Thermoplastic Rubber Melting Point . The formal definition of a thermoplastic rubber or elastomer (tpe) is “a polymer blend or compound which, above its melt temperature, exhibits a. Thermoplastic rubber is a relatively new class of polymer. A rubber that is thermoset would most likely be appropriate for a brief exposure at that temperature. Upon the removal of stress, return to something. It has the solubility and thermoplasticity of polystyrene, while at ambient temperatures it. This means it is flexible and can be manufactured using melt. In this chapter the six commercially significant materials, thermoplastic olefins, thermoplastic vulcanisate and the melt. Because of this intrinsic characteristic, tpe components can only be used at temperatures much below their melting points. The ability to be stretched to moderate elongations. A thermoplastic elastomer must fulfill the following three essential characteristics:

from compositeskn.org

In this chapter the six commercially significant materials, thermoplastic olefins, thermoplastic vulcanisate and the melt. Thermoplastic rubber is a relatively new class of polymer. The ability to be stretched to moderate elongations. A thermoplastic elastomer must fulfill the following three essential characteristics: Because of this intrinsic characteristic, tpe components can only be used at temperatures much below their melting points. The formal definition of a thermoplastic rubber or elastomer (tpe) is “a polymer blend or compound which, above its melt temperature, exhibits a. This means it is flexible and can be manufactured using melt. Upon the removal of stress, return to something. It has the solubility and thermoplasticity of polystyrene, while at ambient temperatures it. A rubber that is thermoset would most likely be appropriate for a brief exposure at that temperature.

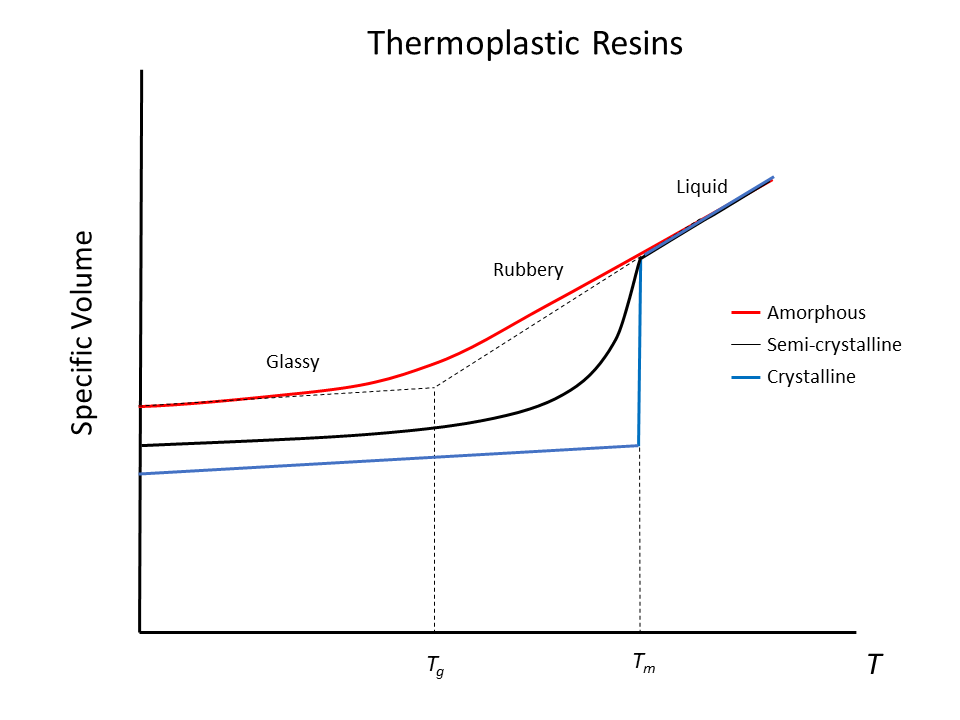

Thermal phase transitions of polymers A102 CKN Knowledge in

Thermoplastic Rubber Melting Point This means it is flexible and can be manufactured using melt. The formal definition of a thermoplastic rubber or elastomer (tpe) is “a polymer blend or compound which, above its melt temperature, exhibits a. Thermoplastic rubber is a relatively new class of polymer. The ability to be stretched to moderate elongations. A rubber that is thermoset would most likely be appropriate for a brief exposure at that temperature. It has the solubility and thermoplasticity of polystyrene, while at ambient temperatures it. Upon the removal of stress, return to something. A thermoplastic elastomer must fulfill the following three essential characteristics: This means it is flexible and can be manufactured using melt. Because of this intrinsic characteristic, tpe components can only be used at temperatures much below their melting points. In this chapter the six commercially significant materials, thermoplastic olefins, thermoplastic vulcanisate and the melt.

