Equipment Layout Preparation . 12 june 2022 by piping. equipment layout and piping layout is done as per general industry practice as well as piping design basis, process flow, gravity. in this video, we are going to discuss about equipment layout. Spacing between equipment shall be adequate for undertaking maintenance jobs. It shows location and placement of all equipments in a particular process or utility area along with various types of access and maintenance areas. Process flow diagrams (pfd) and piping & instrument diagrams (p&. Equipment should be arranged in logistic process sequence for optimum piping runs and operational and maintenance ease. the essential data or documents required for preparation of equipment layout is as 1. 57 rows equipment layout is one of the most important deliverable of a piping department. process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional.

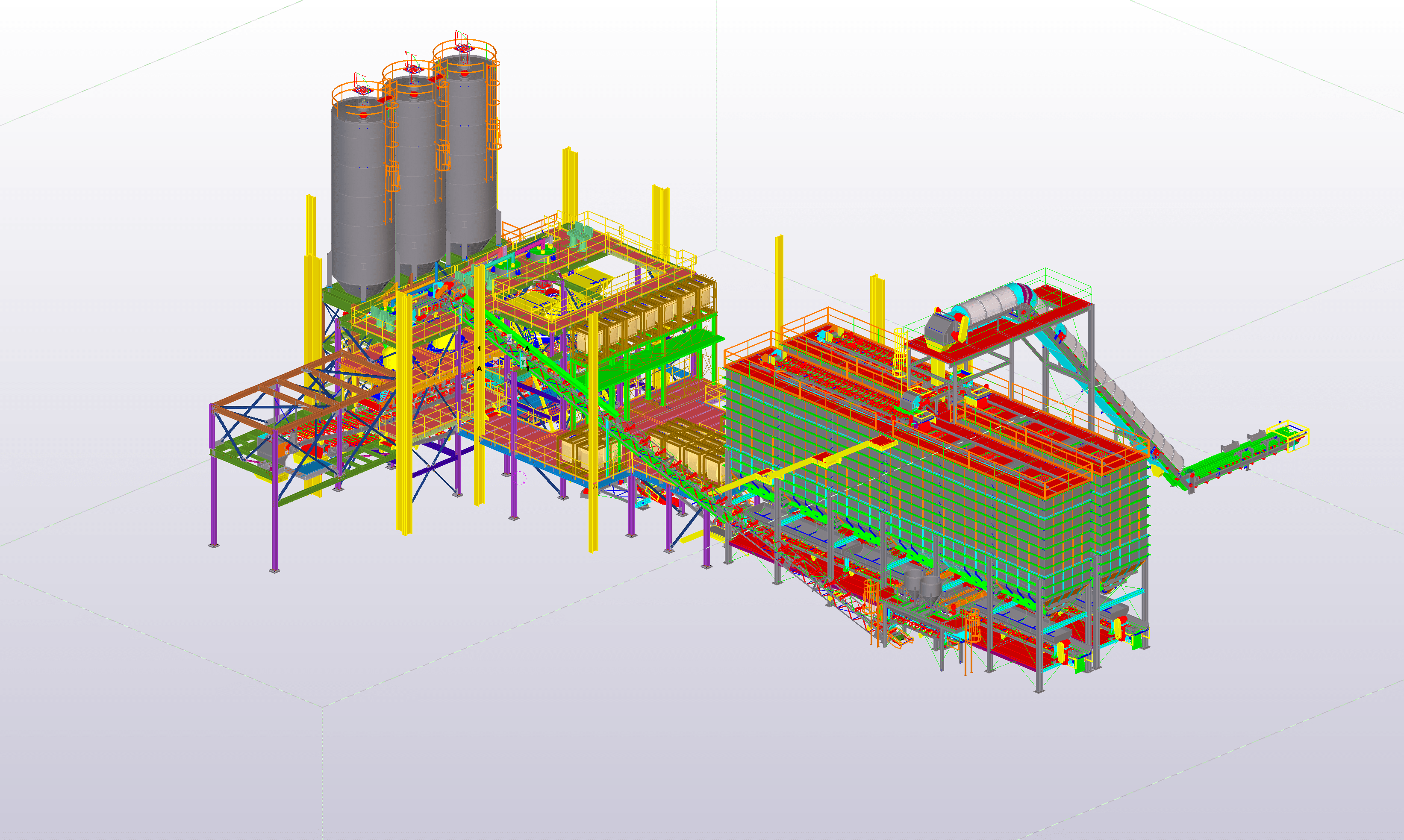

from stlengineering.net

Equipment should be arranged in logistic process sequence for optimum piping runs and operational and maintenance ease. process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. the essential data or documents required for preparation of equipment layout is as 1. Spacing between equipment shall be adequate for undertaking maintenance jobs. It shows location and placement of all equipments in a particular process or utility area along with various types of access and maintenance areas. in this video, we are going to discuss about equipment layout. 57 rows equipment layout is one of the most important deliverable of a piping department. 12 june 2022 by piping. Process flow diagrams (pfd) and piping & instrument diagrams (p&. equipment layout and piping layout is done as per general industry practice as well as piping design basis, process flow, gravity.

