What Is The Hardness Of Measuring Faces Of Anvil And Spindle . The characteristics of case hardening are primarily determined by surface hardness, the effective hardness depth and the depth profile. If the material is too thin, you’ll be measuring the hardness of the supporting anvil more so than the test piece. There are several frequently used methods to measure the hardness of metals, including: Here’s a little chart on the minimum. Measure flatness and parallelism on a micrometer anvil and spindle (episode 11) welcome to quality digest’s new show, “how. Anvils should be checked on a regular basis, typically prior to each use, and if found too compromised they should be replaced. The most significant factors are: Faces may be tipped with tungsten carbide. Measuring faces of anvil and spindle has a hardness of about 800 hv or 62 hrc. 1) thread accuracy, 2) flatness of measuring faces, 3) parallelism between the faces and 4) rigidity of.

from ourelabs.blogspot.com

Measure flatness and parallelism on a micrometer anvil and spindle (episode 11) welcome to quality digest’s new show, “how. The characteristics of case hardening are primarily determined by surface hardness, the effective hardness depth and the depth profile. Measuring faces of anvil and spindle has a hardness of about 800 hv or 62 hrc. If the material is too thin, you’ll be measuring the hardness of the supporting anvil more so than the test piece. Anvils should be checked on a regular basis, typically prior to each use, and if found too compromised they should be replaced. Here’s a little chart on the minimum. 1) thread accuracy, 2) flatness of measuring faces, 3) parallelism between the faces and 4) rigidity of. Faces may be tipped with tungsten carbide. The most significant factors are: There are several frequently used methods to measure the hardness of metals, including:

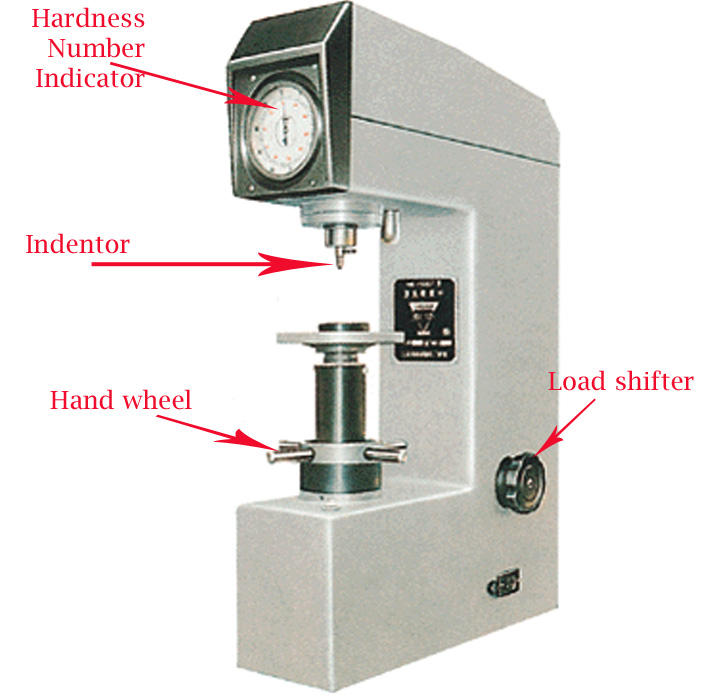

ROCKWELL HARDNESS TEST Ourengineeringlabs

What Is The Hardness Of Measuring Faces Of Anvil And Spindle The most significant factors are: The characteristics of case hardening are primarily determined by surface hardness, the effective hardness depth and the depth profile. There are several frequently used methods to measure the hardness of metals, including: 1) thread accuracy, 2) flatness of measuring faces, 3) parallelism between the faces and 4) rigidity of. Anvils should be checked on a regular basis, typically prior to each use, and if found too compromised they should be replaced. Here’s a little chart on the minimum. Faces may be tipped with tungsten carbide. If the material is too thin, you’ll be measuring the hardness of the supporting anvil more so than the test piece. Measuring faces of anvil and spindle has a hardness of about 800 hv or 62 hrc. Measure flatness and parallelism on a micrometer anvil and spindle (episode 11) welcome to quality digest’s new show, “how. The most significant factors are:

From www.researchgate.net

Rockwell hardness testing machine. Download Scientific Diagram What Is The Hardness Of Measuring Faces Of Anvil And Spindle Faces may be tipped with tungsten carbide. 1) thread accuracy, 2) flatness of measuring faces, 3) parallelism between the faces and 4) rigidity of. If the material is too thin, you’ll be measuring the hardness of the supporting anvil more so than the test piece. Measuring faces of anvil and spindle has a hardness of about 800 hv or 62. What Is The Hardness Of Measuring Faces Of Anvil And Spindle.

From hxeccfxwe.blob.core.windows.net

How To Test Hardness Of A Material at Robert Numbers blog What Is The Hardness Of Measuring Faces Of Anvil And Spindle 1) thread accuracy, 2) flatness of measuring faces, 3) parallelism between the faces and 4) rigidity of. Faces may be tipped with tungsten carbide. Measuring faces of anvil and spindle has a hardness of about 800 hv or 62 hrc. Measure flatness and parallelism on a micrometer anvil and spindle (episode 11) welcome to quality digest’s new show, “how. If. What Is The Hardness Of Measuring Faces Of Anvil And Spindle.

From www.penntoolco.com

Fowler Point Anvil & Spindle Micrometers Penn Tool Co., Inc What Is The Hardness Of Measuring Faces Of Anvil And Spindle Measuring faces of anvil and spindle has a hardness of about 800 hv or 62 hrc. The characteristics of case hardening are primarily determined by surface hardness, the effective hardness depth and the depth profile. There are several frequently used methods to measure the hardness of metals, including: Faces may be tipped with tungsten carbide. Measure flatness and parallelism on. What Is The Hardness Of Measuring Faces Of Anvil And Spindle.

From extrudesign.com

What are the different vernier caliper types? ExtruDesign What Is The Hardness Of Measuring Faces Of Anvil And Spindle The most significant factors are: There are several frequently used methods to measure the hardness of metals, including: 1) thread accuracy, 2) flatness of measuring faces, 3) parallelism between the faces and 4) rigidity of. If the material is too thin, you’ll be measuring the hardness of the supporting anvil more so than the test piece. Faces may be tipped. What Is The Hardness Of Measuring Faces Of Anvil And Spindle.

From www.besmicoptic.com

Multimar 844 Tc Measuring Anvils with Measuring Blades Besmic Optic What Is The Hardness Of Measuring Faces Of Anvil And Spindle The most significant factors are: 1) thread accuracy, 2) flatness of measuring faces, 3) parallelism between the faces and 4) rigidity of. If the material is too thin, you’ll be measuring the hardness of the supporting anvil more so than the test piece. The characteristics of case hardening are primarily determined by surface hardness, the effective hardness depth and the. What Is The Hardness Of Measuring Faces Of Anvil And Spindle.

From www.youtube.com

What to Look For when Choosing your first anvil!! Tip for anvil What Is The Hardness Of Measuring Faces Of Anvil And Spindle 1) thread accuracy, 2) flatness of measuring faces, 3) parallelism between the faces and 4) rigidity of. Faces may be tipped with tungsten carbide. Measure flatness and parallelism on a micrometer anvil and spindle (episode 11) welcome to quality digest’s new show, “how. There are several frequently used methods to measure the hardness of metals, including: Anvils should be checked. What Is The Hardness Of Measuring Faces Of Anvil And Spindle.

