Boring Bar Hole Machining . This technique is utilized when an application requires greater accuracy and exceptional finish. With a lathe, boring machining works by placing the head of the boring bar into the drilled or cast hole. The diameter of the hole,. One of the most common problems machinists make when utilizing boring bars is poor tool selection. Therefore, the primary function of boring is not to create new holes but to process existing holes. Boring machining is a subtractive manufacturing process that uses a specially designed cutting tool to enlarge an already drilled or cast hole. The tooling, machining parameters, and metal removal approach vary significantly based on the workpiece material, desired tolerance, hole depth and diameter, and other factors that can make boring either relatively straightforward In boring machining, the cylinders to precise specifications, engine performance, and reliability can be enhanced. Boring machining is a precise and versatile method used in manufacturing industries to enlarge a hole that has already been drilled. As the lathe rotates the workpiece, the cutting insert cuts into the edges of.

from www.harveyperformance.com

Therefore, the primary function of boring is not to create new holes but to process existing holes. With a lathe, boring machining works by placing the head of the boring bar into the drilled or cast hole. This technique is utilized when an application requires greater accuracy and exceptional finish. As the lathe rotates the workpiece, the cutting insert cuts into the edges of. The diameter of the hole,. Boring machining is a precise and versatile method used in manufacturing industries to enlarge a hole that has already been drilled. In boring machining, the cylinders to precise specifications, engine performance, and reliability can be enhanced. The tooling, machining parameters, and metal removal approach vary significantly based on the workpiece material, desired tolerance, hole depth and diameter, and other factors that can make boring either relatively straightforward One of the most common problems machinists make when utilizing boring bars is poor tool selection. Boring machining is a subtractive manufacturing process that uses a specially designed cutting tool to enlarge an already drilled or cast hole.