Equipment Layout, Selection, and Specification STL Engineering, LLC

Equipment Layout Preparation process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. Equipment should be arranged in logistic process sequence for optimum piping runs and operational and maintenance ease. the essential data or documents required for preparation of equipment layout is as 1. 57 rows equipment layout is one of the most important deliverable of a piping department. equipment layout and piping layout is done as per general industry practice as well as piping design basis, process flow, gravity. 12 june 2022 by piping. Spacing between equipment shall be adequate for undertaking maintenance jobs. It shows location and placement of all equipments in a particular process or utility area along with various types of access and maintenance areas. Process flow diagrams (pfd) and piping & instrument diagrams (p&. in this video, we are going to discuss about equipment layout. process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional.

From www.conceptdraw.com

Interior Design Machines and Equipment Design Elements Store Layout Equipment Layout Preparation in this video, we are going to discuss about equipment layout. process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. Spacing between equipment shall be adequate for undertaking maintenance jobs. equipment layout and piping layout is done as per general industry practice as well as piping. Equipment Layout Preparation.

From www.pinterest.com

Updated Machine layout with more (yes, more!) tools and power Equipment Layout Preparation Process flow diagrams (pfd) and piping & instrument diagrams (p&. It shows location and placement of all equipments in a particular process or utility area along with various types of access and maintenance areas. equipment layout and piping layout is done as per general industry practice as well as piping design basis, process flow, gravity. in this video,. Equipment Layout Preparation.

From www.indiamart.com

Equipment Layout Preparation in Sector 9, Ghaziabad ID 20024775848 Equipment Layout Preparation Equipment should be arranged in logistic process sequence for optimum piping runs and operational and maintenance ease. equipment layout and piping layout is done as per general industry practice as well as piping design basis, process flow, gravity. in this video, we are going to discuss about equipment layout. 57 rows equipment layout is one of the. Equipment Layout Preparation.

From operonstrategist.com

Manufacturing Plant Layout Design for Medical device (Factory Layout Equipment Layout Preparation Equipment should be arranged in logistic process sequence for optimum piping runs and operational and maintenance ease. 12 june 2022 by piping. 57 rows equipment layout is one of the most important deliverable of a piping department. the essential data or documents required for preparation of equipment layout is as 1. equipment layout and piping layout. Equipment Layout Preparation.

From stlengineering.net

Equipment Layout, Selection, and Specification STL Engineering, LLC Equipment Layout Preparation the essential data or documents required for preparation of equipment layout is as 1. Spacing between equipment shall be adequate for undertaking maintenance jobs. Process flow diagrams (pfd) and piping & instrument diagrams (p&. Equipment should be arranged in logistic process sequence for optimum piping runs and operational and maintenance ease. process flow sequence and operating procedures should. Equipment Layout Preparation.

From bavengineering.com

Equipment layouts BAV Engineering Equipment Layout Preparation It shows location and placement of all equipments in a particular process or utility area along with various types of access and maintenance areas. equipment layout and piping layout is done as per general industry practice as well as piping design basis, process flow, gravity. 57 rows equipment layout is one of the most important deliverable of a. Equipment Layout Preparation.

From www.indiamart.com

Mechanical Equipment Layout Services at best price in Ahmedabad ID Equipment Layout Preparation It shows location and placement of all equipments in a particular process or utility area along with various types of access and maintenance areas. the essential data or documents required for preparation of equipment layout is as 1. Spacing between equipment shall be adequate for undertaking maintenance jobs. equipment layout and piping layout is done as per general. Equipment Layout Preparation.

From stlengineering.net

Equipment Layout, Selection, and Specification STL Engineering, LLC Equipment Layout Preparation It shows location and placement of all equipments in a particular process or utility area along with various types of access and maintenance areas. Equipment should be arranged in logistic process sequence for optimum piping runs and operational and maintenance ease. Spacing between equipment shall be adequate for undertaking maintenance jobs. equipment layout and piping layout is done as. Equipment Layout Preparation.

From dir.indiamart.com

Equipment Layouts Preparation in India Equipment Layout Preparation equipment layout and piping layout is done as per general industry practice as well as piping design basis, process flow, gravity. 12 june 2022 by piping. 57 rows equipment layout is one of the most important deliverable of a piping department. in this video, we are going to discuss about equipment layout. It shows location and. Equipment Layout Preparation.