From www.mechanicalmeasuring.com

Micrometer Parts and Their Main Function Mechanical Measuring What Is The Hardness Of Measuring Faces Of Anvil And Spindle 1) thread accuracy, 2) flatness of measuring faces, 3) parallelism between the faces and 4) rigidity of. Here’s a little chart on the minimum. The characteristics of case hardening are primarily determined by surface hardness, the effective hardness depth and the depth profile. The most significant factors are: If the material is too thin, you’ll be measuring the hardness of. What Is The Hardness Of Measuring Faces Of Anvil And Spindle.

From www.knowmastery.com

Mohs Hardness Scale [Measuring Mineral Strength Made Simple] What Is The Hardness Of Measuring Faces Of Anvil And Spindle The most significant factors are: Here’s a little chart on the minimum. There are several frequently used methods to measure the hardness of metals, including: Anvils should be checked on a regular basis, typically prior to each use, and if found too compromised they should be replaced. Measuring faces of anvil and spindle has a hardness of about 800 hv. What Is The Hardness Of Measuring Faces Of Anvil And Spindle.

From www.walmart.com

Precision Anvil Flat Spindle Micrometer 0.0001" Graduation Machinist What Is The Hardness Of Measuring Faces Of Anvil And Spindle Faces may be tipped with tungsten carbide. Here’s a little chart on the minimum. Measuring faces of anvil and spindle has a hardness of about 800 hv or 62 hrc. Anvils should be checked on a regular basis, typically prior to each use, and if found too compromised they should be replaced. 1) thread accuracy, 2) flatness of measuring faces,. What Is The Hardness Of Measuring Faces Of Anvil And Spindle.

From www.researchgate.net

Vickers hardness and fracture toughness measurements on {100} faces of What Is The Hardness Of Measuring Faces Of Anvil And Spindle Here’s a little chart on the minimum. Faces may be tipped with tungsten carbide. If the material is too thin, you’ll be measuring the hardness of the supporting anvil more so than the test piece. Anvils should be checked on a regular basis, typically prior to each use, and if found too compromised they should be replaced. The most significant. What Is The Hardness Of Measuring Faces Of Anvil And Spindle.

From www.slideserve.com

PPT PRINCIPLES OF MECHANICAL MEASURING INSTRUMENTS PowerPoint What Is The Hardness Of Measuring Faces Of Anvil And Spindle There are several frequently used methods to measure the hardness of metals, including: Measure flatness and parallelism on a micrometer anvil and spindle (episode 11) welcome to quality digest’s new show, “how. The characteristics of case hardening are primarily determined by surface hardness, the effective hardness depth and the depth profile. Measuring faces of anvil and spindle has a hardness. What Is The Hardness Of Measuring Faces Of Anvil And Spindle.

From pritchellandhardy.com

Cast Steel Anvil 100lbs Pritchell and Hardy What Is The Hardness Of Measuring Faces Of Anvil And Spindle The characteristics of case hardening are primarily determined by surface hardness, the effective hardness depth and the depth profile. The most significant factors are: Faces may be tipped with tungsten carbide. There are several frequently used methods to measure the hardness of metals, including: Measure flatness and parallelism on a micrometer anvil and spindle (episode 11) welcome to quality digest’s. What Is The Hardness Of Measuring Faces Of Anvil And Spindle.

From www.northlandtool.com

Spindle Runout How to Test, Measure & Reduce What Is The Hardness Of Measuring Faces Of Anvil And Spindle There are several frequently used methods to measure the hardness of metals, including: Measure flatness and parallelism on a micrometer anvil and spindle (episode 11) welcome to quality digest’s new show, “how. Measuring faces of anvil and spindle has a hardness of about 800 hv or 62 hrc. Anvils should be checked on a regular basis, typically prior to each. What Is The Hardness Of Measuring Faces Of Anvil And Spindle.

From www.youtube.com

How To Ep11 Measure Flatness and Parallelism on a Micrometer Anvil and What Is The Hardness Of Measuring Faces Of Anvil And Spindle Faces may be tipped with tungsten carbide. The most significant factors are: If the material is too thin, you’ll be measuring the hardness of the supporting anvil more so than the test piece. The characteristics of case hardening are primarily determined by surface hardness, the effective hardness depth and the depth profile. Here’s a little chart on the minimum. There. What Is The Hardness Of Measuring Faces Of Anvil And Spindle.