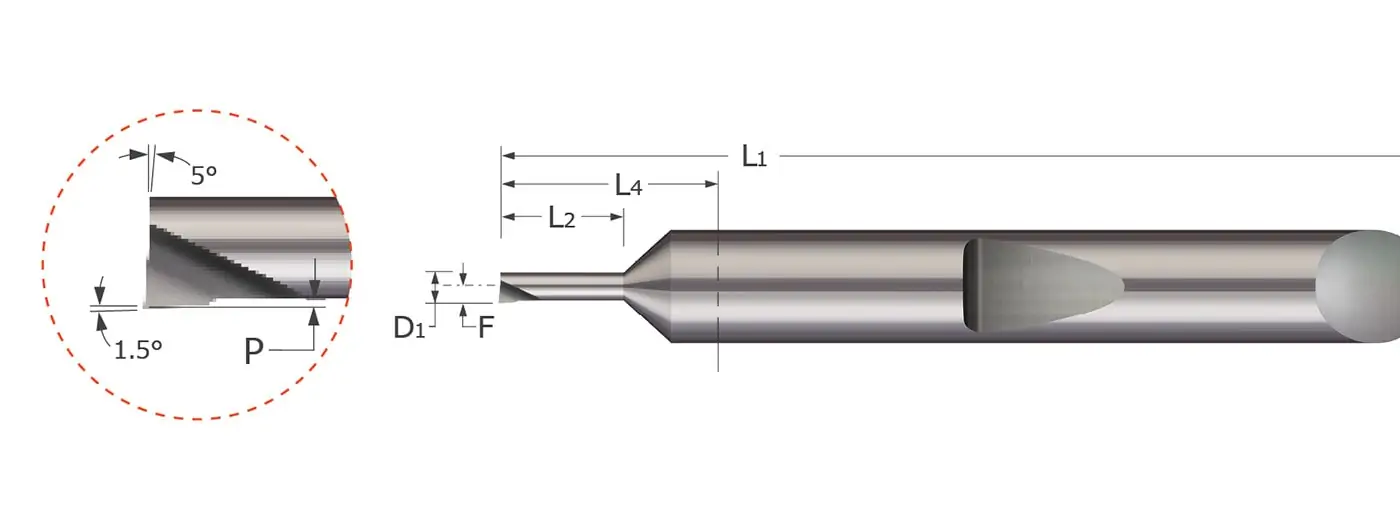

How Boring Bar Geometries Impact Cutting Operations In The Loupe

Boring Bar Hole Machining With a lathe, boring machining works by placing the head of the boring bar into the drilled or cast hole. The diameter of the hole,. With a lathe, boring machining works by placing the head of the boring bar into the drilled or cast hole. As the lathe rotates the workpiece, the cutting insert cuts into the edges of. Boring machining is a precise and versatile method used in manufacturing industries to enlarge a hole that has already been drilled. Boring machining is a subtractive manufacturing process that uses a specially designed cutting tool to enlarge an already drilled or cast hole. Therefore, the primary function of boring is not to create new holes but to process existing holes. The tooling, machining parameters, and metal removal approach vary significantly based on the workpiece material, desired tolerance, hole depth and diameter, and other factors that can make boring either relatively straightforward One of the most common problems machinists make when utilizing boring bars is poor tool selection. This technique is utilized when an application requires greater accuracy and exceptional finish. In boring machining, the cylinders to precise specifications, engine performance, and reliability can be enhanced.

From www.ctemag.com

Boring with a milling machine Cutting Tool Engineering Boring Bar Hole Machining Boring machining is a subtractive manufacturing process that uses a specially designed cutting tool to enlarge an already drilled or cast hole. The tooling, machining parameters, and metal removal approach vary significantly based on the workpiece material, desired tolerance, hole depth and diameter, and other factors that can make boring either relatively straightforward In boring machining, the cylinders to precise. Boring Bar Hole Machining.

From www.aliexpress.com

MZG 10mm 16mm SDACL1010F07 CNC Turning Arbor Lathe Cutter Bar Hole Boring Bar Hole Machining The tooling, machining parameters, and metal removal approach vary significantly based on the workpiece material, desired tolerance, hole depth and diameter, and other factors that can make boring either relatively straightforward The diameter of the hole,. One of the most common problems machinists make when utilizing boring bars is poor tool selection. With a lathe, boring machining works by placing. Boring Bar Hole Machining.

From www.kemalmfg.com

Boring a Hole; Boring Machining; Boring Manufacturing; Boring in Boring Bar Hole Machining Boring machining is a subtractive manufacturing process that uses a specially designed cutting tool to enlarge an already drilled or cast hole. Boring machining is a precise and versatile method used in manufacturing industries to enlarge a hole that has already been drilled. With a lathe, boring machining works by placing the head of the boring bar into the drilled. Boring Bar Hole Machining.

From www.aliexpress.com

D2.0 D7.0 Small hole boring cutter bar alloy boring cutter handle 2 7mm Boring Bar Hole Machining One of the most common problems machinists make when utilizing boring bars is poor tool selection. The diameter of the hole,. As the lathe rotates the workpiece, the cutting insert cuts into the edges of. The tooling, machining parameters, and metal removal approach vary significantly based on the workpiece material, desired tolerance, hole depth and diameter, and other factors that. Boring Bar Hole Machining.

From www.colonialtool.com

Boring Machine Tools Boring Tools Colonial Tool Boring Bar Hole Machining The tooling, machining parameters, and metal removal approach vary significantly based on the workpiece material, desired tolerance, hole depth and diameter, and other factors that can make boring either relatively straightforward The diameter of the hole,. As the lathe rotates the workpiece, the cutting insert cuts into the edges of. In boring machining, the cylinders to precise specifications, engine performance,. Boring Bar Hole Machining.

From www.harveyperformance.com

How Boring Bar Geometries Impact Cutting Operations In The Loupe Boring Bar Hole Machining With a lathe, boring machining works by placing the head of the boring bar into the drilled or cast hole. Boring machining is a precise and versatile method used in manufacturing industries to enlarge a hole that has already been drilled. Boring machining is a subtractive manufacturing process that uses a specially designed cutting tool to enlarge an already drilled. Boring Bar Hole Machining.

From www.dthmachines.com

Portable Boring Bar Tool For Pipe Hole Machining Manufacturers Boring Bar Hole Machining In boring machining, the cylinders to precise specifications, engine performance, and reliability can be enhanced. As the lathe rotates the workpiece, the cutting insert cuts into the edges of. The tooling, machining parameters, and metal removal approach vary significantly based on the workpiece material, desired tolerance, hole depth and diameter, and other factors that can make boring either relatively straightforward. Boring Bar Hole Machining.

