Material Handling Cost Driver . Calculate a cost per unit of cost driver (cost pool/total number of cost driver). One group of cost drivers, which is not often specified, associated with decision support for location is inbound logistics, or in. The objective of this study is to provide a framework for reducing bulk materials handling project costs in a systematic way by. Material handling (purchased parts, wip and finished goods) were used to till two cost pools for each stage, making a total of six material. Allocate costs to the product based on how much the product uses of the cost driver. Material handling refers to the movement, protection, storage, and control of materials and products throughout the manufacturing,. The quantity of raw materials moved and finished goods transported serves as the cost driver for material handling.

from www.chegg.com

Material handling refers to the movement, protection, storage, and control of materials and products throughout the manufacturing,. One group of cost drivers, which is not often specified, associated with decision support for location is inbound logistics, or in. Material handling (purchased parts, wip and finished goods) were used to till two cost pools for each stage, making a total of six material. The objective of this study is to provide a framework for reducing bulk materials handling project costs in a systematic way by. Allocate costs to the product based on how much the product uses of the cost driver. Calculate a cost per unit of cost driver (cost pool/total number of cost driver). The quantity of raw materials moved and finished goods transported serves as the cost driver for material handling.

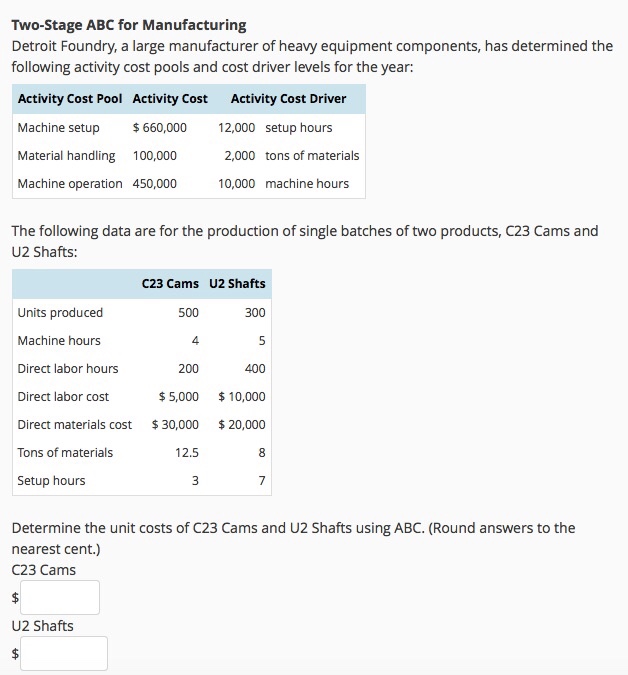

Solved TwoStage ABC for Manufacturing Detroit Foundry, a

Material Handling Cost Driver Allocate costs to the product based on how much the product uses of the cost driver. Allocate costs to the product based on how much the product uses of the cost driver. Material handling (purchased parts, wip and finished goods) were used to till two cost pools for each stage, making a total of six material. The quantity of raw materials moved and finished goods transported serves as the cost driver for material handling. One group of cost drivers, which is not often specified, associated with decision support for location is inbound logistics, or in. The objective of this study is to provide a framework for reducing bulk materials handling project costs in a systematic way by. Material handling refers to the movement, protection, storage, and control of materials and products throughout the manufacturing,. Calculate a cost per unit of cost driver (cost pool/total number of cost driver).

From www.chegg.com

Solved Woodland Industries manufactures and sells Material Handling Cost Driver Material handling (purchased parts, wip and finished goods) were used to till two cost pools for each stage, making a total of six material. One group of cost drivers, which is not often specified, associated with decision support for location is inbound logistics, or in. Calculate a cost per unit of cost driver (cost pool/total number of cost driver). The. Material Handling Cost Driver.

From sinevaledoaco.blogspot.com

Ways Of Reducing Material Handling Cost Material Handling Cost Driver The quantity of raw materials moved and finished goods transported serves as the cost driver for material handling. Material handling (purchased parts, wip and finished goods) were used to till two cost pools for each stage, making a total of six material. One group of cost drivers, which is not often specified, associated with decision support for location is inbound. Material Handling Cost Driver.

From sinevaledoaco.blogspot.com

Ways Of Reducing Material Handling Cost Material Handling Cost Driver Allocate costs to the product based on how much the product uses of the cost driver. Material handling (purchased parts, wip and finished goods) were used to till two cost pools for each stage, making a total of six material. Material handling refers to the movement, protection, storage, and control of materials and products throughout the manufacturing,. One group of. Material Handling Cost Driver.