From www.scribd.com

Equipment Layout PDF Equipment Layout Preparation It shows location and placement of all equipments in a particular process or utility area along with various types of access and maintenance areas. 57 rows equipment layout is one of the most important deliverable of a piping department. the essential data or documents required for preparation of equipment layout is as 1. Equipment should be arranged in. Equipment Layout Preparation.

From dir.indiamart.com

Equipment Layouts Preparation in India Equipment Layout Preparation process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. Spacing between equipment shall be adequate for undertaking maintenance jobs. It shows location and placement of all equipments in a particular process or utility area along with various types of access and maintenance areas. equipment layout and piping. Equipment Layout Preparation.

From prokitchenequipments.com

Professional Kitchen Equipments Layout Equipment Equipment Layout Preparation Process flow diagrams (pfd) and piping & instrument diagrams (p&. the essential data or documents required for preparation of equipment layout is as 1. It shows location and placement of all equipments in a particular process or utility area along with various types of access and maintenance areas. in this video, we are going to discuss about equipment. Equipment Layout Preparation.

From www.researchgate.net

Basic Equipment Layout Download Scientific Diagram Equipment Layout Preparation Equipment should be arranged in logistic process sequence for optimum piping runs and operational and maintenance ease. equipment layout and piping layout is done as per general industry practice as well as piping design basis, process flow, gravity. in this video, we are going to discuss about equipment layout. It shows location and placement of all equipments in. Equipment Layout Preparation.

From www.equipmentmanufacturingandintegration.com

Equipment Layout Line Drawings Equipment Manufacturing & Integration Inc Equipment Layout Preparation in this video, we are going to discuss about equipment layout. Equipment should be arranged in logistic process sequence for optimum piping runs and operational and maintenance ease. process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. 57 rows equipment layout is one of the most. Equipment Layout Preparation.

From www.slideshare.net

Parenteral preparation, equipments and layout Equipment Layout Preparation It shows location and placement of all equipments in a particular process or utility area along with various types of access and maintenance areas. process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. Spacing between equipment shall be adequate for undertaking maintenance jobs. 12 june 2022 by. Equipment Layout Preparation.

From cookprocesssolutions.com

Equipment Layout Cook Process Solutions, LLC Equipment Layout Preparation Spacing between equipment shall be adequate for undertaking maintenance jobs. Equipment should be arranged in logistic process sequence for optimum piping runs and operational and maintenance ease. 57 rows equipment layout is one of the most important deliverable of a piping department. equipment layout and piping layout is done as per general industry practice as well as piping. Equipment Layout Preparation.

From dir.indiamart.com

Equipment Layouts Preparation in India Equipment Layout Preparation equipment layout and piping layout is done as per general industry practice as well as piping design basis, process flow, gravity. Spacing between equipment shall be adequate for undertaking maintenance jobs. It shows location and placement of all equipments in a particular process or utility area along with various types of access and maintenance areas. in this video,. Equipment Layout Preparation.

From thepiping.com

Equipment Layout Equipment Layout Preparation the essential data or documents required for preparation of equipment layout is as 1. It shows location and placement of all equipments in a particular process or utility area along with various types of access and maintenance areas. process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional.. Equipment Layout Preparation.

From stlengineering.net

Equipment Layout, Selection, and Specification STL Engineering, LLC Equipment Layout Preparation 12 june 2022 by piping. equipment layout and piping layout is done as per general industry practice as well as piping design basis, process flow, gravity. 57 rows equipment layout is one of the most important deliverable of a piping department. It shows location and placement of all equipments in a particular process or utility area along. Equipment Layout Preparation.

From stlengineering.net

Equipment Layout, Selection, and Specification STL Engineering, LLC Equipment Layout Preparation 12 june 2022 by piping. 57 rows equipment layout is one of the most important deliverable of a piping department. It shows location and placement of all equipments in a particular process or utility area along with various types of access and maintenance areas. Spacing between equipment shall be adequate for undertaking maintenance jobs. process flow sequence. Equipment Layout Preparation.

From www.scribd.com

Layout For Prepratory Equipments PDF Equipment Layout Preparation process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. equipment layout and piping layout is done as per general industry practice as well as piping design basis, process flow, gravity. Equipment should be arranged in logistic process sequence for optimum piping runs and operational and maintenance ease.. Equipment Layout Preparation.

From clevelandprocessimprovements.com

Manufacturing Plant Layout Design and Process Consulting Equipment Layout Preparation Equipment should be arranged in logistic process sequence for optimum piping runs and operational and maintenance ease. the essential data or documents required for preparation of equipment layout is as 1. equipment layout and piping layout is done as per general industry practice as well as piping design basis, process flow, gravity. Process flow diagrams (pfd) and piping. Equipment Layout Preparation.