From estool.en.made-in-china.com

Tungsten Carbide Internal Thread CNC Deep Hole Machining CNC Extension Boring Bar Hole Machining Therefore, the primary function of boring is not to create new holes but to process existing holes. In boring machining, the cylinders to precise specifications, engine performance, and reliability can be enhanced. This technique is utilized when an application requires greater accuracy and exceptional finish. Boring machining is a subtractive manufacturing process that uses a specially designed cutting tool to. Boring Bar Hole Machining.

From ntkcuttingtools.com

Mogul bars For ID boring operations|NTK CUTTING TOOLS Co., Ltd. Boring Bar Hole Machining One of the most common problems machinists make when utilizing boring bars is poor tool selection. In boring machining, the cylinders to precise specifications, engine performance, and reliability can be enhanced. This technique is utilized when an application requires greater accuracy and exceptional finish. Therefore, the primary function of boring is not to create new holes but to process existing. Boring Bar Hole Machining.

From www.youtube.com

Boring deep hole processing with CKB6180 CNC lathe machine YouTube Boring Bar Hole Machining With a lathe, boring machining works by placing the head of the boring bar into the drilled or cast hole. One of the most common problems machinists make when utilizing boring bars is poor tool selection. The tooling, machining parameters, and metal removal approach vary significantly based on the workpiece material, desired tolerance, hole depth and diameter, and other factors. Boring Bar Hole Machining.

From ar.inspiredpencil.com

Jig Boring Machine Boring Bar Hole Machining Boring machining is a subtractive manufacturing process that uses a specially designed cutting tool to enlarge an already drilled or cast hole. This technique is utilized when an application requires greater accuracy and exceptional finish. With a lathe, boring machining works by placing the head of the boring bar into the drilled or cast hole. The tooling, machining parameters, and. Boring Bar Hole Machining.

From www.youtube.com

Blind hole broaching with a CNC mill YouTube Boring Bar Hole Machining This technique is utilized when an application requires greater accuracy and exceptional finish. Boring machining is a precise and versatile method used in manufacturing industries to enlarge a hole that has already been drilled. In boring machining, the cylinders to precise specifications, engine performance, and reliability can be enhanced. As the lathe rotates the workpiece, the cutting insert cuts into. Boring Bar Hole Machining.

From www.dthmachines.com

Portable Boring Bar Tool For Pipe Hole Machining Manufacturers Boring Bar Hole Machining Therefore, the primary function of boring is not to create new holes but to process existing holes. One of the most common problems machinists make when utilizing boring bars is poor tool selection. The diameter of the hole,. This technique is utilized when an application requires greater accuracy and exceptional finish. The tooling, machining parameters, and metal removal approach vary. Boring Bar Hole Machining.

From anthropology.iresearchnet.com

Tools Machine Tools & Accessories NBH2084 Fine Boring Tool Bar SBJ1008 Boring Bar Hole Machining This technique is utilized when an application requires greater accuracy and exceptional finish. Boring machining is a subtractive manufacturing process that uses a specially designed cutting tool to enlarge an already drilled or cast hole. Therefore, the primary function of boring is not to create new holes but to process existing holes. With a lathe, boring machining works by placing. Boring Bar Hole Machining.

From www.youtube.com

Drilling,Boring & Reaming(Difference) YouTube Boring Bar Hole Machining With a lathe, boring machining works by placing the head of the boring bar into the drilled or cast hole. In boring machining, the cylinders to precise specifications, engine performance, and reliability can be enhanced. Boring machining is a precise and versatile method used in manufacturing industries to enlarge a hole that has already been drilled. One of the most. Boring Bar Hole Machining.

From guling2528.en.made-in-china.com

20mm 25mm 32mm Mcknl12 Internal Turning Cutting Toolholders Steel CNC Boring Bar Hole Machining As the lathe rotates the workpiece, the cutting insert cuts into the edges of. The diameter of the hole,. In boring machining, the cylinders to precise specifications, engine performance, and reliability can be enhanced. Therefore, the primary function of boring is not to create new holes but to process existing holes. With a lathe, boring machining works by placing the. Boring Bar Hole Machining.

