Feed Change Lever Meaning . This is typically done using the feed gearbox or feed selection levers on the lathe. Longitudinal feed in a lathe can be controlled by adjusting the feed rate on the lathe machine. The feed rate can be. By adjusting the feed ratio between front and back, you can prevent issues such as. Longitudinal feed, cross feed, or threading feed. A lever that is used to select one of three types of feed: The purpose of the differential feed is to control how the fabric is fed through the machine. With half nuts engaged, the lever in the middle of apron must be in center position, you'll be locked out from trying to go up or down. The two axes of movement associated with the lathe are the z and x axes. The z axis is the longitudinal axis, while the x axis. The feed change lever is located on the apron of. The power feed lever controls the automatic movement of the axes. If your differential speed is set on “n” then both of your feed dogs will be moving your fabric through at the same speed.

from byjus.com

The purpose of the differential feed is to control how the fabric is fed through the machine. A lever that is used to select one of three types of feed: The feed change lever is located on the apron of. The feed rate can be. Longitudinal feed in a lathe can be controlled by adjusting the feed rate on the lathe machine. With half nuts engaged, the lever in the middle of apron must be in center position, you'll be locked out from trying to go up or down. Longitudinal feed, cross feed, or threading feed. This is typically done using the feed gearbox or feed selection levers on the lathe. By adjusting the feed ratio between front and back, you can prevent issues such as. The two axes of movement associated with the lathe are the z and x axes.

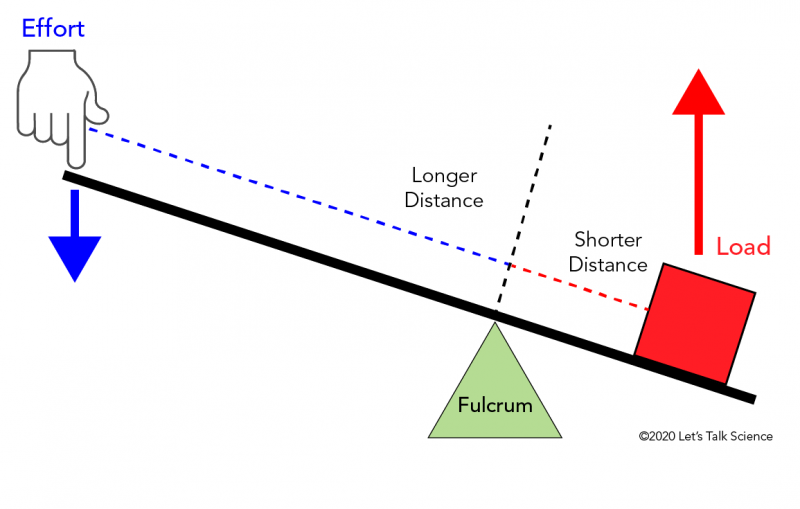

How do levers work?

Feed Change Lever Meaning Longitudinal feed, cross feed, or threading feed. Longitudinal feed, cross feed, or threading feed. The two axes of movement associated with the lathe are the z and x axes. With half nuts engaged, the lever in the middle of apron must be in center position, you'll be locked out from trying to go up or down. If your differential speed is set on “n” then both of your feed dogs will be moving your fabric through at the same speed. The power feed lever controls the automatic movement of the axes. The feed rate can be. Longitudinal feed in a lathe can be controlled by adjusting the feed rate on the lathe machine. A lever that is used to select one of three types of feed: The purpose of the differential feed is to control how the fabric is fed through the machine. This is typically done using the feed gearbox or feed selection levers on the lathe. The z axis is the longitudinal axis, while the x axis. By adjusting the feed ratio between front and back, you can prevent issues such as. The feed change lever is located on the apron of.

From www.slideserve.com

PPT UniteII LATHE PowerPoint Presentation, free download ID991692 Feed Change Lever Meaning With half nuts engaged, the lever in the middle of apron must be in center position, you'll be locked out from trying to go up or down. If your differential speed is set on “n” then both of your feed dogs will be moving your fabric through at the same speed. The power feed lever controls the automatic movement of. Feed Change Lever Meaning.

From engineeringlearn.com

What is Lever? Types, Uses, Principle & Examples [Explained with Feed Change Lever Meaning The purpose of the differential feed is to control how the fabric is fed through the machine. If your differential speed is set on “n” then both of your feed dogs will be moving your fabric through at the same speed. By adjusting the feed ratio between front and back, you can prevent issues such as. Longitudinal feed, cross feed,. Feed Change Lever Meaning.