From amesportablehardnesstesters.com

Raised Flat 1/8" What Is The Hardness Of Measuring Faces Of Anvil And Spindle There are several frequently used methods to measure the hardness of metals, including: The most significant factors are: Measuring faces of anvil and spindle has a hardness of about 800 hv or 62 hrc. Anvils should be checked on a regular basis, typically prior to each use, and if found too compromised they should be replaced. Measure flatness and parallelism. What Is The Hardness Of Measuring Faces Of Anvil And Spindle.

From in.misumi-ec.com

Outside Micrometer, Adjustable Anvil Type NIIGATA SEIKI (SK) MISUMI What Is The Hardness Of Measuring Faces Of Anvil And Spindle If the material is too thin, you’ll be measuring the hardness of the supporting anvil more so than the test piece. Here’s a little chart on the minimum. Measuring faces of anvil and spindle has a hardness of about 800 hv or 62 hrc. Measure flatness and parallelism on a micrometer anvil and spindle (episode 11) welcome to quality digest’s. What Is The Hardness Of Measuring Faces Of Anvil And Spindle.

From www.tec-science.com

Rockwell hardness test tecscience What Is The Hardness Of Measuring Faces Of Anvil And Spindle If the material is too thin, you’ll be measuring the hardness of the supporting anvil more so than the test piece. The characteristics of case hardening are primarily determined by surface hardness, the effective hardness depth and the depth profile. Measuring faces of anvil and spindle has a hardness of about 800 hv or 62 hrc. Here’s a little chart. What Is The Hardness Of Measuring Faces Of Anvil And Spindle.

From sciencenotes.org

Mohs Hardness Scale What Is The Hardness Of Measuring Faces Of Anvil And Spindle The characteristics of case hardening are primarily determined by surface hardness, the effective hardness depth and the depth profile. If the material is too thin, you’ll be measuring the hardness of the supporting anvil more so than the test piece. Measure flatness and parallelism on a micrometer anvil and spindle (episode 11) welcome to quality digest’s new show, “how. The. What Is The Hardness Of Measuring Faces Of Anvil And Spindle.

From ultra-germany.shop

External micrometers, movable anvil and dial mounting hole Tungsten What Is The Hardness Of Measuring Faces Of Anvil And Spindle If the material is too thin, you’ll be measuring the hardness of the supporting anvil more so than the test piece. Measuring faces of anvil and spindle has a hardness of about 800 hv or 62 hrc. 1) thread accuracy, 2) flatness of measuring faces, 3) parallelism between the faces and 4) rigidity of. Faces may be tipped with tungsten. What Is The Hardness Of Measuring Faces Of Anvil And Spindle.

From www.youtube.com

Testing the Anvil Face Hardness of Cheap 66 lb. Amazon Anvil YouTube What Is The Hardness Of Measuring Faces Of Anvil And Spindle Here’s a little chart on the minimum. 1) thread accuracy, 2) flatness of measuring faces, 3) parallelism between the faces and 4) rigidity of. Faces may be tipped with tungsten carbide. The most significant factors are: Measuring faces of anvil and spindle has a hardness of about 800 hv or 62 hrc. Anvils should be checked on a regular basis,. What Is The Hardness Of Measuring Faces Of Anvil And Spindle.

From www.slideserve.com

PPT Hardness Measuring Instrument PowerPoint What Is The Hardness Of Measuring Faces Of Anvil And Spindle The most significant factors are: There are several frequently used methods to measure the hardness of metals, including: The characteristics of case hardening are primarily determined by surface hardness, the effective hardness depth and the depth profile. Measure flatness and parallelism on a micrometer anvil and spindle (episode 11) welcome to quality digest’s new show, “how. Anvils should be checked. What Is The Hardness Of Measuring Faces Of Anvil And Spindle.