From www.aliexpress.com

Damping antiseismic tool bar shockproof and shockproof inner hole Boring Bar Hole Machining In boring machining, the cylinders to precise specifications, engine performance, and reliability can be enhanced. The tooling, machining parameters, and metal removal approach vary significantly based on the workpiece material, desired tolerance, hole depth and diameter, and other factors that can make boring either relatively straightforward As the lathe rotates the workpiece, the cutting insert cuts into the edges of.. Boring Bar Hole Machining.

From www.youtube.com

Large Part Machining Hole Boring Finishing YouTube Boring Bar Hole Machining Therefore, the primary function of boring is not to create new holes but to process existing holes. In boring machining, the cylinders to precise specifications, engine performance, and reliability can be enhanced. Boring machining is a precise and versatile method used in manufacturing industries to enlarge a hole that has already been drilled. Boring machining is a subtractive manufacturing process. Boring Bar Hole Machining.

From www.arno.de

Boring bars Internal machining Boring Bar Hole Machining One of the most common problems machinists make when utilizing boring bars is poor tool selection. This technique is utilized when an application requires greater accuracy and exceptional finish. Boring machining is a precise and versatile method used in manufacturing industries to enlarge a hole that has already been drilled. As the lathe rotates the workpiece, the cutting insert cuts. Boring Bar Hole Machining.

From www.youtube.com

Machining large boring bar YouTube Boring Bar Hole Machining In boring machining, the cylinders to precise specifications, engine performance, and reliability can be enhanced. Therefore, the primary function of boring is not to create new holes but to process existing holes. Boring machining is a precise and versatile method used in manufacturing industries to enlarge a hole that has already been drilled. Boring machining is a subtractive manufacturing process. Boring Bar Hole Machining.

From www.dthmachines.com

Portable Boring Bar Tool For Pipe Hole Machining Manufacturers Boring Bar Hole Machining Therefore, the primary function of boring is not to create new holes but to process existing holes. The tooling, machining parameters, and metal removal approach vary significantly based on the workpiece material, desired tolerance, hole depth and diameter, and other factors that can make boring either relatively straightforward In boring machining, the cylinders to precise specifications, engine performance, and reliability. Boring Bar Hole Machining.

From www.smlease.com

Drilling vs Boring vs Reaming What is the Difference SMLease Design Boring Bar Hole Machining Therefore, the primary function of boring is not to create new holes but to process existing holes. As the lathe rotates the workpiece, the cutting insert cuts into the edges of. The tooling, machining parameters, and metal removal approach vary significantly based on the workpiece material, desired tolerance, hole depth and diameter, and other factors that can make boring either. Boring Bar Hole Machining.

From www.mactechonsite.com

Line Boring Mactech OnSite Field Machining Solutions Boring Bar Hole Machining Therefore, the primary function of boring is not to create new holes but to process existing holes. The tooling, machining parameters, and metal removal approach vary significantly based on the workpiece material, desired tolerance, hole depth and diameter, and other factors that can make boring either relatively straightforward As the lathe rotates the workpiece, the cutting insert cuts into the. Boring Bar Hole Machining.

From www.icarbide.com

1PCS 1.7 MM X 4.0MM x 5MM CARBIDE BORING TOOL LATHE TOOLS icarbide Boring Bar Hole Machining One of the most common problems machinists make when utilizing boring bars is poor tool selection. Boring machining is a precise and versatile method used in manufacturing industries to enlarge a hole that has already been drilled. In boring machining, the cylinders to precise specifications, engine performance, and reliability can be enhanced. Boring machining is a subtractive manufacturing process that. Boring Bar Hole Machining.

From www.aliexpress.com

MZG S0806J SWUBL06 CNC Lathe Toolhoders Small Hole Machining Cutter Boring Bar Hole Machining In boring machining, the cylinders to precise specifications, engine performance, and reliability can be enhanced. Therefore, the primary function of boring is not to create new holes but to process existing holes. The tooling, machining parameters, and metal removal approach vary significantly based on the workpiece material, desired tolerance, hole depth and diameter, and other factors that can make boring. Boring Bar Hole Machining.

From www.harveyperformance.com

Avoid These 5 Boring Bar Mistakes Causing Chatter In The Loupe Boring Bar Hole Machining As the lathe rotates the workpiece, the cutting insert cuts into the edges of. With a lathe, boring machining works by placing the head of the boring bar into the drilled or cast hole. The diameter of the hole,. This technique is utilized when an application requires greater accuracy and exceptional finish. In boring machining, the cylinders to precise specifications,. Boring Bar Hole Machining.

