inside the mould cavity, similar to the metal casting process. Modern injection molding machines have nozzles that can do different things, like separate the melt flow, mix it, or stop it. The three common nozzle tip designs found in the injection molding industry are general purpose,. Types Of Nozzle In Injection Moulding.

From www.dgmfmoldclamps.com

Injection Molding Machine Nozzle Tips Supplier Mould Clamps Manufacturer Types Of Nozzle In Injection Moulding Injection moulding shrinkage is an unavoidable side effect of plastic contracting when it cools inside the mould cavity, similar to the metal casting process. The three common nozzle tip designs found in the injection molding industry are general purpose, reverse taper, and free flow. Types of an injection molding nozzle: 3.2.4 nozzle and nozzle tip the material path in the. Types Of Nozzle In Injection Moulding.

From www.rdray.com

Types of Injection Molding Valves R. DRAY MFG. Types Of Nozzle In Injection Moulding Nozzle tip design and size will impact mold. Modern injection molding machines have nozzles that can do different things, like separate the melt flow, mix it, or stop it. Types of an injection molding nozzle: The three common nozzle tip designs found in the injection molding industry are general purpose, reverse taper, and free flow. Let’s look more closely at. Types Of Nozzle In Injection Moulding.

From www.plasticmouldcompany.com

Injection Molding Plastic mold,custom plastic injection molding Types Of Nozzle In Injection Moulding Nozzle tip design and size will impact mold. 3.2.4 nozzle and nozzle tip the material path in the nozzle and nozzle tip should be smooth without pockets or rough transitions where. Types of an injection molding nozzle: Let’s look more closely at some of the most popular types of nozzles used in molding: Modern injection molding machines have nozzles that. Types Of Nozzle In Injection Moulding.

From pazard.com

5 kinds of Injection molding nozzle tip types you must know Pazard Types Of Nozzle In Injection Moulding Types of an injection molding nozzle: Modern injection molding machines have nozzles that can do different things, like separate the melt flow, mix it, or stop it. Let’s look more closely at some of the most popular types of nozzles used in molding: Nozzle tip design and size will impact mold. The three common nozzle tip designs found in the. Types Of Nozzle In Injection Moulding.

From www.dgmfmoldclamps.com

Injection Molding Machine Nozzle Tips Supplier Mould Clamps Manufacturer Types Of Nozzle In Injection Moulding Modern injection molding machines have nozzles that can do different things, like separate the melt flow, mix it, or stop it. Nozzle tip design and size will impact mold. The three common nozzle tip designs found in the injection molding industry are general purpose, reverse taper, and free flow. Let’s look more closely at some of the most popular types. Types Of Nozzle In Injection Moulding.

From www.youtube.com

How Many Types Of Nozzle Used In Injection Molding Machine(नोजल कितने Types Of Nozzle In Injection Moulding The three common nozzle tip designs found in the injection molding industry are general purpose, reverse taper, and free flow. Modern injection molding machines have nozzles that can do different things, like separate the melt flow, mix it, or stop it. Let’s look more closely at some of the most popular types of nozzles used in molding: Types of an. Types Of Nozzle In Injection Moulding.

From toolanddiemakings.blogspot.com

INJECTION MOULDING MACHINES Tool and die making Types Of Nozzle In Injection Moulding Let’s look more closely at some of the most popular types of nozzles used in molding: Types of an injection molding nozzle: The three common nozzle tip designs found in the injection molding industry are general purpose, reverse taper, and free flow. Nozzle tip design and size will impact mold. Modern injection molding machines have nozzles that can do different. Types Of Nozzle In Injection Moulding.

From pazard.com

5 kinds of Injection molding nozzle tip types you must know Pazard Types Of Nozzle In Injection Moulding Nozzle tip design and size will impact mold. Let’s look more closely at some of the most popular types of nozzles used in molding: Modern injection molding machines have nozzles that can do different things, like separate the melt flow, mix it, or stop it. Types of an injection molding nozzle: The three common nozzle tip designs found in the. Types Of Nozzle In Injection Moulding.

From aic-plastico.com

Injection Molding Nozzle Tips AIC Equipment & PlastiCo® Types Of Nozzle In Injection Moulding Nozzle tip design and size will impact mold. Modern injection molding machines have nozzles that can do different things, like separate the melt flow, mix it, or stop it. Let’s look more closely at some of the most popular types of nozzles used in molding: The three common nozzle tip designs found in the injection molding industry are general purpose,. Types Of Nozzle In Injection Moulding.

From pazard.com

5 kinds of Injection molding nozzle tip types you must know Pazard Types Of Nozzle In Injection Moulding The three common nozzle tip designs found in the injection molding industry are general purpose, reverse taper, and free flow. Types of an injection molding nozzle: Injection moulding shrinkage is an unavoidable side effect of plastic contracting when it cools inside the mould cavity, similar to the metal casting process. Modern injection molding machines have nozzles that can do different. Types Of Nozzle In Injection Moulding.

From www.rdray.com

Types of Injection Molding Valves R. DRAY MFG. Types Of Nozzle In Injection Moulding The three common nozzle tip designs found in the injection molding industry are general purpose, reverse taper, and free flow. Let’s look more closely at some of the most popular types of nozzles used in molding: Types of an injection molding nozzle: 3.2.4 nozzle and nozzle tip the material path in the nozzle and nozzle tip should be smooth without. Types Of Nozzle In Injection Moulding.

From exoiisphe.blob.core.windows.net

How Many Types Of Nozzle In Injection Moulding Machine at Larry Wicker blog Types Of Nozzle In Injection Moulding The three common nozzle tip designs found in the injection molding industry are general purpose, reverse taper, and free flow. Injection moulding shrinkage is an unavoidable side effect of plastic contracting when it cools inside the mould cavity, similar to the metal casting process. Modern injection molding machines have nozzles that can do different things, like separate the melt flow,. Types Of Nozzle In Injection Moulding.

From www.rutlandplastics.co.uk

How does injection moulding work Rutland Plastics Types Of Nozzle In Injection Moulding Let’s look more closely at some of the most popular types of nozzles used in molding: Nozzle tip design and size will impact mold. Injection moulding shrinkage is an unavoidable side effect of plastic contracting when it cools inside the mould cavity, similar to the metal casting process. Modern injection molding machines have nozzles that can do different things, like. Types Of Nozzle In Injection Moulding.

From pazard.com

5 kinds of Injection molding nozzle tip types you must know Pazard Types Of Nozzle In Injection Moulding Nozzle tip design and size will impact mold. Types of an injection molding nozzle: Modern injection molding machines have nozzles that can do different things, like separate the melt flow, mix it, or stop it. Injection moulding shrinkage is an unavoidable side effect of plastic contracting when it cools inside the mould cavity, similar to the metal casting process. Let’s. Types Of Nozzle In Injection Moulding.

From www.stamixco-usa.com

Injection Molding Static Mixing Nozzle (Type SMN) StaMixCo Static Types Of Nozzle In Injection Moulding Types of an injection molding nozzle: The three common nozzle tip designs found in the injection molding industry are general purpose, reverse taper, and free flow. Injection moulding shrinkage is an unavoidable side effect of plastic contracting when it cools inside the mould cavity, similar to the metal casting process. Modern injection molding machines have nozzles that can do different. Types Of Nozzle In Injection Moulding.