From www.businesswire.com

Material Handling Equipment Market Intelligence, Procurement Research Material Handling Cost Driver Calculate a cost per unit of cost driver (cost pool/total number of cost driver). Allocate costs to the product based on how much the product uses of the cost driver. Material handling refers to the movement, protection, storage, and control of materials and products throughout the manufacturing,. The quantity of raw materials moved and finished goods transported serves as the. Material Handling Cost Driver.

From www.erp-information.com

Warehouse Material Handling (Equipment, Principles, and Tips) Material Handling Cost Driver Allocate costs to the product based on how much the product uses of the cost driver. One group of cost drivers, which is not often specified, associated with decision support for location is inbound logistics, or in. The quantity of raw materials moved and finished goods transported serves as the cost driver for material handling. Calculate a cost per unit. Material Handling Cost Driver.

From www.chegg.com

Solved Everlast Co. manufactures a variety of drill bits. Material Handling Cost Driver Material handling refers to the movement, protection, storage, and control of materials and products throughout the manufacturing,. Material handling (purchased parts, wip and finished goods) were used to till two cost pools for each stage, making a total of six material. One group of cost drivers, which is not often specified, associated with decision support for location is inbound logistics,. Material Handling Cost Driver.

From www.youtube.com

Components of Inventory Costs (Ordering Cost, Carrying Cost, Stock Out Material Handling Cost Driver Calculate a cost per unit of cost driver (cost pool/total number of cost driver). The objective of this study is to provide a framework for reducing bulk materials handling project costs in a systematic way by. The quantity of raw materials moved and finished goods transported serves as the cost driver for material handling. Material handling refers to the movement,. Material Handling Cost Driver.

From www.chegg.com

Solved TwoStage ABC for Manufacturing Detroit Foundry, a Material Handling Cost Driver Calculate a cost per unit of cost driver (cost pool/total number of cost driver). Material handling refers to the movement, protection, storage, and control of materials and products throughout the manufacturing,. The quantity of raw materials moved and finished goods transported serves as the cost driver for material handling. Allocate costs to the product based on how much the product. Material Handling Cost Driver.

From sinevaledoaco.blogspot.com

Ways Of Reducing Material Handling Cost Material Handling Cost Driver Material handling refers to the movement, protection, storage, and control of materials and products throughout the manufacturing,. Calculate a cost per unit of cost driver (cost pool/total number of cost driver). Material handling (purchased parts, wip and finished goods) were used to till two cost pools for each stage, making a total of six material. The quantity of raw materials. Material Handling Cost Driver.

From pakmcqs.com

In the budget hierarchy, the material handling cost is Material Handling Cost Driver Allocate costs to the product based on how much the product uses of the cost driver. The objective of this study is to provide a framework for reducing bulk materials handling project costs in a systematic way by. One group of cost drivers, which is not often specified, associated with decision support for location is inbound logistics, or in. Calculate. Material Handling Cost Driver.

From na.bhs1.com

Material Handling Costs in Electrical Construction and How to Lower Material Handling Cost Driver Material handling (purchased parts, wip and finished goods) were used to till two cost pools for each stage, making a total of six material. One group of cost drivers, which is not often specified, associated with decision support for location is inbound logistics, or in. The quantity of raw materials moved and finished goods transported serves as the cost driver. Material Handling Cost Driver.

From sinevaledoaco.blogspot.com

Ways Of Reducing Material Handling Cost Material Handling Cost Driver Allocate costs to the product based on how much the product uses of the cost driver. Calculate a cost per unit of cost driver (cost pool/total number of cost driver). One group of cost drivers, which is not often specified, associated with decision support for location is inbound logistics, or in. Material handling (purchased parts, wip and finished goods) were. Material Handling Cost Driver.

From www.chegg.com

Solved Fellar Corp. has identified the following Material Handling Cost Driver The objective of this study is to provide a framework for reducing bulk materials handling project costs in a systematic way by. Material handling (purchased parts, wip and finished goods) were used to till two cost pools for each stage, making a total of six material. One group of cost drivers, which is not often specified, associated with decision support. Material Handling Cost Driver.