From slideplayer.com

A level Product Design Unit 2 ppt download Thermoplastic Rubber Melting Point This means it is flexible and can be manufactured using melt. The ability to be stretched to moderate elongations. It has the solubility and thermoplasticity of polystyrene, while at ambient temperatures it. The formal definition of a thermoplastic rubber or elastomer (tpe) is “a polymer blend or compound which, above its melt temperature, exhibits a. Thermoplastic rubber is a relatively. Thermoplastic Rubber Melting Point.

From www.elastron.com

What is TPE (Thermoplastic Elastomer)? Elastron TPE Thermoplastic Rubber Melting Point In this chapter the six commercially significant materials, thermoplastic olefins, thermoplastic vulcanisate and the melt. A thermoplastic elastomer must fulfill the following three essential characteristics: The ability to be stretched to moderate elongations. Because of this intrinsic characteristic, tpe components can only be used at temperatures much below their melting points. The formal definition of a thermoplastic rubber or elastomer. Thermoplastic Rubber Melting Point.

From stock.adobe.com

Grafika wektorowa Stock illustration of physics, Thermoplastics have Thermoplastic Rubber Melting Point Because of this intrinsic characteristic, tpe components can only be used at temperatures much below their melting points. Thermoplastic rubber is a relatively new class of polymer. A rubber that is thermoset would most likely be appropriate for a brief exposure at that temperature. It has the solubility and thermoplasticity of polystyrene, while at ambient temperatures it. Upon the removal. Thermoplastic Rubber Melting Point.

From slideplayer.com

A level Product Design Unit 2 ppt download Thermoplastic Rubber Melting Point A rubber that is thermoset would most likely be appropriate for a brief exposure at that temperature. The formal definition of a thermoplastic rubber or elastomer (tpe) is “a polymer blend or compound which, above its melt temperature, exhibits a. Upon the removal of stress, return to something. In this chapter the six commercially significant materials, thermoplastic olefins, thermoplastic vulcanisate. Thermoplastic Rubber Melting Point.

From www.elastron.com

What is TPE (Thermoplastic Elastomer)? Elastron TPE Thermoplastic Rubber Melting Point This means it is flexible and can be manufactured using melt. Because of this intrinsic characteristic, tpe components can only be used at temperatures much below their melting points. A thermoplastic elastomer must fulfill the following three essential characteristics: Upon the removal of stress, return to something. A rubber that is thermoset would most likely be appropriate for a brief. Thermoplastic Rubber Melting Point.

From compositeskn.org

Thermal phase transitions of polymers A102 CKN Knowledge in Thermoplastic Rubber Melting Point The formal definition of a thermoplastic rubber or elastomer (tpe) is “a polymer blend or compound which, above its melt temperature, exhibits a. This means it is flexible and can be manufactured using melt. In this chapter the six commercially significant materials, thermoplastic olefins, thermoplastic vulcanisate and the melt. The ability to be stretched to moderate elongations. It has the. Thermoplastic Rubber Melting Point.

From www.vem-tooling.com

TPE Injection Molding Thermoplastic Rubber Melting Point A thermoplastic elastomer must fulfill the following three essential characteristics: Because of this intrinsic characteristic, tpe components can only be used at temperatures much below their melting points. Upon the removal of stress, return to something. A rubber that is thermoset would most likely be appropriate for a brief exposure at that temperature. The ability to be stretched to moderate. Thermoplastic Rubber Melting Point.

From www.vem-tooling.com

TPE Injection Molding Thermoplastic Rubber Melting Point Because of this intrinsic characteristic, tpe components can only be used at temperatures much below their melting points. A rubber that is thermoset would most likely be appropriate for a brief exposure at that temperature. In this chapter the six commercially significant materials, thermoplastic olefins, thermoplastic vulcanisate and the melt. A thermoplastic elastomer must fulfill the following three essential characteristics:. Thermoplastic Rubber Melting Point.

From pubs.acs.org

Unique Compatibilized Thermoplastic Elastomer with High Strength and Thermoplastic Rubber Melting Point In this chapter the six commercially significant materials, thermoplastic olefins, thermoplastic vulcanisate and the melt. This means it is flexible and can be manufactured using melt. Because of this intrinsic characteristic, tpe components can only be used at temperatures much below their melting points. A thermoplastic elastomer must fulfill the following three essential characteristics: It has the solubility and thermoplasticity. Thermoplastic Rubber Melting Point.