From www.colonialtool.com

Boring Machine Tools Boring Tools Colonial Tool Boring Bar Hole Machining In boring machining, the cylinders to precise specifications, engine performance, and reliability can be enhanced. The tooling, machining parameters, and metal removal approach vary significantly based on the workpiece material, desired tolerance, hole depth and diameter, and other factors that can make boring either relatively straightforward Therefore, the primary function of boring is not to create new holes but to. Boring Bar Hole Machining.

From www.youtube.com

Fully Tunable ChatterFree Boring Bar Increases Machining Performance Boring Bar Hole Machining Therefore, the primary function of boring is not to create new holes but to process existing holes. The diameter of the hole,. With a lathe, boring machining works by placing the head of the boring bar into the drilled or cast hole. The tooling, machining parameters, and metal removal approach vary significantly based on the workpiece material, desired tolerance, hole. Boring Bar Hole Machining.

From at-machining.com

Boring Machining 101 Everything You Need to Know ATMachining Boring Bar Hole Machining The tooling, machining parameters, and metal removal approach vary significantly based on the workpiece material, desired tolerance, hole depth and diameter, and other factors that can make boring either relatively straightforward This technique is utilized when an application requires greater accuracy and exceptional finish. As the lathe rotates the workpiece, the cutting insert cuts into the edges of. Boring machining. Boring Bar Hole Machining.

From chenriprecision.en.made-in-china.com

Threading CNC Metal Machining Boring Bar Small Hole Turning Lathe Tools Boring Bar Hole Machining Therefore, the primary function of boring is not to create new holes but to process existing holes. With a lathe, boring machining works by placing the head of the boring bar into the drilled or cast hole. In boring machining, the cylinders to precise specifications, engine performance, and reliability can be enhanced. Boring machining is a subtractive manufacturing process that. Boring Bar Hole Machining.

From all3dp.com

CNC Boring All You Need to Know All3DP Boring Bar Hole Machining The diameter of the hole,. This technique is utilized when an application requires greater accuracy and exceptional finish. One of the most common problems machinists make when utilizing boring bars is poor tool selection. Boring machining is a precise and versatile method used in manufacturing industries to enlarge a hole that has already been drilled. Boring machining is a subtractive. Boring Bar Hole Machining.

From www.youtube.com

Boring a hole on a lathe YouTube Boring Bar Hole Machining With a lathe, boring machining works by placing the head of the boring bar into the drilled or cast hole. As the lathe rotates the workpiece, the cutting insert cuts into the edges of. This technique is utilized when an application requires greater accuracy and exceptional finish. The diameter of the hole,. In boring machining, the cylinders to precise specifications,. Boring Bar Hole Machining.

From estool.en.made-in-china.com

Tungsten Carbide Internal Thread CNC Deep Hole Machining CNC Extension Boring Bar Hole Machining In boring machining, the cylinders to precise specifications, engine performance, and reliability can be enhanced. Therefore, the primary function of boring is not to create new holes but to process existing holes. The diameter of the hole,. One of the most common problems machinists make when utilizing boring bars is poor tool selection. With a lathe, boring machining works by. Boring Bar Hole Machining.

From technologicalprocess.com

Hole machining drilling and reaming MorekTECHTechniki Wytwarzania i Boring Bar Hole Machining As the lathe rotates the workpiece, the cutting insert cuts into the edges of. With a lathe, boring machining works by placing the head of the boring bar into the drilled or cast hole. The diameter of the hole,. This technique is utilized when an application requires greater accuracy and exceptional finish. Boring machining is a precise and versatile method. Boring Bar Hole Machining.

From www.aliexpress.com

MZG 25mm 32mm 40mm S25S STUCR11 CNC Lathe Cutting Bar Hole Turning Boring Bar Hole Machining Boring machining is a subtractive manufacturing process that uses a specially designed cutting tool to enlarge an already drilled or cast hole. As the lathe rotates the workpiece, the cutting insert cuts into the edges of. The tooling, machining parameters, and metal removal approach vary significantly based on the workpiece material, desired tolerance, hole depth and diameter, and other factors. Boring Bar Hole Machining.