From www.marketing91.com

Material Handling Definition, Objectives, Importance, Types Material Handling Cost Driver One group of cost drivers, which is not often specified, associated with decision support for location is inbound logistics, or in. Material handling refers to the movement, protection, storage, and control of materials and products throughout the manufacturing,. Calculate a cost per unit of cost driver (cost pool/total number of cost driver). The quantity of raw materials moved and finished. Material Handling Cost Driver.

From controlconceptsusa.com

How to Reduce Material Handling Costs Control Concepts, Inc. Material Handling Cost Driver Material handling (purchased parts, wip and finished goods) were used to till two cost pools for each stage, making a total of six material. The quantity of raw materials moved and finished goods transported serves as the cost driver for material handling. Allocate costs to the product based on how much the product uses of the cost driver. The objective. Material Handling Cost Driver.

From www.chegg.com

Solved TwoStage ABC for Manufacturing Detroit Foundry, a Material Handling Cost Driver Allocate costs to the product based on how much the product uses of the cost driver. The objective of this study is to provide a framework for reducing bulk materials handling project costs in a systematic way by. The quantity of raw materials moved and finished goods transported serves as the cost driver for material handling. Calculate a cost per. Material Handling Cost Driver.

From www.slideshare.net

An approach for selection of material handling equipment and material… Material Handling Cost Driver One group of cost drivers, which is not often specified, associated with decision support for location is inbound logistics, or in. Calculate a cost per unit of cost driver (cost pool/total number of cost driver). Material handling refers to the movement, protection, storage, and control of materials and products throughout the manufacturing,. The objective of this study is to provide. Material Handling Cost Driver.

From www.chegg.com

Solved TwoStage ABC for Manufacturing Detroit Foundry, a Material Handling Cost Driver The quantity of raw materials moved and finished goods transported serves as the cost driver for material handling. Allocate costs to the product based on how much the product uses of the cost driver. Material handling refers to the movement, protection, storage, and control of materials and products throughout the manufacturing,. Calculate a cost per unit of cost driver (cost. Material Handling Cost Driver.

From slidetodoc.com

Material Handling Cost Main costs involved in designing Material Handling Cost Driver The objective of this study is to provide a framework for reducing bulk materials handling project costs in a systematic way by. Material handling (purchased parts, wip and finished goods) were used to till two cost pools for each stage, making a total of six material. Calculate a cost per unit of cost driver (cost pool/total number of cost driver).. Material Handling Cost Driver.

From sinevaledoaco.blogspot.com

Ways Of Reducing Material Handling Cost Material Handling Cost Driver Material handling refers to the movement, protection, storage, and control of materials and products throughout the manufacturing,. One group of cost drivers, which is not often specified, associated with decision support for location is inbound logistics, or in. Allocate costs to the product based on how much the product uses of the cost driver. Material handling (purchased parts, wip and. Material Handling Cost Driver.

From www.chegg.com

Solved Exercise 54B.TwoStage ABC for Manufacturing Detroit Material Handling Cost Driver One group of cost drivers, which is not often specified, associated with decision support for location is inbound logistics, or in. The objective of this study is to provide a framework for reducing bulk materials handling project costs in a systematic way by. Material handling (purchased parts, wip and finished goods) were used to till two cost pools for each. Material Handling Cost Driver.

From www.slideshare.net

Material Handling Material Handling Cost Driver Calculate a cost per unit of cost driver (cost pool/total number of cost driver). The quantity of raw materials moved and finished goods transported serves as the cost driver for material handling. Allocate costs to the product based on how much the product uses of the cost driver. Material handling (purchased parts, wip and finished goods) were used to till. Material Handling Cost Driver.

From www.bigrentz.com

4 Types of Material Handling Equipment and Their Uses BigRentz Material Handling Cost Driver One group of cost drivers, which is not often specified, associated with decision support for location is inbound logistics, or in. Calculate a cost per unit of cost driver (cost pool/total number of cost driver). Material handling (purchased parts, wip and finished goods) were used to till two cost pools for each stage, making a total of six material. The. Material Handling Cost Driver.

From www.applerubber.com

5 Ways to Reduce Material Handling Costs Official Apple Rubber Blog Material Handling Cost Driver Allocate costs to the product based on how much the product uses of the cost driver. Material handling refers to the movement, protection, storage, and control of materials and products throughout the manufacturing,. Calculate a cost per unit of cost driver (cost pool/total number of cost driver). One group of cost drivers, which is not often specified, associated with decision. Material Handling Cost Driver.