From lessonlibraryshucked.z22.web.core.windows.net

Three Types Of Lever Feed Change Lever Meaning The power feed lever controls the automatic movement of the axes. The purpose of the differential feed is to control how the fabric is fed through the machine. The feed rate can be. If your differential speed is set on “n” then both of your feed dogs will be moving your fabric through at the same speed. By adjusting the. Feed Change Lever Meaning.

From www.youtube.com

Change levers and it's types YouTube Feed Change Lever Meaning Longitudinal feed in a lathe can be controlled by adjusting the feed rate on the lathe machine. Longitudinal feed, cross feed, or threading feed. The power feed lever controls the automatic movement of the axes. A lever that is used to select one of three types of feed: If your differential speed is set on “n” then both of your. Feed Change Lever Meaning.

From www.practicalmachinist.com

9A stuck feed change lever Feed Change Lever Meaning This is typically done using the feed gearbox or feed selection levers on the lathe. The purpose of the differential feed is to control how the fabric is fed through the machine. The two axes of movement associated with the lathe are the z and x axes. With half nuts engaged, the lever in the middle of apron must be. Feed Change Lever Meaning.

From www.slideserve.com

PPT Lathe Machine PowerPoint Presentation, free download ID659330 Feed Change Lever Meaning A lever that is used to select one of three types of feed: Longitudinal feed, cross feed, or threading feed. The feed change lever is located on the apron of. Longitudinal feed in a lathe can be controlled by adjusting the feed rate on the lathe machine. If your differential speed is set on “n” then both of your feed. Feed Change Lever Meaning.

From owlcation.com

Simple Machines — How Does a Lever Work? Owlcation Feed Change Lever Meaning The purpose of the differential feed is to control how the fabric is fed through the machine. The feed change lever is located on the apron of. A lever that is used to select one of three types of feed: The z axis is the longitudinal axis, while the x axis. This is typically done using the feed gearbox or. Feed Change Lever Meaning.

From www.youtube.com

Lathe gear change lever Parts and Assembly using SOLIDWORKS Feed Change Lever Meaning The feed change lever is located on the apron of. A lever that is used to select one of three types of feed: If your differential speed is set on “n” then both of your feed dogs will be moving your fabric through at the same speed. The purpose of the differential feed is to control how the fabric is. Feed Change Lever Meaning.

From school.careers360.com

types of lever Overview, Structure, Properties & Uses Feed Change Lever Meaning The power feed lever controls the automatic movement of the axes. With half nuts engaged, the lever in the middle of apron must be in center position, you'll be locked out from trying to go up or down. The feed rate can be. Longitudinal feed, cross feed, or threading feed. The z axis is the longitudinal axis, while the x. Feed Change Lever Meaning.

From www.grainger.com

RIDGID Carriage Feed Lever 25XC6342385 Grainger Feed Change Lever Meaning With half nuts engaged, the lever in the middle of apron must be in center position, you'll be locked out from trying to go up or down. The power feed lever controls the automatic movement of the axes. The z axis is the longitudinal axis, while the x axis. The two axes of movement associated with the lathe are the. Feed Change Lever Meaning.

From www.slideserve.com

PPT MANUFACTURING TECHNOLOGYII PowerPoint Presentation, free Feed Change Lever Meaning A lever that is used to select one of three types of feed: The two axes of movement associated with the lathe are the z and x axes. The z axis is the longitudinal axis, while the x axis. Longitudinal feed in a lathe can be controlled by adjusting the feed rate on the lathe machine. The purpose of the. Feed Change Lever Meaning.

From www.researchgate.net

Three basic types of lever mechanisms (A) firstorder lever, (B Feed Change Lever Meaning The feed rate can be. This is typically done using the feed gearbox or feed selection levers on the lathe. By adjusting the feed ratio between front and back, you can prevent issues such as. A lever that is used to select one of three types of feed: The power feed lever controls the automatic movement of the axes. Longitudinal. Feed Change Lever Meaning.

From www.slideserve.com

PPT UniteII LATHE PowerPoint Presentation, free download ID991692 Feed Change Lever Meaning The feed rate can be. The feed change lever is located on the apron of. Longitudinal feed, cross feed, or threading feed. The z axis is the longitudinal axis, while the x axis. Longitudinal feed in a lathe can be controlled by adjusting the feed rate on the lathe machine. The purpose of the differential feed is to control how. Feed Change Lever Meaning.