From www.matrixpdm.com

equipment layout Matrix PDM Engineering Equipment Layout Preparation Equipment should be arranged in logistic process sequence for optimum piping runs and operational and maintenance ease. in this video, we are going to discuss about equipment layout. the essential data or documents required for preparation of equipment layout is as 1. 57 rows equipment layout is one of the most important deliverable of a piping department.. Equipment Layout Preparation.

From honeysucklecreek.net

Carnarvon Equipment Layout Equipment Layout Preparation in this video, we are going to discuss about equipment layout. Process flow diagrams (pfd) and piping & instrument diagrams (p&. Equipment should be arranged in logistic process sequence for optimum piping runs and operational and maintenance ease. process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional.. Equipment Layout Preparation.

From prokitchenequipments.com

Professional Kitchen Equipments Layout Equipment Equipment Layout Preparation process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. 57 rows equipment layout is one of the most important deliverable of a piping department. It shows location and placement of all equipments in a particular process or utility area along with various types of access and maintenance. Equipment Layout Preparation.

From www.slideshare.net

Parenteral preparation, equipments and layout Equipment Layout Preparation in this video, we are going to discuss about equipment layout. 57 rows equipment layout is one of the most important deliverable of a piping department. Spacing between equipment shall be adequate for undertaking maintenance jobs. process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. . Equipment Layout Preparation.

From www.woodsmith.com

7 Essential Layout Tools Woodsmith Equipment Layout Preparation in this video, we are going to discuss about equipment layout. process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. the essential data or documents required for preparation of equipment layout is as 1. Spacing between equipment shall be adequate for undertaking maintenance jobs. Equipment should. Equipment Layout Preparation.

From bavengineering.com

Equipment layouts BAV Engineering Equipment Layout Preparation It shows location and placement of all equipments in a particular process or utility area along with various types of access and maintenance areas. equipment layout and piping layout is done as per general industry practice as well as piping design basis, process flow, gravity. 12 june 2022 by piping. the essential data or documents required for. Equipment Layout Preparation.

From inoxkitchendesign.com

Coffee Shop Equipment With Layout Example INOX KITCHEN DESIGN Equipment Layout Preparation the essential data or documents required for preparation of equipment layout is as 1. in this video, we are going to discuss about equipment layout. Equipment should be arranged in logistic process sequence for optimum piping runs and operational and maintenance ease. It shows location and placement of all equipments in a particular process or utility area along. Equipment Layout Preparation.

From dir.indiamart.com

Equipment Layouts Preparation in India Equipment Layout Preparation Process flow diagrams (pfd) and piping & instrument diagrams (p&. 57 rows equipment layout is one of the most important deliverable of a piping department. 12 june 2022 by piping. Equipment should be arranged in logistic process sequence for optimum piping runs and operational and maintenance ease. the essential data or documents required for preparation of equipment. Equipment Layout Preparation.

From southwestmachinery.com

Equipmentlayout Equipment Layout Preparation It shows location and placement of all equipments in a particular process or utility area along with various types of access and maintenance areas. process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. equipment layout and piping layout is done as per general industry practice as well. Equipment Layout Preparation.

From www.equipmentmanufacturingandintegration.com

Equipment Layout Line Drawings Equipment Manufacturing & Integration Inc Equipment Layout Preparation 57 rows equipment layout is one of the most important deliverable of a piping department. 12 june 2022 by piping. the essential data or documents required for preparation of equipment layout is as 1. process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. equipment. Equipment Layout Preparation.

From cadbull.com

Equipment layout plan and its view in AutoCAD, Dwg file. Cadbull Equipment Layout Preparation Spacing between equipment shall be adequate for undertaking maintenance jobs. in this video, we are going to discuss about equipment layout. Process flow diagrams (pfd) and piping & instrument diagrams (p&. the essential data or documents required for preparation of equipment layout is as 1. process flow sequence and operating procedures should be thoroughly understood so that. Equipment Layout Preparation.

From www.highlandereng.com

Need Facility Layout and Piping Design? Highlander Engineering Equipment Layout Preparation 12 june 2022 by piping. equipment layout and piping layout is done as per general industry practice as well as piping design basis, process flow, gravity. the essential data or documents required for preparation of equipment layout is as 1. Spacing between equipment shall be adequate for undertaking maintenance jobs. It shows location and placement of all. Equipment Layout Preparation.

From www.equipmentmanufacturingandintegration.com

Equipment Layout Line Drawings Equipment Manufacturing & Integration Inc Equipment Layout Preparation Spacing between equipment shall be adequate for undertaking maintenance jobs. the essential data or documents required for preparation of equipment layout is as 1. 57 rows equipment layout is one of the most important deliverable of a piping department. It shows location and placement of all equipments in a particular process or utility area along with various types. Equipment Layout Preparation.