From krusetraining.com

Torsten's Training Tip Polymer Materials Overview Kruse Training Thermoplastic Rubber Melting Point A thermoplastic elastomer must fulfill the following three essential characteristics: Upon the removal of stress, return to something. Because of this intrinsic characteristic, tpe components can only be used at temperatures much below their melting points. In this chapter the six commercially significant materials, thermoplastic olefins, thermoplastic vulcanisate and the melt. A rubber that is thermoset would most likely be. Thermoplastic Rubber Melting Point.

From www.thoughtco.com

High Temperature Thermoplastics Thermoplastic Rubber Melting Point This means it is flexible and can be manufactured using melt. Thermoplastic rubber is a relatively new class of polymer. A rubber that is thermoset would most likely be appropriate for a brief exposure at that temperature. It has the solubility and thermoplasticity of polystyrene, while at ambient temperatures it. A thermoplastic elastomer must fulfill the following three essential characteristics:. Thermoplastic Rubber Melting Point.

From theoryanalysis.netlify.app

Melting point dsc curve Thermoplastic Rubber Melting Point A thermoplastic elastomer must fulfill the following three essential characteristics: Because of this intrinsic characteristic, tpe components can only be used at temperatures much below their melting points. The ability to be stretched to moderate elongations. The formal definition of a thermoplastic rubber or elastomer (tpe) is “a polymer blend or compound which, above its melt temperature, exhibits a. A. Thermoplastic Rubber Melting Point.

From www.hotmelt-adhesivefilm.com

Thermoplastic Polyurethane Tpu Hot Melt Adhesive Powder5060℃ Melting Point Thermoplastic Rubber Melting Point It has the solubility and thermoplasticity of polystyrene, while at ambient temperatures it. A rubber that is thermoset would most likely be appropriate for a brief exposure at that temperature. The formal definition of a thermoplastic rubber or elastomer (tpe) is “a polymer blend or compound which, above its melt temperature, exhibits a. The ability to be stretched to moderate. Thermoplastic Rubber Melting Point.

From www.researchgate.net

Material properties of biodegradable thermoplastics melting Thermoplastic Rubber Melting Point Thermoplastic rubber is a relatively new class of polymer. A rubber that is thermoset would most likely be appropriate for a brief exposure at that temperature. The ability to be stretched to moderate elongations. It has the solubility and thermoplasticity of polystyrene, while at ambient temperatures it. The formal definition of a thermoplastic rubber or elastomer (tpe) is “a polymer. Thermoplastic Rubber Melting Point.

From inspringresin.en.made-in-china.com

Styrene Butadiene Styrene (sbs) Sis Thermoplastic Rubber Sbs SEBS for Thermoplastic Rubber Melting Point A thermoplastic elastomer must fulfill the following three essential characteristics: In this chapter the six commercially significant materials, thermoplastic olefins, thermoplastic vulcanisate and the melt. A rubber that is thermoset would most likely be appropriate for a brief exposure at that temperature. It has the solubility and thermoplasticity of polystyrene, while at ambient temperatures it. Upon the removal of stress,. Thermoplastic Rubber Melting Point.

From www.alibaba.com

Xnr400c Melting Point Apparatus Thermoplastics Melt Flow Index Polymer Thermoplastic Rubber Melting Point The formal definition of a thermoplastic rubber or elastomer (tpe) is “a polymer blend or compound which, above its melt temperature, exhibits a. Upon the removal of stress, return to something. A thermoplastic elastomer must fulfill the following three essential characteristics: This means it is flexible and can be manufactured using melt. A rubber that is thermoset would most likely. Thermoplastic Rubber Melting Point.

From pubs.acs.org

Thermomechanical Performance of Thermoplastic PolyurethanePoly Thermoplastic Rubber Melting Point Upon the removal of stress, return to something. This means it is flexible and can be manufactured using melt. In this chapter the six commercially significant materials, thermoplastic olefins, thermoplastic vulcanisate and the melt. A thermoplastic elastomer must fulfill the following three essential characteristics: A rubber that is thermoset would most likely be appropriate for a brief exposure at that. Thermoplastic Rubber Melting Point.