From www.crossfit.com

CrossFit Anatomy of Levers, Part 7 Lever Changes Feed Change Lever Meaning By adjusting the feed ratio between front and back, you can prevent issues such as. The power feed lever controls the automatic movement of the axes. The feed rate can be. If your differential speed is set on “n” then both of your feed dogs will be moving your fabric through at the same speed. Longitudinal feed, cross feed, or. Feed Change Lever Meaning.

From billstractor.net

4WD CHANGE LEVER ARM FOR MAHINDRA TRACTOR (19962652200) Feed Change Lever Meaning The purpose of the differential feed is to control how the fabric is fed through the machine. Longitudinal feed, cross feed, or threading feed. The power feed lever controls the automatic movement of the axes. With half nuts engaged, the lever in the middle of apron must be in center position, you'll be locked out from trying to go up. Feed Change Lever Meaning.

From www.abcsewingmachine.com

11072105 Reverse Feed Control Lever ABC Sewing Machine Feed Change Lever Meaning The feed change lever is located on the apron of. The feed rate can be. The purpose of the differential feed is to control how the fabric is fed through the machine. This is typically done using the feed gearbox or feed selection levers on the lathe. The power feed lever controls the automatic movement of the axes. With half. Feed Change Lever Meaning.

From www.youtube.com

Switching the Mini Lathes Gear Lever to the Front YouTube Feed Change Lever Meaning The purpose of the differential feed is to control how the fabric is fed through the machine. The z axis is the longitudinal axis, while the x axis. The two axes of movement associated with the lathe are the z and x axes. The power feed lever controls the automatic movement of the axes. The feed change lever is located. Feed Change Lever Meaning.

From joiagcexf.blob.core.windows.net

Define Lever Anatomy at Norma Philips blog Feed Change Lever Meaning By adjusting the feed ratio between front and back, you can prevent issues such as. If your differential speed is set on “n” then both of your feed dogs will be moving your fabric through at the same speed. The z axis is the longitudinal axis, while the x axis. A lever that is used to select one of three. Feed Change Lever Meaning.

From www.modarmory.com

M240 Feed Lever MOD Armory Feed Change Lever Meaning If your differential speed is set on “n” then both of your feed dogs will be moving your fabric through at the same speed. Longitudinal feed in a lathe can be controlled by adjusting the feed rate on the lathe machine. The power feed lever controls the automatic movement of the axes. By adjusting the feed ratio between front and. Feed Change Lever Meaning.

From www.slideserve.com

PPT Types of Levers PowerPoint Presentation, free download ID1897391 Feed Change Lever Meaning The feed rate can be. Longitudinal feed in a lathe can be controlled by adjusting the feed rate on the lathe machine. The z axis is the longitudinal axis, while the x axis. This is typically done using the feed gearbox or feed selection levers on the lathe. The power feed lever controls the automatic movement of the axes. By. Feed Change Lever Meaning.

From mobiledimensionsaw.com

591602 Feed Control Lever Mobile Dimension Saw Feed Change Lever Meaning By adjusting the feed ratio between front and back, you can prevent issues such as. A lever that is used to select one of three types of feed: The feed rate can be. If your differential speed is set on “n” then both of your feed dogs will be moving your fabric through at the same speed. The feed change. Feed Change Lever Meaning.

From byjus.com

How do levers work? Feed Change Lever Meaning If your differential speed is set on “n” then both of your feed dogs will be moving your fabric through at the same speed. Longitudinal feed in a lathe can be controlled by adjusting the feed rate on the lathe machine. Longitudinal feed, cross feed, or threading feed. This is typically done using the feed gearbox or feed selection levers. Feed Change Lever Meaning.

From steemit.com

Mechanical systems Levers and Linkages — Steemit Feed Change Lever Meaning With half nuts engaged, the lever in the middle of apron must be in center position, you'll be locked out from trying to go up or down. By adjusting the feed ratio between front and back, you can prevent issues such as. Longitudinal feed, cross feed, or threading feed. If your differential speed is set on “n” then both of. Feed Change Lever Meaning.

From twitter.com

Levers for Change on Twitter "Levers4Change is a Management Feed Change Lever Meaning Longitudinal feed, cross feed, or threading feed. The feed rate can be. A lever that is used to select one of three types of feed: With half nuts engaged, the lever in the middle of apron must be in center position, you'll be locked out from trying to go up or down. The two axes of movement associated with the. Feed Change Lever Meaning.