From exozsjyud.blob.core.windows.net

What Is Hardness Testing Equipment at Edward Cortez blog What Is The Hardness Of Measuring Faces Of Anvil And Spindle The most significant factors are: If the material is too thin, you’ll be measuring the hardness of the supporting anvil more so than the test piece. Measure flatness and parallelism on a micrometer anvil and spindle (episode 11) welcome to quality digest’s new show, “how. Here’s a little chart on the minimum. Anvils should be checked on a regular basis,. What Is The Hardness Of Measuring Faces Of Anvil And Spindle.

From www.michelli.com

Types of Micrometer Anvils Michelli Weighing & Measurement What Is The Hardness Of Measuring Faces Of Anvil And Spindle Here’s a little chart on the minimum. Faces may be tipped with tungsten carbide. The characteristics of case hardening are primarily determined by surface hardness, the effective hardness depth and the depth profile. Anvils should be checked on a regular basis, typically prior to each use, and if found too compromised they should be replaced. Measure flatness and parallelism on. What Is The Hardness Of Measuring Faces Of Anvil And Spindle.

From ourelabs.blogspot.com

ROCKWELL HARDNESS TEST Ourengineeringlabs What Is The Hardness Of Measuring Faces Of Anvil And Spindle The most significant factors are: Anvils should be checked on a regular basis, typically prior to each use, and if found too compromised they should be replaced. Here’s a little chart on the minimum. If the material is too thin, you’ll be measuring the hardness of the supporting anvil more so than the test piece. Faces may be tipped with. What Is The Hardness Of Measuring Faces Of Anvil And Spindle.

From thermalprocessing.com

Hardness scale conversion Thermal Processing Magazine What Is The Hardness Of Measuring Faces Of Anvil And Spindle Anvils should be checked on a regular basis, typically prior to each use, and if found too compromised they should be replaced. Measure flatness and parallelism on a micrometer anvil and spindle (episode 11) welcome to quality digest’s new show, “how. Faces may be tipped with tungsten carbide. There are several frequently used methods to measure the hardness of metals,. What Is The Hardness Of Measuring Faces Of Anvil And Spindle.

From amesportablehardnesstesters.com

Hardness Testing in Rockwell Scales What Is The Hardness Of Measuring Faces Of Anvil And Spindle The characteristics of case hardening are primarily determined by surface hardness, the effective hardness depth and the depth profile. There are several frequently used methods to measure the hardness of metals, including: Measuring faces of anvil and spindle has a hardness of about 800 hv or 62 hrc. Measure flatness and parallelism on a micrometer anvil and spindle (episode 11). What Is The Hardness Of Measuring Faces Of Anvil And Spindle.

From www.machinistguides.com

How to Read a Micrometer Beginner's Guide Machinist Guides What Is The Hardness Of Measuring Faces Of Anvil And Spindle If the material is too thin, you’ll be measuring the hardness of the supporting anvil more so than the test piece. Measuring faces of anvil and spindle has a hardness of about 800 hv or 62 hrc. Measure flatness and parallelism on a micrometer anvil and spindle (episode 11) welcome to quality digest’s new show, “how. The characteristics of case. What Is The Hardness Of Measuring Faces Of Anvil And Spindle.

From www.besmicoptic.com

Multimar 844 Tb Measuring Anvils with Measuring Blades Besmic Optic What Is The Hardness Of Measuring Faces Of Anvil And Spindle The characteristics of case hardening are primarily determined by surface hardness, the effective hardness depth and the depth profile. If the material is too thin, you’ll be measuring the hardness of the supporting anvil more so than the test piece. 1) thread accuracy, 2) flatness of measuring faces, 3) parallelism between the faces and 4) rigidity of. There are several. What Is The Hardness Of Measuring Faces Of Anvil And Spindle.