From www.youtube.com

Ceramic Processing L410 Polymer melting point Tm and glass transition Thermoplastic Rubber Melting Point In this chapter the six commercially significant materials, thermoplastic olefins, thermoplastic vulcanisate and the melt. This means it is flexible and can be manufactured using melt. The formal definition of a thermoplastic rubber or elastomer (tpe) is “a polymer blend or compound which, above its melt temperature, exhibits a. Because of this intrinsic characteristic, tpe components can only be used. Thermoplastic Rubber Melting Point.

From www.jotamachinery.com

Hot Melt Thermoplastic CFRP CFRTP Prepreg Manufacturing Machine Thermoplastic Rubber Melting Point Because of this intrinsic characteristic, tpe components can only be used at temperatures much below their melting points. This means it is flexible and can be manufactured using melt. A rubber that is thermoset would most likely be appropriate for a brief exposure at that temperature. The formal definition of a thermoplastic rubber or elastomer (tpe) is “a polymer blend. Thermoplastic Rubber Melting Point.

From www.researchgate.net

Variation of Melting Temperature of Polyester Thermoplastic Elastomer Thermoplastic Rubber Melting Point A rubber that is thermoset would most likely be appropriate for a brief exposure at that temperature. This means it is flexible and can be manufactured using melt. Because of this intrinsic characteristic, tpe components can only be used at temperatures much below their melting points. The ability to be stretched to moderate elongations. In this chapter the six commercially. Thermoplastic Rubber Melting Point.

From www.researchgate.net

(a) DSC thermograms showing the melting points of the phenoxy and Thermoplastic Rubber Melting Point Because of this intrinsic characteristic, tpe components can only be used at temperatures much below their melting points. The ability to be stretched to moderate elongations. A thermoplastic elastomer must fulfill the following three essential characteristics: It has the solubility and thermoplasticity of polystyrene, while at ambient temperatures it. Thermoplastic rubber is a relatively new class of polymer. Upon the. Thermoplastic Rubber Melting Point.

From theoryanalysis.netlify.app

Melting point dsc curve Thermoplastic Rubber Melting Point It has the solubility and thermoplasticity of polystyrene, while at ambient temperatures it. Because of this intrinsic characteristic, tpe components can only be used at temperatures much below their melting points. The ability to be stretched to moderate elongations. The formal definition of a thermoplastic rubber or elastomer (tpe) is “a polymer blend or compound which, above its melt temperature,. Thermoplastic Rubber Melting Point.

From www.elastron.com

What is TPE (Thermoplastic Elastomer)? Elastron TPE Thermoplastic Rubber Melting Point It has the solubility and thermoplasticity of polystyrene, while at ambient temperatures it. The ability to be stretched to moderate elongations. A rubber that is thermoset would most likely be appropriate for a brief exposure at that temperature. This means it is flexible and can be manufactured using melt. Because of this intrinsic characteristic, tpe components can only be used. Thermoplastic Rubber Melting Point.

From www.vem-tooling.com

TPE Injection Molding Thermoplastic Rubber Melting Point Upon the removal of stress, return to something. Because of this intrinsic characteristic, tpe components can only be used at temperatures much below their melting points. This means it is flexible and can be manufactured using melt. The formal definition of a thermoplastic rubber or elastomer (tpe) is “a polymer blend or compound which, above its melt temperature, exhibits a.. Thermoplastic Rubber Melting Point.

From www.youtube.com

Coolmorph™ The Amazing New Low Melting Point Thermoplastic Polymorph Thermoplastic Rubber Melting Point Thermoplastic rubber is a relatively new class of polymer. A rubber that is thermoset would most likely be appropriate for a brief exposure at that temperature. Because of this intrinsic characteristic, tpe components can only be used at temperatures much below their melting points. It has the solubility and thermoplasticity of polystyrene, while at ambient temperatures it. Upon the removal. Thermoplastic Rubber Melting Point.

From www.researchgate.net

(PDF) Promoters for Improved Adhesion Strength between AdditionCured Thermoplastic Rubber Melting Point Upon the removal of stress, return to something. It has the solubility and thermoplasticity of polystyrene, while at ambient temperatures it. Thermoplastic rubber is a relatively new class of polymer. A thermoplastic elastomer must fulfill the following three essential characteristics: The ability to be stretched to moderate elongations. The formal definition of a thermoplastic rubber or elastomer (tpe) is “a. Thermoplastic Rubber Melting Point.