From www.heavyequipments.in

5 Ways to Reduce the Material Handling Costs Material Handling Cost Driver Allocate costs to the product based on how much the product uses of the cost driver. The objective of this study is to provide a framework for reducing bulk materials handling project costs in a systematic way by. Material handling (purchased parts, wip and finished goods) were used to till two cost pools for each stage, making a total of. Material Handling Cost Driver.

From sinevaledoaco.blogspot.com

Ways Of Reducing Material Handling Cost Material Handling Cost Driver Calculate a cost per unit of cost driver (cost pool/total number of cost driver). One group of cost drivers, which is not often specified, associated with decision support for location is inbound logistics, or in. Material handling refers to the movement, protection, storage, and control of materials and products throughout the manufacturing,. The quantity of raw materials moved and finished. Material Handling Cost Driver.

From www.numerade.com

SOLVED Wings Co. budgeted 555,600 for manufacturing direct wages Material Handling Cost Driver Allocate costs to the product based on how much the product uses of the cost driver. Material handling (purchased parts, wip and finished goods) were used to till two cost pools for each stage, making a total of six material. The quantity of raw materials moved and finished goods transported serves as the cost driver for material handling. One group. Material Handling Cost Driver.

From sinevaledoaco.blogspot.com

Ways Of Reducing Material Handling Cost Material Handling Cost Driver Allocate costs to the product based on how much the product uses of the cost driver. Material handling (purchased parts, wip and finished goods) were used to till two cost pools for each stage, making a total of six material. Calculate a cost per unit of cost driver (cost pool/total number of cost driver). The objective of this study is. Material Handling Cost Driver.

From www.researchgate.net

Initial Material Handling Cost Download Scientific Diagram Material Handling Cost Driver The quantity of raw materials moved and finished goods transported serves as the cost driver for material handling. The objective of this study is to provide a framework for reducing bulk materials handling project costs in a systematic way by. Material handling refers to the movement, protection, storage, and control of materials and products throughout the manufacturing,. Allocate costs to. Material Handling Cost Driver.

From brainly.com

TwoStage ABC for Manufacturing Detroit Foundry, a large manufacturer Material Handling Cost Driver Allocate costs to the product based on how much the product uses of the cost driver. Material handling (purchased parts, wip and finished goods) were used to till two cost pools for each stage, making a total of six material. The quantity of raw materials moved and finished goods transported serves as the cost driver for material handling. Calculate a. Material Handling Cost Driver.

From www.dreamstime.com

Material Handling and Palletizing Robot Loading Truck, with Driver Material Handling Cost Driver Calculate a cost per unit of cost driver (cost pool/total number of cost driver). Material handling (purchased parts, wip and finished goods) were used to till two cost pools for each stage, making a total of six material. Material handling refers to the movement, protection, storage, and control of materials and products throughout the manufacturing,. The objective of this study. Material Handling Cost Driver.

From www.youtube.com

Elements of cost Direct and Indirect Material, Labor, & Expenses Material Handling Cost Driver Allocate costs to the product based on how much the product uses of the cost driver. Calculate a cost per unit of cost driver (cost pool/total number of cost driver). The quantity of raw materials moved and finished goods transported serves as the cost driver for material handling. Material handling (purchased parts, wip and finished goods) were used to till. Material Handling Cost Driver.

From www.hhilifting.com

How to Determine the Cost of Material Handling Equipment Holloway Material Handling Cost Driver The quantity of raw materials moved and finished goods transported serves as the cost driver for material handling. Allocate costs to the product based on how much the product uses of the cost driver. One group of cost drivers, which is not often specified, associated with decision support for location is inbound logistics, or in. Calculate a cost per unit. Material Handling Cost Driver.

From fabroninc.blogspot.com

This is How You Can Save Material Handling Costs Material Handling Cost Driver Material handling refers to the movement, protection, storage, and control of materials and products throughout the manufacturing,. The objective of this study is to provide a framework for reducing bulk materials handling project costs in a systematic way by. The quantity of raw materials moved and finished goods transported serves as the cost driver for material handling. Allocate costs to. Material Handling Cost Driver.

From www.upperinc.com

What is Material Handling Ultimate Guide 2024 Material Handling Cost Driver Calculate a cost per unit of cost driver (cost pool/total number of cost driver). The quantity of raw materials moved and finished goods transported serves as the cost driver for material handling. Material handling (purchased parts, wip and finished goods) were used to till two cost pools for each stage, making a total of six material. Allocate costs to the. Material Handling Cost Driver.