From www.michelli.com

Types of Micrometer Anvils Michelli Weighing & Measurement What Is The Hardness Of Measuring Faces Of Anvil And Spindle Anvils should be checked on a regular basis, typically prior to each use, and if found too compromised they should be replaced. If the material is too thin, you’ll be measuring the hardness of the supporting anvil more so than the test piece. The most significant factors are: 1) thread accuracy, 2) flatness of measuring faces, 3) parallelism between the. What Is The Hardness Of Measuring Faces Of Anvil And Spindle.

From polysynthesis.au

Shore Hardness Scales Measuring Material Hardness What Is The Hardness Of Measuring Faces Of Anvil And Spindle Anvils should be checked on a regular basis, typically prior to each use, and if found too compromised they should be replaced. Faces may be tipped with tungsten carbide. Measure flatness and parallelism on a micrometer anvil and spindle (episode 11) welcome to quality digest’s new show, “how. 1) thread accuracy, 2) flatness of measuring faces, 3) parallelism between the. What Is The Hardness Of Measuring Faces Of Anvil And Spindle.

From amesportablehardnesstesters.com

The Rockwell Metal Hardness Scales Explained What Is The Hardness Of Measuring Faces Of Anvil And Spindle Measure flatness and parallelism on a micrometer anvil and spindle (episode 11) welcome to quality digest’s new show, “how. The most significant factors are: Faces may be tipped with tungsten carbide. There are several frequently used methods to measure the hardness of metals, including: Here’s a little chart on the minimum. 1) thread accuracy, 2) flatness of measuring faces, 3). What Is The Hardness Of Measuring Faces Of Anvil And Spindle.

From www.corrosionpedia.com

5 Ways to Measure the Hardness of Materials What Is The Hardness Of Measuring Faces Of Anvil And Spindle Here’s a little chart on the minimum. Measure flatness and parallelism on a micrometer anvil and spindle (episode 11) welcome to quality digest’s new show, “how. Anvils should be checked on a regular basis, typically prior to each use, and if found too compromised they should be replaced. Faces may be tipped with tungsten carbide. Measuring faces of anvil and. What Is The Hardness Of Measuring Faces Of Anvil And Spindle.

From www.gigatools.ph

Mitutoyo Spherical Face MicrometerSpherical Anvil & Spindle Series What Is The Hardness Of Measuring Faces Of Anvil And Spindle Measuring faces of anvil and spindle has a hardness of about 800 hv or 62 hrc. Measure flatness and parallelism on a micrometer anvil and spindle (episode 11) welcome to quality digest’s new show, “how. Here’s a little chart on the minimum. There are several frequently used methods to measure the hardness of metals, including: Anvils should be checked on. What Is The Hardness Of Measuring Faces Of Anvil And Spindle.

From www.penntoolco.com

iGaging Point Anvil & Spindle Micrometers Penn Tool Co., Inc What Is The Hardness Of Measuring Faces Of Anvil And Spindle There are several frequently used methods to measure the hardness of metals, including: 1) thread accuracy, 2) flatness of measuring faces, 3) parallelism between the faces and 4) rigidity of. Measure flatness and parallelism on a micrometer anvil and spindle (episode 11) welcome to quality digest’s new show, “how. Faces may be tipped with tungsten carbide. If the material is. What Is The Hardness Of Measuring Faces Of Anvil And Spindle.

From westportcorp.com

Rockwell Hardness Tester Anvils WESTport Corp. What Is The Hardness Of Measuring Faces Of Anvil And Spindle If the material is too thin, you’ll be measuring the hardness of the supporting anvil more so than the test piece. Measuring faces of anvil and spindle has a hardness of about 800 hv or 62 hrc. The characteristics of case hardening are primarily determined by surface hardness, the effective hardness depth and the depth profile. The most significant factors. What Is The Hardness Of Measuring Faces Of Anvil And Spindle.