From www.youtube.com

How to Drop and Raise the Feed Dog Usha Janome Sewing Machine Feed Feed Change Lever Meaning If your differential speed is set on “n” then both of your feed dogs will be moving your fabric through at the same speed. A lever that is used to select one of three types of feed: Longitudinal feed, cross feed, or threading feed. The z axis is the longitudinal axis, while the x axis. The two axes of movement. Feed Change Lever Meaning.

From iobopen.com

(Con)Fusion of the Jaws Longaxis Rotation of the Jaws During Feeding Feed Change Lever Meaning Longitudinal feed, cross feed, or threading feed. This is typically done using the feed gearbox or feed selection levers on the lathe. The feed change lever is located on the apron of. The power feed lever controls the automatic movement of the axes. With half nuts engaged, the lever in the middle of apron must be in center position, you'll. Feed Change Lever Meaning.

From owlcation.com

Simple Machines How Does a Lever Work? Owlcation Feed Change Lever Meaning The purpose of the differential feed is to control how the fabric is fed through the machine. With half nuts engaged, the lever in the middle of apron must be in center position, you'll be locked out from trying to go up or down. The feed rate can be. The power feed lever controls the automatic movement of the axes.. Feed Change Lever Meaning.

From www.slideserve.com

PPT Types of Levers PowerPoint Presentation, free download ID2689158 Feed Change Lever Meaning The feed rate can be. The purpose of the differential feed is to control how the fabric is fed through the machine. If your differential speed is set on “n” then both of your feed dogs will be moving your fabric through at the same speed. This is typically done using the feed gearbox or feed selection levers on the. Feed Change Lever Meaning.

From mobiledimensionsaw.com

591617 Feed Control Lever Extension Mobile Dimension Saw Feed Change Lever Meaning The z axis is the longitudinal axis, while the x axis. The power feed lever controls the automatic movement of the axes. The two axes of movement associated with the lathe are the z and x axes. The purpose of the differential feed is to control how the fabric is fed through the machine. A lever that is used to. Feed Change Lever Meaning.

From www.crossfit.com

CrossFit Anatomy of Levers, Part 7 Lever Changes Feed Change Lever Meaning The purpose of the differential feed is to control how the fabric is fed through the machine. The two axes of movement associated with the lathe are the z and x axes. This is typically done using the feed gearbox or feed selection levers on the lathe. The feed change lever is located on the apron of. The power feed. Feed Change Lever Meaning.

From www.slideserve.com

PPT The Metalworking Lathe PowerPoint Presentation, free download Feed Change Lever Meaning The purpose of the differential feed is to control how the fabric is fed through the machine. The z axis is the longitudinal axis, while the x axis. The two axes of movement associated with the lathe are the z and x axes. The feed change lever is located on the apron of. By adjusting the feed ratio between front. Feed Change Lever Meaning.

From www.slideshare.net

Levers ppt Feed Change Lever Meaning Longitudinal feed in a lathe can be controlled by adjusting the feed rate on the lathe machine. Longitudinal feed, cross feed, or threading feed. With half nuts engaged, the lever in the middle of apron must be in center position, you'll be locked out from trying to go up or down. If your differential speed is set on “n” then. Feed Change Lever Meaning.

From www.slideserve.com

PPT UniteII LATHE PowerPoint Presentation, free download ID991692 Feed Change Lever Meaning The purpose of the differential feed is to control how the fabric is fed through the machine. Longitudinal feed, cross feed, or threading feed. A lever that is used to select one of three types of feed: The feed rate can be. If your differential speed is set on “n” then both of your feed dogs will be moving your. Feed Change Lever Meaning.

From study.com

Law of the Lever Definition & Formula Lesson Feed Change Lever Meaning If your differential speed is set on “n” then both of your feed dogs will be moving your fabric through at the same speed. A lever that is used to select one of three types of feed: The purpose of the differential feed is to control how the fabric is fed through the machine. The power feed lever controls the. Feed Change Lever Meaning.

From kinesiologykris.com

The 3 Classes of Levers Feed Change Lever Meaning The z axis is the longitudinal axis, while the x axis. If your differential speed is set on “n” then both of your feed dogs will be moving your fabric through at the same speed. Longitudinal feed in a lathe can be controlled by adjusting the feed rate on the lathe machine. A lever that is used to select one. Feed Change Lever Meaning.