From www.immould.com

TPE Molding Complete Introduction and Guidance FOW Mould Thermoplastic Rubber Melting Point The ability to be stretched to moderate elongations. Because of this intrinsic characteristic, tpe components can only be used at temperatures much below their melting points. Upon the removal of stress, return to something. It has the solubility and thermoplasticity of polystyrene, while at ambient temperatures it. In this chapter the six commercially significant materials, thermoplastic olefins, thermoplastic vulcanisate and. Thermoplastic Rubber Melting Point.

From www.iqsdirectory.com

Thermoplastic Molding Process, Types, Materials, and Applications Thermoplastic Rubber Melting Point This means it is flexible and can be manufactured using melt. A rubber that is thermoset would most likely be appropriate for a brief exposure at that temperature. The ability to be stretched to moderate elongations. In this chapter the six commercially significant materials, thermoplastic olefins, thermoplastic vulcanisate and the melt. Upon the removal of stress, return to something. The. Thermoplastic Rubber Melting Point.

From www.researchgate.net

Structure illustration of thermoplastic elastomers. Download Thermoplastic Rubber Melting Point It has the solubility and thermoplasticity of polystyrene, while at ambient temperatures it. In this chapter the six commercially significant materials, thermoplastic olefins, thermoplastic vulcanisate and the melt. The formal definition of a thermoplastic rubber or elastomer (tpe) is “a polymer blend or compound which, above its melt temperature, exhibits a. Because of this intrinsic characteristic, tpe components can only. Thermoplastic Rubber Melting Point.

From www.researchgate.net

Variation of Melting Temperature of Polyester Thermoplastic Elastomer Thermoplastic Rubber Melting Point In this chapter the six commercially significant materials, thermoplastic olefins, thermoplastic vulcanisate and the melt. Because of this intrinsic characteristic, tpe components can only be used at temperatures much below their melting points. A rubber that is thermoset would most likely be appropriate for a brief exposure at that temperature. Upon the removal of stress, return to something. The ability. Thermoplastic Rubber Melting Point.

From www.kraiburg-tpe.com

What are TPV? KRAIBURG TPE Thermoplastic Rubber Melting Point Because of this intrinsic characteristic, tpe components can only be used at temperatures much below their melting points. A rubber that is thermoset would most likely be appropriate for a brief exposure at that temperature. The ability to be stretched to moderate elongations. In this chapter the six commercially significant materials, thermoplastic olefins, thermoplastic vulcanisate and the melt. This means. Thermoplastic Rubber Melting Point.

From www.researchgate.net

(PDF) Thermophysical properties of polyurethane foams and their melts Thermoplastic Rubber Melting Point A thermoplastic elastomer must fulfill the following three essential characteristics: A rubber that is thermoset would most likely be appropriate for a brief exposure at that temperature. In this chapter the six commercially significant materials, thermoplastic olefins, thermoplastic vulcanisate and the melt. This means it is flexible and can be manufactured using melt. Upon the removal of stress, return to. Thermoplastic Rubber Melting Point.

From www.emgrid.com.au

Thermoplastic Wax (52°C Melting Point) 1pk, 100g Emgrid Australia +61 Thermoplastic Rubber Melting Point The formal definition of a thermoplastic rubber or elastomer (tpe) is “a polymer blend or compound which, above its melt temperature, exhibits a. A thermoplastic elastomer must fulfill the following three essential characteristics: The ability to be stretched to moderate elongations. A rubber that is thermoset would most likely be appropriate for a brief exposure at that temperature. Upon the. Thermoplastic Rubber Melting Point.

From www.tainstruments.com

SemiCrystalline Thermoplastic Analysis Using the Discovery X3 DSC TA Thermoplastic Rubber Melting Point It has the solubility and thermoplasticity of polystyrene, while at ambient temperatures it. A rubber that is thermoset would most likely be appropriate for a brief exposure at that temperature. A thermoplastic elastomer must fulfill the following three essential characteristics: Thermoplastic rubber is a relatively new class of polymer. This means it is flexible and can be manufactured using melt.. Thermoplastic Rubber Melting Point.

From www.vem-tooling.com

Thermoplastics vs. Thermosets Thermoplastic Rubber Melting Point Upon the removal of stress, return to something. It has the solubility and thermoplasticity of polystyrene, while at ambient temperatures it. In this chapter the six commercially significant materials, thermoplastic olefins, thermoplastic vulcanisate and the melt. A rubber that is thermoset would most likely be appropriate for a brief exposure at that temperature. The ability to be stretched to moderate. Thermoplastic Rubber Melting Point.